CATHODIC PROTECTION OF PLANT AREAS

advertisement

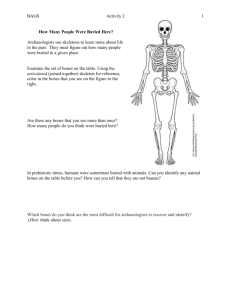

pml prolonging metal life Cathodic Protection Of Plant Areas CATHODIC PROTECTION OF PLANT AREAS i pml prolonging metal life Cathodic Protection Of Plant Areas ii CATHODIC PROTECTION OF PLANT AREAS For the design and installation of cathodic protection systems for buried and submerged structures for plant facilities, the following structures would normally be considered to be included in a cp scheme: a) b) c) d) e) f) Pressurized steel hydrocarbon pipelines Bottom or soil side of above ground storage tanks Buried storage tanks Sea walls and associated anchors Buried portions of process, gas, water, firewater or liquids pipelines Buried or the buried portions of steel valves, hydrants, monitors and fittings Because of the complexity of Plant Facilities, two basic principles may be employed: a) Isolated systems where every buried structure is isolated where it comes above ground giving rise to a large number of insulated flanges. This in turn leads to maintenance and reliability problems because it only requires one bolt in an insulated flange to be short-circuited for the whole system to fail. It is also very difficult to find the offending bolt. b) Blanket system where, except between on plant and off plant facilities, no isolation is provided. This means that all buried metal work on the site is protected including the earthing systems leading to considerably larger systems. pml prolonging metal life Cathodic Protection Of Plant Areas iii Plant facilities usually require a considerable amount of current and are therefore cathodically protected with impressed-current systems unless soil resistivities are very low. Short buried sections of piping, small isolated coated structures, etc., may be protected with galvanic anodes. The impressed current CP system can utilize distributed anodes, local or remote surface anode beds, local or remote deep anodes, or a combination of the above. When choosing and/or combining anode bed types, the conceptual and the final designs must be co-ordinated with other plant operators to ensure all existing facilities are known together with any planned extensions or new facilities. The following is a typical example of an isolated system with a remote surface groundbed. Structures protected or influenced by CP systems must be electrically continuous. Bonds are installed (where required) to ensure electrical continuity. The CP system design will probably use distributed impressed current anodes for CP systems connected to buried facilities in congested areas, such as buried hydrocarbon pipelines inside the plant fence, tank bottoms, ring walls, structures connected to plant ground grids and buried steel reinforced concrete structures. Anode placement, separation distance, current output, and soil resistivity need to be considered when calculating the soil voltage gradient necessary to achieve the minimum required structure-to-soil potential. Additional test stations and soil access test holes may be installed for monitoring cathodic protection levels of these facilities. For isolated structures, typical magnesium anodes with connection boxes would be required for the following structures. a) b) c) d) e) Buried valves: 2 No 27 kg magnesium anodes Pipeline thrust anchors: 4- No 27 kg magnesium anodes Buried gas accumulators: 4- No 27 kg magnesium anodes Electrically isolated sleeve casings: minimum, 2- No 27 kg magnesium anodes each end Thrust bored crossings: minimum, 2- No 27 kg magnesium anodes each end Current Density Criteria Typical minimum current densities detailed in Table I. However, local experience may change these depending upon the application Table I - Minimum Allowable Surface Current Densities Structure Surface Uncoated Copper Uncoated Steel Tape or P-2 Wrap Coal Tar Epoxy Fusion Bonded Epoxy (FBE) Polyethylene (PE) Current Density (mA/sq. m) 40.00 20.00 1.25 0.75 0.10 0.10 pml Cathodic Protection Of Plant Areas prolonging metal life iv Anodes Bulk Plants: The distributed anodes shall be equally spaced around the tank perimeter and shall be installed a minimum of 1/4 the tank diameter from the tank wall and a maximum of one tank diameter from the tank wall and a maximum spacing of 30 meters (center-to-center). Tank Farms and Process Areas: The distributed anodes shall be equally spaced around the tank perimeter and installed a minimum of 1/4 the tank diameter from the tank wall and at a maximum spacing of 20 meters (center-to-center). Distributed Anodes for Piping Distributed impressed current anode installations are required where a remote anode bed will not provide satisfactory current distribution or will not be practical. Distributed anodes are normally used for buried pipelines, or piping installed in congested areas, at fence crossings, at full-thrust anchors, at GOSP manifolds or flow line corridors, and where operational needs dictate. Anode spacing normally varies from 15 to 30 meters, with a 15 meter spacing or less in very congested areas, and up to a 30 meter spacing in less congested areas. The anode distance from buried pipelines or piping will normally be a minimum of 1 meter to a maximum of 5 meters. Anodes to be installed deeper than 15 meters require Hydrology Division, Geological Department approval for drilling depth. Design of cathodic protection system The design of the power supplies and groundbeds are effectively the same as for buried pipelines utilizing the same formulae Monitoring Facilities A test station for measuring pipe-to-soil potential shall be provided at; insulated cased crossings, paved road crossings, thrust-bored road crossings, negative connections, buried bond connections, and other locations as required by operational needs. On inaccessible buried structures and pipelines, one pin or flush mount test stations shall be installed with a permanent zinc reference electrode every 100 meters (or less) or one per structure, or as required by the proponent. In concrete and asphalt (paved) areas, soil access test boxes shall be installed: - one at the beginning and one at the end of each pipeline segment - at the midpoint over buried pipeline segments shorter than 30 meters - at maximum 15 meter intervals over buried pipelines longer than 30 meters, and less than 100 meters pml Cathodic Protection Of Plant Areas prolonging metal life v - at maximum 30 meter intervals on buried pipelines longer than 100 meters - around the periphery and within one (1) meter of tank bottoms, at the mid-point between anodes, with at least one access box per quadrant. All newly constructed tanks shall have reference electrodes installed beneath the bottom plates according to Table II. Table II - Reference Electrodes Beneath the Tank Bottom Plates Tank Diameter (M) No. of Electrodes Location of Electrodes Less than 20 2 Center and midway between center and edge 20 - 39 3 Center and equally spaced on radius line between center and edge 40 - 79 4 Center and one each, equally spaced on 120 deg radius lines between center and edge 80 - 99 7 Center and two each, equally spaced on 120 deg radius lines between center and edge Greater than 100 9 Center and two each, equally spaced on 90 deg radius lines between center and edge Bonding All buried structures influenced by cathodic protection systems shall be electrically continuous. Bonds shall be installed to ensure electrical continuity and to prevent interference. All bond terminations between structures shall be made above-grade in an approved electrical enclosure. The minimum bond conductor size shall be 16 sq. mm (6 AWG). Electrical Isolation Insulating flanges, insulating joints or spools, or other electrical isolating devices are not allowed except to limit protective current flow between plant facilities and off-plot pipelines. Isolating devices shall be located in non-hazardous locations. Isolating devices shall not be installed in any buried or submerged portions of a pipeline. All isolating devices shall be provided with an above-grade bond box.