Supplemental material

advertisement

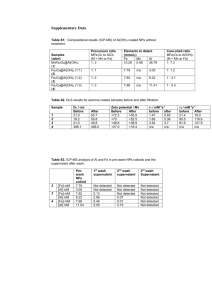

Supplemental material H. T. Yang*, D. Hasegawa, M. Takahashi, and T. Ogawa New Industry Creation Hatchery Center, Tohoku University, Aoba-yama10, Sendai 980-8579, Japan S1 experimental details (1) Synthesis of the monodisperse Fe3O4/SiO2 NPs The modified method can synthesize monodisperse Fe3O4 NPs with an average size ranging from 5.0 to 15.0 nm in one pot without a laborious seeding-growth process. Correspondingly, inverse micelles were used to confine and control the coating of SiO2 on the Fe3O4 NPs, each particle can be limited in a “reaction pool” to form a uniform shell. In a typical experiment for 7.5 nm monodisperse Fe3O4 NPs with a 10.0 nm thick uniform SiO2 shell, polyoxyethylene(5)nonylphenyl ether (6 mmol, Igepal CO-520,) was dispersed in cyclohexane (45 mL). Then, 1 mL of the Fe3O4 NPs solution (1.5 mg/mL of cyclohexane) was added. Ammonium hydroxide (30 %, 300 μL) was added into the resulting mixture to form a transparent, dark solution. Next, 200 μL TEOS was added, and the reaction was continued for 8 h at room temperature. The Fe3O4/SiO2 NPs were collected by a magnet after acetone was added, and redispersed in ethanol after washing several times. (2) Instrumental methods Transmission electron microscopy (TEM, Hitachi HF 2000 operating at 200 kV) was employed to determine the size and size distribution of the NPs. Samples were * Corresponding author: e-mail: htyang@ecei.tohoku.ac.jp, Phone: +81 22 795 7134, Fax: +81 22 263 9402 obtained by drying dispersions of particles on amorphous-carbon-coated copper grids. The particle size histogram determined over a total of 400 particles was fitted using a log-normal distribution of the particle size. The sample deposited on the nonreflective Si substrate (5×5 mm) for X-ray diffraction (XRD) measurement was carried out on a Rigaku 2200 instrument operated at a voltage of 40 kV and a current of 30 mA with Cu Kα radiation. The NPs dispersions were dried and cold-pressed into pellets under a pressure of 4 MPa in a glove box. All samples for magnetic measurements were prepared by cutting 10.0 mg parts from the pellets and were measured using a Quantum Design MPMS-XL5 superconducting interference device. For all the measurements, the diamagnetic background was subtracted. This system can detect magnetic moments in the range of 10-5 to 1 emu with good signal-to-noise ratios. Population (%) 15 10 5 0 5 6 7 8 9 10 11 12 Size (nm) S2. Fe3O4 NPs size histogram (bars) obtained from the TEM images and fitted by a log-normal curve (solid line). The average size is 7.5 nm. Indensity (a.u.) 20 (a) (b) (c) 30 40 50 60 70 80 90 2 (deg) S3. XRD patterns of as-prepared Fe3O4 NPs (a) and Fe3O4/SiO2 NPs with a shell thickness of 3.0 (b) and 12.0 nm (c). With increasing the shell thickness, a broad peak corresponding to the SiO2 amorphous phase is observed at the low diffraction angle. X-ray diffraction patterns of the samples with different SiO2 shell thicknesses yielded reflections corresponding to the cubic inverse spinel structure and an amorphous SiO2 phase. (a) (c) (c) D S4. (a) The photograph of the densely packed pellet (10 mm ×1 mm) of Fe3O4/SiO2 with a 12.0 nm thick shell and (b) an illustration of such a packing. D is the distance from centre to centre of Fe3O4/SiO2 NPs; (c) the correspongding SEM images reveals that most of Fe3O4/SiO2 NPs is close-packed though there are some defects such as cracks and holes in the whole pellet. 80 15.0 nm Fe3O4 NPs 7.5 nm Fe3O4 NPs M (emu/g) Fe3O4 (7.5nm)/SiO2 40 (12.0 nm) NPs 0 -40 -80 -40 -20 0 20 40 H (kOe) S5. Representative hysteresis measurements of 15.0 nm Fe3O4 NPs, 7.5 nm Fe3O4 NPs, and 7.5 nm Fe3O4 NPs coated with a 12.0 nm thick SiO2 shell collected up to 50 kOe at 300 K. The saturation magnetization (Ms) for 15.0 nm Fe3O4 NPs is 80.5 emu/g, close to the value of 84.5 emu/g measured from the commercial magnetite fine powder. Ms for 7.5 nm Fe3O4 NPs and the corresponding Fe3O4/SiO2 NPs with a 12.0 nm thick shell is 70.0 emu/g and 69.0 emu/g, respectively. It means that the decrement of Ms is less than 1.5% even though Fe3O4 NPs were immersed in the aqueous ammonia phase for a short time to form the SiO2 shell. S6 TABLE І Comparison of different parameters of Fe3O4 NPs with different interparticle spacing. P represents the particle powder, Si (i=3, 8, 12) represents the shell thickness of 3.0 nm, 8.0 nm and 12.0 nm. Sample Shell thickness dTEM (nm) D (nm) TB (K) Tirr -TB(K) P S3 S8 S12 0 3.0 8.0 12.0 7.5 10.5 15.5 19.5 0<D<9.0 13.5 23.5 31.5 110 95 80 70 0 20 40 50 For a superparamagnetic particle, the Néel expression of the relaxation time is τ= τ0exp(KV/kBT), where K, V, kB, and T are the magnetic anisotropy constant, the particle volume, Boltzmann’s constant, and the absolute temperature, respectively. The pre-exponential factor, τ0 (estimated to be 10-9–10-10), is a constant related to gyromagnetic precession. The blocking temperature, TB, for a system of particles with mean volume V, is defined as the temperature at which τ =tm, the measurement time. In our experiments, the typical tm at each temperature was approximately 100 s. Therefore, a linear expression V=25kBT/K can be obtained for fitting the experimental curves to Eq.(2) and (3).