Gerald Lockhart Via Fax - SPE Environmental Division

advertisement

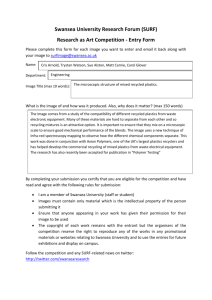

Plastics Technology Magazine 29 West 34th Street, 8th Floor New York, NY 10001 PH: (646) 827-4848 Fax: (513) 527-8801 www.plasticstechnology.com Close-Up On Technology - Recycling Recycled PET/PE Alloys Show Promise In Monofilament, Pallets, Pipe By Jan H. Schut jschut@plasticstechnology.com Alloys of polyethylene and recycled PET were the highlight of the annual SPE Global Plastics Environmental Conference (GPEC) in Detroit in February. In the last 18 months, three European processors have commercialized products made of these novel blends, which are said to be stiff, tough, easy to process, and inexpensive. These are believed to be the first commercial uses of PET/PE blends, though experiments with such combinations have been reported in the technical literature for decades. The existence of commercial products made from such alloys was made public for the first time at GPEC 2004 by Erema North America, which has worked with all three European processors. They all use Erema’s Vacurema continuous solid-stating drum to heat and dry the PET under high vacuum and restore its I.V. One of the three is a Spanish injection molder that uses industrial scrap from five- and seven-layer barrier packaging film (containing PET, EVA, and LDPE) plus PET bottle flake to extrude monofilament for brush bristles. The second is a Belgian molder of shipping containers, which makes pallets out of PET with some HDPE blended in. The third is a U.K. recycler and maker of HDPE drainage pipe, which just qualified dual-wall corrugated pipe for highway drainage made of a similar PET/HDPE alloy. The pipe is expected to be in production within 12 months. Alloying PET and PE doesn’t make economic sense if you start with virgin PET, but it pays off as a use for inexpensive waste streams like colored PET and barrier PET film scrap that normally find only low-value applications or are thrown away. Combining PET and PE can yield unusual properties. The alloys are less brittle than PET and no longer need to be dried before processing. They’re stiffer, better flowing, and faster cooling than HDPE, so they mold and extrude with faster cycles and higher outputs. They also can be downgauged relative to straight HDPE. Other machinery besides Erema’s solid-stater could be used to make the alloys—such as a crystallizing dryer followed by a vented twin-screw extruder modified with a long L/D. The key consideration is how much of virgin PET’s properties must be retained for the intended end product. The initial uses in pipe, bristles, and pallets all need high strength and wear resistance. Erema’s crystallizing dryer and continuous solid-stating unit are helping make the first commercial alloys of recycled PET and HDPE. Erema says it isn’t seeking patents on the alloying process because it believes that too much is known about it through prior technical publications. But that may not rule out potential application patents. The Belgian processor, for example, has applied for patents on use of its material for pallets. Pioneering applications Injection molder Spalex S.A., now merged with Sp. Berner Plastic Group SL in Aldaya (Valencia), Spain, takes five- and seven-layer barrier film scrap from blown film processors and alloys the material in an extruder with PET bottle flake, then extrudes the mix into monofilament for brush bristles. The bristles are said to perform comparably to nylon, but cost much less. The coex film scrap contains enough EVA tie layer to compatibilize the PET and LDPE. Spalex began producing monofilament and molding brushes three years ago using one Vacurema continuous solidstating and extrusion line. It has since added a second Erema line. ‘Beer-Bottle Alloy’ of PET & Nylon Two firms reported at GPEC that barrier beer bottles, another unused PET waste stream, can also be reclaimed by alloying. Clariant Corp. and Johnson Polymer LLC are experimenting with a PET chain extender to compatibilize the PET and nylon from beer bottles. The chain extender is sold in masterbatch form and is called CESA-extend. The active ingredient is an epoxy-functional styrene/acrylic Innova Packaging System N.V. (I.P.S.) in Ieper, Belgium, has alloyed green PET and PE for about six copolymer developed by Johnson Polymer and Clariant (see Learn More box). It is marketed by Clariant primarily months. It compression molds this blend into gray to raise scrap PET’s I.V., an effect that is enhanced by and black shipping pallets. I.P.S. combines about 75% green PET bottle flake with about 25% recycled Erema’s Vacurema device. HDPE plus a substantial amount of unnamed compatibilizer. The result is said to come close to However, the resulting properties of PET/nylon blends with achieving plastic pallet makers’ long-sought goal of CESA-extend suggest that some compatibilizing is taking cost-competitiveness with wood. I.P.S.’s PET/PE place. Clariant and Johnson Polymer tested CESA-extend pallets sell for 6 to 8 Euros ($7.50 to $8.50) apiece with reground beer-bottle preforms. Addition of 1% CESAvs. about 5 Euros ($6.50) for a wooden pallet. extend reportedly raised the Izod impact strength by 20%, tensile strength by 30%, and melt viscosity by a factor of 100. Adding 2% CESA-extend made no further I.P.S. bought its first improvement, Clariant said. PET/PE alloying and molding line from Remaplan Anlagenbau in Landau, Germany, just before Remaplan went out of business last year. The alloying and molding process developed by Remaplan started with a crystallizing dryer, followed by an Erema Vacurema unit and then an extruder. The PET is at about 392 F as it comes out of the solid-stater and goes into the extruder. Relatively little heat is added in the extruder to reach PET’s processing temperature of about 450 F. PE and the compatibilizer are added in the extruder, which continuously pumps the melt into an injector that feeds compression molds. I.P.S. in Belgium is the first processor to alloy PET and PE in compression molded shipping pallets that are nearly cost competitive with wood. Similar machinery is now being built by former Remaplan employees who joined MBM Maschinenbau in Germany. MBM has shipped similar pallet molding lines to Japan. Delleve Plastics Ltd. in Stratford-on-Avon, U.K., worked for three years to qualify dual-wall corrugated pipe made of an alloy of PET and HDPE plus a compatibilizer and an impact modifier. Delleve was bought this year by JFC Manufacturing Ltd.,which will produce the pipe at a new plant in Team, Ireland. Delleve operates its own HDPE recycling plants in the U.K. Up to now, it used the PE in corrugated dual-wall drainage pipe and sold the PET flake to others. The alloying technology will enable it to use all the recyclate internally. The PET/PE alloy exceeds the British Board of Agrément’s HAPAS (Highway Authority Product Approval Scheme) standard for HDPE highway drainage pipe. In fact, the PET/PE pipe “outperformed HDPE and PVC pipe by up to five times,” says Erema’s v.p. of sales, Michael Horrocks. Delleve says single-wall PET/PE pipe of 75-mm diam. showed average initial stiffness of 5.678 kN/m2. “This is as good as our 100-mm HDPE pipe and is certainly over the 2-kN/m2 pass limit for this type of pipe,” Delleve reports. This would allow the PET/PE pipe to be downgauged and still exceed the required properties. The alloy flows so well and cools so fast that the corrugators don’t need vacuum. Erema has had the alloy tested in the U.K. for injection molding. It reportedly molds without predrying, resulting in high properties and cycle times half as long as for HDPE. Ties that bind PET and PE need help to stick together. A variety of compatibilizers—some patented—satisfy this need. EVA is the typical tie layer binding PET to PE in coex films and is also used to alloy condensation polymers to PE. It’s less expensive than other commercial compatibilizers but more may be needed—as much as 5% to 10% by weight. Corrugated pipe is made of an alloy of PET and HDPE that is five times stronger than HDPE alone and extrudes much faster. Erema found that using a two-stage Vacurema system with vacuum on the initial crystallizing dryer allows use of less compatibilizer than with Vacurema alone. It took up to 5% of a functionalized ethylene copolymer to compatibilize PET and PE with just the Vacurema device. But use of the two-stage vacuum system dropped the additive requirement to 0.3% to 0.6%. Plastics Technology Magazine 29 West 34th Street, 8th Floor New York, NY 10001 PH: (646) 827-4848 Fax: (513) 527-8801 www.plasticstechnology.com Close-Up On Technology - Recycling Recycling Conference Shows Off New Ways To Enhance Recycled Plastics By Jan H. Schut jschut@plasticstechnology.com News from the recent SPE Global Plastics Environmental Conference in Detroit includes lots of technological “firsts.” Among them: electronic “noses” to sniff out chemical contaminants in reclaim; long-fiber molded parts made with auto shredder waste and recycled carpets; the U.S. debut of a waterless recycling system commercialized by Germany’s Green Dot program; and new additives to enhance recycled PET bottles. The ‘e-nose’ knows Electronic sniffers that can identify and quantify airborne molecules have been used since the 1980s but not in recycling—until now. While not as sensitive as a canine or even human nose, “e-nose” devices are consistent, objective, and immune to any harmful chemicals they may sniff. Their potential in plastics recycling was presented for the first time by Eric Koester, a consultant for MEGO Consulting, who presented a list of suppliers, web sites, and basic technologies. Some two dozen suppliers globally have e-nose technology, though some are university research departments and others do not offer the instruments commercially E-noses are effective at screening for one or two specific chemicals, not for every chemical contaminant. They can check whether reclaimed containers have been used to hold gasoline or other specific chemicals that would be undesirable contaminants in recycled plastics. Most e-nose devices are used in the security industry to detect explosives, drugs, or anthrax. Hospitals use them to diagnose pneumonia from breath samples. And the food and cosmetics industries use them to check freshness and fragrances. Resin producers use e-noses to check pellets for polymer blend ratios and possible contamination. Other plastics applications include testing the effects of barrier packages on flavors and fragrances. Alpha M.O.S. “e-nose” technology detects chemical contamination in recycled resin. plastics for packaging. At least three e-nose makers have experience with plastics applications. Units range from $5000 for hand-held devices measuring gases in parts per thousand up to $100,000 for industrial-size lab units capable of measuring parts per million. French-based Alpha M.O.S. makes large lab systems, modular systems for on-line analysis, and hand-held units. Pellet or flake samples are heated in a jar, and the sensor “sniffs” the air in the head space. Alpha M.O.S. has over a dozen plastics applications in the U.S., including uses in QC by resin producers and recyclers of Cyrano Sciences has made hand-held e-nose units commercially for two years. Cyrano has four plastics applications, including QC testing of virgin PET and HDPE for bottles. Illumina Inc. is developing a fiber-optic “bead array” to detect chemicals in plastics. Illumina is working with Dow Chemical Co. and Chevron Phillips, but doesn’t have a commercial product for plastics yet. Long fibers toughen ASR Two companies reported that long-glass fibers can boost properties of recycled polymer blends. Salyp NV, a Belgian engineering firm (see PT, May ’01, p. 54) with a proprietary recycling process for auto shredder residue (ASR), presented data on the first U.S. molding trials using its ASR-PP. Mayco Plastics Inc. of Sterling Heights, Mich., a Tier One supplier to DaimlerChrysler, used the reclaimed PP to mold a 3-lb automotive battery-support bracket. Mayco used its own patented long-fiber compounding and molding process to incorporate half-inch glass fibers at 40% by weight. Salyp’s U.S. sales rep, 21st Century Polymers & Associates, expects that PP recovered from ASR will cost 15¢ to 20¢/lb, depending on the scale of production. That’s a discount of 50% or more from the current price of virgin PP. 21st Century will market ASR resins produced by any user of Salyp equipment worldwide. Even without process optimization, Mayco’s initial molding trial made parts that reportedly had more than 75% of the structural properties of fiberreinforced virgin PP. ASR-PP is an amalgamation of many PP grades found in cars, appliances, and other durables. The resulting blend has an MFR of 10.4 g/10 min, density of 0.94 g/cc, tensile strength of 2350 psi, flexural modulus of 80,578 psi, and Gardner impact strength of 160 in.-lb. After adding long glass, Mayco’s test parts had a density of 1.15 g/cc, tensile strength of 20,300 psi, flex modulus of 1.087 million psi, and notched Izod impact strength of 3.4 ft-lb/in. Salyp’s PP recovery system starts with size classification of raw ASR via two large trommels, or screeners, one on top of the other. These units sift ASR at 19,800 lb/hr into four size fractions: under 6 mm, 6 to 16 mm, 16 to 38 mm, and over 38 mm. The two smallest fractions contain ferrous fines, glass, textiles, and organic matter. After extracting the metal, the rest can be compressed into fuel briquettes for steel or cement production. Auto-shredder PP recovered by Salyp in Belgium is test-molded with long glass into car-battery brackets.. The largest size fraction consists of plastic chunks and urethane foam. The two are separated by a compressing roller developed by Central Materials Handling in Peoria, Ill. It compresses the foam but not solid plastic. When the compressed foam is released after passing under the roller, it springs back, jumping high enough off the conveyor that it can be mechanically separated from the solid plastic at about 3300 lb/hr. Solid plastics, together with the 16-to-38 mm fraction, go together into an integrated three-step separation process. The first step separates plastics, metals, and wood from fibers and textiles. The second step shreds the plastics, metal, and wood to 16 to 25 mm at about 4400 lb/hr while removing ferrous metals and light materials. The third step optically identifies nonferrous metals and wood and removes them with air jets from the plastic at 6600 lb/hr. The plastic is then washed using bacteriological cleaners. Sludge is extracted from the water, which is recirculated. The next step is the core of Salyp’s process: thermal separation by resin type (PP, PE, ABS, PS, and PC). Chips are preheated on a vibrating table under infrared heaters and then spread one-layer thick on a conveyor. They pass under additional IR banks, which heat the chips to the Vicat softening point of the lowest-temperature resin in the mix. The chips then go under a roller with grooves that trap only the softened pellets, which are then scraped off by a brush. Remaining chips are heated to the Vicat temperature of the next highest-temperature resin, removed by a grooved roll, and so on. The thermal process can separate up to 3300 lb/hr. Salyp’s full-scale pilot line in Belgium can recycle 66 million lb/yr of ASR, yielding about 20% of that weight in reclaimed resin. Metal contaminants are also recovered. Salyp hopes to sell its equipment to auto shredders in the U.S., Europe, Japan, and China. Meanwhile, researchers at the Georgia Institute of Technology in Atlanta reported on test results with another mixed-polymer recyclate—obtained from post-consumer carpet. The mix is primarily nylon 6 from the face fiber, together with PP from backing fabrics, calcium carbonate-filled SBR latex from binders, and lots of contamination. Georgia Tech studied the use of styrenic block copolymers to compatibilize the different polymers in the blend and added long-glass fiber to boost strength and rigidity. The test material came originally from Wellman Inc., Shrewsbury, N.J. Wellman sorts post-consumer carpet by face fiber, shreds the carpet so that much of the latex, calcium carbonate, and dirt drops out, and then bales the remaining fibers. Georgia Tech palletized these fibers on a special vented single-screw extruder with a crammer feeder and in-line shredder. This model NGR A-Class Type 55 VSP was built by Next Generation Recyclingmaschinen GmbH in Austria (which has several U.S. distributors). Barrel temperatures are set from 392 F at the feed throat to 500 F at the downstream end in order to melt both the PP and nylon 6. After filtering with a 20-mesh screen, the pelletized compound contains 64% nylon 6, 11% PP, 2% nylon 66, and 23% calcium carbonate. The pellets were dried and molded into test plaques, which had tensile strength of 5970 psi, flexural strength of 9460 psi, flex modulus of 324,000 psi, and elongation at break of 3.3%. Pellets were ground into powder and compression molded together with 30% long-glass mat into 1-ft-square plaques. These samples had flexural strength of 16,000 psi, flex modulus of 560,000 psi, and elongation at yield of 5.9%. ‘Dry cleaning’ plastics Duales System Deutschland, the German government office that oversees the “Green Dot” system for recycling packaging waste, has set up a subsidiary to market its proprietary technology. Called Systec, the new commercial unit is introducing to the U.S. its Waterless Mechanical Purifier, first built for in-house use in 1997. Systec has sold 23 units since then, mostly in Germany and Asia, for cleaning post-consumer bags and agricultural film. One is in Calgary, Alberta, removing labels and liquid residue from PET bottle flake. Subsequent water washing is still needed to remove glue. Systec doesn’t disclose the inner mechanics of its waterless purifier, except to say that it uses a rapidly rotating centrifuge to combine impact and acceleration forces with a powerful pneumatic air stream. Throughput from one unit ranges from 2000 to 4500 lb/hr, depending on resin. Usable output is 10% to 20% less, depending on contamination level. The waterless purifier costs around $133,000. Systec also sells its NIR sorting technology to identify and separate containers by polymer. It has sold three units. Upgrading RPET The SPE conference also presented a novel additive to upgrade recycled PET bottles. Clariant Masterbatches launched a new family of reactive additives that impart long-chain branching, which raises the I.V. of RPET without the need for solid-stating in a reactor. The chain extender, called CESA-Extend (see PT, Apr. ’03, p. 15), restores molecular weight to the original level or higher without hurting mechanical or thermal properties or crystallinity. Conventional chain extenders require predried PET to be heated under high vacuum in a solid-state reactor for several hours. They can produce gels from uncontrolled chain branching. CESAExtend doesn’t require predried PET or vacuum and can be processed in a conventional twin-screw extruder. It is also said to produce fewer gels. Clariant says its new additives have a further advantage in that they improve compatibility of RPET with other polyesters, PC, and nylon in subsequent compounding. The active ingredient is a proprietary functional acrylic oligomer from Johnson Polymer LLC in Sturtevant, Wis., which has joint patents on the technology with Clariant. It reportedly works on any polycondensation resin, including PC, This novel waterless mechanical recycling nylon, acetal, TPU, PBT, and blends of the above, but is more system, developed and sold by the German efficient in PET, less so in nylon. It reacts with end groups such Green Dot organization, is used to clean postas amines, isocyanates, carboxylates, and hydroxyls. consumer bottle flake and agricultural film. The additive improves melt strength so much that PET can be extrusion blow molded and even extruded into blown film. Extruding virgin undried PET (0.75 I.V.) plus 3% of CESA-Extend with no vacuum on the extruder reportedly yields PET with 0.780 I.V. The same PET extruded without chain extender drops to 0.543 I.V. Recycled PET with 0.558 I.V. plus 2% CESA-Extend yields 0.673 I.V.; 3% yields 0.720 I.V. Plastics Technology Magazine 29 West 34th Street, 8th Floor New York, NY 10001 PH: (646) 827-4848 Fax: (513) 527-8801 www.plasticstechnology.com Keeping-Up with Extrusion Make PET Blown Film With New Chain Extender—April 2003 A new family of chain-extending additives being developed Clariant Masterbatches in Winchester, Va., raises PET's I.V. to levels comparable to those produced by conventional solid-stating. Clariant says just 1% of one product, CESA-Extend, can raise the I.V. of fiber-grade or recycled PET from 0.72 to 0.83. The improvement in melt strength is so dramatic that Clariant has been able to blow PET film with 1% to 3% CESA-Extend. The additive promotes long-chain attachment at both ends of a PET chain, forming a web of attached chains with greater melt strength. Chain attachment also improves surface antiblock characteristics in sheet, Clariant reports. The company has sampled selected customers under secrecy agreements since last fall and announced the new additives at the SPE Global Plastics Environmental Conference in Detroit in February. Clariant Additive Masterbatches 382 Arbor Court Winchester, VA 22602 Phone (540) 665-1865 Fax (549) 665-2917 Plastics News (Crain Communication) 1725 Merriman Road Akron, OH 44313-5283 Phone: 330-836-9180 www.plasticsnews.com editorial@plasticsnews.com Firms harvest new uses for soy-based resins By Rhoda Miel PLASTICS NEWS STAFF MOLINE, ILL. (Sept. 13, 12:05 p.m. EDT) -- More than 60 years after Henry Ford tested a soybean-based plastic for automotive panels, the material is beginning to make headway in some commercial applications. Agricultural equipment makers like Deere and Co. and Case New Holland Global NV are using soy-based polyester resin on large structural parts and finding it can compete with traditional plastics. A Deere 9860 STS Row Crop Combine harvests soybeans. Deere has been making slow but steady advances with soy-based sheet molding compound parts for its combines. (Deere and Co. photo) “The soybean-based material will probably come into its own soon, depending on its use,” said John Cerny, a staff engineer in Moline-based Deere’s John Deere’s plastics composite group. “The volumes are going up.” Deere has used 500,000 pounds of soy-based resin, starting with a 1997 experiment using it on a component door for a baler. Case uses a soy oil-based polyurethane for exterior trim on its AFX series combines, with 370 pounds of the resin used on each vehicle. The companies also are looking into the possibility of a soy polyurethane foam for seat padding. “We’re moving ahead and we have an opportunity on some of our tractor hoods, industrial equipment parts and there are other opportunities out there,” Cerny said. “We also see in the future, and closer to that, the possibility of using soy in some of the cushioning in seats. That seems to be an area of great potential.” Soy and other bio-based resins have been on the fringes for years, with supporters making previous claims about its potential. Automaker Henry Ford first demonstrated his soy-based resin panels in 1941. The difference now is that the material is proving out processability improvements combined with U.S. federal incentives for bio-based material and rising raw material costs, said Lawrence Drzal, a professor of chemical engineering and materials science at Michigan State University and director of its composite materials and structures center. The Department of Agriculture has set a target to have 10 percent of its purchases by 2010 come from soybean and other renewable resource materials, climbing to 50 percent by 2050. “That’s the carrot part of the equation in increasing the use of bio-based resins,” Drzal said. “The stick is the increasing oil prices.” Use of resins using soybean oil — and similar vegetable-based oils — will be gradual, Drzal predicted, with a few key players like John Deere pushing the material forward. “There aren’t any major hurdles that are going to require a breakthrough,” he said. “This is going to be an evolutionary process, a deliberate process where you have targets you want to meet.” Interest has increased in the polymer, said Dwight Rust, business development manager for resin supplier Ashland Chemical Co.’s composite polymers group. Other users also have contacted Ashland to test out its use in everything from transportation and furniture to architectural and construction. None have made the commercial commitments of the farm equipment makers yet, though. At John Deere, the soy resin program nearly ended because of cost issues just as it began. The first part, the baler door, was produced through resin transfer molding as a replacement for a troublesome metal part. The door looked good, Cerny said, but was too expensive to manufacture. The development group put it in an internal design show, though, and it had a strong enough response that Deere went back to the drawing board. The new design switched processing to sheet molding compound, rather than RTM. The change made the material cost competitive because the soy-based SMC could even outperform standard resins in the mold, with better flow, reduced repair issues and an improved surface for painting. “You’re not going to be able to go to the shelf and just take a soy oil and replace it with a petroleum oilbased product,” Drzal said. “It’s going to have to be carefully developed.” That is not to say soy resins have a clear shot everywhere, even within Deere. There have been problems with a soy urethane used in reaction injection molding, for example, he said, but it is proving an ability to stand on its own elsewhere in the right application. “Our first issue is cost,” he said. “If it’s environmentally friendly, that’s OK too.” The United Soybean Board provides a link between farmers and end users while promoting the crop. It has placed a strong emphasis on backing projects that have real commercial prospects, said Eric Niemann, a Nortonville, Kan., farmer and chairman of the group’s new uses committee. “We’ve talked to [end users], we’ve understood that the bottom line is cost, cost, cost,” he said. The group wants to take its data and enthusiasm beyond universities and into the real world. The farmers have visited Detroit to meet with automakers to discuss what they would need from a soy-based resin, and are enthusiastic about the Ford Motor Co.’s Model U concept vehicle that debuted in 2003, with a soy composite tailgate. Still they realize that it must prove itself. “We want to use this material,” Cerny said. “We want to continue to use this material, but if something else comes along that’s less expensive, our supply people are going to look at that too.” Plastics News (Crain Communication) 1725 Merriman Road Akron, OH 44313-5283 Phone: 330-836-9180 www.plasticsnews.com editorial@plasticsnews.com Industry weighing in on biobased plastics Steve Toloken DETROIT -March 01, 2004 Advocates of plastics made from soybeans or other plant materials like to tout their wares as having an environmentally friendly footprint, where raw materials are replenished as quickly as the next growing season in a cycle they dub ``birth to reincarnation.'' The big challenge for the industry, though, seems to be getting out of the delivery room. How to see biobased polymers mature beyond infancy was the talk among the engineers, consultants and academics at the Society of Plastics Engineers' Global Plastics Environmental Conference, held Feb. 1819 in Detroit. The event was abuzz with positive predictions for bioplastics, tempered with the reality of the marketplace. ``The real issues are bringing it out from the researcher's bench to the real world,'' said John Cerny, staff engineer for biobased polymers with John Deere Inc.'s technology center in Moline, Ill. Deere is using a thermoset resin that is 25 percent renewable, from soy and corn, in hood and body panels in its combines, and plans to expand that to other products, Cerny said. Case LLC is also using soy-based resin in a combine, part of a market development push by agricultural equipment manufacturers. Other companies, like Sony Corp. and Ford Motor Co., have dabbled in vegetable-based plastics. But basic questions need to be answered before large manufacturers like car companies will be comfortable using plant-based polymers, said Phil Sarnacke, an industry consultant with OmniTech International, Ltd., in Midland, Mich. OmniTech works for the United Soybean Board. Sarnacke and David Reed from General Motors Corp., delivered a paper to the conference that recommended that auto makers launch a cooperative precompetitive research program to evaluate biobased polymers, and create a database of cost, performance and environmental issues for engineers to reference. ``The auto [industry's] lack of use of biomass products is in part due to a lack of thorough, critical evaluation of the biomass products and their potential,'' they wrote. Those pushing biobased polymers see potential. Biobased materials are used in about 3 percent of the $280 billion U.S. market for polymers and chemicals now, but some estimates say that will grow to 20 percent by 2010, said Margaret Baumann, president of consulting firm G.H. Associates in Lebanon, N.J. Biopolymers could offer a homegrown economic advantage to the U.S. plastics industry, which has been hurt by steep price increases in natural gas, she said. The U.S. industry could regain some global competitiveness by tapping American agriculture for feedstock, and at the same time reduce the country's dependence on foreign energy sources and lessen greenhouse gas generation, Baumann said. Biopolymers that are achieving success now, she said, are adding value, like providing a soft touch for products like drapes. Another example: Deere's Cerny said its soy-based resin parts are better because they do not need to be repainted or repaired as often. The Deere parts made with biobased resins are cost competitive, but the company still wants prices for biobased resin to drop 10-15 percent, Cerny said. While biopolymers were the toast of the conference - they were the single largest paper topic this year proponents conceded that they're not always the slam-dunk environmental win that some assume. John Dorgan, a chemistry professor at the Colorado School of Mines, said that some studies, like an August 2000 article in Scientific American magazine, have challenged the idea that bioplastics are defacto more environmentally friendly. The report claimed that some bioplastics require more energy to produce than some traditional petrochemical-based plastics, although it did note that some bioplastics fared better than their petroleum cousins. A study delivered at the conference compared using soy and petroleum in making polyol, a primary ingredient of polyurethane foam, and initially found that the petroleum-based version was more environmentally friendly, mainly because of the environmental harm from modern farming. But then researchers looked at the underlying data and found incorrect assumptions about pesticide runoff and farming practices. When those were changed, soy came out looking better, said Jack Pollack, a consultant with OmniTech. The company was able to convince government researchers doing the study to correct their data, he said. Evaluating environmental impact can be subjective, but biobased plastics still offer significant chances to reduce energy use and combat global warming, and are part of a longer-term shift toward more sustainable manufacturing practices, said Ramani Narayan, professor of chemical and biochemical engineering at Michigan State University in East Lansing, Mich. Plastics News (Crain Communication) 1725 Merriman Road Akron, OH 44313-5283 Phone: 330-836-9180 www.plasticsnews.com editorial@plasticsnews.com DEERE & CO. CHASSIS CLAIMS TWO AWARDS Roger Renstrom PLASTICS NEWS CORRESPONDENT April 21, 1997 IRVINE, CALIF. -- A 27-pound thermoset Deere & Co. pre-production chassis captured awards as both the best agriculture, lawn and garden entry and the best single part in the SPI Structural Plastics '97 competition. John Cerny Jr., a Deere plastics applications developer, sees a future for the fully tested design and use of sheet molding compound, although Deere has yet to find an appropriate application for the chassis, which was engineered using computer-aided design and manufacturing. The original concept focused on a rear-engine riding mower until that market diminished. Other possible applications include lawn and garden tractor, golf cart, utility vehicle and even small electric-powered car, Cerny said in an interview at Structural Plastics '97 in Irvine. The design reduced part count by 140 vs. an equivalent metal rider and produced a quieter ride. Virtually nothing can vibrate or come loose. Quantum Composites Inc. of Midland, Mich., supplied its Quantum 8000 SMC material consisting of vinyl ester hybrid with a 64 percent fiberglass reinforcement. Conventional SMC material contains about 27 percent reinforcement. Development work at the Deere & Co. technical center in Moline, Ill., began in 1991. Hoegner's Tool & Die in Moline completed the mold and Bailey Corp.'s PreMix unit in Lancaster, Ohio, compression molded the chassis' 4-millimeter-thick walls using 400 tons of force in a four-minute cycle. Deere conducted 300 hours of testing at a Florida facility and a separate 600-hour actuator test using hydraulic cylinders in an advanced design verification. Cerny cited several ways to mass-produce the chassis cheaply: compression molding, injection molding, liquid composite molding or hand layup. ``Compression molding is cost-effective for mass production,'' he said. ``The integrated chassis and suspension system act basically as a spring'' and handle all structural stress, Cerny noted. The structure is rigid but flexes throughout its length and width to absorb loads. A U.S. patent was issued in September 1996, protecting the design of the chassis as incorporating the suspension unit. Two-piece injection molded ABS skins weigh a total of 8 pounds and serve aesthetic purposes only. In early work, Deere conducted parallel development of this thermoset concept and, in Horicon, Wis., another involving thermoplastic. For test purposes, three thermoset vehicles and 12 thermoplastic vehicles were built, but the downturn in the rear-engine riding mower market scuttled the thermoplastic idea. ``Both were functional and reliable, but the thermoplastic exhibited creep,'' Cerny said. Plastics News (Crain Communication) 1725 Merriman Road Akron, OH 44313-5283 Phone: 330-836-9180 www.plasticsnews.com editorial@plasticsnews.com Processor News March 22, 2004 Omnium improving recyclable bumper DETROIT- French automotive molder Plastic Omnium Co. this year will launch the second generation of an automotive bumper designed to improve recyclability while also using recycled material. The firm, based in Levallaois, France, first began producing the polyolefin bumper in July 2002 for the Renault SA Megane. The bumper system replaces metal connections with plastic components, reduces overall weight by 20 percent and can be dismantled in less than one minute. The updated unit set for production later this year will use 61/2 pounds of recycled polypropylene generated from worn-out garbage containers, Plastic Omnium sales representative David Kramer said during the Society of Plastics Engineers' Global Plastics Environmental Conference. The event was held Feb. 18 in Detroit. The recycled plastic will be used as the substrate, with virgin material for the outer skin. Plastics News (Crain Communication) 1725 Merriman Road Akron, OH 44313-5283 Phone: 330-836-9180 www.plasticsnews.com editorial@plasticsnews.com Scrap system nets top honor Steve Toloken DETROIT -March 01, 2004 One of the challenges of recycling plastics from electronics is fundamental - how do you communicate what you have collected amid the mishmash of resins and additives coming in the door, from computers to TVs to cell phones? An industry consortium run from Tufts University in Medford, Mass., thinks it has the answer with a system that for the first time categorizes the materials. The consortium, called the Stakeholder Dialogues for Recycling Engineering Thermoplastics from Used Electronics Equipment, picked up the top environmental award from the Society of Plastics Engineers' Global Plastics Environmental Conference, held Feb. 18-19 in Detroit. The Tufts group published its guidelines in 2003 as part of the Institute of Scrap Recycling Industries standards for handling electronic scrap. ``It is basically the communication tool between buyers and sellers,'' said Patricia Dillon, manager of the project and an adjunct faculty member at the Gordon Institute at Tufts. The project included participants from electronics manufacturers, resin suppliers, industry trade groups and government officials. The Tufts group also has been active in making recommendations to the federal government on greenpurchasing guidelines for electronics. Federal agencies spend $38 billion a year on electronics. Some of the recommendations simply codify general trends in product design, like not using pentaBDE and octaBDE as flame retardants. But Dillon said others forge new ground by recommending use of recycled content or using biobased materials. The project also recommends not painting plastic parts, and it suggests a hierarchy for processing end-oflife plastics, rating reuse as best, followed by mechanical recycling, then chemical recycling, using plastics as an energy source in metal smelting, and finally incineration that recovers energy from the plastic. The recommendations have been submitted to the Environmental Protection Agency, which is using them to rank the environmental friendliness of electronic products. EPA's effort will result in an Electronic Product Environmental Assessment Tool, similar to the agency's Energy Star program, which endorses products that cut energy use. ``In the future [government agencies] could say `We're only going to purchase it if it is EPEAT compliant,' '' Dillon said. Other SPE GPEC award winners include: * New Technology and Materials. DuPont Engineering Polymers and Japanese automotive supplier Denso Corp. won for a project to take glass-filled nylon radiator tanks and recycle the material back into radiator tanks. * Emerging Technologies. Scotts Co. in Marysville, Ohio, won for developing a spray trigger for its pesticide that foams the chemical, allowing it to be visible on the weed for up to a minute. The company said that allows consumers to use less foam and reduce environmental harm from pesticides. * Enabling Technologies. Erema North America Inc., of Ipswich, Mass., won for its VacuRema system of recycling PET bottles into food-grade applications. * Environmental Design Award. Furniture maker Herman Miller Inc. of Zeeland, Mich., won for its Mirra chair. The chair uses 42 percent recycled content, is assembled using energy from wind power, and had a tough to disassemble steel-polymer spine replaced by nylon. * Biobased Materials Award. Ashland Specialty Chemicals Co. in Dublin, Ohio, won for its Envirez 5000 resin, which contains 25 percent content from soy and corn. The resin is used in John Deere Inc. combines. * Environmental Stewardship. This award had three winners: Delta Plastics of the South, in Stuttgart, Ark., for a system of collecting and recycling 25 million pounds of its agricultural irrigation tubing; Hancor Inc., in Findlay, Ohio, for its EcoFirst pipe; and Harbec Plastics Inc., in Ontario, N.Y., for its onsite power system. Plastics News (Crain Communication) 1725 Merriman Road Akron, OH 44313-5283 Phone: 330-836-9180 www.plasticsnews.com editorial@plasticsnews.com APC, carmakers explore scrap-to-fuel process Rhoda Miel DETROIT -February 23, 2004 Can mixed automotive scrap be turned into usable diesel fuel? Modern alchemists at the research firm Changing World Technologies Inc. already have turned a 5-gallon bucket's worth of automotive shredder residue into a small vial of oil through a demonstration of its depolymerization process. Now the auto industry's Vehicle Recycling Partnership - backed by General Motors Corp., Ford Motor Co. and DaimlerChrysler AG - and the American Plastics Council are financing a small-scale probe tracking more detailed information on the process and whether it is a feasible alternative to landfilling auto scrap. ``We did find out that they can do something with shredder residue,'' said Gerry Winslow, a coordinator for VRP, during the Society of Plastics Engineers' Global Plastics Environmental Conference, held Feb. 18 in Detroit. ``Now we're going to find out what exactly they can do.'' Other companies have suggested chemical recycling processes in the past to handle hard-to-recycle mixed plastics and rubber, but high costs have meant that few actually have reached a commercial stage. Changing World Technologies of West Hempstead, N.Y., is researching ways to draw usable material out of a variety of waste, including plastics, rubber, medical waste and even municipal sewage sludge. It has one commercial application of its program, a plant in Carthage, Mo., processing 200 tons daily of internal organs and other scrap from a turkey plant and turning it into 500 barrels' worth of fuel oil. The company uses a proprietary thermal depolymerization system to convert the hydrocarbons and organic materials into oil and other products. In-house CWT studies predicted it could turn 100 pounds of PET and high density polyethylene bottles into 70 pounds of oil, 16 pounds of natural gas, 6 pounds of carbon solids and 8 pounds of water. About 75 percent of the weight of a typical car or truck is recycled in the United States, with auto scrapyards pulling the value from engine parts and metal, Winslow said. The remaining components, including mixed plastics, glass, cloth and foam, go through a shredder and are shipped to landfills. VRP has studied ways to separate out the plastics from that residue and has joined with APC and the U.S. government's Argonne National Laboratories to continue research into commercially viable systems. The CWT system is worth looking into for another potential alternative, said Mike Fisher, technology director for Arlington, Va.-based APC. So far, though, the council and its partners do not have many details on how the system would work. The auto and plastics groups did not do a break-down of what materials were in the sample it sent to CWT for the first study, Winslow said, and because it was a free ``snapshot,'' could not get full details of the results. With the new research, the groups have far more information on what they are shipping to the company's research and development facility in Philadelphia. The groups also will have more access to specifics of the process, including information on any problems coming from chlorine or lead content within the materials and the actual costs of any commercial process. ``We are going to gain more knowledge on what they are doing,'' he said. ``If it turns out that the fuel oil costs more through this than I can get buying it at the local store, then once again we have to see that recycling is not going to work if it has to be subsidized.'' Plastics News (Crain Communication) 1725 Merriman Road Akron, OH 44313-5283 Phone: 330-836-9180 www.plasticsnews.com editorial@plasticsnews.com Industry weighing in on biobased plastics Steve Toloken DETROIT -March 01, 2004 Advocates of plastics made from soybeans or other plant materials like to tout their wares as having an environmentally friendly footprint, where raw materials are replenished as quickly as the next growing season in a cycle they dub ``birth to reincarnation.'' The big challenge for the industry, though, seems to be getting out of the delivery room. How to see biobased polymers mature beyond infancy was the talk among the engineers, consultants and academics at the Society of Plastics Engineers' Global Plastics Environmental Conference, held Feb. 1819 in Detroit. The event was abuzz with positive predictions for bioplastics, tempered with the reality of the marketplace. ``The real issues are bringing it out from the researcher's bench to the real world,'' said John Cerny, staff engineer for biobased polymers with John Deere Inc.'s technology center in Moline, Ill. Deere is using a thermoset resin that is 25 percent renewable, from soy and corn, in hood and body panels in its combines, and plans to expand that to other products, Cerny said. Case LLC is also using soy-based resin in a combine, part of a market development push by agricultural equipment manufacturers. Other companies, like Sony Corp. and Ford Motor Co., have dabbled in vegetable-based plastics. But basic questions need to be answered before large manufacturers like car companies will be comfortable using plant-based polymers, said Phil Sarnacke, an industry consultant with OmniTech International, Ltd., in Midland, Mich. OmniTech works for the United Soybean Board. Sarnacke and David Reed from General Motors Corp., delivered a paper to the conference that recommended that auto makers launch a cooperative precompetitive research program to evaluate biobased polymers, and create a database of cost, performance and environmental issues for engineers to reference. ``The auto [industry's] lack of use of biomass products is in part due to a lack of thorough, critical evaluation of the biomass products and their potential,'' they wrote. Those pushing biobased polymers see potential. Biobased materials are used in about 3 percent of the $280 billion U.S. market for polymers and chemicals now, but some estimates say that will grow to 20 percent by 2010, said Margaret Baumann, president of consulting firm G.H. Associates in Lebanon, N.J. Biopolymers could offer a homegrown economic advantage to the U.S. plastics industry, which has been hurt by steep price increases in natural gas, she said. The U.S. industry could regain some global competitiveness by tapping American agriculture for feedstock, and at the same time reduce the country's dependence on foreign energy sources and lessen greenhouse gas generation, Baumann said. Biopolymers that are achieving success now, she said, are adding value, like providing a soft touch for products like drapes. Another example: Deere's Cerny said its soy-based resin parts are better because they do not need to be repainted or repaired as often. The Deere parts made with biobased resins are cost competitive, but the company still wants prices for biobased resin to drop 10-15 percent, Cerny said. While biopolymers were the toast of the conference - they were the single largest paper topic this year proponents conceded that they're not always the slam-dunk environmental win that some assume. John Dorgan, a chemistry professor at the Colorado School of Mines, said that some studies, like an August 2000 article in Scientific American magazine, have challenged the idea that bioplastics are defacto more environmentally friendly. The report claimed that some bioplastics require more energy to produce than some traditional petrochemical-based plastics, although it did note that some bioplastics fared better than their petroleum cousins. A study delivered at the conference compared using soy and petroleum in making polyol, a primary ingredient of polyurethane foam, and initially found that the petroleum-based version was more environmentally friendly, mainly because of the environmental harm from modern farming. But then researchers looked at the underlying data and found incorrect assumptions about pesticide runoff and farming practices. When those were changed, soy came out looking better, said Jack Pollack, a consultant with OmniTech. The company was able to convince government researchers doing the study to correct their data, he said. Evaluating environmental impact can be subjective, but biobased plastics still offer significant chances to reduce energy use and combat global warming, and are part of a longer-term shift toward more sustainable manufacturing practices, said Ramani Narayan, professor of chemical and biochemical engineering at Michigan State University in East Lansing, Mich. Plastics News (Crain Communication) 1725 Merriman Road Akron, OH 44313-5283 Phone: 330-836-9180 www.plasticsnews.com editorial@plasticsnews.com Cloths could find new life in vehicles Rhoda Miel DETROIT -March 01, 2004 The cloths used in auto assembly plants to clean engine parts are receiving a second life as plastic components in cars and trucks. Mobile Fluid Recovery Inc. and Contec Inc. have coordinated an effort that is reusing 100,000 pounds of polypropylene and polyester cloth wipes annually. A potential change in federal regulations may mean more of the isopropyl alcohol-soaked material could go into the recycling stream in the future. Individual states now decide whether alcohol in the wipes - used to clean car parts and also in screen printing for electronic components - require special handling as a hazardous material, said David Briggs, executive vice president for MFR. The federal government is reviewing a national standard for the material. Evansville, Ind.-based MFR can clean the wipes, leaving 8 gallons of hazardous material behind out of a 50-gallon barrel of soaked cloth, greatly reducing the disposal cost. The textile left behind is then ready for recycling. The polyester ends up in tubes used to absorb liquid spills, but the polypropylene-based material can be used in recycled resin blends, Briggs said at the Society of Plastics Engineers' Global Plastics Environmental Conference in Detroit. ``That's the neat process behind the whole thing,'' said Deavron Farmer, an account manager for Matrixx Inc., the Evansville compounder that worked with MFR in developing the recycling technology. Matrixx found that the cleaned wipes could be treated the same as any other PP-based textile or film heated nearly to its melting point to a stage where it can go into a normal regrinding process. DaimlerChrysler AG, which had one of its Auburn Hills, Mich.-based Chrysler Group assembly plants involved in the study, further pushed to see if the regrind could meet its own specifications for plastics. Matrixx put it into a 20 percent talc filled PP, with the wipe-based regrind making up 20 percent of the polypropylene, that met Chrysler standards, Farmer said. The material is used in unseen components such as wheel housings and wire harnesses. MFR now is collecting and cleaning wipes from 11 auto assembly plants, with General Motors Corp. and Fuji Heavy Industries Ltd.'s Subaru assembly plant in Lafayette, Ind., participating. Other compounders also are taking part in the program, Briggs said. Canon Communications LLC 11444 W. Olympic Blvd. Ste. 900 Los Angeles, CA 90064 Phone: (310) 445-4200 Kevin O'Grady, Group Publisher Separating plastics from metals gains steam By Modern Plastics Editorial Staff A 55:45 joint venture formed by MBA Polymers (Richmond, CA) and Guangzhou Iron & Steel Enterprises Holdings Ltd. (GISE), called GISE-MBA New Plastics Technology Co. Ltd., will build and operate a mechanical recycling plant for end-of-life (EOL) E/E goods, white goods, and automotive parts in the Nansha development area, using MBA's separation technology. The technology separates not only plastics from the (mostly mixed metals) shredder residue but also separates plastics by material. Mike Biddle, founder of MBA, says the new plant—the first large-scale commercial one using the technology—will be able to process about 40,000 tonnes/yr by early 2005. A pilot plant in Richmond, operating for nearly a decade, could process 10,000 to 15,000 tons/yr if enough EOL goods were collected. In the U.S. they are not, but he says the next two to three years is expected to bring legislation in China requiring manufacturers to take back EOL goods and develop recycling plans for these. Flextronics, the world's largest contract electronics manufacturer, is a minority investor in MBA Polymers as is another "major player in the plastics industry" that Biddle did not disclose. MBA is already in talks regarding other plants in China. Interest is also strong in Europe, Taiwan, Korea, Singapore, and India, says Biddle. Manufacturer takeback of EOL goods is already legislated in Japan, Taiwan, and Korea and soon will be in Europe. According to the new report 'Electronics Recycling: What to Expect from Global Mandates' from Raymond Communications, electronics manufacturers in Europe alone may need to spend up to $40 billion to prepare takeback and recycling systems for compliance with the Waste Electrical and Electronics (WEEE) directive, which takes effect in 2006. Sony, Electrolux, Braun, and Hewlett-Packard already have formed an alliance to handle their panEuropean collection scheme. The report states that nine Japanese electronics firms spent more than $1.5 billion on environmental design and compliance in 2001-2002. In the U.S., the Environmental Protection Agency has stopped financial support of the National Electronics Product Stewardship Initiative; it now receives only private funding. A California law taxing televisions to support recycling of those produces still awaits approval from the recently elected governor.