2.2 Grating, Floor Plate, and Guardrail Removal

advertisement

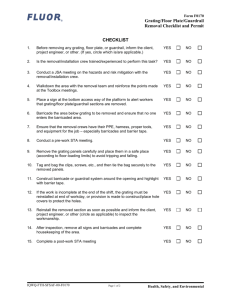

ExxonMobil/Fluor W3QR Site Specific Procedure 3323 Date 18Jan2011 Rev 0 Practice 000.653.3306 Date 01Sep2009 Page 1 of 7 ® GRATING, FLOOR PLATE, AND GUARDRAIL REMOVAL PURPOSE This procedure establishes the requirements for removing grating, floor plate, and guardrails, and protecting personnel from potential fall hazards as a result. SCOPE This procedure includes the following major sections: General Requirements Permits Grating and Floor Plate Removal/Reinstalling APPLICATION This procedure applies to work activities and employees under the control of Fluor and its contractors. DEFINITIONS None. Health, Safety, and Environmental ExxonMobil/Fluor W3QR Site Specific Procedure 3323 Date 18Jan2011 Rev 0 Practice 000.653.3306 Date 01Sep2009 Page 2 of 7 ® GRATING, FLOOR PLATE, AND GUARDRAIL REMOVAL 1.0 GENERAL REQUIREMENTS A Grating/Floor Plate/Guardrail Removal Checklist and Permit (Form F0170) must be completed and approved before any grating, floor plate, or guardrail or clamp, clip, or other retaining piece is loosened, adjusted, modified, or removed (whether partial or fully). Supervision must ensure that removal of grating, floor plate, or guardrail is necessary to perform the task. Once it is established that removal is necessary, supervision must review the work to minimize the amount of grating, floor plate, and/or guardrail to be removed. Supervisors, together with the HSE Representative, must review the actual work location to confirm that removal of the grating, floor plate, or guardrail is the only way to perform the task safely. Only those crafts/trades that are specifically trained to perform such work (such as “structural steel workers”) will be allowed to remove/replace grating, floor plate, and guardrail. Fall protection must be provided for those working inside a barricade, as required by Procedure 3001. No opening must ever be left unguarded … post a watch if necessary. When working in the area of removed grating or floor plate, ensure adequate lighting is provided to illuminate the opening. Warn and inform other personnel in the area of the removed grating or floor plate. All grating or floor plate must either be reinstalled at the completion of the work task or at the end of the shift, or a floor hole cover is installed that meets the requirements of section 3.1. No opening must remain beyond the end of a shift, unless a new permit is obtained. General rules for handling floor grating and floor plate include the following: Comply with all building, area, and site safety rules. Wear the minimum personal protective equipment (such as safety glasses, leather gloves, and toe protection). Use safety harness and life lines as required by Procedure 3001, Fall Protection. Health, Safety, and Environmental ExxonMobil/Fluor W3QR Site Specific Procedure 3323 Date 18Jan2011 Rev 0 Practice 000.653.3306 Date 01Sep2009 Page 3 of 7 ® GRATING, FLOOR PLATE, AND GUARDRAIL REMOVAL Determine the weight of the item to be lifted before attempting the lift. Ensure the appropriate lifting tools/equipment will be used; do not use hands unless hand-holds or handles are provided. Avoid placing hands near the opening of grating, floor plate, decking, or manhole covers when removing or replacing them. Be alert for pinch points. Request assistance in lifting when necessary, then lift together and coordinate movements carefully. Maintain proper footing when prying or lifting. Be aware of potentially unsafe conditions that may exist if a pry/lifting bar should slip. Barricaded areas will be large enough to maintain adequate work area space and good housekeeping procedures in accordance with Procedure 3300, Housekeeping. Permanent lifting handles must be installed if grating or floor plate is routinely removed for maintenance access. Floor penetrations will be adequately protected with “kick plates.” 2.0 PERMITS 2.1 Permit to Work If the permit to work process is in use, a Permit to Work must be obtained (Form F 0181) in accordance with Procedure 1302, Permit to Work. 2.2 Grating, Floor Plate, and Guardrail Removal Before grating, floor plate, or guardrail can be removed, a Grating/Floor Plate/Guardrail Removal Checklist and Permit will be completed by the supervisor and the required approvals obtained. A copy of the checklist and permit must be placed in the general area where the grating/floor plate/guardrail is removed, with the original filed in the project office. The requirements of this permit must be addressed during the pre-task safety meeting held with all involved employees before work commences. Health, Safety, and Environmental ExxonMobil/Fluor W3QR Site Specific Procedure 3323 Date 18Jan2011 Rev 0 Practice 000.653.3306 Date 01Sep2009 Page 4 of 7 ® GRATING, FLOOR PLATE, AND GUARDRAIL REMOVAL 2.3 Grating/Floor Plate/Guardrail Removal Permit Issuer Training and Authorization The appointment and training of Grating/Floor Plate/Guardrail Removal Authorized Permit Issuers is similar to Permit to Work and Confined Space Entry Permit Authorized Permit Issuers (refer to Procedure 1302). However, in addition, they will have sound and thorough knowledge in matters relating to the preparation and conduct of grating, floor plate, and guardrail removal. Practical experience in preparing grating/floor plate/guardrail removal permits under guidance may be appropriate. Appointment is made in writing on Form F0205, Authorized Permit Issuers, by the Project Manager. Note: 3.0 When performing grating/floor plate/guardrail removal in an operating facility, it is a common requirement to use the facility “grating/floor plate/guardrail removal permit process” instead of the process described above. GRATING AND FLOOR PLATE REMOVAL/REINSTALLING 3.1 Removal A hazard checklist and Job Safety Analysis (JSA), Form F0100, and a Safety Task Assignment (STA), Form F0101, will be completed. A piece of grating or floor plate will never be removed or left out without: installing a rigid barricade, guardrail, or equivalent, which will entirely encompass the opening, or properly covering the opening. If a floor hole cover(s) is used, it must: Be constructed to adequately support without failure, at least twice the weight of any person(s) and/or equipment to which the cover may be subjected Be cleated or secured by means of wire tie downs, clips, or other equivalent fastening method Visibly identify the hazard on the cover, DANGER – HOLE COVER – DO NOT REMOVE (refer to Procedure 3301, Barricades, Signs, and Tags). Health, Safety, and Environmental ExxonMobil/Fluor W3QR Site Specific Procedure 3323 Date 18Jan2011 Rev 0 Practice 000.653.3306 Date 01Sep2009 Page 5 of 7 ® GRATING, FLOOR PLATE, AND GUARDRAIL REMOVAL If rigid barricading or guardrail is used, it will: Be constructed of wood (2 inches by 4 inches/5.1 centimeters by 10.2 centimeters), angle iron or rigid material of comparable strength, or a combined system of components capable of achieving the same level of protection such as wire rope and stanchions Have a complete toprail (no voids) Have a toprail height of not less than 39 inches (99.1 centimeters) and not more than 42 inches (106.9 centimeters) above the grate floor Have a complete midrail installed at a point midway between the top edge of the toprail and the grate floor, with exception of the designated access point to the removed grate(s) opening Employees working inside the barricaded area will wear appropriate fall protection. The area below the intended opening (whether grating, floor plate, or guardrail removal) that may be affected by the overhead hazard(s) will be barricaded and sign-posted to prevent access. 3.2 Reinstalling The remaining grates/floor plates bordering the removed grate(s)/floor plate(s) opening must be protected from movement or slippage. The existing grating/floor plate can be secured by wiring down, installing clips, or other means capable of being secured. Grating/floor plates must be set in an area so as not to create a tripping hazard or interfere with other contractors or work activities. Stacks will be organized and uniform in accordance with floor-loading limits, and not present a safety hazard. When reinstalling gratings and floor plates, ensure that the grating/floor plate is correctly positioned and fastened. After work has been completed and before the barricade is removed, all grating, floor plates, and guardrails must be checked to verify that all clamps and clips have been secured. Health, Safety, and Environmental