Solvent Vapour Mediated Interdiffusion and

advertisement

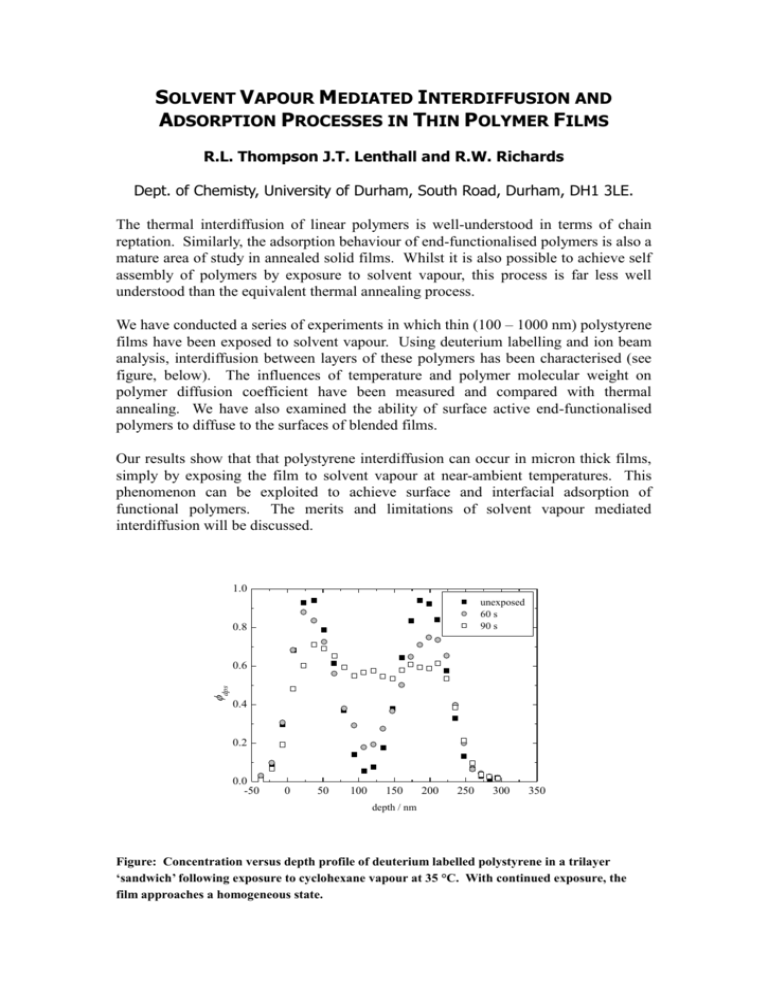

SOLVENT VAPOUR MEDIATED INTERDIFFUSION AND ADSORPTION PROCESSES IN THIN POLYMER FILMS R.L. Thompson J.T. Lenthall and R.W. Richards Dept. of Chemisty, University of Durham, South Road, Durham, DH1 3LE. The thermal interdiffusion of linear polymers is well-understood in terms of chain reptation. Similarly, the adsorption behaviour of end-functionalised polymers is also a mature area of study in annealed solid films. Whilst it is also possible to achieve self assembly of polymers by exposure to solvent vapour, this process is far less well understood than the equivalent thermal annealing process. We have conducted a series of experiments in which thin (100 – 1000 nm) polystyrene films have been exposed to solvent vapour. Using deuterium labelling and ion beam analysis, interdiffusion between layers of these polymers has been characterised (see figure, below). The influences of temperature and polymer molecular weight on polymer diffusion coefficient have been measured and compared with thermal annealing. We have also examined the ability of surface active end-functionalised polymers to diffuse to the surfaces of blended films. Our results show that that polystyrene interdiffusion can occur in micron thick films, simply by exposing the film to solvent vapour at near-ambient temperatures. This phenomenon can be exploited to achieve surface and interfacial adsorption of functional polymers. The merits and limitations of solvent vapour mediated interdiffusion will be discussed. 1.0 unexposed 60 s 90 s 0.8 dps 0.6 0.4 0.2 0.0 -50 0 50 100 150 200 250 300 350 depth / nm Figure: Concentration versus depth profile of deuterium labelled polystyrene in a trilayer ‘sandwich’ following exposure to cyclohexane vapour at 35 °C. With continued exposure, the film approaches a homogeneous state.