Fluid-oxidat

advertisement

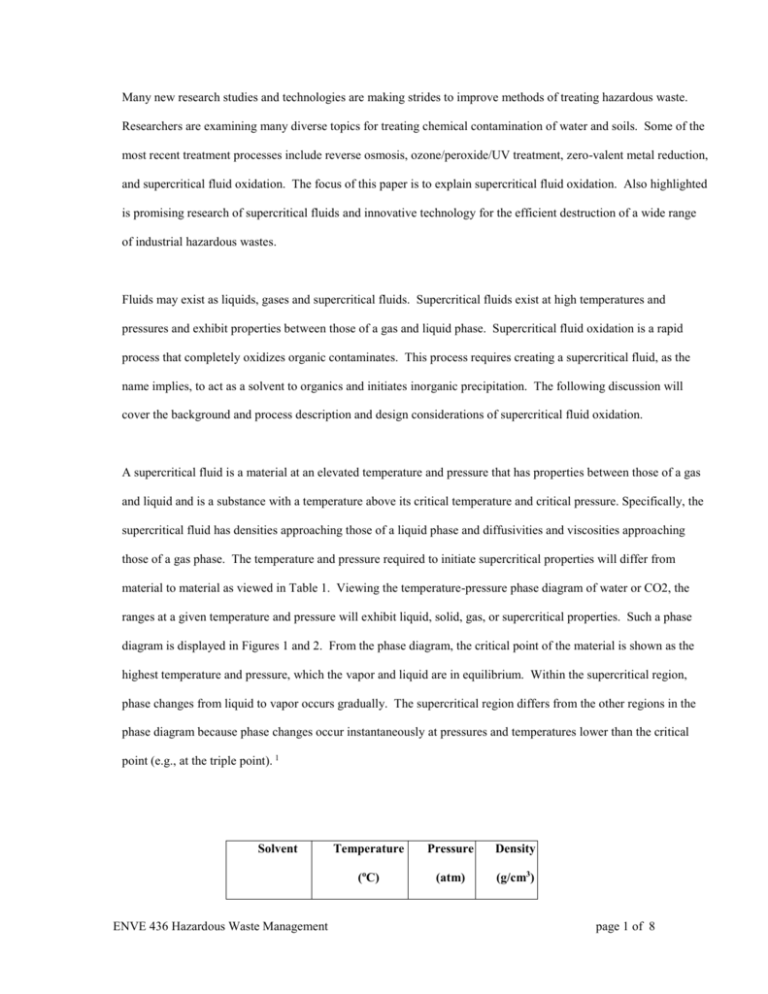

Many new research studies and technologies are making strides to improve methods of treating hazardous waste. Researchers are examining many diverse topics for treating chemical contamination of water and soils. Some of the most recent treatment processes include reverse osmosis, ozone/peroxide/UV treatment, zero-valent metal reduction, and supercritical fluid oxidation. The focus of this paper is to explain supercritical fluid oxidation. Also highlighted is promising research of supercritical fluids and innovative technology for the efficient destruction of a wide range of industrial hazardous wastes. Fluids may exist as liquids, gases and supercritical fluids. Supercritical fluids exist at high temperatures and pressures and exhibit properties between those of a gas and liquid phase. Supercritical fluid oxidation is a rapid process that completely oxidizes organic contaminates. This process requires creating a supercritical fluid, as the name implies, to act as a solvent to organics and initiates inorganic precipitation. The following discussion will cover the background and process description and design considerations of supercritical fluid oxidation. A supercritical fluid is a material at an elevated temperature and pressure that has properties between those of a gas and liquid and is a substance with a temperature above its critical temperature and critical pressure. Specifically, the supercritical fluid has densities approaching those of a liquid phase and diffusivities and viscosities approaching those of a gas phase. The temperature and pressure required to initiate supercritical properties will differ from material to material as viewed in Table 1. Viewing the temperature-pressure phase diagram of water or CO2, the ranges at a given temperature and pressure will exhibit liquid, solid, gas, or supercritical properties. Such a phase diagram is displayed in Figures 1 and 2. From the phase diagram, the critical point of the material is shown as the highest temperature and pressure, which the vapor and liquid are in equilibrium. Within the supercritical region, phase changes from liquid to vapor occurs gradually. The supercritical region differs from the other regions in the phase diagram because phase changes occur instantaneously at pressures and temperatures lower than the critical point (e.g., at the triple point). 1 Solvent ENVE 436 Hazardous Waste Management Temperature Pressure Density (oC) (atm) (g/cm3) page 1 of 8 Carbon 31.1 73.0 0.460 Water 374.15 218.4 0323 Ammonia 132.4 111.5 0.235 Benzene 288.5 47.7 0.304 320.6 41.6 0.292 281.0 40.4 0.270 Dioxide Toluene Cyclohexane Table 1 Supercritical Properties for Various Solvents Once supercritical properties are obtained, organics within the waste stream can either be removed or destroyed. Removal occurs when an organic waste stream meets a supercritical fluid. Organics are known to have high solubility in supercritical fluid thus partitioning from the contaminate inflow. Once the supercritical fluid dissolves the organics, removal of the waste from the supercritical fluid is accomplished by either reducing the pressure or temperature. Reducing the temperature or pressure will then decrease the solubility of the organics in supercritical fluid thus creating a concentrated extract Pressure reduction typically occurs by passing the flow through a pressure reduction valve. Temperature reduction can occur by passing the flow by a heat exchanger that is effective in the recycling process to reheat the fluid to the supercritical state. 2 Once supercritical properties are obtained, organics within the waste stream can either be removed or destroyed. Removal occurs when an organic waste stream meets a supercritical fluid. Organics are known to have high solubility in supercritical fluid thus partitioning from the contaminate inflow. Once the supercritical fluid dissolves the organics, removal of the waste from the supercritical fluid is accomplished by either reducing the pressure or temperature. ENVE 436 Hazardous Waste Management page 2 of 8 Figure 1 Pressure Temperature Phase Diagram for Water.3 Figure 2 Pressure Temperature Phase Diagram for CO2.4 Reducing the temperature or pressure will then decrease the solubility of the organics in supercritical fluid thus creating a concentrated extract Pressure reduction typically occurs by passing the flow through a pressure reduction valve. Temperature reduction can occur by passing the flow by a heat exchanger that is effective in the recycling process to reheat the fluid to the supercritical state. 5 In supercritical fluid oxidation the organic compound is destroyed rather than removed. In normal environmental oxidation processes, molecular oxygen takes so long to oxidize an organic compound at ambient temperatures and pressures that it is considered non-reactive. However, when air is brought to supercritical conditions, the oxidation potential is vastly increased (Watts, 1998). With the conditions for oxidation potential increased and the ability of the supercritical fluid to contain all of the organics, the destruction of organics occurs rapidly. LaGrega indicated that with the proper conditions (temperature = 600 -650 oC) the residence or reactor detention time can be less than one minute with 99.9999% removal efficiencies. From bench scale studies, various compounds have yielded specific efficiencies, temperatures, and time to obtain destruction as viewed in Table 2. Under supercritical conditions, the inorganic compounds are influenced. At ambient temperature and pressure, the dielectric constant is high thus producing high inorganic solubility. Under supercritical conditions the dielectric constant decreases with increasing temperature which then decreases the solubility of inorganic compounds.. The reaction of inorganic compounds to supercritical properties is the inverse to that of hydrocarbon compounds (Figure 3) in that the later increases in solubility with increasing temperature. APPLICATIONS ENVE 436 Hazardous Waste Management page 3 of 8 In the past, practical applications of supercritical fluids were limited to the food processing and extraction industry. Supercritical fluids put to use for extraction and separations began in the 1970’s and 1980’s. Each year tens of millions of kilograms of the world’s coffee and tea is decaffeinated using supercritical carbon dioxide. 6 In Germany for example, most decaffeinated coffee is produced using this method. Not only does this result in a cleaner industrial process, but it also ensures that the final product is purer because it has not been exposed to harmful solvents. Environmental applications of supercritical fluids are seen in both pollution prevention and remediation of wastes. Supercritical fluids provide an environmentally friendly alternative for solvents used in industrial applications. One of the properties of supercritical fluids is their excellent ability to dissolve other substances. For example, CO2 is currently being used to replace harmful hazardous solvents and acts as a reaction medium for materials processing. CO2 can be removed from the environment, used as a environmentally friendly solvent, and returned as CO2. Solubility of greases and oils is very high in supercritical CO2 and no residues remain after cleaning. Another use in industry is textile dyeing. Industry is developing CO2 soluble dyes that will eliminate dyed wastewater as a hazardous waste. ENVE 436 Hazardous Waste Management page 4 of 8 Table 2 Results of Bench-Scale Evaluation Tests of Supercritical Fluid Oxidation. Figure 3 Properties of Water at 250 atm ENVE 436 Hazardous Waste Management page 5 of 8 Supercritical fluids are important additions to remediation efforts. The solubility behavior of Naphthalene in Supercritical Carbon Dioxide is shown in figure 4 below. This curve is a general representation of the behavior of most compounds dissolving in supercritical fluids. Supercritical CO2 also acts as a solvent to leach metals from solutions, soils and other solids. Another application of supercritical CO2 is recovery of uranium from aqueous solutions generated in the reprocessing of nuclear fuels. Supercritical water acts as an excellent solvent to remove and reduce wastes. For example, water when mixed with organics and oxygen, under supercritical conditions, will greatly reduce the production of Nox and Sox compared with incineration practices, (figure 5 below). This is because water is readily miscible with both oxygen and organics and can achieve very high destruction efficiencies with very short residence times (1min). 7 This technology is also being considered for the destruction of chemical weapons and stockpiled explosive, as well as the cleanup of industrial waste streams, municipal waste and used water from naval vessels. 8 DESIGN CONSIDERATIONS Challenges facing this new technology are scaling and corrosion. The byproduct of the process is a highly corrosive mineral acid. In addition, salts will form is bases are added to neutralize. The salts formed are insoluble in water under these conditions. Another important design consideration in the development of supercritical water oxidation is the optimization of reactor operating temperature and feed preheats temperatures. 9 Increasing temperature or pressure may favor better oxidation or solvent properties, however cost will increase due to pumps and heating. However to reduce costs, one may pick a supercritical fluid that has a lower critical temperature and critical pressure. Finally, these fluids are extremely corrosive to holding chambers and are flammable under supercritical conditions. ENVE 436 Hazardous Waste Management page 6 of 8 Figure 4 Solubility of Naphthalene in Supercritical Carbon Dioxide (45 deg C) Figure 5 Supercritical Water Oxidation Process ENVE 436 Hazardous Waste Management page 7 of 8 La Grega, M.D., Buckingham, P.L., &Evans, J.C., ‘Hazardous Waste Management’, 1 st edition, McGraw-Hill, 1994 2 La Grega, M.D., Buckingham, P.L., &Evans, J.C., ‘Hazardous Waste Management’, 1 st edition, McGraw-Hill, 1994 3 Radel, S.R., Navidi, M.H., ‘Chemistry”1st edition, West Publishing Company, St.Paul, MN, 1990 4 Radel, S.R., Navidi, M.H., ‘Chemistry”1st edition, West Publishing Company, St.Paul, MN, 1990 5 La Grega, M.D., Buckingham, P.L., &Evans, J.C., ‘Hazardous Waste Management’, 1st edition, McGraw-Hill, 1994 6 McHugh, M.A. , &Krukonis, V.J., ‘Supercritical fluid extraction, principles and practice’, 2 nd edition, Stoneham, MA: Butterworth Heinemann, 1994 7 Tester, J.W. , etal, in ‘Emerging technologies in hazardous waste management III’, ACCS symposium Series 518, (Eds D.W. Tedder & F.G. Pohland), Washington DC: American Chemical Society, 1993, 35 Brennecke, Joean F. “New applications of supercritical fluids’ Chemistry and Industry no 21 (Nov 4. 1996) p. 831-4 8 Brennecke, Joean F. “New applications of supercritical fluids’ Chemistry and Industry no 21 (Nov 4. 1996) p. 8314 9 Rice, S.F. Steeper, R.R., ‘Oxidation rates sof common organic compounds in supercritical water’ Journal of Hazardous materials V.59 no 2-3 (Apr.98) p.261-78 1 Graphs and Figures obtained from World Wide Web: www.jumpnet.com/~ewt/scwo.htmlFigure 4, Solubility of Naphthalene in Supercritical Carbon Dioxide Figure 5, Supercritical Water Oxidation Process ENVE 436 Hazardous Waste Management page 8 of 8