Irradiation of VPT faceplates

advertisement

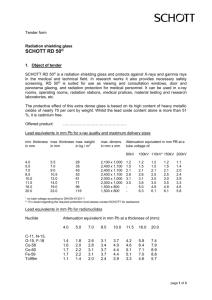

DRAFT DOCUMENT- V4 Irradiation of VPT faceplates - part 1 Peter R Hobson Department of Electronic and Computer Engineering Brunel University Uxbridge UB8 3PH Samples A number of faceplate samples were provided by Electron Tubes (UV glass), by Hamamatsu (borosilicate, UV glass, quartz, radiation-resistant glass) and Dmitri Seliverstof (C96-1 glass). In addition two samples of optical quality glass with added cerium oxide were provided by Schott, UK. All samples were flat and polished on both sides. Source All samples were irradiated with 60Co photons (E=1.173 MeV and 1.333 MeV) in the dark at a constant temperature of 19.5 C. Schedule The irradiations were performed at the dose rates given in table 1. The dose in air was measured using a Farmer dose meter (type 2502/3 from Nuclear Enterprises with a 0.6 cm3 cell). The doses quoted in the table were corrected from dose in air to a dose in Pyrex glass (80% SiO 2). Not all the glass samples received the fifth irradiation step. Irradiation First Second Third Fourth Fifth Rate (Gy.hr-1) 1.66 11.0 11.0 11.0 11.0 Dose (Gy) 121 512 1839 1558 140 Cumulative Dose (Gy) 121 633 2472 4030 4170 A second set of irradiations, at 11Gy.hr-1, was performed on three UV glass faceplates from Hamamatsu (figure 8) Absorption measurement Samples were measured using a Perkin-Elmer Lambda-9 spectrophotometer within one hour of the end of each irradiation. The data were taken at 1nm.s-1 with a 2.0 nm resolution and an integration time constant of 0.5 s. The measurement aperture (illuminated area on the sample) was 5 mm. The data plotted are the induced absorption, that is after subtraction of the original unirradiated value. Some baseline correction, using data at 650 nm, has been used due to small instrumental offsets that affect certain samples. Figure 1 shows the absorbances, uncorrected for refractive index or sample thickness, before irradiation of all the glass samples discussed in this report. The absorbance shown here is dominated by Fresnel reflectance, at long wavelengths, or by a cerium absorption edge (glasses C96-1, BK7G18 and K6G05) at short wavelengths. Some instrumental effects have led to small baseline shift in EB01/2, whose unirradiated absorbance is too low. Page 1 16/02/16 DRAFT DOCUMENT- V4 Unirradiated 1 0.9 0.8 Absorbance 0.7 0.6 C96-1 HB02 HB05 K5G20 BK7G18 EB01/2 0.5 0.4 0.3 0.2 0.1 0 350 400 450 500 550 600 650 Wavelength (nm) Figure 1 Uncorrected absorbance before irradiation of the samples discussed in this report Results Electron Tubes UV glass Glass is Schott 8337B Sample thickness was measured to be 2.41 mm. The results are shown in figure 2 Electron Tubes UV glass (EB01/2) Induced absorbance (/mm) 0.04 4170 Gy 4030 Gy 2472 Gy 633 Gy 121 Gy 0.03 0.02 0.01 0 350 400 450 500 550 600 650 -0.01 Wavelength (nm) Figure 2 Radiation induced absorbance (normalised to a thickness of 1mm) for the UV glass sample provided by Electron Tubes Page 2 16/02/16 DRAFT DOCUMENT- V4 Hamamatsu UV glass Glass is Schott 8337B Sample thickness was measured to be 1.06 mm. The results are shown in figure 3. Subsequently three further samples were provided and tested, they are discussed below (figure 8). Hamamatsu UV glass (HB02) >4170 Gy 4170 Gy 4030 Gy 2472 Gy 633 Gy 121 Gy Induced Absorbance (/mm) 0.04 0.03 0.02 0.01 0 350 400 450 500 550 600 650 -0.01 Wavelength (nm) Figure 3 Radiation induced absorbance (normalised to a thickness of 1mm) for the first UV glass sample provided by Hamamatsu Hamamatsu borosilicate glass Glass is a standard Schott borosilicate used as the default choice for photomultiplier faceplates Sample thickness was measured to be 1.06 mm. The results are shown in figure 4 Page 3 16/02/16 DRAFT DOCUMENT- V4 Hamamatsu borosilicate (HB05) Induced Absorbance (/mm) 0.04 4030 Gy 2472 Gy 633 Gy 0.03 0.02 0.01 0 350 400 450 500 550 600 650 Wavelength (nm) Figure 4 Radiation induced absorbance (normalised to a thickness of 1mm) for the standard borosilicate glass sample provided by Hamamatsu Russian radiation resistant glass This is a cerium oxide doped glass produced in Russia Sample thickness was measured to be 1.61 mm. The results are shown in figure 5. The improvement in the absorbance with radiation as evidenced by the negative numbers in the UV and blue, although unexpected is not unheard of for glasses. There is no evidence of systematic measurement error. Russian rad-resistant (C96-1) Induced absorbance (/mm) 0.04 4030 Gy 2472 Gy 633 Gy 121 Gy 0.03 0.02 0.01 0 350 -0.01 400 450 500 550 600 650 Wavelength (nm) Page 4 16/02/16 DRAFT DOCUMENT- V4 Figure 5 Radiation induced absorbance (normalised to a thickness of 1mm) for the cerium oxide doped radiation resistant glass sample provided by Dmitri Seliverstof. Schott radiation resistant optical glass Two samples of Schott optical glass which have had cerium oxide added were provided by the UK agents. These have excellent optical quality and would in general be very closely controlled batch to batch. Schott list a number of radiation resistant optical glasses, but only about four, including the two tested here, are readily available at present. Sample thickness of the BK7G18 was 5.22 mm and the K5G20 was 5.19 mm Schott BK7G18 Induced absorbance (/mm) 0.04 4030 Gy 2472 Gy 633 Gy 121 Gy 0.03 0.02 0.01 0 350 -0.01 400 450 500 550 600 650 Wavelength (nm) Figure 6 Radiation induced absorbance (normalised to a thickness of 1mm) for the BK7G18 sample provided by Schott, UK Schott K5G20 Induced absorbance (/mm) 0.04 4030 Gy 2472 Gy 633 Gy 121 Gy 0.03 0.02 0.01 0 350 -0.01 400 450 500 550 600 650 Wavelength (nm) Figure 7 Radiation induced absorbance (normalised to a thickness of 1mm) for the K5G06 sample provided by Schott, UK Page 5 16/02/16 DRAFT DOCUMENT- V4 Hamamatsu UV glass (second batch of samples) Glass is Schott 8337B, these samples were sent at a later date than the first sample tested (figure 3). It is not known if they came from a different melt of 8337B Sample thickness was measured to be 1.0 mm. All three samples showed no sign of radiation damage effects at either of the two doses. The induced absorption data for the worst sample are shown in figure 8 H a m a m a ts u U V g la s s (H B 1 4 ) 0 .0 1 Induced Absorbance (/m m ) 3600 Gy 685 Gy 0 350 400 450 500 550 600 650 -0 .0 1 W a v e le n g th (n m ) Figure 8 Worst case radiation induced absorbance (normalised to a thickness of 1mm) for the second set (three) of UV glass faceplates from Hamamatsu. ) for the first UV glass sample provided by Hamamatsu Annealing The change in induced absorbance of two of the faceplates made from Schott 8337B glass was measured after the samples had been kept for several months in the dark at normal, but uncontrolled, laboratory temperature. Both the sample from Hamamatsu (HB02) and that from Electron Tubes (EB01/2) showed annealing at all wavelengths of interest over the period of 280 and 287 days respectively (figure 9a and 9b). Page 6 16/02/16 DRAFT DOCUMENT- V4 H a m a m a ts u U V g la s s (H B 0 2 ) 0 .0 5 >4 1 7 0 G y Induced Absorbance (/m m ) 0 .0 4 Anne a l in da rk 0 .0 3 0 .0 2 0 .0 1 0 350 400 450 500 550 600 650 -0 .0 1 W a v e le n g th (n m ) Figure 9a Annealing of induced absorbance after 280 days in the dark for glass HB02 Electron Tubes UV glass (EB01/2) Induced absorbance (/mm) 0.05 0.04 4170 Gy Anneal in dark 0.03 0.02 0.01 0 350 -0.01 400 450 500 550 600 650 Wavelength (nm) Figure 9b Annealing of induced absorbance after 287 days in the dark for glass EB01/2 Page 7 16/02/16 DRAFT DOCUMENT- V4 Discussion and conclusions The significant induced absorbance shown by the standard borosilicate glass faceplate (figure 4) clearly shows why a radiation-resistant glass must be chosen. The three cerium oxide doped glasses (C96-1, BK7G18 and K5G06) are all excellent but suffer from two problems. In all three cases the unirradiated absorbance is high at wavelengths below 400 nm1 (the samples are all a pale yellow colour), and the thermal properties of the two Schott glasses are such that graded seals would be needed increasing the length and cost of a VPT. It is not known whether the Russian C96-1 glass suffers from this second problem. The Schott 8337B UV glass faceplates are significantly more radiation resistant than standard borosilicate. This is in part due to the damage occurring in the mid-UV region so that in our application we only see the longer wavelength tails (the unirradiated cut-off is around 230 nm). The first two samples (figures 2 and 3) show very similar damage profiles, with the sample from Electron Tubes being systematically more resistant. However the second test, on three samples from Hamamatsu, showed essentially no damage at the maximum dose of 3600 Gy, at least within the noise levels of our measurements. This variability in the performance of the 8337B glass is likely to be intrinsic to a technical glass whose characteristics are not tightly controlled in the way that they are for optical glasses such as BK7G18. The author is unaware of previous studied made on the 8337B glass so cannot comment on how typical these fluctuations might be. A third set of three UV faceplates from Hamamatsu will be irradiated in October 1999. From this study one can conclude 1. Cerium doped radiation resistant glasses are a good choice from the point of view of damage, but they will cut off some of the PbWO4 scintillation light even when undamaged and will require (for Schott glasses at least) expensive and space consuming graded seals 2. Some useful self-annealing of both the damaged Schott 8337B UV glass has been observed. 3. The Schott 8337B UV glass is a good choice for the faceplate even although it does show some damage. Making a pessimistic assumption about how the induced absorbance might scale with dose, Derek Imrie showed 2 that the maximum loss in scintillation light at the inner edge of the calorimeter would be less than 14% after ten years operation at high luminosity (see figure 10 reproduced from his figure 4) 1 2 P R Hobson "Schott Radiation Resistant Glasses" 2 March 1998 D C Imrie "VPT Faceplates Of UV-Transmitting Glass?" 3 October 1998 Page 8 16/02/16 DRAFT DOCUMENT- V4 1 .0 2 0 RE LATIV E PH OTO ELE CT RO N R ES PO NS E AF TER 5 x 10^5 pb-1 1 .0 0 0 R ELAT IVE RESPON SE 0 .9 8 0 0 .9 6 0 0 .9 4 0 0 .9 2 0 0 .9 0 0 0 .8 8 0 0 .8 6 0 0 .0 0 .5 1 .0 1 .5 2 .0 2 .5 3 .0 3 .5 Figure 10. Relative photoelectron response as a function of at an integrated luminosity of 5x105 pb-1. The VPT faceplate is assumed to be made from the Electron Tube UV glass sample EB01/2. 4. Further tests on UV faceplates up to a total integrated dose of 50 kGy (or higher) must be performed as a matter of urgency 5. Batch testing of 8337B glass before faceplates are sealed to VPT tube assemblies is strongly recommended. Page 9 16/02/16