Fireflay zapobiega eksplozjom i pożarom

advertisement

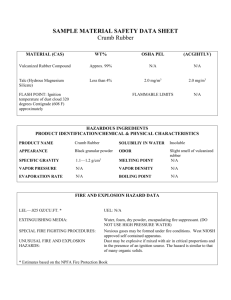

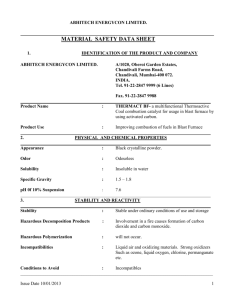

Firefly system prevents from fires and explosions Jerzy Krzyżowski jkrzyzowski@bredband.net Advanced technology notices and cooles off hot particles of wood dust, before they become the main reason of fire or explosion in electric devices, in wood industry and pellets' production plants. Firefly started its activities on the market in the 1970's and that was the time when a first detector for chipboard production plants was invented. Soon it turned out that the area of its potential application is much wider. Temperature and mass The most important elements of a particular Firefly detector are infrared sensors, whose aim is to notice energy in the moving mass of material. In processes, where dry, flammable materials are applied, there is a strong risk of fires as well as explosions of different materials and dusts. Fire and explosions are often caused by a hot material created throughout the process. The main sources of ignition are mills and drying rooms, transport fans, screw transporters and rotational transporters (being refered to as the sources of generating ignition). Problems can be created as a result of influencing of a material with mechanical friction (because of overloading tank, mechanical wear of equipment or its damaging etc.) Risk areas suitable for fire or explosion of dust occurmainly in spaces, where a dry, fragmented material occurs in conducive concentrations and the mixture with the oxygen (air). Such conditions occur in places like dust extractors, filters, shields, chutes and storage tanks. Operating Firefly system minimises the risk of fire and the explosion of dust in the risk area of protected zone. It is done by detecting sources if ignition in the early stage and putting them out, before they get to the risk area. The system records the amount of moving hot particles. If a detector notices a single source of ignition, then a sprinkler acting for two seconds starts. System is programmed in a way, that enables for continuing the operating of the equipment at this stage. However, if the frequency of appearing of ignition sources stands out the risk level defined before, or if the sensors will be indicating flames, then the assembly line will be stopped by a signal sent from headquarters and the alarm goes off. Detect Firefly possesses a broad range of detectors suitable for different applications. The detecting of hot particles takes place with the help of infrared sensors (IR) opeating, in the reach of long infrared waves. This enables detecting all sparks, hot particles as well as hot red particles. All Firefly detectors are immune to day light and they do not cause false alarms. Before choosing a particular detector it is vital to define the minimal temparature of ignition of processed material. In fact, a particular material can have different temperature of ignition, depending on wheather the event takes place in the cloud of dust or wheather it creates the dropping layer. For instance, the dust in the air has the temperature of ignition on the level of 470 °C ( in dust extractors, filters), whereas dust lying in the layers of dust has the temperature of ignition on the level of 260 °C ( magazine silos, tanks etc.) Detector notices sparks, hot particles or hot notions possessing the temperature higher than the characteristic temperature for a particular detector (for instance 250 or 400 °C.). This type of detector is applied in the pneumatic transport or in chutes. In case of transporters, the detector is placed the further from the danger zone. Whereas chutes are concerned, a particular material needs to have at least 300 millimetres of free falling, before it passes detector. Putting out of fire After detection the source of ignition has to be put out effectively or seen off befor it gets to the risk area. Firefly can offer a wide range of different methods of putting out a fire, depending on kind of application used and the avalilability of eqtinguishing media (such as water fog, steam, carbon dioxide). Regardless of chosenmethod, the time of reaction for Firefly preventing-protective system, from the moment of detection till the full developmentof action in the extinguishing area is always less than 300 ms (including the security margin). It means that, in the canals of pneumatic transport, the extinguishing zone must be located within the exact distance of 9 meters after detector (when applying the speed of moving material as 30 meters/ per second) from detector in the direction of extinguishing zone) or 500 millimeters in the case of chutes with free falling. Nozzles had to be placed on the different sides of a canal/chute. In this way they create an effective zone of putting out a fire, covering the whole cross-section of the canal, “attacking”: the source of ignition from all sides. Uncontrolled development of situation in 95 percent leads to fire a nd in 5 percent leads to explosion. Currently over 75 percent of Firefly production is being exported. Production and assembling of equipment is located in Stockholm. Firefly has its market-agents in the US, Germany, Denmark, France, Great Britain, Finland, Norway, Spain, Austrialia, Turkey, Lebanon and of course in Poland - We work together with our market-agents and subsidiary suppliers by conducting seminars, and training workshops, and then the agens visit potential customers and offer them supplies of our products – Michael Willnier explains. During period of first 10-15 years, the majority of production was created to satisfy the needs of the domestical market in Sweden. Exporrt expanded afterwards, and currently the new markets for our products are the Asian and the South American countries. The Central Europe has always been a big market. Production of heat and pellets procution plants. In Sweden we have approximately 90-95 percent share in the market of securities in production pellets business and energetics connected with biomass, despite the fact that in the eighties competitive systems turned up on the market. When the problem of securing filters is taken into account, even simpler technique is able to solve it, whereas in this segment the competition stays on the same level. Presence on new markets Wood industry, chipboard and plywood production, industriual application of pellets, tobacco industry, grocery industry, and the other industries where explosion can appear are our big customers. Currently, the turnover stays at the level of 6 million Euro and the firm is present on Stockholm stock exchange. In our work we always start from analysis of risk in a particular process – Anders Bergström says – In this way we indetify the sources of creating dangerous partticles, (for intstance devices like wood mills). During production of pellets, there appear many sources of this type, hoverer, it is not possible to notice it while supervising the operating of equipment, because only the mixture of wood dust and the air is highly explosive. During the analysis stage we examine the project as well as the production stage very carrefully, so that we can design the system detecting all possible sources of ignition in the best way. That to it the hot particles can be cooled or taken away from the risk zone. GT/TD detektor OAD detector MGD gas detector sprinklers Puting out fire by using water steam Screens. We produce many kinds of screens, with the time of reaction shorter than 50 milliseconds. switchboard Taking out the dangerous mass from the process.