Lectures - Australian Maritime College

advertisement

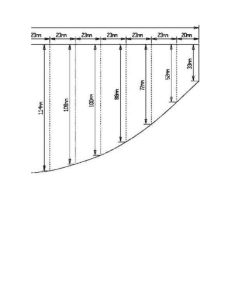

By Dr. Prasanta K Sahoo Senior Lecturer (Hydrodynamics) Table of Contents INTRODUCTION ............................................................................................................................................ 1 METHODICAL SERIES ................................................................................................................................. 1 STANDARD SERIES AND REGRESSION ANALYSIS .......................................................................................... 2 RESISTANCE PREDICTION BY EMPIRICAL AND STATISTICAL METHODS...................................................... 12 SOME FINAL REMARKS ........................................................................................................................... 20 THE RECOMMENDED 'MAGIC CUBE' FOR AMECRC .................................................................. 24 REGRESSION ANALYSIS .................................................................................................................................. 25 APPENDAGE RESISTANCE ..................................................................................................................... 29 REFERENCES .................................................................................................................................................... 30 PROPULSION ................................................................................................................................................ 32 PROPULSION FACTOR FOR HIGH-SPEED VESSELS ....................................................................................... 40 PROPELLER SCALE EFFECTS............................................................................................................................ 40 NOMENCLATURE ......................................................................................................................................... 44 REFERENCES .................................................................................................................................................... 44 ii Introduction METHODICAL SERIES a) Nordstrom b) Series 60 c) De Groot Series d) Norwood ad Silverleaf Data e) Series 63 f) Series 64 g) SSPA Series h) NPL Series i) Series 65, 65B j) MARIN Series k) AMECRC Series Resistance Prediction by testing in Towing Tank Graphical and Numerical methods of Resistance Prediction a) Clement (1964) b) Doust (1961) c) Van-Oortmerssen d) Holtrop and Holtrop & Mennen e) Jin Pin-zhong et at f) Savitsky & Brown g) Radojcic h) Compton i) Lahtiharju et al j) etc 1 Standard Series And Regression Analysis Taylor Series CP = 0.48 to 0.86 B/T = 2.25, 3 and 3.75 W/[Lwl/100]3 = 20 to 250 CM constant at 0.925 /(Lwl)3 = 0.3 to 8.75x10-3 Cs= S* (Lwl)0.5 for different values of B/T ATTC friction line to calculate Pe and CA = 0.0004 Figure 1: Taylor’s Series 2 Figure 2: Taylor’s Series 3 Nordstrom Series 1936 In 1936, Nordstrom [1]** published the results of tests carried out at the Royal Institute of Technology in Stockholm with 14 different round bilge models, 5 of which were tested at more than 1 draught. Three of these models, each tested at 3 different draughts, form a small systematic series. The results of resistance tests with these models, carried out in calm water, were originally analysed with Froude's frictional resistance coefficients. Even though no turbulence stimulating devices were adopted, subsequent analyses of the results have not revealed low enough resistance values to suspect significant influence of laminar flow. Figure 3 * indicate reference number at end of text 4 The results obtained by Nordstrom are now only rarely used, with the exception of the results for the small systematic series. As originally presented, the results are only useful for a full-scale displacement range of between 10 and 30 m 3. A more applicable presentation of these results is given in Fig. 1, in which the residual resistancedisplacement weight ratio RR/ is given as a function of the length-displacement ratio L / 1/ 3 and the volumetric Froude number Fn. The residual resistance values in Fig. 3 are based on a re-analysis carried out by De Groot [2] using the 1947 ATTC friction line with CA = 0. - Round bilge hull forms - tested at 3 diff. drafts - Useful for full scale displacement up to 30m3 - Refer fig 1. - for results where L and Fn RR / f 1/ 3 V g1 / 3 De - Groot Series In 1951, De Groot [2] published the results of tests with 31 round bilge, high-speed hull forms, 7 of which were tested at 2 or more draughts. These models were tested at the Netherlands Ship Model Basin (NSMB). draughts, constitute a small Four of these 31 models, each tested at 4 systematic series. Tests with these 4 models were also carried out in the towing tank of the Delft University of Technology. The results of resistance tests with all 31 models, carried out in calm water, were analysed using the 1947 ATTC friction coefficients. For the small systematic series, De Groot presented a diagram displaying the values of the residual resistance coefficient CR = RR / 1 2 p SV2 as a function of V / L and the displacement-length ratio /(0.1L)3 which diagram is often referred to by other workers in the field. More benefit of the work carried out by De Groot, however, lies in the fact that he derived a single graph (Fig. 8 of Ref. 2), showing the average resistance of 76 models (including the Nordstrom data) as a function of the displacement-length ratio for the speed range corresponding to 5 V/ L = 1.0 to 3.5. Unfortunately, the total resistance values given were for model lengths of 2.25 metres only. Even though De Groot showed how to use this graph in arriving at a prediction of the resistance of a new design, this procedure has not found general acceptance. At NSMB, however, these results are used up to this day as a standard to which the results of model resistance tests of fast, round-bilge hull forms are compared in order to arrive at a first qualification of the lines of a new design. To facilitate preparing a resistance prediction using this average data, the total model resistance values referred to have been converted to values of the residual resistancedisplacement weight ratio RR/ by using the average value for the wetted surface of the models given by S = 2.75 L , and the 1947 ATTC friction coefficients. These residual resistance values are given in Fig. 3. - 31 round bilge high speed hull forms - 7 of these tested at 2 or more draft tested at NSMB ( now known as MARIN) - analysed using ATTC - 47 friction coeff. - CR represented as V f , 3 L .1L - Obtained a single graph showing the average resistance of the models as a function of displacement length ratio for - The total resistance values for model lengths of 2.5m. - This procedure has not found acceptance. - To facilitate preparing a resistance prediction using this average data, total model resistance have been converted to values of the residual resistance to displacement ratio by using the average value for friction coefficients.- fig 2. The Marwood and Silverleaf Data In 1960, Marwood and Silverleaf [3] presented the results of resistance tests with approximately 30 unrelated round-bilge forms carried out at the Ship Division of the 6 British National Physical Laboratory. Mean resistance lines were given for these models, together with lines representing 5 and 10 per cent deviations from the mean lines. From these results, Marwood and Silverleaf confirmed earlier observations by Nordstrom and De Groot that other than the length-displacement ratio, and the Froude number, no clear evidence of any important systematic variation in resistance with other parameters can be discerned in the speed range considered, contrary to the case for the low speed range and the planing speed range. The Marwood and Silverleaf resistance data presents the resistance coefficient EHP 427.1 / V2 2/ 3 for a range of values of the speed-length ratio and the displacement-length ratio for a standard length of 100 feet. The values of the speedlength ratio V ratio L covered is from 1.4 to 3.5 and the values of the length-displacement L / 1/ 3 covered is from 5.2 to 8.2. These results have not been converted to RR/ - values here as was done for the De Groot data, since this would only form a duplication of the De Groot data, in that both present average results. Series 63 Results of resistance tests with models of five 50 feet round bilge utility boats were reported on by Beys [4] in 1963. These tests were carried out in the towing tank of the Davidson Laboratory of the Stevens Institute of Technology. These models form a methodical series in that the body plans of all 5 models are geometrically similar. The parent model has a nominal length-beam ratio of 4. All other models were derived from this parent model by multiplying the waterline and buttock spacings of the parent model by a constant so as to obtain nominal L/B values 2.5, 3.0, 4.0, 5.0 and 6.0. The models had a length of 3 feet. Unfortunately, this procedure of deriving a systematic series leads to changes not only in L/B, but also in B/T (and hence in C B, CP, LCB, etc.) when tests at equal length-displacement ratios are carried out such as is the case here. To obtain the same L/1/3 for the model with L/B = 2.5 as for the model with L/B = 6.0, for example, a relatively smaller draught has to be adopted for the model with the largest beam. Therefore, the differences in the resistance values between the different models at equal length-displacement and Froude number values cannot be attributed solely to differences in L/B only. Nevertheless, the results obtained with these 5 models are 7 useful to designers requiring more information on the influence on resistance of hull form parameters other than the length-displacement ratio. The residual resistance- displacement weight ratio RR/ for each of these models are, accordingly, given here in Figs. 3, 4, 5, 6 and 7 in the format used in Figs. 1 and 2. The presented residual resistance values were derived from the measured total resistance by means of the 1947 ATTC friction line with CA = 0. - Tested in Davidson Lab. - Models of 50ft round bilge utility boats. - Body plans of 5 models geometrically similar - Parent model L/B = 4. - All models obtained by waterline and buttock spacing by a constant L/B=2.5,3,4,5,6 - Model length 3ft. Changing L/B ratio - changes B/T ratio - Which changes (B, Cp, LCB etc) 1 To obtain same L/ 3 for L/B = 2.5 & L/B = 6 for the beamier vessel smaller draft required. 1 So different in resistance values at equal L/ 3 for different models cannot be attributed to changes in L/B only. - RR/ for each model shown in fig 3, 4, 5, 6 & 7. - obtained using ATTC 47 friction coefficient & CA = 0. Series 64 (1965) Results of tests with 27 models of slender, high-speed, round-bilge displacement forms at the David W. Taylor Naval Ship Research and Development Center were published by Yeh [5] in 1965. These 27 models comprise a systematic series of which the varied parameters are /(0.01L)3 (from 15 to 55), B/T (from 2 to 4) and CB (from 0.35 to 8 0.55). On assigning values to /(0.01L)3 or L/1/3, B/T and CB, the L/B value is no longer free to choose since: C B L / 1 / 3 L B B/T 3 The L/B values of these 27 models thus range from 8.454 to 18.264. The speed range covered corresponds to values of the Froude number F n from 0 to 1.5 (equivalent to a range in V/ L from 0 to 5.0). The results of the resistance tests in calm water were reduced to residuary resistance values by Yeh, by using the 1947 ATTC frictional resistance coefficients with CA = 0. Due to the rather extreme type of hull forms in this series, the resistance results for the individual models are not often used or referred to. Average resistance values for the complete series, however, are frequently adopted for use in parametric studies for slender ships and other purposes. For this reason the average residual resistance- displacement weight ratio RR/, as a function of L/1/3 and Fn, is shown in Fig. 8. In preparing this figure the data for /(0.01L)3 = 20 and CB = 0.45 was not considered because of the "inconsistency" of this data with the results for the other models of the series. - 27 models of slender high speed round bilge displacement forms at DTMB. / 0.01L 3 - B/T 2-4 - CB 0.35 - 0.55 varied from 15 to 55 On fixing the value of / 0.01L 3 or L/1/3 B/T, CB & L/B are no larger free C B L / 1 / 3 L as B B/T 3 = 8.454 to 18.264 Speed range Fn 0 to 1.5 9 Resistance tests were reduced to residuary resistance values making ATTC 1947 friction coefficient and CA = 0. Average resistance value for the complete series is frequently adopted. 1 The average RR/ ratio - f (L/ 3 & Fn) shown in figure 8. SSPA Series (1968) In 1968, Lindgren and Williams [6] presented the results of resistance tests with a methodical series of 9 models of high-speed, round bilge displacement vessels carried out at the Swedish State Shipbuilding Tank (SSPA). The hull form parameters varied were L/1/3 (values of 6, 7 and 8) and B/T (values of 3.0, 3.5 and 4.0). The value of the block coefficient CB was kept equal to 0.40 for all models, resulting in L/B values ranging from 4.62 to 8.20 by virtue of Eg.14. The speed range covered corresponds to a range in the Froude number Fn from 0.4 to 1.2 (equivalent to a range in V/ L from 1.34 to 4.0). The residuary resistance values of the models were obtained by using the 1957 ITTC frictional resistance coefficients. Up to a Fn value equal to about 0.90, the results for the 3 B/T values are almost identical, again leading to the observation that in the speed range between Fn = 0.4 and about 0.9 the length-displacement ratio is the only significant parameter. For this speed range the residuary resistance-displacement weight ratio RR/ of this series is shown in Fig. 9, as a function of L/1/3 and Fn. - 9 models of high speed round bilge displacement forms L/ 1 3 6, 7 & 8 B/T 3, 3.5, 4 CB - constant at 0.4 10 L/B - 4.62 - 8.2 by virtue of 1/ 3 3 CB L / L B B/ T Speed range Fn = 0.4 to 1.2. Using ITTC - 57 residuary resistance values were obtained. Results show for Fn = 0.4 to 0.9 length / displacement ratio is the only significant parameter. 1 Refer figure 9 to see RR/ as function of L/ 3 & Fn. NPL Series Very useful resistance data on high-speed, round bilge displacement forms have been published by Marwood and Bailey [7] in 1969 and by Bailey [8] in 1976, concerning the tests carried out at the Ship Division of the British National Physical Laboratory with a systematic series of 22 models of which L/B and B/T were varied. Five models were tested having a L/B value of 3.33 with B/T values ranging from 3.19 to 10.21, 6 with L/B equal to 4.54 with B/T values ranging from 1.72 to 6.87, 4 with L/B equal to 5.41 with B/T values ranging from 1.94 to 4.86, 4 with L/B equal to 6.25 with B/T values ranging from 1.93 to 5.80 and 3 models with L/B = 7.50 with B/T values ranging from 2.01 to 4.02. Other main hull form parameters were kept constant (C B = 0.397, CP = 0.693 and the longitudinal centre of buoyancy LCB was positioned 6.4% L aft of the midship section). The speed range covered corresponds to values of the Froude number ranging from 0.3 to 1.20 (equivalent to a range in V/ L from 1.0 to 4.0). The residuary resistance values were calculated from the measured model resistance by subtracting the frictional resistance as determined by means of the 1957 ITTC skin friction formulation. The residuary resistance-displacement weight ratio was then 11 plotted against L/1/3 for various Fn values for each L/B value. These figures are reproduced here as Figs. 10, 11, 12, 13 and 14. Resistance Prediction by Empirical and Statistical Methods Kafali's Graphical Method In 1959, Kafali [9] published a graphical procedure for estimating the effective horse power of small, round bilge high-speed vessels. The procedure adopts the following formula: V PE C V L in which PE = 2 effective horse power = displacement in tons V = ship speed in knots L = waterline length in feet. In above eqn. C is a constant, the value of which is to be determined from graphs. These graphs display C as a function of V/ L , L/1/3 (where L is in feet and is in tons) and B/T. One graph is provided for B/T = 3.65 and another for B/T = 4.45. In Ref. 9, it is stated that the value of C was determined from model tests. No details of these tests are provided, however. The values for the length-displacement ratio adopted in these graphs range from 19 to 26 (equivalent to values of L/1/3 of between 5.84 to 8.00). The speed range covered correspondence to a Froude number range of 0.35 to 0.85 (equivalent to V/ L values from 1.2 to 2.9). Equation and the associated graphs for C, are valid for the bare-hull case, ie. for hulls without appendages, as is the case for the methodical series data given in section 3. In this method, the influence of length on frictional resistance is ignored. Only one value for CP was used in determining the value of the constant C. On using an allowance of between +5 and +10% to account for the effects of roughness and appendages, Kafali 12 finds a good agreement between the results of the method and trial results for a 20.8 ft. and a 112 ft. motorboat. Clement's Graphical Method A graphical procedure for the prediction of the total resistance of small, round bilge, high-speed craft was published by Clement in 1964 [10]. The Nordstrom data [1] and the Marwood and Silverleaf data [3] were used by Clement to derive a set of eight graphs presenting the total resistance-weight ratio RT/, dependent on the displacement weight , the length-displacement ratio L/1/3 and the volumetric Froude number Fn. Each graph is valid for one value of Fn . Graphs are provided for Fn = 1.2, 1.4, 1.6, 1.8, 2.0, 2.2, 2.4 and 2.6. The values of the length-displacement ratio covered by the graphs range from 5.2 to 8.2, while the displacement weight values range from 5,000 to 100,000 pounds. As explained in section 2, a dependence on displacement or length is necessary when the total resistance is adopted as the dependent variable in lieu of the residual resistance because of the dependence of skin friction on the Reynolds number. In deriving the RT/ values given in the graphs, Clement made use of the Froude friction coefficients. He used values for the wetted surface following from the formula S = 0.157L2 (with L in feet), which formula is valid for the average value of the (unrelated) models of Ref. 3. Application of the model-ship correlation factor CA, as outlined in section 2, is not possible on using total resistance values derived from graphs such as presented to Clement. To arrive at realistic full-scale values of the resistance, use of an integral allowance of approximately =10% seems appropriate for small vessels [3]. Van Oortmerssen's Numerical Method Van Oortmerssen used a multiple regression technique to obtain a numerical expression for the residual resistance of small ships. This work, published in 1971 [11], was based on 970 resistance data points of 93 models of small vessels tested at NSMB. The basic expression adopted for the residual resistance was derived from a theoretical model of the wave resistance of a travelling, two-dimensional pressure disturbance, having peaks at the equivalent at the equivalent stem and stern positions and a pressure minimum in 13 between, such as occurs for vessels with no parallel middle body. The range of parameters for which the coefficients of the basic expressions are valid, are as follows: - waterline length between 8 and 80 metres; - displacement volume between 5 and 3000 cubic metres; - length-beam ratio between 3 and 6.2; - breadth-draught ratio between 1.9 and 4.0; - prismatic coefficient between 0.50 and 0.73; - midship section coefficient between 0.70 and 0.97; - longitudinal centre of buoyancy between -7% L and +2.8% L forward of 0.5 L; - half angle of entrance of design waterline between 10° and 46°. The speed range covered by the 970 data points lie in the Froude number range between 0 and 0.50 (equivalent to a V/ L range of 0 to 1.70). Some extrapolation to higher speeds is permissible, however, because of the theoretical nature of the basic expression. The numerical expression is as follows: RR mFn2 /9 mFn2 mFn2 mFn2 C1e C2 e C3e . sin Fn 2 C4 e . cos Fn 2 in which 1000 C1 = 79.32134 - 0.09287 LCB - 0.00209 LCB2 - 246.45896 CP + 187.13664 CP2 - 1.42893 L/B + 0.11898 (L/B)2 + 0.15727 CWL - 0.00064 CWL2 - 2.52862 B/T + 0.50619 (B/T)2 + 1.62851 CM 1000 C2 = 6714.88397 + 19.83 LCB + 2.66997 LCB2 - 19662.024 CP + 14099.904 CP2 + 137.33613 L/B - 13.36938 (L/B)2 - 4.49852 CWL + 0.021 CWL2 + 216.44923 B/T - 35.07602 (B/T)2 - 128.72535 CM 1000 C3 = - 908.44371 + 2.52704 LCB - 0.35794 LCB2 14 + 755.1866 CP - 48.93952 CP2 + 9.86873 L/B - 0.77652 (L/B)2 + 3.79020 CWL - 0.01879 CWL2 - 9.24399 B/T + 1.28571 (B/T)2 + 250.6491 CM 1000 C4 = 3012.14549 + 2.71437 LCB + 0.25521 LCB2 - 9198.8084 CP + 6886.60416 CP2 - 159.92694 L/B + 16.23621 (L/B)2 - 0.82014 CWL + 0.00225 CWL2 + 236.3797 B/T - 44.1782 (B/T)2 + 207.2558 CM and m = 0.14347 CP -2.1976 In the formulas for 1000C1, 1000C2, 1000C3 and 1000C4, the value of CWL is based on the value of iE in degrees. In the above expressions, CWL = iE. L/B, where iE is the half angle of entrance of the design waterline. The values of L/B and B/T can be based on the waterline values of L, B and T, although Van Oortmerssen used the displacement length L D rather than the waterline length, where LD was defined as half the sum of the length between perpendiculars and the waterline length. Numerical Method Derived by Mercier and Savitsky Mercier and Savitsky [12] carried out a regression analysis of the resistance results obtained by Nordstrom [1] for a small systematic series (9 models), by De Groot [2] for a small systematic series (12 models), by Beys [4] for the series 63 (21 models), by Yeh [5] for the series 64 (27 models), by Lindgren and Williams [6] for the SSPA series (9 models), and by Marwood and Bailey [7] for the NPL series (23 models). The results obtained by Clement and Blount [13] for the series 62 hard-chine hull forms (17 models) were also incorporated in the data base. Formulas were derived for the total resistancedisplacement weight ratio RT/ for eleven values of the volumetric Froude number, 1.0, 1.1 to 2.0, for a displacement of 100000 lbs. Four parameters were selected for 15 inclusion in the resistance equations as independent variables. displacement-length ratio These are the 1/ 3 / L , the beam loading coefficient C / B3, the square root of the angle of entrance of the load water line in degrees 2i E , and the ratio of transom area to maximum section area AT/AX. Although the formulas derived by Mercier and Savitsky were originally intended for predicting the resistance of planing craft in the preplaning, displacement mode, they can also be successfully used for predicting the resistance of displacement hulls, since 101 of the 118 sets of model data used, are those of round-bilge, displacement hulls! The general form of the resistance equation adopted by Mercier and Savitsky is as follows: RT / A1 A2 X A4 U A5W A6XZ A7 XU A8XW A9 ZU A10ZW A15W2 A18XW2 A19ZW2 A24UW2 A27WU2 where X = 1/ 3 / L, Z / B3 , U 2i E and W A T / A X The values of the coefficients A1 to A27 are given in Table 4 for the eleven values of the Froude number and a displacement weight of 100000 lbs (444.97375 kN). In using above equations it is essential to remain within the range of values of the independent variables used in the data base. Gross errors can occur otherwise. For other displacement values, other water temperatures, friction coefficients or C A values, Eg, 18 can be corrected according to the following expression: R T / corr R T / Eg.18 C f 1 C F Eg.18 C A 1 2 . In Eg. 19, (RT/) corr (RT/) Eg.18 S 2 .F n 2/3 = corrected value of RT/, = value of RT/ according to Eg. 18, 16 CF1 = friction coefficient for alternative displacement, water temperature or friction formulation, CF Eq.18 = friction coefficient according to the 1947 ATTC friction formulation, CA = appropriate value of the model-ship correlation factor, S = wetted surface. Table 4. Values of the coefficients in Eg. 18 as a function of Fn for = 100000 lbs in sea water at 15°C using the 1947 ATTC friction coefficients with CA = 0. Fn = 1.0 Fn = 1.1 Fn = 1.2 Fn = 1.3 Fn = 1.4 Fn = 1.5 A1 0.06473 0.10776 0.09483 0.03475 0.03013 0.03163 A2 -0.48680 -0.88787 -0.63720 0.0 0.0 0.0 A4 -0.01030 -0.01634 -0.01540 -0.00978 -0.00664 0.0 A5 -0.06490 -0.13444 -0.13580 -0.05097 -0.05540 -0.10543 A6 0.0 0.0 -0.16046 -0.21880 -0.19359 -0.20540 A7 0.10628 0.18186 0.16803 0.10434 0.09612 0.06007 A8 0.97310 1.83080 1.55972 0.43510 0.51820 0.58230 A9 -0.00272 -0.00389 -0.00309 -0.00198 -0.00215 -0.00372 A10 0.01089 0.01467 0.03481 0.04113 0.03901 0.04794 A15 0.0 0.0 0.0 0.0 0.0 0.08317 A18 -1.40962 -2.46696 -2.46696 -2.15556 -0.95276 -0.70895 A19 0.29136 0.47305 0.47305 1.02992 0.97757 1.19737 A24 0.02971 0.05877 0.05877 0.05198 0.02413 0.0 A27 -0.00150 -0.00356 -0.00356 -0.00105 -0.00140 0.0 Fn = 1.6 Fn = 1.7 Fn = 1.8 Fn = 1.9 Fn = 2.0 A1 0.03194 0.04343 0.05036 0.05612 0.05967 A2 0.0 0.0 0.0 0.0 0.0 A4 0.0 0.0 0.0 0.0 0.0 A5 -0.08599 -0.13289 -0.15597 -0.18661 -0.19758 A6 -0.19442 -0.18062 -0.17813 -0.18288 0.20152 A7 0.06191 0.05487 0.05099 0.04744 0.04645 A8 0.52049 0.78195 0.92859 1.18569 1.30026 A9 -0.00360 -0.00332 -0.00308 -0.00244 -0.00212 A10 0.04436 0.04187 0.04111 0.04124 0.04343 A15 0.07366 0.12147 0.14928 0.18090 0.19769 A18 -0.72057 -0.95929 -1.12178 -1.38644 -1.55127 17 A19 1.18119 1.01562 0.93144 0.78414 0.78282 A24 0.0 0.0 0.0 0.0 0.0 A27 0.0 0.0 0.0 0.0 An analysis of the still water value of the wetted surface of the models comprising the data base resulted in the following formula, with an accuracy of + 9% for 95% of the cases comprising the data base. S / 2 / 3 2.262 L/ 1/3 1 0.046 B/T 0.00287 (B/T) 2 Numerical Method Derived by Holtrop and Mennen Recently, Holtrop and Mennen [14] published the results of a statistical analysis of the results of resistance tests with 191 models of different types of ships at NSMB, including moderately fast displacement craft. The maximum value of the Froude number of the data base was 0.45, however, restricting the application of the derived formulas to the low speed range of the kind of craft addressed in this paper (as is the case with Van Oortmerssen's formulas). Again, however, Holtrop and Mennen based their formulation for the residual resistance on a theoretical expression for the wave resistance, which should allow some extrapolation to higher Froude number values. Contrary to other data discussed in this paper, the expression for the residual resistance derived by Holtrop and Mennen must be used in conjunction with a calculation of the frictional resistance adopting the form factor concept. For high-speed round bilge displacement vessels the Holtrop and Mennen formulas can be used as follows. The frictional resistance is calculated from: R F 1 2 SV 2 C F l k C A where S is the still water wetted surface, V the ship speed, CF the friction coefficient according to the 1957 ITTC formulation, CA the model-ship correlation factor, and k the 18 form factor accounting for the effect of the three-dimensional hull form on frictional resistance. The value of l + k can be determined from the following formula: l k 0.93 T / L 0.22284 .B / L R 0.92497 .0.95 C P .052145 .1 C P 0.0225 LCB 0.69060 in which LR is the length of the run, which can be determined from the following formula: L R / L l CP 0.06CP .LCB /4CP 1 The wetted surface for use in Eg. 21 can be calculated from the following formula: S L2T B CM 0.4530 0.4425CB 0.2862CM 0.003467 B / T 0.3696C WP The formula for the residual resistance is as follows: R R / C.e m l F n d m 2 cos Fn in which C = m1 = 2 2223105 (B/L)3.78613. (T/B)1.07961. (90-iE)-1.37565 0.0140407 L/T - 1.75254 1/3 /L - 4.79323 B/L -8.07981 CP + 13.8673 CP2 - 6.984388 CP3 d = m2 = -0.9 -1.69385 CP2 e-0.1 /Fn2 and = 1.446 CP - 0.03 L/B. The half angle of entrance of the load water line can be determined from: 19 i E 125.67 B / L 162.25C P 234.32C P 0.155087 LCB 2 3 3 Some Final Remarks The methods presented in this paper for the estimation of the calm-water resistance of high-speed, round bilge ships is restricted to the estimation of the bare-hull resistance only. No account is given of how to derive the additive resistance of various kinds of appendages such as bilge keels, rudders, propeller shafting, bossings, etc. Also, no systematic attempt has been made to determine the validity and accuracy of the reviewed methods for different types of hull forms as covered by parameters such as L / 1/ 3 , L/B, B/T, CB, etc. The main aspect dealt with in this paper is the state-of-the art of estimating the barehull resistance of high-speed, round-bilge ships, in the preliminary design stage, with an emphasis on the dependence of the resistance on various hull form parameters to facilitate design decisions. 20 21 22 23 The Recommended 'Magic Cube' for AMECRC It is recommended that the current AMECRC series of two models should be extended as shown below which will involve the design and testing of an additional seven hull forms and which would encompass a range of hull forms which could conceivably be required commercially. While there would appear to be the potential for a conflict of interest between the requirements of pure research and the requirements of the market, the ultimate proof of the validity of both MARIN and AMECRC research will be the full scale results. Full scale 24 results are more likely to be achieved in that zone of the magic cube which encompasses the currently perceived requirements of the market. The proposed magic cube in Fig.4 below is believed to be the best compromise of both requirements. The range of L/B. B/T and CB have been extended as far as possible without including full scale configurations with no practical application. Fig.4 - Recommended 'Magic Cube' of AMECRC Regression Analysis - A Technique with broad applications Statistical means to fit an equation through a given set of data Quality and Quantity of data - Data sample distribution in data base Range of actual database 25 - Good regression analysis if the data distribution is homogenous Random model data: error percentage increase in resistance prediction offers a better quantitative value for comparison purposes - Errors are generally due to a) Hull shape or dimensions outside the limits of the prediction method b) Scaling errors c) Model result measuring errors and poor database 26 HOLTROP Type of hull forms: A variety of hull forms ranging from tugs and trawlers to naval vessels Range of parameters: Cp 0.55-0.85, L/B 3.9-9.5 Speed range: Fn 0.05-0.50 SAVITSKY & BROWN Type of hull forms: Prismatic and transon stern Range of parameters: ie 5. 0 65, L / 1/3 3 13, AT / A X 0.5 1. 0 LCG position (%0.5L) 0.015-0.065 Speed range: Pre-planing Fnv < 2.0, Planing Fnv > 2.0 VAN OORTMERSSEN Type of hull forms: Tugs and trawlers Range of parameters: Average displacement of 600 tonnes, mean L/B 4.6, mean L 48m, mean Cb 0.6 and mean ie 22 degrees Speed range: Fn < 0.60 RADOJCIC Type of hull forms: Series 62 and Series 65 Range of parameters: A p / 2 / 3 4. 25 9.5, L / B 2. 36 6. 73 deadrise angle at 50%L 13-37.4 degrees, 27 position of LCG from transom 30-44.8% of L Speed range: Fnv 1.0-3.5 COMPTON Type of hull forms: Transom stern hulls of round and hard chine bilge Range of parameters: Displacement-Length ratio of 105-150, position of LCG to length ratio -0.13 to -0.02, L/B 4-5.2 Speed range: Fn 0.1-0.6 JIN PING-ZHONG ET AL Type of hull forms: Round bilge Displacement hulls Range of parameters: i e 7.6 26.6, /0.1L 1.5 5.7, A T / A X 0.05 0.40 1/ 3 Cp 0.6-0.66, LCB Position as % of L 0-6.4 Speed range: Fn 0.4-1.0 LAHTIHARJU ET AL Type of hull forms: Round bilge and Hard Chine Vessels AT / A X 0.16 0.82, L / 1/3 4. 47 8. 3, B3 / 0. 68 7. 76 Range of parameters: L / B3. 33 8. 21, B / T1. 72 10. 21, Cx 0.567 0.888 for round bilge hulls and AT / A x 0. 43 0. 995, L / 1/3 4. 49 6.81 for hard chine vessels Speed range: Fnv 1.8-3.2 28 Appendage Resistance The appendage resistance was calculated separately for each appendage rather than adding the wetted surface area to the bare hull and performing the analysis at once. The expressions for resistance are given below: Exposed Shafting, Stern Tubes and Bossings [2] 1 V 2 L d 1.1sin 3 C F 2 RA Where CF is calculated with Rnd Vd , where L is the length of shaft, d is the diameter and is the inclination of shaft relative to keel. Struts and Rudders [2] 4 1 t t V 2 2 S C F 1 2 60 2 c c RA Where CF is calculated with Rnc Vc , t/c is the thickness to chord ratio. Bilge Keels [4] RA 1 2z V 2 S B C F 2 2 x y Where CF is calculated with SB as the bilge keel wetted surface area and RnL Vl Transom Wedges [1] 1 R A 0.0052 0.046c S V 2 2 Where is the wedge angle and is the trim angle of vessel. Air Resistance [4] RAIR CD 1 AT V2 2 AIR 29 References 1. Nordstrom, H.F., "Some Tests with Models of Small Vessels", Teknisk Tidskrift, Skeppsbyggnadskonst, 1936. Published in English as publication No.19 of the Swedish State Shipbuilding Experiment Tank, Göteborg, 1951. 2. Groot, D. de., "Weerstand en voortstuwing van motorboten", Schip en Werf, 1951. Published in English in International Shipbuilding Progress, Vol.2, No.6, 1955. 3. Marwood, W.J., and Silverleaf, A., "Design Data for High Speed Displacement Type Hulls and a Comparison with Hydrofoil Craft", Third Symposium on Naval Hydrodynamics, ONR ACR-65, 1960. 4. Beys, P.M., "Series 63 Round Bottom Boats", Davidson Laboratory, Stevens Institute of Technology, Report No. 949, 1963. 5. Yeh, H.Y.H., "Series 64 Resistance Experiments on High-Speed Displacement Forms", Marine Technology, July 1965. 6. Lindgren, H. and Williams, A., "Systematic Tests with Small, Fast Displacement Vessels, Including a Study of the Influence of Spray Strips", Proceedings of Diamond Jubilee International Meeting, Society of Naval Architects and Marine Engineers, 1968. 7. Marwood, W.J., and Bailey, D., "Design Data for High-Speed Displacement Hulls of Round-Bilge Form", British National Physical Laboratory, Ship Division, Report No.99, 1969. 8. Bailey, D., "The NPL High-Speed Round-Bilge Displacement Hull Series", Royal Institution of Naval Architects, Maritime Technology Monograph No.4, 1976. 9. Kafali, K., "The Powering of Round Bottom Motorboats", International Shipbuilding Progress, Vol.6, No.54, 1959. 30 10. Clement, E.P., "Graphs for Predicting the Resistance of Round Bottom Boats", International Shipbuilding Progress, Vol.11, No.114, 1964. 11. Oortmerssen, G. van, "A Power Prediction Method and Its Application to Small Ships", International Shipbuilding Progress, Vol.18, No.207, 1971. 12. Mercier, J.A., and Savitsky, D., "Resistance of Transom-Stern Craft in the PrePlanning Regime", Davidson Laboratory, Stevens Institute of Technology, Report No.1667, 1973. 13. Clement, E.P., and Blount, D., "Resistance Tests of a Systematic Series of Planing Hull Forms", Transactions, Society of Naval Architects and Marine Engineers, Vol.71, 1963. 14. Holtrop, J. and Mennen, G.G.J., "A Statistical Power Prediction Method", International Shipbuilding Progress, Vol.25, No.290, 1978. 31 Propulsion In carrying out the investigation, the following constants for operating conditions were carried throughout: Operating Medium: Sea Water (Salinity level 3.5%) Water Temperature: 180C Water Density: 1.0252 t/m3 (ITTC, 1963) Kinematic Viscosity: 1.10438 x 10-6 m2/s Sea State 4 or 5 For the vessel and propeller the following parameters were used: Wake Deduction Fraction (w): 0.03 Condition: 1.0 < FN < 2.0 Thrust Deduction Fraction (t): 0.015 Condition: 1.0 < F N < 2.0 Number of Propeller blades (Z): 4 Rotation Rate (n): 8.1 rps (s-1) With a set rotation rate and blade number, it is possible to determine the best propeller by varying P/D, BAR and D. Software was then developed within Microsoft Excel using the VBA programming language to handle multiple calculations and vary all the three propeller parameters as mentioned previously. The program takes advantage of the polynomial expression published in [5] for the Wageningen B-screw Series for Rn=2 x 106 ; 47 KQ C (J) s t (P/D) (A E /A O ) u (Z)v n 1 39 KT C (J) (P/D) (A /A s t E O) u (Z)v n 1 The various coefficients for C, s, t, u and v are shown in Table 6 and 7 below for thrust coefficient KT and KQ respectively. 32 Table 6: Coefficients for the KT polynomial representing the Wageningen BScrew Series Propellers for a Reynolds number of 2 x 106. Thrust Coefficient (KT) n C s t u v 1 0.00880496 0 0 0 0 2 -0.204554 1 0 0 0 3 0.166351 0 1 0 0 4 0.158114 0 2 0 0 5 -0.147581 2 0 1 0 6 -0.481497 1 1 1 0 7 0.415437 0 2 1 0 8 0.0144043 0 0 0 1 9 -0.0530054 2 0 0 1 10 0.0143481 0 1 0 1 11 0.0606826 1 1 0 1 12 -0.0125894 0 0 1 1 13 0.0109689 1 0 1 1 14 -0.133698 0 3 0 0 15 0.00638407 0 6 0 0 16 -0.00132718 2 6 0 0 17 0.168496 3 0 1 0 18 -0.0507214 0 0 2 0 19 0.0854559 2 0 2 0 20 -0.0504475 3 0 2 0 21 0.010465 1 6 2 0 22 -0.00648272 2 6 2 0 23 -0.00841728 0 3 0 1 24 0.0168424 1 3 0 1 25 -0.00102296 3 3 0 1 26 -0.0317791 0 3 1 1 27 0.018604 1 0 2 1 28 -0.00410798 0 2 2 1 29 -0.000606848 0 0 0 2 30 -0.0049819 1 0 0 2 31 0.0025983 2 0 0 2 32 -0.000560528 3 0 0 2 33 -0.00163652 1 2 0 2 34 -0.000328787 1 6 0 2 35 0.000116502 2 6 0 2 36 0.000690904 0 0 1 2 37 0.00421749 0 3 1 2 38 5.65229E-05 3 6 1 2 39 -0.00146564 0 3 2 2 33 Table 7: Coefficients for the KQ polynomial representing the Wageningen BScrew Series Propellers for a Reynolds number of 2 x 106. Torque Coefficient (KQ) n C s t u v 1 0.00379368 0 0 0 0 2 0.00886523 2 0 0 0 3 -0.032241 1 1 0 0 4 0.00344778 0 2 0 0 5 -0.0408811 0 1 1 0 6 -0.108009 1 1 1 0 7 -0.0885381 2 1 1 0 8 0.188561 0 2 1 0 9 -0.00370871 1 0 0 1 10 0.00513696 0 1 0 1 11 0.0209449 1 1 0 1 12 0.00474319 2 1 0 1 13 -0.00723408 2 0 1 1 14 0.00438388 1 1 1 1 15 -0.0269403 0 2 1 1 16 0.0558082 3 0 1 0 17 0.0161886 0 3 1 0 18 0.00318086 1 3 1 0 19 0.015896 0 0 2 0 20 0.0471729 1 0 2 0 21 0.0196283 3 0 2 0 22 -0.0502782 0 1 2 0 23 -0.030055 3 1 2 0 24 0.0417122 2 2 2 0 25 -0.0397722 0 3 2 0 26 -0.00350024 0 6 2 0 27 -0.0106854 3 0 0 1 28 0.00110903 3 3 0 1 29 -0.000313912 0 6 0 1 30 0.0035985 3 0 1 1 31 -0.00142121 0 6 1 1 32 -0.00383637 1 0 2 1 33 0.0126803 0 2 2 1 34 -0.00318278 2 3 2 1 35 0.00334268 0 6 2 1 36 -0.00183491 1 1 0 2 37 0.000112451 3 2 0 2 38 -2.97228E-05 3 6 0 2 39 0.000269551 1 0 1 2 40 0.00083265 2 0 1 2 41 0.00155334 0 2 1 2 42 0.000302683 0 6 1 2 34 43 -0.0001843 0 0 2 2 44 -0.000425399 0 3 2 2 45 8.69243E-05 3 3 2 2 46 -0.0004659 0 6 2 2 47 5.54194E-05 1 6 2 2 To make these results applicable for Reynolds Numbers greater than 2 x 10 6 a correction is applied, again as published in [5] and shown in table 8 and 9. 9 K T C (J) s (P/D)t (A E /A O ) u (Z)v ( LogRn 0.301) x n 1 13 K Q C (J) (P/D) s t (A E /A O ) u v (Z) ( LogRn 0.301) x n 1 Table 8: Coefficients for the ∆KT polynomial for Reynolds number >2 x 10 6. ∆KT n C s t u v x 1 0.000353485 0 0 0 0 0 2 -0.00333758 2 0 1 0 0 3 -0.00478125 1 1 1 0 0 4 0.000257792 2 0 1 0 2 5 0.000064192 2 6 0 0 1 6 -1.10636E-05 2 6 0 0 2 7 -2.76305E-05 2 0 1 1 2 8 0.0000954 1 1 1 1 1 9 3.2049E-06 1 3 1 2 1 Finally, the KT and KQ values for the propeller are the sum of the two components. It is specified the following conditions need to be adhered to before the above methods can be employed: No. of blades 2≤Z≤7 Blade Area Ratio (BAR) 0.3 ≤ AE/AO ≤ 1.05 Pitch ratio (normally taken at 0.7R) 0.5 ≤ P/D ≤ 1.40 35 Table 9: Coefficients for the ∆KQ polynomial for Reynolds number >2 x 106. ∆KQ n C s t u v x 1 0.000591412 0 0 0 0 0 2 0.00696898 0 1 0 0 0 3 -6.66654E-05 0 6 0 0 0 4 0.0160818 0 0 2 0 0 5 -0.000938091 0 1 0 0 1 6 -0.00059593 0 2 0 0 1 7 7.82099E-05 0 2 0 0 2 8 5.2199E-06 2 0 1 0 1 9 -8.8528E-07 1 1 1 0 2 10 2.30171E-05 0 6 0 0 1 11 -1.84341E-06 0 6 0 0 2 12 -0.00400252 0 0 2 0 1 13 0.000220915 0 0 2 0 2 And Total Thrust Coefficient = KT + ∆KT and Total Torque Coefficient = KQ + ∆KQ Given that the number of blades has been fixed at 4, the BAR and P/D ratios can be varied between these values. The diameter of the propeller is limited to between 1.5 metres and 1.95 metres; the specified propeller being 1.801 metres [6]. By systematically varying the parameters within the polynomials, a series of data is produced at varying propeller configurations, allowing developed thrust curves to be calculated. TREQ = RT 1 t TDEV ρn 2D 4 K T where T is the thrust produced (kN) RT is the total resistance (bare hull + air+ appendages + added resistance in waves in sea state 4 where H1/3 = 2.5 m + additional frictional resistance due to fouling taken at 18%) ρ is the water density (t/m3) n is the rotation rate of the propeller (RPM in s-1) D is the propeller diameter (m) KT is the thrust coefficient of the propeller 36 O KT J 2 KQ where J is the advance coefficient for the propeller J VA and KQ nD is the torque coefficient of the propeller. The advance velocity is V A=V(1-w) – with w being the wake deduction fraction of the vessel. To widen the extent of analysis the data was filtered and reduced to only those developed thrust curves, which intersected the required thrust curves. The required thrust curves are directly calculated from the resistance of the vessel and its speed. The data was further filtered to those curves, which intersect within 1 knot of the specified service speed. Having found the propeller characteristics we must firstly verify the results produced by the software, determine weather or not the thrust produced fits within the operational envelope of the specified engine and then apply cavitation theory to ensure there will be no ill effects due to this phenomenon. To verify the results the propeller characteristics found were used in the KT-KQ-J charts for the Wageningen B-screw series to find the thrust developed and open water efficiency. We can then proceed to find whether or not the developed thrust fits within the engine envelope at the required rotation rate. In doing so the following calculations, taken from Lewis (1988), were used, assuming a mechanical drive train for the following calculations: Required brake power of the engine (kW) Brake power of engine accounting for gear box efficiency (kW) Shaft power (kW) Power delivered to propeller (kW) Efficiency of propeller in behind hull condition PBReq u ired PB ηM PB PS ηGB PS PD ηS PD T VA ηB η B η R ηO 37 ηM is the mechanical efficiency (taken as 0.97 [2]) PB is the brake power GB is the gear box efficiency taken as 0.98 ηB is the efficiency behind the hull = ηO ηR ηO Open water efficiency of the propeller, obtained by selection of propeller PS is the shaft power ηS is the shaft efficiency (taken as 0.98 [2]) PD is the delivered power to propeller ηR is the relative rotation efficiency (taken as 0.99 [4], Condition: 1.0 < F N < 2.0 and the vessel’s FN is approximately 1.55) Finally to check for cavitation the following expressions are used in association with the Burrill’s Chart (1943), σ P0 PV 2 1 2 ρVR where σ is the cavitation number P0 – PV is the pressure at the shaft centre line kN/m2 P0 = PATM + ρgh, where g is acceleration due to gravity (m 2/s) and h is the propeller immersion to shaft centreline. PATM is taken as 98.1 kN/m2 PV is the vapour pressure of the fluid (1.7 kN/m 2) VR2 0.7πnD2 V A2 AP 1.067 0.229P D from Taylor’s formula [5] AD where AP is the projected area of the propeller (m2) AD is the developed area of the propeller (m2) τ T 2 1 2 ρVR A P where is the thrust-loading coefficient. 38 Using the values for and σ so calculated we can then observe any cavitation prediction from the chart as derived by Burrill (1943). The detailed results are shown in Appendix F. The Burril’s chart is shown below. Figure 4: Burrill’s chart to determine cavitation. 39 Propulsion Factor for High-Speed Vessels Figure 5: Wake & Thrust fractions for typical vessel types [5]. Propeller Scale Effects Open water characteristics are frequently determined from model experiments on propellers run at high speed and having diameters of the order of 200-300mm. The question is how the reduction in propeller speed and increase in diameter at full scale will affect the propeller performance characteristics. The scale effect affecting performances are essentially viscous in nature and as such are primarily due to boundary layer phenomenon dependent on Reynolds number. Due to methods of testing model propellers and the consequent changes in R n between model and full scale, there can arise a different boundary layer structure to the flow over the blades. While it is generally recognised that most full scale propellers have a primarily 40 turbulent flow over the blade surface, this need not be the case for the model where laminar flow can prevail over significant parts of the blade. At present the principal analytical tool available is the 1978 ITTC performance prediction method, which is based on a simplification of Lerb's equivalent profile procedure. Lerbs showed that a propeller can be represented by the characteristics of an equivalent section at a non-dimensional radius .7R or 75R. Calculation of performance characteristics is as follows: Revised thrust & torque characteristics are KTs = KTm - KT KQs = KQm - KQ Where scale corrections KT & KQ are given by KT = cZ -.3 CD (P/D) D KQ = cZ + 0.25 CD D Where m & s = suffixes for model and ship CD = change in drag coefficient introduced by differing flow regimes at model and full scale and is given as = CDM - CDS 2t 0.044 5 Where CDM = 2 1 c 1/ 6 2 / 3 Rn Rn 41 2.5 and c 2t CDS = 2 1 1.89 1.62 log10 c K p Here t = section thickness to chord ratio = c 0.185 0.00125Z Z A 2.073 E AO P/D = pitch ratio c = Chord length Rn = local Reynolds number all relating to the section located at 0.75R Kp = blade roughness 30 x 10-6 m In this method it is assumed that the full-scale propeller blade surface is hydro dynamically rough and scaling procedure considers only the effect of R n on the drag coefficient. In calculating the Rn based on chord length of the section and the undisturbed inflow velocity Rn = VRc and VR the resultant velocity at .7R is found by VR2 .7nD2 VA2 42 Example Propeller particulars D = 6.5m P 0.907 D 0.75R AE = 0.726 Ao Z=4 t/c = .0305 c/D = 0.42 chord dia ratio = scale factor = 22 ns = revs = 2.079 sec -1 Open water tests are J KTO KQO o 0 0.4959 0.06646 0 0.1 0.4514 0.06106 0.118 0.2 0.4051 0.05562 0.232 0.3 0.3574 0.341 0.4 0.3082 0.04443 0.442 0.5 0.2578 0.03858 0.532 0.6 0.2062 0.03249 0.606 0.7 0.1573 0.656 0.8 0.1004 0.01938 0.66 0.9 0.0464 0.01226 0.542 0.95 0 0.0501 0.0261 0.00584 0 43 Nomenclature Deadrise angle in degrees S Wetted Surface Area (m2) Displacement in tonnes T Draught at LCF (m) mass density of fluid (t/m3) t Thickness (m) and also thrust Running Trim (degrees) deduction fraction Shaft Angle to Keel (degrees) V Velocity (m/sec) Wedge Inclination (degrees) VCG Vertical Centre of Gravity (m) AIR Density of Air (kg/m3) w Wake fraction AT Transverse Projected Area (m2) B Beam (m) c Chord Length (m) CB Block coefficient CD Coefficient of Drag CF ITTC ’57 friction line d Shaft Diameter (m) D Propeller diameter (m) Fb Froude beam number V gB Fn Froude Number V gL V Fn Froude beam number ie Half angle of entrance of load g1 / 3 waterline in degrees L Length (m) LCG Longitudinal Centre of Gravity (from AP in m) LWL Length of waterline (m) P/D Pitch ratio RA Appendage Resistance (kN) RAIR Air Resistance Rn Reynold’s Number RT Total Resistance including sea state 4 44 References 1 Savitsky, D. and Brown, P. W. (1976), “Procedures for Hydrodynamic Evaluation of Planing Hulls in Smooth and Rough Water.” Marine Technology, Vol. 13. 2 AMECRC notes p.193 3 Lewis, E., (ed.), 1988, Principles of Naval Architecture, SNAME publication, Vol. 2. 4 Blount, D. L., and Bjarne, E., 1989, “Design and Selection of Propulsors for HighSpeed Craft”, Proceedings J.Lips-Propeller Sysmposium, 21-22 September, Noordwyk on Sea, NL, pp 5.1-5.24.7 5 Bernitas, M.M., Ray, D. and Kinley, P., 1981, “KT, KQ and Efficiency Curves for Wageningen B-Series Propellers”, The University of Michigan, College of Engineering, No. 237, pp 1-102. 6 Sahoo, P., (2003) Ship Resistance and Propulsion-Lecture Notes 2003, Australian Maritime College, Launceston, Australia. 44