9.3 Reactivity of Metals, Ores and Metal Extraction

advertisement

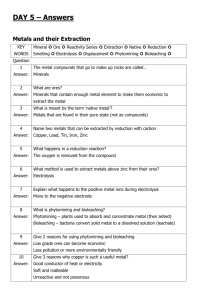

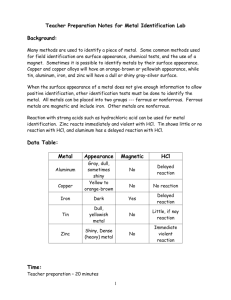

9.3 Metals, Ores and Extraction You should remember studying the reactivity series of metals in Year 8. The most reactive metals are placed at the top. These metals react vigorously with water, acid and oxygen. Metals in the middle react moderately with acids and oxygen, whilst those at the bottom don't even react with acids and react very slowly, if indeed at all, with oxygen in the air. The more reactive a metal is the more likely it is to form a compound. The more reactive a metal, the more stable its compound. Therefore, the more reactive a metal, the more difficult it is to extract. This is because the more reactive a metal, the more strongly it combines with another non-metallic element like oxygen or sulphur and the more energy is needed to separate the metal. Although most metals occur as compounds, some metals are so unreactive that they do not readily combine with oxygen in the air or any other element present in the Earth's crust, and so can be found as the metal itself (sometimes referred to as a 'native' metal). For example, a metal, most frequently found ‘native’ is gold (and sometimes copper and silver) and no chemical separation or extraction is needed. In fact all the metals below hydrogen can be found as the 'free' or 'native' element, although they occur mainly as compounds combined with non-metals like oxygen or sulphur, or the TOPIC 9.3 METALS, ORES AND EXTRACTION 1 carbonate ion in their ores. Therefore, for most metals, their naturally occurring compounds require processing via chemical reactions to obtain the free metals. 9.3.1 Displacement reactions A metal will displace (take the place of) a less reactive metal in a metal salt solution. For example, iron + copper sulphate iron sulphate + copper Fe(s) + CuSO4 (aq) (blue) FeSO4 (aq) + Cu(s) (pale green) (brown) Copper sulphate is blue while iron sulphate is a very pale green solution. During the reaction the blue solution loses its colour and the iron metal is seen to turn brown as the displaced copper becomes deposited on it. If a less reactive metal is added to a metal salt solution there will be no reaction nothing will happen! For example, iron is less reactive than magnesium. iron + magnesium sulphate no reaction In these displacement reactions the metals are competing for the non-metal negative ion or anion. In the above examples the non-metal anion is sulphate, SO42-. Reactions using anions such as chlorides or nitrates can also be used. The order of the metals in the reactivity series can be worked out by using these types of reaction. For example tin would be seen to displace lead from lead chloride but would not react with iron chloride. tin + lead chloride tin chloride + lead Sn (s) + PbCl2 (aq) SnCl2 (aq) + Pb (s) But… tin + iron chloride no reaction Sn(s) + FeCl2(aq) no reaction Therefore tin must be above lead but below iron in the reactivity series. TOPIC 9.3 METALS, ORES AND EXTRACTION 2 9.3.2 Ores Most metals are found as metal compounds in rocks and minerals in the Earth’s crust. If there is enough metal in the rock to make it economically worth extracting, then the rock is called an ore. Aluminium, for example, is the most common metal in the Earth's crust. The usual ore that aluminium is extracted from is called bauxite - which contains mostly aluminium oxide, Al2O3. Copper is much rarer, but fortunately can be found in high-grade ores (ones containing a high percentage of copper) in particular places. Because copper is a valuable metal, it is also worth extracting it from low-grade ores as well. Metals ores are commonly oxides, for example bauxite (Al2O3), haematite (Fe2O3) and rutile (TiO2) Ores can also be sulphides, for example pyrite (FeS2) and chalcopyrite (CuFeS2) Reducing the metal compound to the metal Why is this called ‘reduction’? At its simplest, where you are starting from metal oxides, the ore is being reduced because oxygen is being removed. This is the opposite of a process called oxidation which is the gain of oxygen. Fe2O3 Al2O3 Removal of oxygen = reduction Removal of oxygen = reduction Fe Al The substance that reduces the metal oxide to the metal is called the reducing agent TOPIC 9.3 METALS, ORES AND EXTRACTION 3 9.3.3 Extracting metals from their ores There are various economic factors you need to think about in choosing a method of reduction for a particular ore. These are all covered in detail on other pages in this section under the extractions of particular metals. What follows is a quick summary. You need to consider: the cost of the reducing agent (e.g. carbon, a common reducing agent, is cheap) energy costs (for example, electrical energy for electrolysis is expensive) the purity of the metal (sometimes carbon is left in the metal as an impurity, which affects the properties of the metal). Environmental considerations - some of which will have economic costs. 9.3.4 Iron Metals below carbon (such as iron) can be extracted by heating the oxide with carbon or carbon monoxide. The non-metallic elements carbon will displace the metals less reactive than carbon in a smelter or Blast Furnace, e.g. iron or zinc and metals lower in the series. Therefore metals like iron, copper, tin, lead, zinc can readily be extracted by reaction-reduction of their oxides using coke. Environmental problems in mining and transporting the raw material Loss of landscape due to mining, processing and transporting the iron ore, coke and limestone. Noise and air pollution (greenhouse effect, acid rain) involved in these operations. Extracting iron from the ore Loss of landscape due to the size of the chemical plant needed. Noise. Atmospheric pollution from the various stages of extraction. For example: carbon dioxide (greenhouse effect); carbon monoxide (poisonous); sulphur dioxide from the sulphur content of the ores (poisonous, acid rain). Disposal of slag, some of which is just dumped. Transport of the finished iron. Recycling Saving of raw materials and energy by not having to first extract the iron from the ore. Avoiding the pollution problems in the extraction of iron from the ore. Not having to find space to dump the unwanted iron if it wasn't recycled. (Offsetting these to a minor extent) Energy and pollution costs in collecting and transporting the recycled iron to the steel works. TOPIC 9.3 METALS, ORES AND EXTRACTION 4 The Blast Furnace The basic set-up of the Blast Furnace is shown in the diagram below. The top part is where the three solid ingredients are added (iron ore, coke and limestone). Hot air is blown in at the bottom, and this reacts with the carbon in the coke to produce carbon dioxide. The carbon dioxide reacts with more carbon to form carbon monoxide. The carbon monoxide then reduces the iron oxide to iron. The temperature of the furnace is higher than the melting point of iron, so iron is produced as a liquid and collects at the bottom of the furnace. Impurities called slag are lighter than liquid iron, so they float on the surface and are removed separately. There are three key chemical reactions that happen in the Blast Furnace which convert iron oxide into iron are: Carbon + oxygen carbon dioxide C (s) + O2 (g) CO2 (g) Carbon dioxide + carbon Carbon monoxide CO2 (g) + C (s) 2CO (g) Iron oxide + carbon monoxide iron + carbon dioxide Fe2O3 (s) + 3CO (g) 2Fe (l) + 3CO2 (g) TOPIC 9.3 METALS, ORES AND EXTRACTION 5 Cast iron The molten iron from the bottom of the furnace can be used as cast iron. Cast iron is very runny when it is molten and doesn't shrink much when it solidifies. It is therefore ideal for making castings - hence its name. However, it is very impure, containing about 4% of carbon. This carbon makes it very hard, but also very brittle. If you hit it hard, it tends to shatter rather than bend or dent. Cast iron is used for things like manhole covers, guttering and drainpipes, cylinder blocks in car engines, Agatype cookers, and very expensive and very heavy cookware. Steel Most of the molten iron from a Blast Furnace is used to make one of a number of types of steel. There isn't just one substance called steel - they are a family of alloys (mixtures of iron with carbon or various metals). Mild steel Mild steel is iron containing up to about 0.25% of carbon. The presence of the carbon makes the steel stronger and harder than pure iron. The higher the percentage of carbon, the harder the steel becomes. Mild steel is used for lots of things - nails, wire, car bodies, ship building, girders and bridges amongst others. High-carbon steel High-carbon steel contains up to about 1.5% of carbon. The presence of the extra carbon makes it very hard, but it also makes it more brittle. High-carbon steel is used for cutting tools and masonry nails (nails designed to be driven into concrete blocks or brickwork without bending). You have to be careful with high-carbon steel because it tends to fracture rather than bend if you mistreat it. TOPIC 9.3 METALS, ORES AND EXTRACTION 6 Special steels These are iron alloyed with other metals. For example: Type of steel Iron mixed with Special properties Uses Stainless steel Chromium and nickel Resists corrosion Cutlery, cooking utensils, kitchen sinks, industrial equipment for food and drink processing Titanium steel Titanium Withstands high temperatures Gas turbines, spacecraft Very hard Rock-breaking machinery, some railway track (e.g. points), military helmets Manganese steel Manganese 9.3.5 Copper Copper can be extracted from copper-rich ores by heating the ores in a furnace (smelting). The copper produced by smelting is too impure to use, so it is purified by electrolysis. However, the supply of copper-rich (high grade) ores is limited, hence they are very valuable, and production costs are quite high. Because of its position in the reactivity series of metals, copper can be extracted using carbon in a smelting furnace. Copper is below carbon in the Reactivity Series (it’s less reactive), and so can be displaced by carbon from its compounds, e.g. copper oxides or sulfides. However, in practice, modern copper smelters can actually manage the extraction without using carbon (coke) and then electrolysis is usually used to purify the impure copper from the smelter. Ores that are rich in copper are becoming scarce so new methods of extracting copper are being developed to exploit low-grade ores. A low-grade ore is one with low concentrations of copper, and research is going on to try and exploit waste material left over from processing high-grade ores. TOPIC 9.3 METALS, ORES AND EXTRACTION 7 Purification of copper using electrolysis The purification uses an electrolyte of copper(II) sulphate solution (CuSO4), impure copper anodes (positive electrodes), and strips of high purity copper for the cathodes (negative electrodes). The diagram shows a very simplified view of a cell. At the cathode, copper(II) ions (Cu2+) are deposited as copper metal. Cu2+(aq) + 2e- → Cu (s) At the anode, copper goes into solution as copper(II) ions (Cu2+). Cu (s) → Cu2+(aq) + 2eFor every copper ion that is deposited at the cathode, in principle another one goes into solution at the anode. The concentration of the solution should stay the same. All that happens is that there is a transfer of copper from the anode to the cathode. The cathode gets bigger as more and more pure copper is deposited; the anode gradually disappears. In practice, it isn't quite as simple as that because of the impurities involved. What happens to the impurities? Any metal in the impure anode that is below copper in the electrochemical series (reactivity series) doesn't go into solution as ions. It stays as a metal and falls to the bottom of the cell as an "anode sludge", together with any unreactive material left over from the ore. The anode sludge will contain valuable metals such as silver and gold. TOPIC 9.3 METALS, ORES AND EXTRACTION 8 Uses of copper Amongst other things copper is used for: Electrical wiring. It is a very good conductor of electricity and is easily drawn out into wires. Domestic plumbing. It doesn't react with water, and is easily bent into shape. Boilers and heat exchangers. It is a good conductor of heat and doesn't react with water. Making brass. Brass is a copper-zinc alloy. Alloying produces a metal harder than either copper or zinc individually. Bronze is another copper alloy - this time with tin. Coinage. In the UK, as well as the more obvious copper-coloured coins, "silver" coins are also copper alloys - this time with nickel. These are known as cupronickel alloys. UK pound coins and the gold-coloured bits of euro coins are copper-zinc-nickel alloys. TOPIC 9.3 METALS, ORES AND EXTRACTION 9 9.3.6 Aluminium Metals above carbon in the reactivity series cannot usually be extracted with carbon or carbon monoxide. So, metals more reactive than carbon are usually extracted by electrolysis of the purified molten ore or other suitable compound. Electrolysis is the process of breaking down a compound using electrical energy. The process of electrolysis uses of large amounts of energy in the extraction of these reactive metals and makes them expensive to produce. The electrolysis cell The diagram shows a very simplified version of an electrolysis cell used to extract aluminium from aluminium oxide. The electrode reactions The aluminium ore used to extract aluminium is BAUXITE which contains aluminium oxide (Al2O3). It is dissolved at high temperature in a substance called CRYOLITE in the electrolysis cell. Aluminium is released at the cathode (negative electrode). Aluminium ions are reduced by gaining 3 electrons to form the neutral aluminium atoms. Al3+ + 3e- → Al The oxide ions (O2-) travel to the anodes (positive electrodes) and produce oxygen gas. 2O2- → O2 + 4eHowever, at the temperature of the cell, the carbon anodes burn in this oxygen to give carbon dioxide and carbon monoxide. Thus, continual replacement of the anodes is a major expense. TOPIC 9.3 METALS, ORES AND EXTRACTION 10 Although the carbon lining of the cell is labelled as the cathode, the effective cathode is mainly the molten aluminium that forms on the bottom of the cell. Molten aluminium is siphoned out of the cell from time to time, and new aluminium oxide added at the top. The cell operates at a low voltage of about 5–6 volts, but at huge currents of 100,000 amps or more. The heating effect of these large currents keeps the cell at a temperature of about 1000°C. Economic considerations The high cost of the process because of the huge amounts of electricity used. Energy and material costs in constantly replacing the anodes. Energy and material costs in producing the cryolite, some of which gets lost during the electrolysis. Uses of aluminium Aluminium is usually alloyed with other elements such as silicon, copper or magnesium. Pure aluminium isn't very strong, and alloying it adds to it strength. Aluminium is especially useful because it: has a low density is strong when alloyed is a good conductor of electricity has a good appearance resists corrosion because of the strong thin layer of aluminium oxide on its surface. This layer can be strengthened further by anodising the aluminium. Aluminium is used for Reason Aircraft Light, strong, resists corrosion. Other transport such as ships' superstructures, container vehicle bodies, tube trains. Light, strong, resists corrosion. Overhead power cables (with a steel core to strengthen them). Light, resists corrosion, good conductor of electricity. Saucepans Light, resists corrosion, good appearance, good conductor of heat. TOPIC 9.3 METALS, ORES AND EXTRACTION 11 9.3.7 Titanium Other extraction methods are used in special cases. A more reactive metal can be used to displace and extract a less reactive metal but these are costly processes as the more reactive metal also has to be produced in the first place! Titanium is another very useful metal but expensive to produce. Titanium extraction The extraction of titanium takes place in a couple of steps. The first stage involves converting titanium(IV) oxide, TiO2, into titanium(IV) chloride, TiCl4. The ore rutile (impure titanium(IV) oxide) is heated with chlorine and coke (a cheap source of carbon) at a temperature of about 900°C. Reduction of the titanium chloride by sodium metal then takes place. Titanium chloride + sodium titanium + sodium chloride TiCl4 + 4Na Ti + 4NaCl Uses of titanium Titanium is corrosion resistant, very strong and has a high melting point. It has a relatively low density (about 60% that of iron). It is also the tenth most commonly occurring element in the Earth's crust. That all means that titanium should be a really important metal for all sorts of engineering applications. In fact, it is very expensive and only used for rather specialised purposes. Titanium is used, for example: in the aerospace industry - for example in aircraft engines and air frames for replacement hip joints for pipes, etc, in the nuclear, oil and chemical industries where corrosion is likely to occur. TOPIC 9.3 METALS, ORES AND EXTRACTION 12 Why is titanium so expensive? Titanium is very expensive because it is awkward to extract from its ores - for example, from rutile, TiO2, and you can't use carbon reduction. As we have seen, titanium can't be extracted by reducing the ore using carbon as a cheap reducing agent. This is not because titanium is more reactive than carbon but because titanium forms a carbide, TiC, if it is heated with carbon, so you don't get the pure metal that you need. The presence of the carbide makes the metal very brittle. That means that you have to use an alternative reducing agent. In the case of titanium, the reducing agent is either sodium or magnesium. Both of these would, of course, first have to be extracted from their ores by expensive processes. Other problems The titanium is produced by reacting titanium(IV) chloride, TiCl4 - NOT the oxide - with either sodium or magnesium. That means that you first have to convert the oxide into the chloride. That in turn means that you have the expense of the chlorine as well as the energy costs of the conversion. High temperatures are needed in both stages of the reaction. With titanium, however, you make it one batch at a time. Titanium(IV) chloride is heated with sodium or magnesium to produce titanium. The titanium is then separated from the waste products, and an entirely new reaction is set up in the same reactor. This is a slow and inefficient way of doing things. TOPIC 9.3 METALS, ORES AND EXTRACTION 13 Summary When metals are placed in a list showing the trend in their chemical reactivity we call it The ____________________________. The metals at the top include the Group ____ metals p___________, s__________ and l____________. These react vigorously with _____________, oxygen and _____________. Metals at the ___________ of the list react __________ or not at all. The more reactive a metal the more ______________ its compound. Therefore, the more reactive a metal, the more _____________ it is to extract, ie more ______________ is needed to separate the metal from the other elements in the compound. A chemical ________________ is required to separate the elements. Those metals that are so unreactive that they occur as the element itself are known as _____________ metals, eg ______________. Reactions where a metal will take the place of a less reactive metal in a metal compound are called ____________________ reactions. For example (complete the eqns) magnesium + copper sulphate ____________ + ___________ Mg(s) + CuSO4 (aq) ____________ + ___________ (blue) If a less reactive metal is added to a metal salt solution there will be ____________________________ eg.iron and sodium chloride. The __________ of the metals can be worked out by using these types of reaction. The metal that is displaced must lie _________ the metal that displaced it. When metals are found in a rock at an appreciable level that makes it worth extracting we call the rock an __________. Aluminium ore is called _________________, iron ore is ________________ and titanium ore is _____________. TOPIC 9.3 METALS, ORES AND EXTRACTION 14 The process of extracting the metal is called ___________________ because it involves removing ________________. The substance that reduces the metal oxide to the metal is called the______________________. The method used needs to consider ___________, purity and effects on the ___________________________. Iron is extracted using ____________________ as a reducing agent in a _____________ furnace. Aluminium is more reactive than iron and needs _____________________ to extract it from its ore. This is more expensive as it uses a lot of _______________________ energy. Copper is also extracted in a furnace by smelting but is impure so needs electrolysis to __________ it. purify blast stable electrolysis reactivity series reducing agent difficult reaction displacement reactivity potassium MgSO4 below water native energy cost Cu bottom electrical haematite bauxite environment carbon monoxide sodium TOPIC 9.3 METALS, ORES AND EXTRACTION slowly oxygen acid 15 lithium 1 reduction rutile no reaction ore magnesium sulphate gold copper