« SPECIAL INCINERATOR FOR

advertisement

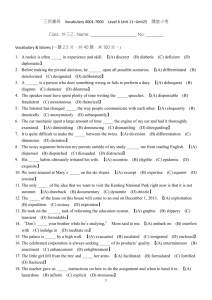

1/10 GWG Gesellschaft für Wiederverwertung von Gebrauchsgütern (GBR) Hanker Lin 林文輝 Germany Address : Am Hofgarten 17,53113 Bonn , Germany Taiwan Address : No.109, NAN-HWA street , Tao-Yuan city , Taiwan ,ROC. 台灣 Taiwan contact Tel no.0932-169-191,099-129-0808 ,Fax no:03-332-8806, Website:www.taiwan.what.cc// « SPECIAL INCINERATOR FOR THE DESTRUCTION OF INDUSTRIAL WASTE » MODEL HP 5000 First approch of Technical description and Quotation October 1999 A.T.I-Incinerators Müller 2/10 GWG Gesellschaft für Wiederverwertung von Gebrauchsgütern (GBR) Hanker Lin 林文輝 Germany Address : Am Hofgarten 17,53113 Bonn , Germany Taiwan Address : No.109, NAN-HWA street , Tao-Yuan city , Taiwan ,ROC. 台灣 Taiwan contact Tel no.0932-169-191,099-129-0808 ,Fax no:03-332-8806, Website:www.taiwan.what.cc// 1 - GENERAL Reminder of base data : * Proposal for the supply and the installation of an incinerator with a capacity of 1000 kg/h or 144 tons/week (special model H.P. 1500 for industrial waste). * It is recalled that this furnace must be able to work according to variable operating ranges up to 24h/24 - 6d/w. * The emission gas into the atmosphere will be in accordance with the European regulation with a gas treatment by means of neutralization and filtration. * Our installation will be in accordance with the decree of the 25th January 1991, relating to the incineration facilities published in the bulletin of the 3 March 1991 which has been issued by the French Republic giving details of laws and official announcements. * The installation which is proposed, is designed according to the local climatic data. * According to our settlement enclosed, we have provided an easy accessibility to all equipment and sets of easy and rapid measure points in order to analyse rejected gas (such as dusts, carbon monoxide , HCL, T°...) by accepted organisms. * The control panel will be fitted with a functional synoptic view showing the operating situation of the whole installation 2 - TECHNICAL DESCRIPTION The incineration unit will include : I) One container dumper (bucket) II) One loading system III) One combustion chamber (special for industrial waste) IV) One post-combustion V) One gas cooling system VI) One waste gas treatment system A.T.I-Incinerators Müller 3/10 GWG Gesellschaft für Wiederverwertung von Gebrauchsgütern (GBR) Hanker Lin 林文輝 Germany Address : Am Hofgarten 17,53113 Bonn , Germany Taiwan Address : No.109, NAN-HWA street , Tao-Yuan city , Taiwan ,ROC. 台灣 Taiwan contact Tel no.0932-169-191,099-129-0808 ,Fax no:03-332-8806, Website:www.taiwan.what.cc// TECHNICAL DESCRIPTION OF EACH EQUIPMENT: I) CONTAINER DUMPER (BUCKET) : * Welded-mechanical framework enabling to lift and turn a standard container of 1000 litters fitted with lateral throats. * The mechanical control is achieved through one hydraulic jack and two limits of travel enabling to control the start and the stopping of tipping. II) LOADING SYSTEM : * A welded-mechanical set in strong sheet steel with lateral reinforcing pieces and a clamp on the side face of the incinerator. * The pusher in strong sheet steel contains one shield in heat resisting insulant, which prevents from its deformation when opening the guillotine door. * This loading proceeding is very easy and safe for the staff operating it and it enables no direct contact with the combustion stove. * The whole loading system is entirely automatic : - Opening of the loading lock - Returning of the container and putting waste into the lock - Closing of the lock - Opening of the guillotine door - Run-on of the loading pusher - Return of the pusher - Closing of the guillotine door * A new loading is possible if it is allowed by the control and adjustment panel. III) SPECIAL COMBUSTION CHAMBER FOR INDUSTRIALWASTE A.T.I-Incinerators Müller 4/10 GWG Gesellschaft für Wiederverwertung von Gebrauchsgütern (GBR) Hanker Lin 林文輝 Germany Address : Am Hofgarten 17,53113 Bonn , Germany Taiwan Address : No.109, NAN-HWA street , Tao-Yuan city , Taiwan ,ROC. 台灣 Taiwan contact Tel no.0932-169-191,099-129-0808 ,Fax no:03-332-8806, Website:www.taiwan.what.cc// * Cylindric and horizontal chamber in strong sheet and support feet. * Bricking up will be made of refractory bricks and thermal insulators providing a minimal temperature on the sheet metal. * The nature of the refractory bricking up is designed for meeting mechanical, corrosive and thermal requirements. * The combustion chamber will be composed of 8 stages of combustion, each one equipped with a pusher in order to assure permanently the moving forward and the turnaround of waste. * Each combustion stage is laterally equipped with primary air nozzles to assure the perfect combustion. * Each stage will also be equipped with a combustion burner so as to allow the independent control of each burner on each stage. * Each stage can treat 250 kg of waste. Composition of the refractory bricking up ; Insulator : * Using temperature : 1000°C maxi * Nature : Calcium silicate * Thickness : l10 mm Refractory : * Using temerature : 1550°C maxi * Nature : 42% of aluminium * Thickness : 220 mm Combustion burners : * The combustion hearth will be fitted with two burners above-mentioned enabling to assure a correct combustion temperature for the complete destruction of the waste. * Automatic burning and monobloc casting guiding flames fitted with an electronic ignition device and a permanent ventilation. A.T.I-Incinerators Müller 5/10 GWG Gesellschaft für Wiederverwertung von Gebrauchsgütern (GBR) Hanker Lin 林文輝 Germany Address : Am Hofgarten 17,53113 Bonn , Germany Taiwan Address : No.109, NAN-HWA street , Tao-Yuan city , Taiwan ,ROC. 台灣 Taiwan contact Tel no.0932-169-191,099-129-0808 ,Fax no:03-332-8806, Website:www.taiwan.what.cc// Air ventilator : * One primary and secondary air ventilator distributes the needed oxygen in the incinerator. * One motorised valve regulates the ventilator according to the combustion situation. * The ventilator pressure will be 500 mm H2O which allows to pierce the burning waste bulk and to avoid the unburning ratio. IV) POST-COMBUSTION * The second phase of combustion is a post-combustion at high temperature of the gases produced by the combustion chamber. The high content of CO in these gases permits a re-lighting by simple air injection with the post-combustion burners. This processing is therefore especially well adapted to a treatment of gas. * The post-combustion of gases takes place at a temperature of 1000°C to 1200°C. The cylindric form of the post-combustion chamber, combined with Vortex effet by the secondary air injection, which have been particularly designed and patented by ATI-MULLER, allows an extremely efficient mixing of gases during 2 seconds, enabling to assure the achievement of very low hydrocarbon refuse. This contributes also to limit the soot production in the downstream and the quantity of solid to be treated in dust remover system. * The design of the post-combustion burners is similar to the combustion burners. * After burning is fitted with inspection doors so that a periodical cleaning of dust can be achieved. * The post-combustion is lined with high thermal insulating materials with a thickness of 270 mm V) GAS COOLING SYSTEM * The gases have to be cooled by the energy recuperation boiler in a type of smoke tubes in order to low down the temperature from 900 °C to 200 °C. This cooling of the gases is indispensable to pass these gases into the filter which will treat them. * The calories from the boiler will be evacuated by an air/water exchanger (cooling tower). * Vertical monobloc tube boiler with double circuits. * Made of MARTIN thick sheet, the body of the boiler assembled by automatic welding. All internal weld seams in contact with gas are doubled on the water side. A.T.I-Incinerators Müller 6/10 GWG Gesellschaft für Wiederverwertung von Gebrauchsgütern (GBR) Hanker Lin 林文輝 Germany Address : Am Hofgarten 17,53113 Bonn , Germany Taiwan Address : No.109, NAN-HWA street , Tao-Yuan city , Taiwan ,ROC. 台灣 Taiwan contact Tel no.0932-169-191,099-129-0808 ,Fax no:03-332-8806, Website:www.taiwan.what.cc// * The exchanger is made of special reinforced thick tubes. * The boiler is insulated by a thermal insulator protected by a galvanized iron sheet jacket. * A metallic base allows the distribution of the load on the foundations. * Heat insulated smoke box. * Sealed and heat insulated soot door. * In standard hot water series, the operating pressure is approximately 3 Bars. Connecting sleeves between the post-combustion and the boiler : * Metal sleeve with thermal insulator and refractory lining with insulating fibrous panels. * Connecting metal sleeve between the smoking box of the boiler and the filter. Accessories : * Empty valve * Safety valve * Thermometer * Two aquastats Control and regulation : * Integration of the control and regulatlon devices of boiler on the incinerator control panel. * Wiring VI) WASTE GAS TREATMENT SYSTEM * Leaving the hot water recuperation boiler, the gas have a temperature between 200 °C to 250 °C (for abbatoir waste, hospital waste and industrial waste) and contain pollutants consisting of dusts, HCI, S02, HF, heavy metal, dioxins and furans. * Our principe consists in injecting two neutralizing substances ; Sponglacal to neutralize acids like HCI, S02, HF and Sorbalit to absorb dioxins and furans. * These neutralizing chemical products are stored in two separated hoppers. They are injected into each reactor which effects a gas/neutralizer mixture to purify the pollutant. * Coarse dust particles are separated by centrifugal force in the ceramic filter inlet. A.T.I-Incinerators Müller 7/10 GWG Gesellschaft für Wiederverwertung von Gebrauchsgütern (GBR) Hanker Lin 林文輝 Germany Address : Am Hofgarten 17,53113 Bonn , Germany Taiwan Address : No.109, NAN-HWA street , Tao-Yuan city , Taiwan ,ROC. 台灣 Taiwan contact Tel no.0932-169-191,099-129-0808 ,Fax no:03-332-8806, Website:www.taiwan.what.cc// * The flow of flue gas is then evently drawn-in over filter elements. * The residuary dusts remain over filter elements while purified flue gases flow through. * After an adjustable space of time, a compressed air jet is inducted the inside of the elements by the counterflow pulsating cleaning system. This is achieved alternatively by cloth group. This compressed air jet allows the sudden coming off the dust agglomerated over elements into the dust collecting basin situated under the filter housing. * After the dust has been entirely filtered out, purified flue gases are drawn out by means of the I/D fan through a temperature control valve. Component parts and design The dust extraction system featuring a ceramic filter consists of the following elements : * Filter housing intended for filter modules * Filter modules with ceramic filter elements (module and elements are positioned in such a way that they can be replaced horizontally on the clean air side). * Compressed air cleaning system featuring a compressed air reservoir, electromagnetic valves and electronic control. * Supporting columns with anchoring bolts. * Fan's base plate (mounted). * Connecting flanges. VII) EMISSION GAS GUARANTEE AFTER OUR GAS TREATMENT SYSTEM WITH SPONGIACAL AND SORBALIT INJECTION AND CERAMIC FILTER * Gas flow : 15000 Nm3/h * Gas temperature outlet of filter : 150 °c * Carbon monoxide : < 50 mgr/Nm3 * Total dusts : < 10 mgr/Nm3 * HCI : < 10 mgr/Nm3 * HF : < 1 mgr/Nm3 A.T.I-Incinerators Müller 8/10 GWG Gesellschaft für Wiederverwertung von Gebrauchsgütern (GBR) Hanker Lin 林文輝 Germany Address : Am Hofgarten 17,53113 Bonn , Germany Taiwan Address : No.109, NAN-HWA street , Tao-Yuan city , Taiwan ,ROC. 台灣 Taiwan contact Tel no.0932-169-191,099-129-0808 ,Fax no:03-332-8806, Website:www.taiwan.what.cc// * S02 : < 50 mgr/Nm3 * Dioxins and furans : < 0.1 Ngr/Nm3 *T.O.C : < 10 mgr/Nm3 * Cadmium : < 0.05 mgr/Nm3 * Mercury : < 0.05 mgr/Nm3 * Other heavy metal VIII) TECHNICAL FEATURES : < 5 mgr/Nm3 DESIGNATIONS Destruction capacity MODEL H.P. 5000 1000 kg/hour (144 tons/week) Operating time 24 hours/day 6 days/week Average L.C.P of waste 7000 kcal/kg Temperatures * Combustion * Postcombustion 700-900 °C 1000-1200 °C Power of Burners * Combustion * Postcombustion 8 x 400 Kw 2 x 400 Kw Installed electric power 160 Kw Chimney: * Height from ground * Diameter 10.00 m 0.95 m Ventilation of Room * High * Low 45 dm² 55 dm² Weight of total installation 200 tons 3 - ARE NOT INCLUDED IN OUR PROPOSAL A.T.I-Incinerators Müller 9/10 GWG Gesellschaft für Wiederverwertung von Gebrauchsgütern (GBR) Hanker Lin 林文輝 Germany Address : Am Hofgarten 17,53113 Bonn , Germany Taiwan Address : No.109, NAN-HWA street , Tao-Yuan city , Taiwan ,ROC. 台灣 Taiwan contact Tel no.0932-169-191,099-129-0808 ,Fax no:03-332-8806, Website:www.taiwan.what.cc// * Opening in the roof for the passing of the chimney with tight connection * Civil engineering works * Building * High and low ventilation's * Electric connection on our control panel (three phases 380 Volts + neutral + earth) * Fuel connections on our burners * Handling equipment and assembling of the incinerator ( 3 fitters during 10/15 days following our technical document) * Town water connection (3 bars), piping 8*13 * Any other furnitures or services not to be stated in this present quotation. 4 - QUOTATION * One complet special incinerator H.P. 5000 with One gas cooling suytem and One waste gas treatment system for industrial waste (turn key base). 5 - SPARE PARTS LIST FOR CONSUMABLE AND INCIDENTAL 1 temperature regulation box 2 burners control box 1 burner engine 2 starting electrodes 1 fuel oil pump 1 ionisation tester A.T.I-Incinerators Müller 10/10 GWG Gesellschaft für Wiederverwertung von Gebrauchsgütern (GBR) Hanker Lin 林文輝 Germany Address : Am Hofgarten 17,53113 Bonn , Germany Taiwan Address : No.109, NAN-HWA street , Tao-Yuan city , Taiwan ,ROC. 台灣 Taiwan contact Tel no.0932-169-191,099-129-0808 ,Fax no:03-332-8806, Website:www.taiwan.what.cc// 2 jets (buses) 1 electric box with relay, fuses etc. 6 - CONDITION OF SUPPLY * Manufacturing terms * Transportation term * Assembly and adjustment * Starting up : 8 months : 1 months : 2 months : 1 months Total : 12 months * Payment conditions - The order will be operative only after receiving the L/C. - 20% : Of the total amount to be paid against order - 80% : Of the total amount to be paid against Bill of landing A.T.I-Incinerators Müller