DBOM for Sustainability: A Research Paper

advertisement

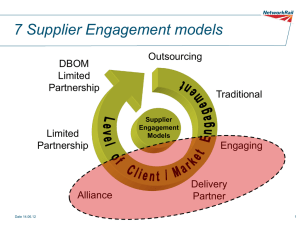

EVALUATING DESIGN-BUILD-OPERATE-MAINTAIN DELIVERY AS A TOOL FOR SUSTAINABILITY Peter Dahl1, Michael Horman2, Teresa Pohlman3, and Michael Pulaski4 ABSTRACT Building and other capital projects usually have a clear distinction between project development phases (i.e. design and construction), and the operations and maintenance phases of a facility. Over the life of the facility, operations and maintenance expenses often far exceed the initial cost of a facility. Importantly, the decisions made early in a project have a strong affect on the life cycle costs of a building. Operation and maintenance knowledge needs to be incorporated early in design to make these critical decisions. High performance green building projects extensively use methods to evaluate the impact of design features over the life of the facility. Techniques such as life cycle cost analysis, energy modeling, and daylight simulation help to evaluate long term impacts of building features. Project delivery methods strongly affect the way project teams are brought together, thus impacting the quality of decisions made in a project. Design-Build has been shown to introduce often crucial and reliable construction input during design to improve the performance of a project. Likewise, the Design-Build-Operate-Maintain (DBOM) project delivery system brings critical operations and maintenance knowledge into design. With this knowledge, better decisions can be made resulting in a higher performing building. As a result, a more efficient and sustainable facility will be turned over to the owner. A review of literature reveals that DBOM has not yet been widely adopted to achieve sustainable project goals. This paper defines the DBOM delivery system, explores the benefits of DBOM, investigates the ability of DBOM to achieve important sustainable initiatives and concludes that this is a promising development for the advancement of sustainable projects. KEYWORDS DBOM, Delivery Methods, Sustainability, Operations and Maintenance 1 Depart. Arch. Engr., Pennsylvania State Univ., 104 Engr. Unit A, University Park, PA 16802; PH (814) 865-6394; FAX (814) 863-4789; EMAIL: pkd109@psu.edu 2 Depart. Arch. Engr., Pennsylvania State Univ., 104 Engr. Unit A, University Park, PA 16802; PH (814) 865-6394; FAX (814) 863-4789; EMAIL: mjhorman@engr.psu.edu 3 Pentagon Renovation and Construction Program Office, 100 Boundary Channel Drive, Arlington, VA 22202; PH (703) 614-2173; FAX (703) 693-8972; EMAIL: teresa.pohlman@whs.mil 4 Depart. Arch. Engr., Pennsylvania State Univ., 104 Engr. Unit A, University Park, PA 16802; PH (814) 865-6394; FAX (814) 863-4789; EMAIL: mhp110@psu.edu 1 INTRODUCTION High performance green buildings are the fastest growing market sector in the architecture/engineering/construction (AEC) industry. These buildings strive to reduce the environmental impact of buildings through reduced energy consumption, efficient use of resources, and improved indoor environmental quality. While high performance buildings typically have a higher cost of construction, life cycle costs can be significantly decreased over the life of the building. Both public and private owners are realizing that high performance green buildings represent a valuable asset. Operations and maintenance (O&M) costs represent the greatest expenditures to an owner over the life of a building, typically amounting to three times that of the initial expense. However, these costs are usually determined very early in the project necessitating the need for high quality, and timely, O&M information (see Fig. 1). For instance, Romm (1994) argued that when just one percent of a project’s up-front costs are spent, up to 70 percent of its life-cycle costs may already be committed. Thus, the contractor and O&M staff must provide input early in the project in order to affect the annual costs of a building. $ Fig. 1. Level of Influence on Cost as compared to time. (After Paulson 1976). Unfortunately, O&M information is not always introduced to the project as effectively as possible. Increasingly, commissioning is used as a way of introducing O&M data to the design and construction activities of a project. While a positive move, this approach addresses broad and generic operational and maintenance issues lacking specificity such as particular equipment issues. It also rarely accounts for the unique capabilities of the firms slated to provide the O&M services. Recent research at Penn State has shown that the project delivery method affects both the levels of sustainability achieved and the cost effectiveness of these buildings. Leading owners, like the Pentagon and Toyota Motor Corporation, have been able to achieve high performance buildings through effective project delivery rather than increased budgets. A key factor in reaching these achievements is a high level of integration between design and construction. A project delivery model that achieves a high level of integration with O&M has the potential to improve the environmental capabilities of high performance buildings. 2 The Design-Build-Operate-Maintain (DBOM) delivery method utilizes a single contract to provide design, construction, operation and maintenance functions. This allows for the contractor and O&M staff to be involved in the design process from the start of the project. This is important because the building designers receive rapid feedback about the constructability, maintainability and usability of the building. This paper critically explores the ability of DBOM to achieve greater integration between the design, construction, operation and maintenance phases of a building. Having clearly defined the DBOM method, the advantages and weaknesses of the delivery system can be compared to Design-Build (DB) and Design-Bid-Build (DBB) methods. In this paper, connections and synergies will be identified between DBOM and improved operations and maintenance input. It is argued that this is one of the pillars needed for a high performing project team, a high performance building, and high performance building operations for the life of the facility. DESIGN-BUILD-OPERATE-MAINTAIN (DBOM) DELIVERY SYSTEM In DBOM delivery, a contractor performs the role of operator for the facility in addition to the design and construction of the building. The contractor, usually a joint venture between a design-build firm and an operations firm, holds a single contract with the owner. The term for the O&M of the facility is typically 10-15 years. By introducing the O&M team to the designers and contractors early in the project, the first cost knowledge base of the designers and contractors is complemented with a life cycle cost knowledge base of the O&M team. It is critical to involve the individuals who will be directly responsible for upkeep of the facility on a daily basis. Design, construction, operations and maintenance of the building are all combined under one contract forming a DBOM contracting team. The four typical phases of a project (planning, design, build, operation and maintenance) are now completed by one entity. This contracting arrangement varies greatly from DB and DBB as one entity is contracted in place of three separate entities (the designers, the constructors, and the operators and maintainers). Incorporating all of the project contracts into one DBOM contract means the owner has a single point of contact, and the project team can communicate and coordinate more effectively, as they are all working under the same contract. Most importantly, the DBOM contract provides incentive for the contractor to design and construct the facility in order to minimize operational and maintenance costs. Upon award of the DBOM contract, the owner negotiates both a project cost and an annual O&M cost for the specified contract period. If the actual costs to operate and maintain the facility exceed that of the fee, the contractor pays out of their own pocket; if the actual costs are less than the fee, the difference is pure profit for the contractor. Other penalties and awards can be defined within the contract to provide further incentives to the project team. Build-Operate-Transfer (BOT) is a similar contract structure, but has some key differences. BOT projects incorporate the design, construction, O&M of the facility by the project team, called the “concession”. A major difference between BOT and DBOM, is that BOT normally includes the financing of the project by the concessionaire, which necessitates the involvement of a financial institution. Another important difference between the two 3 contracts is the inclusion of project feasibility studies and conceptual development within the BOT contract, while the owner typically performs these steps when using a DBOM contract. THE BENEFITS OF DBOM There are many benefits to owners to use a DBOM delivery method. They include improved performance in terms of energy efficiency (sustainability) and operating costs, reduced financial risk, relief of commissioning responsibility, delivery process improvements that remove contractual barriers and less operational risk to the owner. Sustainability: The DBOM contract provides an inherent incentive for the project team to reduce the O&M costs of the facility. The project team’s efforts will most likely focus on increasing the efficiency of the major building systems including the HVAC, electrical and plumbing systems, as these systems use a significant amount of energy. Reducing energy consumption will reduce energy costs. By collaborating with the other designers to clarify the loadings and performance characteristics of the whole system, the design can undergo additional iterations to perform more efficiently. An example of this comes from the design of building finishes, lighting and mechanical systems. By communicating a reliable reflectance of all surfaces in a space, the lighting designer can design the space more accurately and use a smaller factor of safety. Communication can continue to the mechanical designers who can, in turn, decrease the size of the mechanical system because of the reduced heating load resulting from the changes to the lighting. Similar to a DB contract, the DBOM contract enables all of the designers to communicate more freely as they are all under the same prime contract. Importantly, DBOM allows the introduction of O&M knowledge during design. With DBOM, team members will typically have a greater opportunity to develop the connections and synergies in the design and maintenance of the building. Benefits of this can be as simple as assuring access to clean air filters, to significant changes to system design based on knowledge of equipment reliability. The O&M team also makes more informed decisions about their procedures because they have a deeper understanding of the design intent, thus reducing the likelihood that they undermine building performance through inappropriate maintenance. If the project team is able to anticipate a defined fee to operate and maintain the facility, the designers can design the systems to function within the budget. By using higher performing products, the team can anticipate the subsequent savings accrued over the contract period. The team can justify an increased effort on crucial systems by using the savings from higher operating performance to fund the increased costs of either the products or design time. For example, if the team calculates the baseline energy consumption of the building, the team can define the minimum efficiency or performance required by the building systems using a life cycle cost analysis with estimated energy costs. Other systems can be evaluated as compared to this baseline system allowing the team to make a more informed decision. The team benefits by increasing the profitability of the project, the owner benefits by reducing the energy use of the building, and society benefits by using its resources more effectively. 4 Having O&M personnel contracted from the beginning of a project will enable sustainable practices to be woven into operations and maintenance practices. Recognizing the importance of O&M practices to sustainable building goals, the US Green Building Council’s Leadership in Energy and Environmental Design (LEED®) system awards points for a range of O&M practices. These practices include establishing a formal O&M staff educational program; establishing a comprehensive Best Practices Equipment Preventative Maintenance Program; and a system for continuous optimization of systems that regulate indoor comfort and the conditions (temperature, humidity and CO2). Through involvement in project development, O&M staff develops a deeper understanding of the sustainability of the building and become invested in the programs intended to maximize the building’s capabilities. Financial benefits: Using a DBOM delivery method helps the operability and maintainability of the building by requiring the team to commit to a baseline cost for O&M of the building. Since the contract can be structured so that the contractor will only be paid a set amount to design, build, operate and maintain the building, the team is motivated financially to be more conscious of design decisions that affect costs for the extended contract period. In this way, DBOM reduces the risk to an owner’s capital expenses. As the O&M of a building can exceed the construction cost five fold (U.S. Federal Facilities Council, 2001), an owner using DBOM can anticipate the overall costs of the project with a greater amount of certainty. Commissioning responsibility: Commissioning of the project is often a substantial percentage of the overall construction schedule and can be a significant cost to the owner. In DBB projects as well as DB, it is usually in the owner’s best interest to hire an independent commissioning agent. This is intended to reduce bias in the evaluation and calibration of building systems. In using DBOM, the responsibility for commissioning can be moved to the contractor as they are now responsible for operating and maintaining the building systems. Project process: A more efficient and effective delivery system can result from the use of DBOM contracts. DBOM allows for operability and maintainability reviews by the O&M firm to be conducted in parallel with the constructability reviews throughout the design process. Thus, the designers can more effectively incorporate improvements to the design as input is coming from the builders and the users. With all stakeholders defined and involved at the start of the project, the need for major design changes late in the project process can be prevented. Finally, the lack of barriers between the project team members allows for more effective communication and a quicker response time. The design team is able to discuss potential changes with the O&M firm, and in turn, the impacts on the long term operating costs and sustainable features of the building can quickly be conveyed to the designers. Risk: While most commercial construction projects have a one year warranty with many building systems being warranted for a longer period, a DBOM project has a warranty through the end of the DBOM contract (typically 10-15 years) on the entire building. Since the maintenance of the building is included in the same contract as design, construction and operation, the contracted entity assumes this risk, not the owner. The owner can have greater 5 confidence that once the building is built, it will be operated and maintained cost effectively because these costs directly affect the profitability of the project to the DBOM entity. Essence of DBOM: Having defined the benefits and limitations of DBOM, the essential characteristics of this delivery method can now be identified. These are summarized in Table 1, and contrasted against Design-Bid-Build and Design-Build. Table 1. The Essence of DBOM. (Smith and Castellana 2004). Delivery System Design-BidBuild (DBB) Organization Advantages Disadvantages Owner contracts Design, Construction and O&M separately Design is defined prior to bidding Allows owner to be handsoff Ideally, low risk to owner Minimal input from constructors, building operators Expect longer durations Adversarial relationships formed DesignBuild (DB) Owner contracts Design and Construction under one contract Operations and Maintenance contracted/ performed separately Input from constructors early in design Good for experienced and inexperienced owners Improved quality and shorter durations expected compared to DBB Minimal input from building operators Owner loses some control of design Requires a project team experienced with DB DesignBuildOperate Maintain (DBOM) Owner contracts Design, Construction, Operations and Maintenance under one contract. Input from constructors and building operators early in design Improved quality and shorter durations Increased emphasis on a reduction of long term operating costs through the structure of the contract Further reduction of owner control over design and operation of the building Requires additional planning from the owner in the conceptual stage Requires a project team with clear understanding of the DBOM delivery method Limited “checks and balances” IMPLEMENTATION While the DBOM delivery method can provide many benefits to the building, project teams must understand that the project development process requires a different approach as compared to a traditional delivery system and even design-build. The differences start with a change in the way the proposal is requested by the owner. The RFP: The most successful uses of DBOM have occurred when, prior to the release of a Request for Proposal (RFP), the owner defined the project in terms of performance standards. This identifies a baseline for the project describing the need for the project, the external impacts of the project and a synopsis of the timing and cost for the project to be most 6 effective. By defining the project in terms of performance standards, the contractor has the flexibility to deliver the building to take advantage of their capabilities, while ensuring the building achieves the needs of the owner and users. This promotes innovation in design solutions and construction techniques harnessing the skills of the project team. A Request for Expressions of Interest (RFEI) often precedes the RFP to allow the owner to identify parties interested in the project and to give the owner a sense of what is needed in the RFP (which is usually developed during programming). Multiple parties often form a consortium for DBOM projects by partnering to deliver the requested services. An example of this process is found on The Seattle Monorail Project, which will provide 22.53 km (14 miles) of monorail service in Seattle, WA. The project uses a DBOM contract which was recently awarded to the Cascadia Monorail Company, a team of partnering firms including financial institutions, designers, engineers, contractors and facility managers. Construction on the project began in the Fall of 2004, and a fully operational system is anticipated in the Summer of 2009. The estimated cost is approximately $1.6 billion, with the project anticipated to break even on operating expenses by the year 2020. In the Seattle Monorail Project, specific questions were identified in the RFEI, including the scope and length of the contract, the financial structure of the project, and specific characteristics of the project requiring more attention and explanation. The RFP, developed with feedback included from the RFEI evaluations, was issued as a performance based document. The RFP included guidelines and requirements that describe the needs of the building users and is further detailed in Table 2. Table 2. Typical contents of a DBOM Request for Proposals. Contents of a DBOM RFP Project Background and Objectives Performance Based Description of Facility Project Scheduling Needs Project Cost and Funding Restrictions Scope of O&M services Basis of Proposal Review Explanation Communicate the current situation and the reason for the project Describe the needs and requirements for the project, allowing for the design to fit the needs of construction, operations and maintenance Communicate the timeline of design, construction, operations and maintenance phases Communicate the budget for the project, and any foreseen restrictions during the contract period Describe the extent to which the contractor will be operating and maintaining the facility Communicate how the proposal will be evaluated When describing the needs of a facility in the RFP, Nash (2001) calls special attention to specifying a minimum level of service, including a penalty clause for insufficient O&M of the facility, and allowing for a change to be made to the minimum levels of service provided for the building. By describing a minimum level of service in terms of performance requirements, the contractor retains flexibility in the design of the space and the owner ensures that the facility will still meet the needs of their occupants. If the basic needs of the facility change, the contract requires a mechanism, such as a change order, to modify the minimum level of service. 7 On the Seattle Monorail Project, it was also beneficial for the RFP to be organized in terms of the different phases of the project, including the Concept Development, Design, Construction, and Operations & Maintenance phases. This ensured all phases were fully understood and no phases were overlooked. For DBOM to be effective, the evaluation of proposals should be based on best value rather than lowest bid. The term “value” varies greatly depending on owner needs, but, as illustrated by Doran (2000), can include the quality of design, the quality of technical submittals, the financial strength of the contractor as a whole, and the business merit of the proposal. The Pentagon Renovation and Construction Program Office (PENREN/C) places a large portion of their evaluation on the past performance of the contractor. Overall value can be evaluated by the owner in any terms they see fit, however, value must be defined within the RFP for the bidders to fully understand and embrace. PENREN/C understood this, and their success can be, in part, attributed to the creation of an effective RFP. The formation of a project team: Few companies have the capabilities to fully design, build, operate and maintain a building entirely in-house. This creates a need for partnering or a joint venture to combine the expertise from the design phases and the construction phases with the O&M phase. Design-Build firms are well poised to partner with facilities management firms to create a DBOM team, as design and construction abilities are already in-house. Compensation/risk allocation: Throughout a DBOM project, the owner retains ownership of the project. However, the owner should understand that the project team is working from a performance contract, which reduces owner control over some design, construction, operation and maintenance decisions. In turn, the project does not require extraneous manpower as in DBB and DB projects. A smaller staff for the owner can mean reduced expenses during the project. By allowing the contractor to make the necessary decisions to deliver the facility, the owner transfers a considerable amount of the risk of decision making to the contractor. In return for the contractor accepting this risk, they receive a fee, the amount of which is set during contract negotiations. Contract period: Inherently, DBOM will have a longer contract period than DB. The inclusion of a period of operations and maintenance clearly extends the contract significantly. While the O&M phase does not require the design and construction portions of the team on a daily basis, if problems do arise the O&M staff must be able to enlist the assistance of the designers and contractors to address the issue in a prudent manner. After the initial period of O&M, the owner may wish to exercise a contract option to extend the service agreement. CASE STUDY: THE POTENTIAL FOR DBOM AT THE PENTAGON Having identified the key elements of DBOM, an example of the use of this type of delivery approach helps to evaluate the capabilities of DBOM. Constructed between 1941 and 1943, the Pentagon is the world’s largest office building with over 613,200 square meters (6.6 million square feet) of floor space, but has never undergone a major renovation. With as 8 many as 20 localized power outages occurring each day, and systems are so antiquated that they could no longer be maintained, the building had to be renovated to support the Department of Defense. The renovation of the entire Pentagon, will be completed in 2010, with a congressional mandate not to exceed $1.2 billion. Building controls contract: Throughout the project, the remaining four wedges of the building must continue to operate as usual despite the major upgrades and replacement of building systems. Johnson Controls (JCI) is contracted to provide and install sensors throughout the building, which are controlled from a centralized operations control center. JCI was also contracted to create this control center, which included designing, engineering, commissioning, and furnishing it with consoles and audiovisual systems for every building system in the Pentagon. Training was also provided for the building staff to operate and manage the state of the art system. The structure for the JCI contract possesses many similarities to the DBOM contract, but is based on an Indefinite Delivery Indefinite Quantity (IDIQ) format. While the JCI contract does not specifically cover the operation of the control systems, they did provide initial design and construction services, and continue to provide ongoing building managementrelated services. As with DBOM, these services have a limited life, terminating upon completion of the renovation in 2010. The Pentagon Renovation and Construction Program Office: The Pentagon is a prime site for implementing a DBOM contract. Currently, the building maintenance office performs design reviews on the various renovation projects. However, budgetary and complex legal restrictions limit the number of improvements that can be incorporated into a project prior to construction. Consequently, a number of these improvements are performed by the building maintenance office during operation. This provides an ideal opportunity for a DBOM delivery system to be used to spend a portion of the future savings of the improvements. Further, if these changes are realized earlier in the building process and incorporated into the design, it may be possible to reduce their associated cost and overall schedule. The Pentagon already utilizes performance-based contracts, which, as noted earlier, is the type of approach that achieves best results in DBOM. It will be important that the O&M portion of the contract not be defined as an option, but made integral to the contract. If O&M is placed as an option only, the inherent motivations for the contract team to design and construct the building for the most effective maintenance may never be realized. PENREN/C has many of the DBOM prerequisites in place, but like many owners, continues to manage capital projects and operations separately. Integrating capital and operations budgets can be one of the simplest ideas to promote lifecycle performance of a building that is also one of the most difficult to implement. This has been, and continues to be a significant research and policy challenge. Evaluation: The value of an ongoing integrated presence of JCI and their knowledge of the control systems at the Pentagon was most critically demonstrated in the response to the September 11 terrorist attack. While praising the performance of the building control systems, Steven Carter, the Pentagon Building Maintenance Office liaison stated: “You cannot imagine how important it was to have a (JCI) programmer on hand to (enable building systems rerouting) happen automatically.” DBOM and IDIQ promote close ties between 9 design, construction, and operation to improve the performance a facility. The Pentagon building management could rely on consistent expertise in the operation of this most critical of facilities. The JCI contract at the Pentagon did not use all DBOM capabilities, yet many benefits were realized. Adopting a performance-based definition of O&M and integration between capital and operations budgets are likely to help PENREN/C take greater advantage of DBOM. CONCLUSIONS Using DBOM allows an owner to focus the project team towards the lifecycle of building systems. By allowing the project team to increase their own profitability through decreasing O&M costs, building systems can be designed and constructed with operating performance rather than initial cost in mind. Increased integration of the project team can foster collaboration among architects, engineers, constructors and building operators, facilitating a high performing project team. Systems can be “right sized” when they are designed with reliable O&M procedures in mind. Sustainability will shift from being something the team strives for to the byproduct of a highly effective building process. The DBOM delivery method provides a single source for design, construction, operation and maintenance of buildings that will prove to be the tool for facilitating high performance project teams to deliver high performance buildings. REFERENCES Anumba, C.J., et al. (2000). ''Integrating Concurrent Engineering Concepts in a Steelwork Construction Project.'' Concurrent Engineering: Research and Applications, 8(3). Doran, P., Koutalidis, C., and Lau, P. (2000). "The Design/Build/Operate Project Delivery Method: A How to Seminar for Industries and Municipalities." Enviro Expo 2000, Boston, Massachusetts. NASA Systems Engineering Handbook. SP-610S, June 1995. http://ldcm.nasa.gov/library/Systems_Engineering_handbook.pdf, 10/28/04. Nash, C. (2001). "Design of New Financing Schemes for Urban Public Transport." THREDBO7, Molde, Norway. Paulson, B.C. (1976). "Designing to Reduce Construction Costs." Journal of the Construction Division, 102(C04): 588. Romm, J. (1994). Lean and Clean Management. Kodansha America Inc., New York. Seattle Monorail Project, DBOM RFP. www.archives.elevated.org, 10/28/04. Smith, N.C. and Castellana, P. (2004). DBOM Update: Independent Evaluation of Alternative Approaches Relating to Operations and Maintenance Component of DBOM Contract for the SMP Green Line. Nossaman Guthner Knox & Elliott, Los Angeles, CA. U.S. Federal Facilities Council. (2001). Sustainable Federal Facilities: A Guide to Integrating Value Engineering, Life Cycle Costing, and Sustainable Development. Federal Facilities Technical Report No. 142. National Academy Press. Washington, DC. 10