Aquatic eco-systems are undergoing dramatic changes due to

advertisement

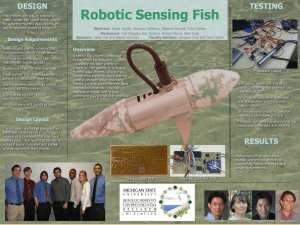

Autonomous Robotic Fish to detect Harmful Algae Blooms (HABS) FINAL PROPOSAL: Design Team: 4 Team Facilitator: Dean Aslam Team members: Taha Tareen, Jamie Jacobs, Stephen Garrett, Woodard Williams Eric Jackson, Carl Coppola, Robert Morris, Allen Eyler Date: 02/4/09 EXECUTIVE SUMMARY Aquatic ecosystems are undergoing dramatic changes due to human activities and change in climate, which results in environmental pollution and affects human wellbeing. The proliferation of Harmful Algal Blooms (HABs) is caused by cyanobacteria producing toxins which accumulate rapidly in water bodies, thus proposing a great danger to our lives. At Michigan State University, the goal is to advance knowledge and transform lives. Through detecting harmful algal blooms (HABS) in threedimensional water bodies, this project gives students an opportunity to achieve the goals of MSU by making the world a healthier place. To achieve the goals set by the team, the most critical issues surrounding the project are the implementation of Graphical User Interface (GUI), digital signal controller (DSC), and the wireless integration. The following steps are to be taken as the basic requirements of the project. For bacteria detection the HAB sensor will be interfaced in to the circuit and the GUI will be updated accordingly. An infrared sensor (IR) will also be implemented for avoiding collisions in water bodies. The electrical casing inside the fish will be made for locking the circuit inside and is according to the conceptual design of the robotic fish itself which also has a compass integrated for the direction movement. Finally demonstrating the fish in the water tank or a lake will provide the results and ensure success. The final design is a smooth body fish, similar to the current shape, with two fins used for balance and one bottom fin used as a rudder. The bottom rudder fin will be used for direction control. Whiskers will be placed on the front of the fish for collision detection. The PCB, battery pack, and servo will be contained in an aluminum water tight container inside the fish body. The bulk of the weight will be distributed towards the middle of the fish to provide the best weight distribution scheme. Upon completion the robotic fish will sense HAB, avoid harmful collisions, and swim in the intended direction. TABLE OF CONTENTS Introduction………………………………………………………………....2 Background …………………………………………………………….......2 Design Specifications………………………………………………….........2-6 Table 1 and 2…………………………………………………...............3 Table 3 and 4…………………………………………………………...4 Table 5,6 and 7…………………………………………………………5 FAST Diagram……………………………………………………………...6-7 Figure 1………………………………………………………………….7 Conceptual Designs…………………………………………………….......7-10 Figure 2 and 3…………………………………………………………..8 Figure 4 and 5…………………………………………………………..9 Figure 6 and 7…………………………………………………………..10 Rankings of Conceptual Design………………………………………........11 Table 8 and 9…………………………………………………………..11 Proposed Design Solution…………………………………………………..12 Figure 8………………………………………………………………...12 Risk Analysis……………………………………………………………….12-13 Project Management Plan…………………………………………………..13-15 Budget………………………………………………………………………..15 Table 10…………………………………………………………………15 1 INTRODUCTION With the environment constantly changing due to human abuse of the planet, scientists are constantly faced with the challenge of coming up with new, more effective methods of understanding/predicting an ecosystem’s response time to global change. One of the more severe concerns of the planet is the aquatic ecosystems. As a result of different contaminants and toxins already disturbing our water, proper functionality of ecosystems and human welfare are dangerously at risk. More specifically, the abundance of harmful algal blooms (HABs) is becoming a more critical issue. In freshwater, HABs are caused by cyanobacteria producing potent toxins. These toxins can negatively impact water supplies and accumulate in fish. In the purpose of this project is to continue the development of an autonomous robotic fish that can detect harmful blooms. Consequently, this specific research should be able to open the door for better ways of monitoring the various water bodies of the Earth, and in the future, better ways of understanding ecosystem behavior. BACKGROUND In 2005, the robotic fish project was initiated by the Smart Microsystems Laboratory (SML) on the campus of Michigan State University. The mission of SML is to enable smarter, smaller, integrated systems by merging advanced modeling, control and design methodologies with novel materials and fabrication processes. The purpose of this task was to build small mobile platforms to be used in aquatic wireless sensor networks. Since August of 2005, SML has developed three generations of robotic fish. The first design, G1, was developed by a senior design team. It was equipped with a microcontroller and wireless communication and was controlled through graphical user interface. The outer shell was a commercially available toy fish, modified to accommodate the circuitry. In August 2006, the G1 greatly improved on the specific problems such as space optimization and waterproofing of the circuit. The second version of the G1 was smaller size and weight. Additionally, it was equipped with a temperature sensor which allowed for a more life like, true mobile sensing capabilities. However, like the first model, the circuit was still confined to a toy fish shell. In 2007, a new prototype was introduced with ranging abilities and a custom built outer shell. New methods were also used to for better waterproofing the circuit. In 2008, the robotic fish was upgraded once again. This time the main focus of the upgrade consisted of computation capabilities. Instead of using a microcontroller, a digital signal controller was used which allowed for the implementation of two more complex ranging algorithms. Also, this design included an onboard battery power source which allowed for increased hours of run time. Throughout each generation of the robotic fish, the most significant prototype constraints included: the design of the outer shell to keep the circuit completely dry, mobility, and using the proper applications to transform the robotic fish from a mere fixed sensing circuit to a mobile robot. DESIGN SPECIFICATIONS The objective of this project is to build an autonomous robotic fish that is capable of three dimensional diving, wireless feedback controls, and detecting harmful algae blooms in diverse aquatic ecosystems. The product will exist as a prototype for developing a group of sensor carrying robotic fish that will monitor lakes and possibly help prevent deteriorating water quality. In order to accomplish the goal of our project the group determined which requested design criteria was feasible for the given time constraints. Table 1, shown below reflects these decisions. 2 Table 1. Feasible Design Criteria Design Components Feasible? HAB Sensor Collision Sensors Direction Control Body Shape P P P P WTC Accel./ Pressure Micro Packaging Propulsion Gyro. Sensor Camera P P O O O Solar Panel O To fulfill the objective the following constraints, ordered in terms of importance to the customer, must be satisfied: 1.) The robotic fish must be interfaced with a small sensor that can detect harmful algae blooms in water bodies. The desirability of this aspect of the design is very high. The sensor detects cyanobacterial (algal) pigments that emit fluorescence when excited by certain light waves. The sensor would then record the concentration of algae and send information remotely to a laptop on shore. HAB Sensors – Shown in Table 2 below Cyclops 7: The Cyclops 7 is a submersible fluorometer designed for integration into a third party platform that supplies power and data logging. This product boasts low power consumption (less than 300mW), small size (weight: 5 oz; length: 4.3’’ x 0.9’’), and light sensitivity (dynamic range: low 0-5 µg/l; high 0-500 µg/l). The Cyclops 7 is designed to integrate with the C6 Multi-sensor platform. The sensor platform adds an extra 6 lbs and 10.2‘’ to the product size. Phytoflash: The phytoflash is a submersible active fluorometer that can be used to detect natural concentrations of cyanobacteria in diverse water systems. The phytoflash is small in size (weight in water: 1.01 lbs; length: 12’’ x 3 ‘’), light sensitive (dynamic range: low 0-5 µg/l; high 0-100 µg/l), and has low power consumption (consumes less than 1W). The device does not require integration into a specific third party source. Table 2. Feasible Sensors HAB Sensor Usable? Best? Cyclops 7 Phytoflash LI190SZ YSI 6131 P P O O P O O O 2.) The graphical user interface (GUI), digital signal controller, and circuit board must be updated. Currently the GUI, digital signal controller, and circuit board are designed for a fish that moves in two dimensions. For the robotic fish to work correctly, all components of the phase one, two dimensional fish must be upgraded and interfaced with sensors. 3.) The robotic fish should be equipped with wireless feedback controls. The feedback control will allow the team to precisely know which direction the robotic fish is heading. This will be accomplished by interfacing the fish with a compass or magnetometer. Direction Control Servo: A servo is a small device that has an output shaft used to control the direction of the fish. The output shaft can be set to specific angular positions by sending a signal to the servo. As the signal changes the angular position of shaft also changes. 3 DC Motor: A small DC motor use output torque converted from a power source to direct the robotic fish. This option would be the most power consuming. IPMC: Ionic polymer metal composite (IPMC) materials are highly active actuators that bend in the presence of low voltage. When the polarity of the voltage is reversed the polymer bends in the other direction. This bending motion resembles the movement of a fish and provides similar mobility in the water. Table 3. Feasible Direction Control Direction Control Servo DC Motor IPMC P P P O P O Usable? Best? 4.) The robotic fish must be interfaced with a sensor that can detect approaching objects. This sensor will protect the fish from crashing into rigid objects and becoming damaged. The sensor will detect an object and an event will occur in the circuitry that will allow the fish to turn and avoid the obstacle. Collision Sensors- Shown in Table 4 below IR Sensors: Collision avoidance sensors send infrared (IR) signals in the form of radio waves to detect an approaching object. The sensor then sends a signal back to the microcontroller allowing time for evasive action. Whiskers: Artificial whiskers will be attached to the front of the robotic fish for navigation purposes. When the whiskers collide with an object the amount of deformation of the whisker shape will determine the voltage signal sent back to the microcontroller. This allows the robotic fish to either swim through trivial obstructions or avoid more stable structures. Table 4. Feasible Collision Detection Sensors Collision Sensors Usable? Best? IR Sensors Whiskers P O P P 5.) The robotic fish should possess a versatile packaging scheme and a suitable body shape. With the help of team members with a mechanical engineering background, an upgraded robotic fish body and packaging can possibly enhance the state of the art of robotic fish. The robotic fish should resemble the appearance of an actual fish and the encasing must be water proof so that the electrical components will be protected. Body Shape- Shown in Table 5 below Jellyfish: The body of design one is shaped like a jellyfish with a long fin connected to the bottom. The design would float on the water and survey the surface. The fin would be there for stability in the water and direction control. Tuna Fish: This body shape is composed of two dorsal fins for direction and a causal fin (tail) for propulsion. This body shape allows for hydrodynamic mobility in the water. The polymer in the tail would produce the propulsion for this design. Manta Ray: The manta’s diamond shaped body is a perfect model for lake exploration. The pectoral fin would be used to guide the fish and keep it stable while a causal fin would propel the device in the water. 4 Tuna Fish 2: The same body shape as tuna fish 1 with no bottom rudder fin. Design 1: Jellyfish Design 4: Tuna Fish 2 Design 3: Manta Ray Design 2: Tuna Fish Table 5. Feasible Body Designs (pictures above) Body Shape Design 1 Design 2 Design 3 Design 4 O P O P Usable? Water Tight Compartment (WTC) Packaging – Shown in table 6 below Pill Bottle: The shape of a pill bottle would keep out water with a twist on cap and house the electronic components inside. There might be extra unused room because of the width of a pill bottle. Pop Bottle: The length and width of a pop bottle would be perfect for the tuna fish design. The only problem that would arise is cutting opening the bottle to store the components inside and then sealing it. Pop Can: The pop can is made of aluminum so opening and soldering a part of the can close would be an advantage in this design. Table 6. Feasible Water Tight Compartment Designs WTC Packaging Usable? Rank? Pill Bottle Pop Bottle Pop Can P 3 P 2 P 1 6.) The robotic fish should be capable of swimming 1.5 cm/s or faster. To effectively monitor a lake within the battery life of the robot, the fish should be able to swim 1.5 cm/s. An increased speed will also enable the sensor to detect more harmful algae. Propulsion – Shown in Table 7 below Single IPMC: A single IPMC would be used like the causal fin of a fish. The horizontal bending motion of the material would propel the robotic fish forward. Multiple IPMC: Multiple IPMC would provide more power to propulsion and allow the device to move faster. Propellers: Propellers would be created using a dc motor. The torque outputted from the motor would rotate, displacing the water and moving the fish forward. The concern of this option is power consumption. Table 7. Feasible Propulsion Designs Propulsion Single IPMC Multi. IPMC Propellers Usable? Best? P P O O O O 5 7.) The team must demonstrate the operation of the mobile sensor platform (including wireless communication and GUI) in a water tank. Demonstration of the robotic fish in a tank will prove the capability of the project to move to an actual lake, if environmental conditions allow. Also, the operation of the fish in water will be tested. The autonomous robotic fish will be designed based on the preceding criteria. To determine the desirability of a design, the following set of criteria has been developed: 1.) Function This parameter determines if the design follows the mandatory constraints identified above. It is the first and most important aspect of the design. 2.) Size The robotic fish body must be large enough to hold the HAB sensor and the other electrical components. Also, what must be considered is that if the fish is large in size and light in weight it will displace more water and have a difficult time submerging. 3.) Weight The weight of the robotic fish design can affect ascension or descension in the water. To descend the fish must weigh more than the water it is displacing. To ascend the fish must be more buoyant than the water. A design with the ability to control weight while in the water is preferable. 4.) Energy Consumption The robotic fish will run on batteries, so monitoring energy consumption is relevant to a good design. The rate of power consumed directly determines how long the device can stay in the water and detect harmful algae. A robotic fish that can use less energy and still be effective in its operation is highly desired. 5.) Reliability This parameter concerns the ability of the design to perform tasks and operate in a consistent manner. 6.) Aesthetics Appearance can have a large impact on marketability. A robotic fish that has a very close resemblance to a real fish can draw a lot of attention by looks alone. 7.) Delivery Date A design that is too complicated may not be achievable by the delivery date. Each design must therefore be rated on its feasibility of completion time. FAST DIAGRAM In Figure 1 below is the FAST diagram for the design of the HAB sensor. A FAST diagram was not completed for the entire scope of the project because it would be extremely large. 6 ASK HOW ASK WHY Select Sensor with size, weight, and interface suitable for mounting on the robotic fish Build Robotic Fish that detects Harmal Algal Blooms (HABs) Identify Suitable Cyanobacterial Sensor to detect HABs Interface Sensor Design Circuit Board Survey Existing Cyanobacterial Sensors Select proper Digital Signal Controller (DSC) and Graphical User Interface (GUI) to accommodate sensor Determine appropriate placement and most suitable design Figure 1. Fast Diagram CONCEPTUAL DESIGN DESCRIPTIONS Using the preliminary matrices shown in the design specifications portion of this document four designs were proposed as solutions. The first proposed solution will be referred to as design 2a for the remainder of this paper. All four of our designs have the exact same placement of the HAB sensor and whiskers, which can be seen in figure 3 below. Design 2a has the body type as shown in Figure 2 below. The tail of the fish will consist of two IPMC (artificial muscle polymer). The two IMPCs will work in a “V” to “I” motion. In this way, IMPCs could provide more forward propulsion. The bottom fin will be used as a rudder, which is connected to a servo. This rudder will be used for direction control. The two fins coming out of the fish at angles will provide extra balance to the fish. Inside the fish body will be a controller PCB, a servo, and a battery pack. In design 2a, taking a birds eye view of the fish, the battery pack, servo, and PCB will be distributed from one side of the fish to the other as shown in Figure 3 below. The second proposed design will be referred to as 2b for the remainder of the paper. The body shape is exactly the same as the body shape for design 2a. The main differences between the two designs are the placement of the battery pack, PCB, and servo, as well as the number of IPMCs. In design 2b there will only one IPMC providing forward propulsion. In this design the PCB will be placed above the servo and the batteries. The servo will be positioned in the middle of the fish between 2 separated batteries, see Figure 4 below for a sketch. The third proposed design solution will be referred to as 4a for the remainder of the paper. The body shape is similar to that of both design 2a and 2b but here will be no rudder fin. The body design is shown in Figure 5 below. The 2 fins that were used for balance in the first two designs will be used for direction control. These two fins will be connected to the servos. As shown in Figure 6 below, design 4a makes use of 2 servos again. The movement of these 2 IPMCs will be exactly as like the situation stated above. In design 4a, the battery pack will be split and the servo will be placed in the center. The PCB will be placed in the back of the fish towards the tail. The fourth proposed design will be referred to as 4b for the remainder of the paper. The body shape will be exactly the same as design 4a. Design 4b will make use of only one IPMC but will also use 2 servos. Each servo will be controlling a separate side fin. The placement of the PCB, battery pack, and 2 servos is shown in Figure 7 below. The servos will be placed at an angle and the PCB will be towards the bottom of the fish between the servos. The battery pack will be behind this, toward the tail of the fish. 7 Figure 2. Body Design for 2a and 2b Whiskers Battery Pack HAB Sensor PCB Servo IPMC Figure 3. Proposed Design 2a Top View 8 Servo Battery Pack PCB IPMC Figure 4. Proposed Design 2b Top View Figure 5. Body Design for 4a and 4b 9 Battery Pack Servo PCB IPMC Figure 6. Proposed Design 4a Top View Servo PCB Battery IPMC Figure 7. Proposed Design 4b Top View 10 DESIGN RANKINGS Determination of the current design concept was attained through a series of comparisons of key qualities and attributes believed to be integral in both the design process and desired operation of the robotic fish. First, a feasibility matrix was developed in order to reduce the number of conceptual designs to the two that best accomplished the most important functions. Table 8. shows the designs and which criteria needed to be fulfilled. If a certain design was believed to be unable of sufficiently fulfilling a criterion, it received an “x”, corresponding to a design flaw, and the two designs with the fewest flaws would proceed to the next stage of comparison. Table 8. Feasibility Matrix for All Original Design Concepts Feasibility Matrix - Semifinals Design 2a Design 2b Design 4a Design 4b Direction Control HAB Sensor Collision Detect. Weight Dist. Single IPMC Cost Manufacturable Critical Flaws P P P O O P P 2 P P P P P P P 0 P P P P O P P 1 P P P P P P P 0 After being compared, the two designs chosen to proceed were Designs 2b and 4b. The second stage of design comparison was facilitated via a selection matrix, which is shown below, in Table 9. Table 9. Selection Matrix for 2 Final Design Concepts Selection Matrix - Finals Weighting Design 2b Design 4b Servo Quantity Weight Cost Batt. & PCB Loc. Rudder Loc. Maneuverability Power Consum. Heat Generation Submersible Fish Mimicry 8 7 5 4 3 6 10 9 2 1 Total Score: 1 1 1 1 2 2 1 1 2 1 2 1 2 1 1 1 2 2 1 1 66 87 Each factor was first weighted by importance on a scale of 1-10, with 10 being the most important and 1 being the least. Each design was then ranked against the other on how well it met each criterion. The design which met the desired criterion best received a rank of 1, while the other was ranked 2, unless both designs fulfilled the criterion equally, in which case, both were given a rank of 1. Once ranked, the weight of each criterion was multiplied by the rank given for each design, and scores were calculated by summing the products for each design. The design with the lower score was then chosen to be the current design concept. As can be seen, the winning concept turned out to be the Design 2b concept. 11 PROPOSED DESIGN SOLUTION As shown in Figure 8 below the electrical and mechanical design plan has been determined. The beginning phases of the electrical design and the mechanical design will be making forward progress simultaneously. The electrical engineers will be working on the PCB design while the mechanical engineers are working on the body design and body construction. The body shape and design must reflect the shape and size of the PCB. After these two objectives have been completed the water tight construction can begin. At this point the testing can begin on the full model. Along the way testing will be done on individual parts of the fish. For a more detailed description of these tests see the attached Gantt chart. Electrical Design Mechanical Design PCB Design Body Design Part Purchasing (ICs, HAB sensor, etc.) PCB Modeling (Express PCB) Body Modeling (Unigraphics NX6) PCB Construction Body Construction GUI Modification/ Debugging Circuit Testing Electrical Component Organization WTC Installation Hydrodynamic Analysis (FLUENT) Electrical Component Installation Dry-Testing In-Water Testing Debugging/Modification Debugging/Modification Key Process WTC Body Casing WTC Testing Casing Testing Lake Demonstration Process Component Final Process Figure 8: Design Solution Process Diagram RISK ANALYSIS 1.) The robotic fish must be interfaced with the HAB sensor: The risk involved in integrating the HAB sensor is the highest and most critical. The integration of the sensor is the most sought out requirement for the robotic fish and thus, the essential focus of 12 2.) 3.) 4.) 5.) 6.) our project. The most critical issues are the size of the sensor, the dissipation of heat and the decoding of the data. The graphical user interface (GUI), digital signal controller, and circuit board must be updated: The risk involved around this specific design specification is moderate because it all previous coding was done in C#. The team must modify the original code according to the design parameters and the features surrounding the project. The robotic fish should be equipped with wireless feedback controls: The wireless feedback control is a moderate risk because the directional movement of the fish must be known at all times and corrected immediately to ensure the fish is moving in the correct and intended direction always. The robotic fish must be interfaced with a sensor that can detect approaching objects: The risk involved in incorporating the IR sensor or whiskers is low. The group does not anticipate any problems in this area. The robotic fish should have a versatile packaging scheme and body shape: The fish needs to have a water tight packaging scheme which must enclose the PCB, the battery pack, and the servos and enclose it completely so it is water proof. The body shape also has to be designed to integrate everything so that it operates as expected. Considering all these factors of size, waterproofing and overheating, the team believes this area will be a high risk. The robotic fish should be capable of swimming 1.5 cm/s or faster: The sponsors have informed the team that speed is not a huge factor it is, therefore, projected to be a low risk. PROJECT MANAGEMENT PLAN In the following sections, the technical tasks to be completed by each member of the group are explained. Carl will be fulfilling two main duties, along with several other ME group tasks, which include building the body, WTC, and in-water testing. The first main duty will be to mediate between the EE and ME members of the group by explaining technical ideas when necessary and helping in the design of both the mechanical and electrical aspects of the project. The latter includes, but is not limited to, aiding in the programming of the GUI, design and construction of the PCB, CAD modeling of the body design, and . Carl’s second main duty will be the integration of the electrical components into the final body. This entails organizing the electrical components and constructing a water-tight compartment (WTC) that will enclose said components. In addition, once the WTC has been constructed and the electrical components installed, he will dry-test everything prior to installation into the body, ensuring that all the electrical and mechanical components are working and operating in concert as desired. After the dry-test and any required debugging, he will install the WTC into the body and test again to make sure that everything works correctly within the body. Once installed and working correctly, in-water testing will be conducted and the results will be shown to the professional and faculty advisors who will give feedback on the prototype and decide if any changes need to be made. Eric will be taking measurements of the physical parameters of the packaging. The parts will be modeled using NX modeling software, and built by using the tools in the Machine Shop. The physical materials required consist mainly of aluminum sheets and an aluminum can. This process will begin in the middle of March, and the preliminary phase should last about two weeks. After each optimization phase, necessary changes will be made to the models and to the physical casing. This should last for the remainder of the project period, until a final product is made. Allen Eyler will work on the CAD modeling (In UGS NX and in Ansys) and fluid simulation (in FLUENT) of the robotic fish in order to optimize the design. Once this design has been finalized, 13 he will assist with the manufacturing of the fish. After manufacturing, he will participate in the testing and troubleshooting of the final product. Woodard and Jamie are responsible for the PCB design. Currently they have the wireless base station populated and ready for use. Also, they have the up to date photos for the existing controller PCB, as well as, the parts list required to assemble the PCB for the specific project. Woodard and Jamie have the Gerber files that give us the particulars of the PCB. However from the files obtained, there are some discrepancies between the photos and the Gerber files. In an effort to proceed accordingly, Dr. Tan's graduate assistant, Freddie Alequin, has been contacted to clarify and provide proper documentation of the differences between the photos and Gerber files. The digital signal controllers (DSC) have been ordered. Next, Jamie and Woodard will deliver a sufficient PCB design layout for each component of the project. When this task is complete, they will know the appropriate size the PCB and the design can be completed and sent out for manufacturing. When the PCB is returned the parts can be soldered on the board. Testing will be done to ensure the board is working correctly and this will conclude the main deliverables for this section. Taha Tareen and Stephen Garrett will be responsible for the coding of the DSC to be used in the project. The timeline for the deliverables for the whole programming will take about 15 days. The tasks are going to be divided in writing the lines of code for all our inputs and outputs. The inputs include the temperature sensor, battery indicator, whisker sensor, HAB sensor, microphone module, digital compass, In-circuit serial programmer (ICSP) and the wireless module. The outputs peripheral connections to the DSC will be going to the in-circuit serial programmer, wireless module, the actuator module and the compass. The outputs to the ICSP are needed to reprogram the DSC in case of some unexpected bug errors or simply for updating purposes. The output connection to the buzzer is also very important for the ranging purposes of the fish and to the actuator module for the movement of the fish as well. To code all these inputs/outputs this timeline will be divided to about 2 days per input/output. Robert will be filling several roles in this project. These are research of: design, and analysis of the body and fin shape, particularly concerning the area of hydrodynamics, as well as the construction and testing of the fish body. The first of these roles, the research of the body and fin shapes, involves researching previous robotic fish, particularly with regards to body decisions, as well as studies on the efficiency and thrust of various fin shapes. From this research, Robert will design a body shape to be optimized with regards to several hydrodynamic properties, primarily drag, as well as component fitting. To optimize the design, the computer analysis program FLUENT will be utilized to analyze potential designs and the results will be used to determine the optimal design. If time allows, the HEEDS optimizer may be used to assist in the creation of the body shape. Once the most promising designs have been designed, initial body shape testing will be performed to verify the results from the computer analysis programs. Once this initial design work is completed, Robert will assist the other group members in the construction of the robotic fish. Finally, Robert will assist in the testing of various aspects of the robotic fish. The proposed schedule identifies a feasible timeline for the completion of the project and all required deliverables. Also, because two distinct disciplines of engineering are collaborating to bring the robotic fish into reality, there exists a sub-schedule for each group. While still operating as one team and sharing ideas, the electrical engineers follow an electrical construction schedule while the mechanical engineers follow a mechanical construction schedule. This way, both components of the device can be constructed simultaneously and then combined to assemble the complete prototype. The project is scheduled for completion in early April. 14 A summary of the schedule is as follows: Completion Date Pre-proposal 2/06/2009 Proposal 2/20/2009 Oral proposal presentation 2/23/2009 Electrical construction 3/16/2009 -circuit assembly Student Technical Lecture 3/20/2009 Demonstration #1 3/20/2009 Mechanical construction 3/24/2009 -casting assembly Electromechanical Integration 4/7/2009 Demonstration #2 4/10/2009 Final Report 4/29/2009 Final Demonstration 5/1/2009 Attached is the full schedule (Gantt chart) viewable in Microsoft Project. BUDGET: The price and quantities for all required purchases are listed below in Table 10. The items listed with a $0.00 cost were recently given to us so no longer require purchase. The largest purchase was the Turner Electric HAB sensor, Cyclops 7. The group researched the Cyclops 7 sensor, along with many other sensors, and through conversations with both the sponsors this sensor was decided chosen. The solid standard C-7 testing apparatus will allow us to test the sensor (once integrated) without placing the sensor in the water. This will prove to be useful as the group nears the end of the project for testing and debugging. Other than these major purchases all purchases are standard PCB components for the controller PCB inside the fish. Table 10. Price List Manufacturer Sipex E-Switch Analog Devices Tyco Electronics Amp Lumex Opto Digi International/Maxstream Fairchild Semiconductors Ohmite Susumu Co Ltd Tyco Electronics Amp Tyco Electronics Alcoswitch Norcomp Inc. Linx Technologies Maxstream Nichicon Susumu Co Ltd Susumu Co Ltd Susumu Co Ltd Susumu Co Ltd Susumu Co Ltd Susumu Co Ltd Susumu Co Ltd Panasonic-ECG Panasonic-ECG Panasonic-ECG Micrel Inc. National Semiconductor International Rectifier Diodes Inc. Honeywell SSEC Harwin Yageo Murata Electronics N. America Kemet Pulse Taiyo Yden Microchip Turner Electric Turner Electric Turner Electric Turner Electric Total Cost MFG Part Number Qty Price/Unit SP3203EEY-L/TR 1 $0.00 EG1218 1 $0.00 ADP667ANZ 1 $0.00 5520250-3 1 $0.00 SSL-LX5093GD-12V 1 $0.00 XB24-AWI-001 1 $0.00 2N3904BU 1 $0.00 TA205PA1R00JE 2 $2.00 RR1220P-202-D 1 $0.14 640453-6 1 $0.35 MMS42 1 $3.69 25631001RP2 2 $3.07 ANT-2.4-CW-RH 1 $4.74 JF1R6-CR3-4I 1 $5.00 UVR1V470MDD 4 $0.11 RR1220P-471-D 4 $0.14 RR1220Q-560-D 1 $0.14 RR1220P-683-D 3 $0.14 RR1220P-393-D 3 $0.14 RR1220P-223-D 1 $0.14 RR1220P-101-D 2 $0.14 RR1220P-102-D 5 $0.14 ECH-U1C103GX5 6 $0.35 ERJ-6GEYJ915V 1 $0.08 ERJ-6GEYJ515V 1 $0.08 MIC29300-3.3WU 1 $5.45 LM62CIM3 1 $0.98 IRF7307TRPBF 2 $1.18 1N5817-T 1 $0.42 HMC6352 1 $30.00 M22-7140642 1 $1.38 9C08052A1002FKHFT 4 $0.01 GRM21BF51C106ZE15L 5 $0.25 B45197A3336K309 2 $0.72 P1167.563NLT 1 $1.44 LMK212SD104KG-T 3 $0.48 DSPIC30F4013 4 $8.83 2100-000-C 1 $1,768.00 2100-750 1 $75.00 2100-900 1 $349.00 Warranty 1 $150.00 Total $0.00 $0.00 $0.00 $0.00 $0.00 $0.00 $0.00 $4.00 $0.14 $0.35 $3.69 $6.14 $4.74 $5.00 $0.44 $0.56 $0.14 $0.42 $0.42 $0.14 $0.28 $0.70 $2.10 $0.08 $0.08 $5.45 $0.98 $2.36 $0.42 $30.00 $1.38 $0.04 $1.25 $1.44 $1.44 $1.44 $35.32 $1,768.00 $75.00 $349.00 $150.00 $2,452.94 Circuit Base Station Base Station Base Station Base Station Base Station Base Station Base Station Fish Fish Fish Fish Fish Fish Fish Fish Fish Fish Fish Fish Fish Fish Fish Fish Fish Fish Fish Fish Fish Fish Fish Fish Fish Fish Fish Fish Fish Fish Fish Fish Fish Fish Item Description Serial Transceiver with Logic Selector 3V RS 232 Switch Slide SPDT 30V 0.2A PC MNT IC REG LDO 5V or ADJ LIN 8-DIP Connector Mod Jack 6-6 R/A PCB 50AU LED 5MM 12V Green Diffused Module Zigbee 1MW w/wire ant NPN Transistor 200mA Res Thick film power 1.0 Power RES 2.0K OHM 1/10W .5% 0805 SMD CONN HEADER RTANG 6POS .100 TIN SWITCH SLIDE 4PDT 2POS MMS SER CONN RCPT 2MM VERT SGL ROW 10POS ANTENNA 2.45GHZ 1/4 WAVE RP/SMA 2.4Ghz 2.4Ghz ant U.FL fem to RPSMA fem cable CAP 47UF 35V ELECT VR RADIAL RES 470 OHM 1/10W .5% 0805 SMD RES 56 OHM 1/10W .5% 0805 SMD RES 68.0K OHM 1/10W .5% 0805 SMD RES 39.0K OHM 1/10W .5% 0805 SMD RES 22.0K OHM 1/10W .5% 0805 SMD RES 100 OHM 1/10W .5% 0805 SMD RES 1.0K OHM 1/10W .5% 0805 SMD CAP .01UF 16V PPS FILM 0805 2% RESISTOR 9.1M OHM 1/8W 5% 0805 RES 5.1M OHM 1/8W 5% 0805 SMD IC REG LDO 3A 3.3V TO263 IC TEMPERATURE SENSOR SOT-23 MOSFET N+P 20V 4.3A 8-SOIC DIODE SCHOTTKY 20V 1A DO-41 MODULE COMPASS DGTL 2AXIS 24PLCC 2x6 Switch Socket Resistor 10k ohm 1/8W 5% 0805 Ceramic Capacitor 10uF 16V Y5V 0805 Capacitor Tantalum 33uF 16V 10% Low ESR INDUCTOR PWR SHIELDED 42UH SMD CAP CER .10UF 10V 0805 LOW DIST DSC Microcontroller HAB Sensor Cyclops 7 Hab Sensor Cord Solid Standar C-7 Testing Apparatus Sensor Warranty 15