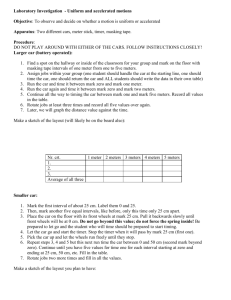

Metrological and Technical Requirements

advertisement