Electrodeposition of Manganese Dioxide

advertisement

Electrodeposition of Manganese Dioxide

Josh Farris

Shawn Martin

Department of Materials Science and Engineering

Michigan Technological University

MY 3110 Technical Report

April 28, 2004

Problem Statement

The process of manufacturing MnO2 will be discussed using electrolysis methods. This

paper will determine the mathematical aspects and processes of producing MnO2 using

thermodynamics of materials and electrochemistry.

Proposed Approach

Electrodeposition is the deposition of a conductive material from a plating solution by the

application of electric current. Electrolytic Manganese Dioxide (EMD) can be formed

from the direct electrolysis of an aqueous bath of Manganese Sulfate and Sulfuric acid.

Two graphite cathodes and a single titanium anode are placed in this aqueous bath at an

elevated temperature and superatmospheric pressure. The temperature ranges from

between 120 degrees C and 155 degrees C. By having the electrolysis take place at

higher temperatures and pressures, this allows there to be a significantly higher current

density with respect to the total anode surface. With such an increase in current density,

a higher rate of production of MnO2 is achieved. This allows there to be smaller

electrolysis units and cuts down on capital investment. With an increase in the current

density passivation may occur. Passivation is the formation of an insulating oxide film

that can build up on the titanium anode, which can disrupt the deposition of the MnO2 by

blocking the MnO2 from being deposited onto the anode. At high temperatures and

pressures this eliminates the problem of passivation.

One negative effect caused by the raise in temperature, at normal current densities, is that

it has the tendency to reduce the average specific surface area (SSA) of the MnO2

product. This has a negative impact on the overall performance of the material when it is

used as cathode active material in an alkaline cell. Some ways of solving this problem

are by increasing the current density, or by adding a soluble titanium dopant to the

aqueous bath. By adding a soluble titanium dopant, such as TiSO4, this incrementally

increases the SSA of the MnO2 product. The desired SSA of the MnO2 is between 18

and 45 m^2/g for good performance in an alkaline cell. This is because if you have more

than 45 m^2/g, the individual crystallites become smaller and the number of crystallites

per unit volume becomes larger. This leads to smaller pores between the crystallites and

makes it harder for water molecules to enter and hydroxyl ions to leave when the MnO2

is used in an alkaline cell. This decreases the reaction rate of the battery which results in

poor performance. If you have a SSA of less than 18 m^2/g, there is an insufficient

surface for the electrochemical reaction to take place.

The soluble titanium dopant, TiSO4, makes beneficial changes on the primarily γ-MnO2

crystalline structure. This enhances the performance characteristics of the product by

having a higher open circuit voltage (OCV) and a higher capacity when used for an

alkaline cell.

The resulting MnO2 can have a slightly lower real density of MnO2 (4.2-4.38 g/cm^3).

This is because of higher level of crystal imperfections, such as combined water, cation

vacancies, twinning faults, and [SO4]- anions. These also contribute to higher OCV and

better performance.

Advantages of this procedure are that it produces a high quality MnO2, the rate of

production can be increased by several fold due to the fact that the current density is

increased, less needed investment in plating equipment and size of the plant needed in

order to perform the operation, and the labor can be decreased because of the shorter

plating cycles and time spent monitoring the process.

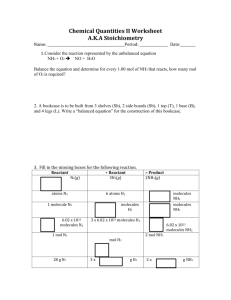

Process

The electrolysis bath has an MnSO4 concentration between 0.2 and 2.0 mol/liter and the

H2SO4 concentration is between 0.1 and 1 mol/liter. Usually this is a 2 to 1 ratio

MnSO4 and the H2SO4, respectively. An anode and a cathode are inserted in the

aqueous bath and are enclosed in a casing forming the cell. The electrodes are connected

by a direct current source, outside the casing. The anode is connected to the positive

terminal of the direct current source, where the oxide is formed, while the cathode is

connected to the negative terminal. The bath is then heated to a temperature of about 120

degrees C with a current density of between 12.5 and 37 A/ft^2 of the anode surface. The

electrolysis bath is replenished continuously as the electrolytes are spent so the

concentration can remain constant at all times. The MnO2 becomes deposited on the

anode and accumulates for approximately 1 ½ to 3 weeks until a thickness of about 1-3

cm is achieved. The anodes are removed and the MnO2 can be removed by mechanical

shock. The MnO2 that is recovered can be crushed, ground, washed, neutralized and

dried conventionally. Then this is used as cathode material along with Zinc and

Potassium Hydroxide.

A comparison to the conventional EMD process is:

- the operating temperature is 80-98 ° C instead of 120-155 ° C

- normal atmospheric pressure

- current density is 5-8 A/ft^2, rarely exceeds 10 A/ft^2 because of passivation

Calculations and Results

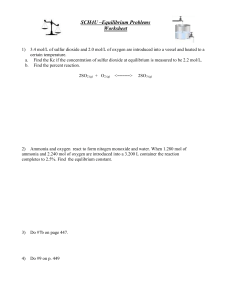

The Mn2+ cation that is floating around in the aqueous solution has some H2O molecules

attached to them. In order for the cation to move into the anode, it has to discharge the

molecules and move across the double layer and enter the anode. The double layer

consists of a plane of charges on the anode and a plane of charges in the solution. A

model that we used for this is called the Helmholtz model. The rate of discharge of

cations across the double layer without a potential difference applied is given by the

Eyring equation

k+(→M)=(kT/h)exp{-ΔGm‡(→M)/RT}

[1]

where k is boltzmann’s constant, T is temperature (K), h is planck’s constant, ΔGm‡ is the

activation Gibbs function at the point where it reaches its maximum, and R is the gas

constant. (→M) means the flow is from the solution to the metal.

As some electrical potential is introduced, the Gibbs function of activation changes

across the double layer and gives us a new equation for the Gibbs function as

‡

m (→M)=

‡

m is

ΔGm‡(→M)+z+FαΔφ(M,S) [2]

the Gibbs function of activation for the motion towards the electrode

with an applied potential, z+ is the cation charge, F is the faraday, α is the fraction of the

distance between the inner helmholtz plate and the outer helmholtz plate where the Gibbs

function is the largest, and the Δφ(M,S) is the applied voltage plus the equilibrium

potential from the reaction.

In the presence of a potential difference , the rate coefficient changes a bit and is

calculated by the equation

+

(→M)=(kT/h)exp{-

‡

m (→M)/RT}

[3]

This is just substituting the newly found Gibbs function with the potential difference for

the equilibrium value.

Once the rate coefficient is found, it can be used to find the flow of current at the anode.

At a region right outside the double layer, there will be an average number of cations per

unit area (σ+ (outside)). The number of cations that are passing through unit area of the

double layer per unit time gives the current density

j+(→M)=z+e σ+

+

(→M) [4]

e is the charge on an electron.

On the inner side of the double layer there is a number of cations per unit area, σ+(inside).

There will be a flow of current away from the electrode as well

j+(←M)=z+e σ+

+

(←M)

[5]

There will be a net flow of current towards the electrode and it will be the difference of

equations [4] and [5]. This gives the dependence of the net current density on the

potential difference.

When the electrode is at equilibrium with the solution, there is a potential difference,

Δφe(M,S). This value can be referenced in a handbook for the reaction

Mn4++2e-→Mn2+

Δφe=1.21

The difference between the actual potential difference and the equilibrium value is known

as the overpotential, η. This leads to the Butler-Volmer equation

j+(→M,net)=je+{exp[-z+α ηF/RT]-exp[z+(1-α) ηF/RT]}

The overpotential is the voltage that is needed in order to overcome the reversal of Mn4+

back to solution as Mn2+. This voltage makes the reaction happen in only one direction.

The Butler-Volmer equation gives a final result of the net flux of cations deposited onto

the electrode.

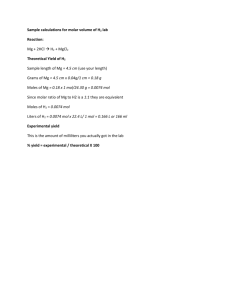

* Mathcad document attached of calculations used in the experiment

Conclusion

This process is definitely better than the conventional method for preparing MnO2. It

gives a higher quality product that has a lower discharge rate when it is placed in the

alkaline cells. It is more cost efficient for companies to produce the material as well.

References

US Patent No: 6585881 B2 Date of Patent: July 1, 2003

Handout we received from you

Ruetschi, Paul. Cation-Vacancy Model for MnO2, Journal of the Electrochemical

Society, Dec. 1984

F 96487

J

Ion rate transfer from Mn2+(aq) to Mn4+(aq)

z 2

1

mol V

R 8.3144

GfMn4 o F z

J

o 1.21V

T 393 K

I

5 1

GfMn4 2.335 10

J

mol

mol K

34

h 6.626

J s

kb 1.38 10

K

23 J

number of charge

H2SO4 .009

MnSO4 .016

mol

L

Mn2 1

U .1 .101 .8

Eyring Equation:

GfM n4

kb T

R T

k1

e

h

24

k1 4.191 10

mol

L

mol

L

at equilibrium at 393 K rate of formation of EMD

Mn2 .016

Hz

5 J

Gtot 2.299 10

mol

z 2

H2( U) U

mol

L

H2 .009

non equilibrium G

This is the charge on the Mn ion (+2)

With potential (non-equilibrium):

.5

U 1.2 1.23 10

Vo( U) U V

Gnon( U) GfMn4 z F Vo( U)

Gnon( U) GfMn4 z F Vo( U)

o 1

Gtot

z F

o 1.191V

o

R T

2 F

1.201V

ln

Mn2

H2

When a potential difference is added to the system the Gibbs energy changes as we move

across the double layer.

5 10

5

0

Gnon( U)

5 10

5

1 10

6

10

5

0

U

Gibbs Energy of Mn2+ going to Mn4+ under a potential

of 1.41 volts.

4 1

Gnon( 1.41) 9.745 10

J

mol

The rate coefficient equation under a potential difference:

Gnon( 1.41)

kb T

R T

k2

e

h

42

k2 3.469 10

k2

k1

rate coefficient under a potential difference of -1.41 volts.

Hz

19

The flux of charges depositing onto the

Anode is given by the following equation:

8.278 10

F 96487

for reduction

J

mol V

GfMn4

T

Q

10

19

jright( Q) kb exp

z

1.062

10

C

7.13

exp

2

0.5

h

2

R T

R T

m

17

solving for Q

The overpotential in this equation is determined by subtracting

the equilibrium potential from the applied voltage.

Given

exp .25 V

jright( Q) exp .25 V

R T

R T

F

F

.068

2

.4 cm

Find ( Q) 3267.5592000000000000 ln 1.4217413562637086053 10

-42

A s

3267.5592000000000000 ln 1.4217413562637086053 10

-42

2

5 kg m

Q 2.848 10

2

s mol

Used

A

A s

J

2 mol

C cm

2

m

2

J

5 kg m

2.848 10

2 mol

2

C cm

s mol

2

m

2 ( Q) J

2 ( Q) J

Given

17

G

GfMn4

T

mol

10

fMn4

T

mol

19

19

kb exp

exp 2 0.5

kb exp

z 1.062 10 C 7.13

z 1.062 10 C inside_concent exp 2 0.5

h

2

R T

h

R T

R T

R T

m

In order to find the net flux across the double layer, we need to have the average number

of cations/unit area on the outside of the OHP and the average number of cations/unit

area on the inside of the IHP. Then you can plug these into the butler-volmer equation

and find a net flux across going back and forth from the anode.

79

Find ( inside_concent)

8.3584769549344291729 10

17 1

outside 7.13 10

2

m

2

m

79

( butler volmer)equation

inside

thx mathcad...

( funny)

8.3584769549344291729 10

2

m

17

19

je_forward z 1.062 10

C 7.13

10

2

k1 exp 2 0.5

m

C k1 inside exp 2 0.5

19

je_backward z 1.062 10

JenetM je_forward exp 2 0.5

1.21 V F

R T

1.21 V F

R T

.050 V F

R T

.050 V F

exp 2 0.5 R T je_backward

54 C

JenetM 1.0716467040505287894 10

2

m s

basically the reaction will not occur at equilibrium.

56

53

2.4481756061374865327 10

10

U .05 .1 6

( U) U V

exp .5 2 5 V

56

10

jNetB_V

F

exp .5 2 5 V F 1.321 108

( R T)

( R T)

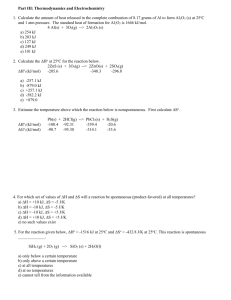

Composition ratios of the solvents in equilibrium

R 8.3144

GfH2SO4 745000

T 393

GfMnO2 465100

GfH2O 237100

GfMnSO4 1080000

GfH2SO4 GfMnO2 GfH2O GfMnSO4

ln( A )

R T

GfH2SO4 GfMnO2 GfH2O GfMnSO4

R T

e

CH2SO4

CMnSO4

14

1.665 10

14

1.665 10

Composition ratios in equilibrium.

Gibbs Free energy of formation for the entire reaction (non-equilibrium):

CbH2SO4 .009

CbH2SO4

CbMnSO4 .016

CbMnSO4

0.563

GfH2 0

2.299 105

GfMnSO4 R T ln CbH2SO4 GfH2 GfMnO2 GfH2O GfMnSO4 R T ln CbMnSO4

Gtot

5

2.299 10