gardharia

advertisement

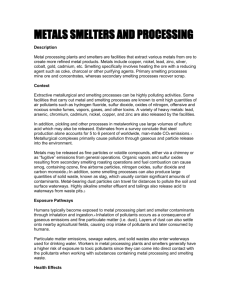

CURRICULUM VITAE NILESHKUMAR K. GARDHARIA (B.Sc. PHYSICS) E-Mail ID: gardharianilesh@yahoo.co.in Contact No.:- +91 9426960727 (M) +91 2641664517 (R) Career Objective To seek good opportunity with higher responsibilities where I can utilize my creative talents in Smelter/hot metal operation field, I have both the qualification and experience which may lead the organization towards growth and to work in an Innovative, Competitive & Challenging World. Educational Qualification Discipline: - Bachelor of Science (Physics) in june1991 with 56.61% Institute : -Gujarat College, Ahmadabad. University: - Gujarat University Professional Summary & Company Profile (1) Currently working at HINDALCO Industries Ltd.(Unit:Birla Copper) , Dahej as Assistant Manager (Process). The Manufacturing unit of Premium ADITYA BIRLA GROUP(ABG),The largest single location copper smelter unit of the world having capacity of 5 lac ton(primary copper) /annum using a renowned technologies like Outokumpu Finland and Mitsubishi Process Japan for copper smelting. And in addition having sulfuric acid & phosphoric acid plant, precious metal recovery plant, slag beneficiation plant. Our unit accredited with ISO: 9001 and ISO: 14001. Duration of work: 19TH Nov-1997 to till date. Growth Plan: Nov.1997 to Jan. 2001-----Junior Technician Jan. 2001 to Jan. 2004--- -Technician Jan. 2004 to Jan. 2007-----Senior Technician Jan. 2007 to July. 2008-----Asst. Engineer July. 2008 to July 2011-----Engineer July. 2011 to cont.----------Asst. Manager Project Work Experience Play a major roll in commissioning, start up and stabilizing of Outokumpu flash smelting furnace, Mitsubishi Smelting furnaces, Demag (Germany) Electric slag cleaning furnace. as well as row material handling sytem,Off gas dust handling system,Dryers,Bag filters, Jacket cooling & Cooling towers facilities KEY PERFORMANCE AREA: I am working as a SHIFT In-Charge (Process) in Copper Smelter. As a Shift In Charge Process responsible for operate entire copper smelter plant smoothly with optimum available resources and as per SOP’s. Implement Strict Process Control by discipline in work culture. Develops a well motivated and strong smelting team by providing the necessary talent leadership and technical guide. Particular focus on safety, product quality, health and the impact on the environment of smelting operations. Manage Team of 01 Engineer, 02 Asst. Engineers, 10 technicians, 10 operators and 30 contract workers and manage relationship on a respectful and organization’s value driven manner. Assisting, Asst. General Manager in preparation of various production and Process analysis and parameter reports Process Improvements by New SOP’s and continuous improvement & Development by KAIZEN Models Knows Operation system like, PLC (AB) for Mannesmann DEMAG for electric furnace. Yokogawa DCS (Centum CS) for flash smelting furnace. Yokogawa DCS (Centum CS 3000) for Mitsubishi smelting furnace. Technical Trainings and Seminars: Attended the exclusive training at JAPAN (Mitsubishi Material Corporation, Naoshima Smelter) during 22/10/2004 to 23/11/2004 for the purpose of extensive training on Mitsubishi Smelting Process I have participated in different technical Trainings & Seminars like KAIZEN; manage self and others, safety, first aid. Computer Proficiency Operating System: Window 98, XP, 07. M.S.Office. proficiency WCM, (2) (Unit Worked at GUJARAT GUARDIAN LTD, Ankleshwar, Gujarat, India of Guardian ind. Corporation USA) as a plant operator. One of the most reputed float glass and premium quality mirror manufacturer ISO 9001company in Asia region. Having capacity of 600 TPD with 2 mm to 12 mm thickness range. I performed my role in various sections like hot end (Furnace, Tin bath, Batch house) and glass cutting m/c at cold end. Duration of work: 28/12/1992 to 14/11/1997 JOB PROFILE: *Performed duty at PLC based cutting operation bridge, quality marking booth, powder coating m/c. * follow up and communicate with ware house in charge for put up & shifting Boxes as per cutting size schedule of various thickness of glass. *follow up and communicate with hot end in charge for glass ribbon widen out, narrow down, thickness change over and for defects/quality of glass and Cross breaks and lehr splits in the glass ribbon. *worked at tin bath area for thickness change over, ribbon widens out and narrows down, monitoring twill m/c for ribbon control at control room. *worked at natural gas fired glass melting furnace. System Used: yokogawa DCS (micro excel), PLC (Zippe-Germany) Personal Information Date of Birth Sex Mailing Address Pass Port Details Hobbies Languages Known Marital Status Nationality : 14th Feb, 1971 : Male : D-18/3, Birla Copper Township At & Post:Dahej Dist:-Bharuch(Gujarat/India) PIN-392130 : No:- F0647273, Valid uo to 26.09.2014 : Reading, making friends, Traveling, music Playing volleyball, cricket, exercise : English, Hindi, and Gujarati. : married. : Indian. The information stated above is true and that I’ll take the responsibility with all my sincerity. Yours Sincere, Place: Dahej/Bharuch NILESHKUMAR GARDHARIA