Geochem Processing SOP

advertisement

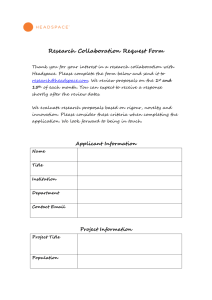

TDI-Brooks GEOCHEMICAL SAMPLE PROCESSING PROCEDURE As soon as the piston core is retrieved on-deck, geochemical sample processing begins. Every effort is made to minimize the time between core retrieval, sample processing, and storage at -l5 to -20C. Upon retrieval, the sediment core liner is labeled in 20-cm sections. The specification for labeling the core with Section Numbers is shown in Table 1. The labeled core is then cut into sections with a special core liner cutter developed by the Ocean Drilling Program (ODP). This liner cutter eliminates plastic shavings that can contaminate the sediment. A picture of a core being cut with this cutter is shown in Figure 1. The cutter is clipped in place around the liner, and a special double-sided blade sinks into the liner about 3 mm. The cutter is then rotated around the liner, cutting a neat, shaving-free section end. Table 2 lists the specification for which three core sections are sampled. The section numbers selected for geochemical processing vary with core recovery. Table 1. Core Section Numbering Convention with Corresponding Depth Interval. Section Number 01 02 03 04 05 06 07 08 09 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 Depth Interval (cm) 0-20 20-40 40-60 60-80 80-100 100-120 120-140 140-160 160-180 180-200 200-220 220-240 240-260 260-280 280-300 300-320 320-340 340-360 360-380 380-400 400-420 420-440 440-460 460-480 480-500 500-520 520-540 540-560 560-580 580-600 1 TDI-Brooks Figure 1. Core being cut into 20-cm sections using special core-liner cutter. 2 TDI-Brooks Table 2. Core Sections Selected for Processing Based on Length of Core. # of Core Sections Geochemical Section #s Archive Section # 1 01 none 2 01 02 none 3 01 02 03 none 4 01 02 04 03 5 02 03 05 04 6 03 04 06 05 7 04 05 07 06 8 05 06 08 07 9 05 07 09 08 10 05 08 10 09 11 06 09 11 10 12 06 10 12 11 13 06 10 13 12 14 06 10 14 13 15 06 10 15 14 16 06 10 16 15 17 06 11 17 16 18 06 11 18 17 19 10 15 19 18 20 10 15 20 19 21 10 15 21 20 22 11 16 22 21 23 11 16 23 22 24 11 16 24 23 25 11 20 25 24 26 11 20 26 25 27 11 20 27 26 28 15 21 28 27 29 15 21 29 28 30 15 21 30 29 Each core section taken for processing is extruded and the top and bottom 1-cm of sediment is discarded. The core material is then sampled for the various analytical requirements. An example of three geochemistry sections and an archive section taken as a part of this program is shown in Figure 2. This photograph shows 20-cm sections already cut from a core. They are labeled “10”, “15”, and “20”. Referring to Table 2, these sections must have come from a core containing 20 sections total length. This equates to a core that is 4.0 meters long. When such a core is pulled from the core barrel, the liner containing the core material is immediately placed in the graduated processing trough shown in Figure 1. The top of the core is adjusted in the trough so that the top of the core lines up with the beginning of section one marked on the trough. The bottom section is that length of core that is comprised of a full section. Almost always, this means that the bottom section designated is longer than 20 cm, because the partial section below it is not cut off prior to extruding. Through this procedure, the actual core recovery is almost always slightly longer than core length logged for the core. 3 TDI-Brooks Figure 2. Sections taken for geochemical processing from a piston core. Geochemical samples for total scanning fluorescence, C15+ hydrocarbons, and biomarkers are extruded directly into labeled plastic ZipLok bags by inverting the bag inside-out and sampling about one-third (6 cm) of the section length as shown in Figure 3. The bag is then carefully reversed and sealed. This method eliminates contact with extraneous materials, thus minimizing contamination. When necessary, clean stainless steel utensils are used to help in sampling. Duplicate bags are filled from each section. One bag is for analysis and the other is for backup (archive). The air is squeezed out of the bags, and they are sealed and laid flat in the freezer. Figure 3. Extruding sediment for geochemical analysis. 4 TDI-Brooks The final one-third (5 cm) of the section material is used to sample for headspace gases. This material can be “popped” into a 500 mL can by connecting the liner to the groove in the top of the can and forcing the plug of sediment into the can with a “thump” of the can onto the processing table. An example of the final set of geochemical samples is shown in Figure 4. For each core, the resulting set of labeled samples includes 3 pair of duplicate bags (6 bags total), 3 cans, and one whole-round section to be saved as an archive sample. Figure 4. The set of geochemistry samples taken from a piston core. After the 5-cm sediment section of sample for headspace analysis is placed into the 500 mL can, 165 mL of clean, degassed, poisoned (with 50g sodium azide per 5 L) seawater is added. The headspace can is purged with nitrogen to remove ambient gases before sealing. The process of purging the can’s headspace after water is added is shown in Figure 5. All samples are frozen at -15° to -20°C. Figure 5. Purging the headspace of a sample-filled can with nitrogen before sealing. 5 TDI-Brooks A core log sheet is also completed for each site. The core log data are input directly into a computer onboard ship. The core logs are bound and provided as a permanent record of the core collection program. The core log consists of core description, core location, water depth, sections sampled, depth of any oil-staining or gas pockets, presence of hydrogen sulfide, obvious large fauna, sedimentary features, etc. Any unusual features are photographed and sampled. A complete set of core logs for this program is included as a separate report or separate volume. GC ANALYSIS OF CANS FOR HEADSPACE GASES Headspace gas analysis refers to the determination of interstitial light hydrocarbon gases including methane, ethane, propane, iso-butane, n-butane, neo-pentane, iso-pentane, and npentane (C1-C5). The headspace gases are sampled through the septum of the equilibrated sample can with the needle of a gas-tight syringe or automated sample loop. One (1.0) mL of gas is injected onto a packed GC column. The gases are separated and detected by a flame ionization detector (GC/FID). External standards are used for quantitation. A calibration curve is established by analyzing each of 5 calibration gas mixtures in replicate and fitting the data to a straight line for each analyte using the least squares technique. Sample responses for each analyte gas are then compared to the calibration curve to derive the concentrations of each gas in each sample in ppmV headspace. Analytes are identified based on their retention time. Figure 6 shows a chromatogram of analysis of a sample containing substantial concentrations of thermogenic gas. In this figure, the numbers associated with each peak are the retention times in minutes for that compound. For example, the retention time for methane is 1.89 minutes and that for ethane is 3.77 minutes. Figure 6. Chromatogram of thermogenic gases in a canned sample. 6 TDI-Brooks The gas chromatograph’s ChemStation software automatically integrates analyte peaks based on their retention times. The analyst visually confirms that each analyte peak is integrated correctly by the software. Concentrations of analytes in samples are calculated based on the concentration and response of external standard compounds. If a sample contains greater than 500 ppmV of methane, the can is sent for carbon isotopic analysis, otherwise, once analysis is complete, the headspace can is opened to measure the mass of sediment and volume of headspace. From these measurements, the volume ratio of canned sediment to headspace is calculated. This “mud/HS” ratio is estimated for unopened cans by weighing the can and calculating the apparent ratio using the average density of all measured samples. The concentrations of the light hydrocarbon gases in the can headspaces are then multiplied by the mud/HS ratio of the corresponding can to yield the reported concentrations of gas as volume gas at NTP per unit volume of sediment. They are reported as parts per million by volume (ppmV). 7