Introduction and Solid Solution Thermal

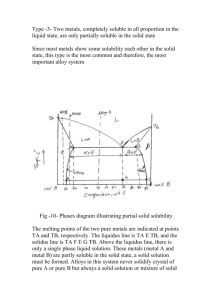

advertisement

Engineering - TEDs - Introduction & Solid Solution Diagrams Structure | TEDs | Plastics | Metallurgy | Metrology | Steels & Iron | Information Tables | Exam Papers | Syllabus Introduction Thermal Equilibrium Diagrams contain special information about changes that take place in alloys during cooling. An Alloy is a combination of two or more elements, at least one of which has to be a metal. A Binary Alloy is an alloy made up of 2 metals, (for example brass is made up of copper and zinc). Alloys can improve the properties of pure metals. Engineering requires that close attention is paid to the composition of alloys and the temperatures at which major changes take place. The first type of alloy we will look at is a Solid Solution Alloy. Solid Solution Alloys There are two types of Solid Solution Alloys. They are : 1. Substitutional Solid Solution 2. Interstitial Solid Solution The following points are relative to all Solid Solution Alloys : Both metals are completely soluble in one another. One type of crystal is formed. Under a microscope, looks like a pure metal. Usually stronger and harder, poorer electrical conductivity but not as elastic 1. Substitutional Solid Solution Alloys Atoms of both metals are of similar size. Direct substitution takes place. Substitution normally at random. If ordered, it is called a Superlattice. In the above diagram the Parent Metal is represented by the blue spheres. The Substituted Atoms are represented by the black spheres. 2. Interstitial Solid Solution Alloys Parent metal atoms are bigger than atoms of alloying metal. Smaller atoms fit into spaces, (Interstices), between larger atoms. If ordered, as below, it is again called a Superlattice. In the above diagram the Parent Metal is represented by the blue spheres. The Substituted Atoms are represented by the black spheres. The Interstice is the gap between 3 or more touching spheres. Both of the above diagrams are 2-dimensional representations of a crystalline structure. For example, take the 4 atoms in the top left of the Substitutional Solid Solution alloy diagram. These 4 atoms represent the four corners on one side of a Basic Cubic Unit Cell. In the diagram you can see the sides of 3 whole cells, and 3 half cells, (bottom 6 atoms). If you can imagine, the rest of the cells go back into the screen. With the Interstitial Solid Solution diagram, you are looking at the side of a Body Centered Cubic Unit Cell. Some Solid Solution Alloys Alloy Unit Cell Structure Copper - Nickel FCC Copper - Gold FCC Gold - Silver FCC Nickel - Platinum FCC Molybdenum - Tungsten BCC Iron - Chromium BCC The Cooling Curve of Copper The study of Thermal Equilibrium Diagrams is based on the study of the cooling curves of Alloys. As a result it is important to understand the cooling curve of a non-Alloy. We are using the element Copper. The Copper cools from being molten to 1083°C when a dramatic change takes place. The Copper starts to solidify. It is very important to note that the Copper solidifies totally with no drop in temperature. The opposite is also true, in that, when Copper is being melted it turns from a solid to a liquid with no change in the Copper's temperature. The points of importance to an engineer on a cooling curve diagram are the temperatures at which Solidification Starts and Solidification Ends. For a pure metal the temperature for both is the same. When heating a solid pure metal, it is seen that the metal will change from a solid to a liquid at constant temperature. This is called the Melting Point Temperature. The heat that is used up in the transition from a solid to a liquid is called hidden or Latent Heat. Remember this only happens for pure metals. Composition of Alloys Two metals may be alloyed in many different amounts. The composition is the amount of each metal, in percentage form, that is in the Alloy, e.g. 80% A and 20% B. This means that the alloy is composed of 80% of metal A and 20% of metal B. How A Thermal Equilibrium Diagram Is Made To explain how a Thermal Equilibrium Diagram, (TED), is made we will look at the development of the Copper - Nickel T.E.D. 100% Copper 80% Copper - 20% Nickel 60% Copper - 40% Nickel 40% Copper - 60% Nickel 20% Copper - 80% Nickel 100% Nickel Firstly a Cooling Curve is developed for each of the different alloy compositions that the Engineer is concerned with. This provides the information as shown above. For each composition of the alloy the Critical Temperatures are noted, (i.e. the temperatures at which Solidification Starts and Solidification Ends). This information is then transferred to another graph where all of the different compositions can be shown together, (shown below). Note : It is important to notice on the Cooling Curves of the alloys, that as they solidify there is a drop in temperature. Remember that for pure metals there is no change in temperature. This can be plainly seen in the Cooling Curves of 100% Copper and 100% Nickel. The Critical Temperatures from the six Cooling Curve Graphs are then marked on the graph relative to their own alloy composition. The marks are then joined up, and the result is a Thermal Equilibrium Diagram. This graph can then be used like a picture to tell us what state the alloys are in at whatever temperature. On a Solid Solution T.E.D. there are 2 important lines and 3 important areas. The Liquidus Line, which joins the Solidification Start points on the T.E.D., tells us that above the line the alloys are liquid. The Solidus Line, which joins the Solidification End points on the T.E.D., tells us that below the line the alloys are solid. In between the Liquidus Line and the Solidus Line the alloys are a mixture of solid and liquid, like porridge or wallpaper paste. Example Take the alloy 60% Copper - 40% Nickel. We can see from the T.E.D. that at 1100°C the alloy is solid. At 1250°C the alloy is in its pasty stage, and at 1400°C the alloy is a liquid. The states of solid, liquid and pasty on a T.E.D., are termed Phases and every time a line is crossed the alloy changes from one phase to another. To Find The Ratio Of Phases Between The Liquidus And Solidus Lines It may be important to know exactly what the composition of the phases are in the pasty area at a certain temperature for a certain alloy. It can be accepted that the closer the point in question is to the Liquidus Line then the more liquid will be present, and that the closer the point is to the Solidus Line the more solid will be present. However we can find out more accurately using The Lever Law. You may need to find out what ratio of phases exist at a temperature of 1268°C for the 60% Copper - 40% Nickel alloy. You can judge from the diagram that there is going to be more liquid present. 1. Draw a line across the T.E.D. at the temperature you are interested in. This is called a Tie Line. 2. Draw a vertical line from the alloy in question to the Tie Line. We will call this the Alloy Line. 3. Label the points where the Tie Line crosses the Liquidus Line, (A), the Tie Line intersects the Alloy Line, (B), and where the Tie Line meets the Solidus Line, (C). 4. Now draw lines vertically from A and C to the Percentage Composition of the T.E.D.. From here you can work out the distances from A to B and from B to C. You can see that the distances are the same for both metals. AB = 65 - 60 = 5 BC = 60 - 48 = 12 According to The Lever Law : Mass of Solid / Mass of Liquid = AB / BC 5 / 12 = 0.42 This confirms that at 1268°C for the 60% Copper - 40% Nickel alloy there is more liquid than solid present.