Leviathan - ISR - International Submarine Races

advertisement

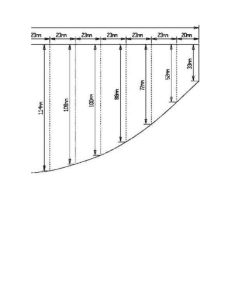

Seacoast International Submarine Team Langdon Tarbell, Ryan Forbes, Matt Crist, Tyler Dutile, Sean LaMontagne, Mike Cargill Hull The hull is made of many layers of fiberglass with a foam core. Construction of the hull The hull was constructed using plywood ribs spaced 6 inches apart to create the general shape of the sub. We chose the foam core construction method because would help create a strong righting point as well as a more robust frame. Safety and Life Support • Safety The safety buoy is a positively buoyant cutout of the hull. It has been attached to a spool of cord that will act as a dead-man switch. The positively buoyant hatch will open when the hatch release is pulled. • Life Support SCUBA Spare Air Propulsion • Power unit Consists of a bicycle drive system mounted upside down and a right angle gear. This unit is mounted to an aluminum plate that is fiberglassed to the hull . • CW-CW Right Angle Gear Transfers the motion from the bicycle to the shaft. • Shaft A universal Joint attached to a steel pipe supported by a Teflon bearing with dual propellers attached to the end of the shaft. Propulsion (Cont.) Dual Propeller • Impeller The impeller is used to increase the amount of water that is pushed over the blades of the propeller. • Propeller We took the idea of a basic 2 bladed boat propeller and modified it to suit our specifications. IE- power, input, RPM, pitch, Controls and Control Surfaces • Dive Plans The dive planes are controlled by the movement of a curved piece of steel bolted to the shaft that extends from the planed. • Rudders The rudders are controlled by a cable with one end attached to a rudder ring on one end and an actuator. • Stern Planes They are fixed to counteract the rotational torque from the propeller.