Dakota LS Design Info (Sewage)

advertisement

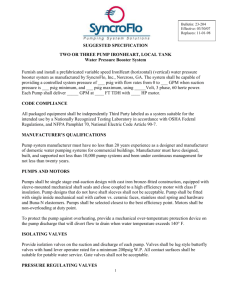

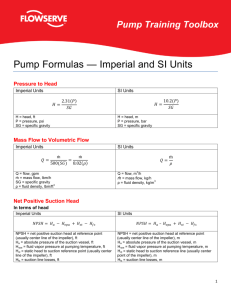

DAKOTA PUMP INCORPORATED P. O. BOX 947 - MITCHELL, SD 57301 - PHONE (605) 996-6636 - FAX (605) 996-6067 sales@dakotapump.com DP I Sewage Pump Station Design Information What city or authority will the station be located? What is the actual site name? (street, road, ect...) What are the pump conditions? ___________ GPM @ ____________ TDH What power is available? _____ wire/_____ phase/60 hertz/______(120/208/230/460) What is the proposed grade elevation? _______ What is the proposed slab elevation? ______ What type of pumping station is best for the application? Flooded suction with dry pit non-clog pumps Vertical builtogether or vertical flex coupled pumps Typically the most efficient for flows 100 GPM and higher Positive suction head required Longest practical design life (20+ years) Widest pump condition range More easily applied to special requirements (flowmeters, ect...) Most reliable with low maintenance costs Vacuum-Priming Wet Well Mounted Fiberglass enclosure Maximum suction lift of 16' Semi-Buried (If high suction lift is greater than 16') Vertical builtogether pumps Lower initial and installation costs, however, more costly to maintain More accessible than flooded suction stations Self- Priming Wet well mounted Fiberglass enclosure Buried can station Shallower bury than flooded suction due to self-prime capacity Less efficient than flooded suction Pneumatic Ejector More efficient for flows under 100 GPM Designers and Fabricators of Water & Wastewater Pumping Stations No wet well required What size pump chamber? _______ (7,8,9,10,11,12, 13, 14 or obround) foot diameter _______ What is the desired inside height What diameter entrance tube? 36 inch or 48 inch Is a maintenance lift an option? Is a separate equipment tube an option? (Normally installed in large obround stations) What type of cathodic protection? Anode packs How many packs? Is an anode test panel required? Impressed current Any special coatings on the chamber and entrance tube exterior? Fiberglass coating Polyurethane foam insulation Other ___________________ Pump Selection How many pumps required? (Minimum should be two) Pump performance? Speed (900 RPM - 1200 RPM - 1800 RPM) Desired efficiency? Pump motors enclosure type (ODP (typical) - TEFC) Pump drive configuration (builtogether - flexible coupled - v-belt drive) Pump with mechanical seals or packing? (Mechanical seals are standard) What type of piping? Ductile Iron (standard) Steel (standard for vacuum prime type stations) What size of piping? (Typically limited velocities from 2 FPS to 7 FPS) What type of isolation valves? Plug valves Resilient wedge gate valves Double disc gate valves What type of check valves? Lever & spring Lever & weight Cushioned (air or oil)(normally for high head applications) Other ________________ Any special options? Flow meters Vibration isolators Other ___________________ What type of power and control enclosure? (Nema 1 is standard) Is a single-phase transformer required? Designers and Fabricators of Water & Wastewater Pumping Stations What type of starters? Across the line Reduced voltage Other _______________ What type of level controls? Mercury float Switches Bubbler type level controller Standard Solid State Ultrasonic level controller Submersible transducer Other ________________ What Alarm functions are required? High wet well Low wet well Station Flooding Pump fail Pump temperature Power Failure Unauthorized entry Other ______________________________________________________ What type of alarm indicators? 120 Volt alarm light and horn 12 Volt alarm light and horn with battery backup Telephone dialer Telemetry What type of environmental equipment? Lighting Incandescent Fluorescent Ventilation Blower (standard) Heater (standard) Dehumidifier (standard below grade) Sump Pump (standard below grade) Emergency lighting Other __________________ Any pressure gauges required? Designers and Fabricators of Water & Wastewater Pumping Stations