1. introduction

INFLUENCE OF SIZE AND DISTRIBUTION OF COLOR COMPONENTS

ON COLOR VALUES OF WOVEN FABRIC

Assoc. Prof. Krste Dimitrovski, DSc

Helena Gabrijelčič, BSc

University of Ljubljana, Faculty of Natural Science and Technology,

Department of Textiles, Ljubljana, Slovenia

Abstract: Woven fabrics simulation more or less successful presents color values of woven fabrics on the computer screen and on the paper. The color values of woven fabrics depend on color values of differently colored threads, fabrics is made from, and on constructional parameters (the fineness, density and weave). They all contribute to the size and distribution of differently colored component which make the total color appearance and color values of woven fabric simulation. While the fineness and density of thread influence only on size of color component, the weave is affecting both the size and distribution of color component. It is possible to obtain different color values on woven structure only with the change of weave. The present research work is trying to find out how big is the influence of weave on the color values of woven fabrics simulation and consequently to a real woven fabric. In this purpose simulation of woven structures in different weaves and with different colored threads in warp and weft system are prepared. Color deviations between structures in different weaves are theoretically and spectrophotometrically analyzed.

Key words: thread density, influence of weave, colour values, colour differences

1. INTRODUCTION

The colour of fabrics made of differently coloured threads is not influenced only by the colour values of individual components – warp and weft threads and their number but also by a fabric constructional parameters such as the warp and weft threads fineness, density and weave. The influences of these constructional parameters on colour values of woven fabrics haven’t been objectively determined yet, because the problem is very complex. Beside experimental measurements the way to solve this problem is to use theoretical calculations, which are based on geometry of interlacing point. So with analytical estimation of the influence of the threads fineness and density, coupled with equations for determining colour differences in the CIE

L*a*b* colour space, the fractions of individual colour components in a colour repeat can be determined relatively precisely and on that basis also its colour values. But the fact is that in such calculations, except in the number of the warp and weft interlacing points, a weave with its specifies never appears, as do threads fineness and density.

2. THEORETICAL PART

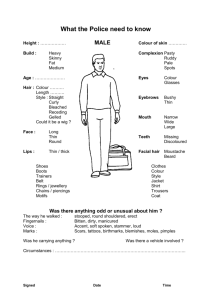

2.1 Basic weaves and geometrical arrangement of their interlacing points

Plain weave is the simplest and the most common weave with the smallest repeat unit. It is characterised by the tightest and maximally possible interlacing of the warp and weft threads. All other weaves have reduced interlacing of the warp and weft threads and larger repeat units,

Figure 1. In these weaves the agglomeration of warp and weft interlacing points increases the size of colour components on fabric and grouping into a narrow areas with prevailing surfaces of one colour.

1

a b c

Figure 1: Schematic presentation of weaves with different size of repeat and agglomeration: a – plain, b – rep 2/4 and c – basket 4/4.

2.2 Colour values of woven fabrics made of different coloured threads

The warp and weft interlacing point is made up of three different colour components: warp thread, weft thread and the space between threads, which all contribute to the colour values of a final fabric, Figure 2.

2

warp weft

1 3

2 1/g w

1/g o

1

3

2 d w d o

Figure 2: Schematically presentation of the density of warp and weft threads (g o

, g w

) and warp and weft diameter (d o

, d w

).

Colour values of colour repeat in the weave can be calculated if taking in consideration colour values of its colour components (warp, weft and space between threads) and constructional parameters of woven structure (threads diameter and warp and weft density). Every single component in one repeat has its surface, which size and shape depend on threads diameter and density. The characteristics of components surface change with a change of constructional parameters. As a consequence the fraction of single colour component of woven fabrics is more or less perceivable and calculated with equation (1):

3

Ui

u on , ot

n ot , oi

n oi u on , wt

n wt , oi u wn , ot

n ot , wi

n wi u wn , wt

n wt , wi

(1) where n is the number of all points in a colour repeat; u on

, ot

is the content of the warp thread colour in the warp interlacing point; n ot

, oi

is the number of the warp points on i colour warp threads; u on

, wt is the content of the warp thread colour in the weft interlacing point; n wt

, oi

is the number of the weft points on i colour warp threads; n oi

is the sum of the warp and the weft points on i colour warp threads = n ot

, oi

+n wt

, oi

; u wn

, ot

is the content of the weft thread colour in the warp interlacing point; n ot

, wi

is the number of the warp points on i colour; u wn

, wt

is the content of the weft thread colour in the weft interlacing point; n wt

, wi

is the number of the weft points on i colour wefts; n wi is the number of the warp and the weft points on i colour wefts = n ot

, wi

+n wt

, wi

.

Colour differences between standard fabric and pattern are then calculated by using the following equation:

3,4

E

* ab

( n i

1

( a

* i

U i

)

a

* s

)

2

( i n

1

( b

* i

U i

)

b

* s

)

2

( i n

1

( L

* i

U i

)

L

* s

)

2

(2)

where a

* v

, b

* v

and L

* v

are colour values of the pattern; a* s

, b* s

and L* s are the colour values of the standard fabric; a* i

, b* i

and L* i

are the colour values of i component; U i

is the content of i component in a colour repeat.

3. EXPERIMENTAL PART

Computer simulations of seven different weaves were prepared by using the Arahne CAD system.

5

All weaves were chosen with the same ratio between the number of warp and weft interlacing points on the face side and identical constructional parameters: plain-1, rep 2/4-2, rep

2/8-3, twill 4/4-4, basket 4/4-5, twill 8/8-6 and basket 8/8-7. The warp threads of pattern are red, weft threads are yellow and the foundation is white with L*, a*, b*, C* ab

and h ab

colour values given in Table 1.

Table 1: Measured L*, a*, b* and calculated C* ab

, h ab colour values of red warp thread, yellow weft thread and white foundation.

Colour value

L* a* b*

C* ab h ab

(

)

Warp-red

47,18

57,65

17,49

60,24

16,87

Weft-yellow

84,71

-7,29

69,69

70,07

95,97

Foundation-white

94,16

4,14

-11,20

11,94

290,29

Three groups of simulation were constructed:

group A with constant warp and weft thread fineness 30 tex and density from initial 30 threads/cm with the reduction of 10 % to 27 threads/cm;

group B with constant warp and weft thread fineness 20 tex and density from initial 40 threads/cm with the reduction of 10 % to 36 threads/cm;

group C with constant warp thread fineness 20 tex and weft thread fineness 40 tex and density from initial warp density 40 threads/cm with the reduction of 10 % to 36 threads/cm and initial weft density 20 threads/cm with the reduction of 10 % to 18 threads/cm.

The fractions of individual threads and of foundation reflectance were determined by calculation on the basis of constructional parameters, which are presented in Table 2. With the help of colour values of warp and weft threads and fractions of colour component (U o

-warp, U w

-weft,

U f

-foundation) the theoretical colour values L*, a*, b*, C* ab

and h ab

of different weaves were calculated.

6,7,8

Colour values of the obtained surfaces were measured with the Spectrolino

SpectroScan spectrophotometer of GretagMacbeth. Light source was D65.

Table 2: Constructional parameters of fabric and calculated fractions of the warp and weft threads and the space between the threads (foundation) for pattern 1 to 7.

Group Pattern

A 1-7

Warp g o d o

(mm)

30 0,304

27 0,304

U o

0,496

0,484 g w

30

27

Weft d w

(mm)

0,304

0,304

U w

0,496

0,484

Fund. Cover

U f factor

0,007

0,032

0,992

0,968

B

C

1-7

1-7

1-7

1-7

1-7

40

36

40

36

0,248 0,4997

0,248 0,494

0,248 0,644

0,248 0,611

40

36

20

18

0,248

0,248

0,351

0,351

0,4997 0,0006

0,494 0,0115

0,354 0,0024

0,350 0,0395

0,9994

0,989

0,998

0,961

Finally, colour differences

E* ab

were defined by means of equations (1) and (2) between plain weave taken as standard and other weaves.

B

C

A

4. RESULTS OF MEASUREMENTS

In the Table 3 and on Figures from 3 to 5 theoretically calculated and measured colour values

L*, a*, b*, h ab

, C* ab

and colour differences

E* ab

between plain weave-1 and other weaves 2-7 are presented. Patterns are plain - Pl, rep 2/4-Re2/4, rep 2/8-Re2/8, twill 4/4-Tw4/4, basket 4/4-

Ba4/4, twill 8/8-Tw8/8 and basket 8/8-Ba8/8. Index c and hatched line means calculated and index m and full line means measured.

Table 3: Calculated and measured colour values L*, a*, b*, h ab

, C* ab

and colour differences

E* ab

between plain weave and other weaves of fabric groups A, B and C in different densities and fineness.

Group

Density

(thr/cm)

Fineness

(tex)

Col. value

Calcul all weaves

Pl Re 2/2 Re 2/8

Measured

Tw 4/4 Ba 4/4 Tw 8/8 Ba 8/8

Tt o

=30 L*

Tt w

=30 a* g o

=30 g w

=30

Tt o

=30

Tt w

=30 a* g o

=27 g w

=27

Tt o

=20 g o

=36 g w

=18

66,16

24,52 b* 43,17

C* ab h ab

(

49,64

) 60,40

E* ab

L* 66,85

24,02 b* 41,84

C* ab h ab

(

48,24

) 60,14

E* ab

L* 65,95

Tt w

=20 a* g o

=40 g w

=40 b*

24,68

43,59

C* ab h ab

(

50,09

) 60,48

E* ab

Tt o

=20 L*

Tt w

=20 a* g o

=36 g w

=36 b*

66,27

24,44

42,96

C* ab

49,43 h ab

(

) 60,36

E* ab

Tt o

=20 L*

Tt w

=40 a* g o

=40 g w

=20 b*

60,57

33,90

35,89

C* ab

49,37 h ab

(

) 46,63

E* ab

Tt o

=20 L*

Tt w

=40 a* b*

62,16

32,21

34,62

C* ab

47,29 h ab

(

) 47,06

E* ab

64,80

25,68

39,45

47,07

56,93

3,75

63,33

24,98

40,46

47,55

58,30

10,38

62,23

27,05

37,82

46,50

54,43

6,45

58,66

34,90

32,64

47,78

43,08

6,20

59,69

33,75

32,45

46,82

43,88

2,88

63,04

26,27

40,09

47,93

56,77

5,39

53,06

28,26

37,42

46,90

52,94

10,32

61,69

30,45

37,16

48,04

50,67

3,83

61,44

30,55

35,24

46,63

49,08

2,16

56,69

38,53

28,88

48,15

36,86

1,21

58,67

36,22

30,15

47,12

39,77

0,73

62,15

27,43

38,50

47,27

54,53

3,40

63,26

29,08

37,69

47,60

52,34

1,15

61,48

31,64

36,09

47,99

48,76

2,28

60,86

32,65

34,53

47,52

46,60

0,43

56,80

39,06

29,00

48,65

36,60

0,70

58,54

36,94

29,74

47,42

38,84

1,50

62,00

29,14

37,71

47,66

52,30

1,55

63,36

28,16

37,02

46,51

52,74

0,00

60,38

33,21

34,86

48,14

46,39

0,00

61,19

32,65

34,81

47,73

46,83

0,00

57,19

39,63

28,90

49,05

36,10

0,00

59,15

35,78

30,48

47,01

40,43

0,00

61,97

30,31

36,69

47,59

50,44

0,00

65,35

24,82

40,48

47,48

58,49

5,20

67,45

18,43

46,74

50,24

68,48

20,24

63,92

24,67

39,97

46,97

58,31

9,89

60,39

30,89

34,83

46,55

48,44

11,04

60,17

32,16

33,08

46,14

45,81

4,57

64,79

24,36

42,05

48,60

59,91

8,49

59,66

33,14

33,03

46,79

44,91

8,08

59,95

34,75

31,86

47,14

42,51

1,90

63,46

26,04

39,77

47,54

56,78

9,22

63,04

29,05

37,84

47,70

52,48

5,05

63,69

26,19

40,16

47,95

56,89

5,66

63,73

27,36

38,27

47,04

54,44

1,53

58,98

34,29

32,38

47,16

43,36

6,62

60,67

32,33

33,49

46,55

46,02

4,83

67,20

18,98

45,03

48,87

67,14

18,77

63,68

26,49

38,81

46,99

55,69

7,76

65,93

21,71

43,88

48,96

63,68

11,89

63,92

26,19

38,51

46,57

55,78

2,53

Tt o

=30, Tt w

=30, g o

=30, g w

=30

L*m

C*m

L*c

C*c a*m hm

Tt o

=30, Tt w

=30, g o

=27, g w

=27 a*c hc b*m b*c

75,00

65,00

55,00

45,00

35,00

25,00

15,00

Pl Re2/4 Re2/8 Tw 4/4 Ba4/4 Tw 8/8 Ba8/8

Weave

Pl Re2/4 Re2/8 Tw 4/4 Ba4/4 Tw 8/8 Ba8/8

Figure 3: Calculated-c and measured-m colour values L*, a*, b*, h ab

, C* ab

of group A.

Tt o

=20, Tt w

=20, g o

=40, g w

=40 Tt o

=20, Tt w

=20, g o

=36, g w

=36

L*m

C*m

L*c

C*c a*m hm a*c hc b*m

75,00 b*c

65,00

55,00

45,00

35,00

25,00

15,00

Pl Re2/4 Re2/8 Tw 4/4 Ba4/4 Tw 8/8 Ba8/8

Weave

Pl Re2/4 Re2/8 Tw 4/4 Ba4/4 Tw 8/8 Ba8/8

Figure 4: Calculated-c and measured-m colour values L*, a*, b*, h ab

, C* ab

of group B.

Tt o

=20, Tt w

=40, g o

=40, g w

=20 Tt o

=20, Tt w

=40, g o

=36, g w

=18

L*m

C*m

L*c

C*c a*m hm a*c hc b*m

75,00 b*c

65,00

55,00

45,00

35,00

25,00

15,00

Pl Re2/4 Re2/8 Tw 4/4 Ba4/4 Tw 8/8 Ba8/8

Weave

Pl Re2/4 Re2/8 Tw 4/4 Ba4/4 Tw 8/8 Ba8/8

Figure 5: Calculated-c and measured-m colour values L*, a*, b*, h ab

, C* ab

of group C.

5. DISCUSSION

5.1 Influence of constructional parameters on fractions of warp, weft and foundation

In experimental work three groups of fabric simulations were constructed. In group A the initial fabric has the same number of fineness and density in both threads systems 30 tex and 30 threads/cm. With such construction the cover factor of a fabric is 0,992 and the foundation influences is nearly negligible with the fraction 0,007. In group B the difference between warp and weft fineness and density of initial fabric is high. The influence of low warp and weft fineness of 20 tex fineness is substituted with high threads density 40 threads/cm, but cover factor is remaining high 0,9994 and the foundation fraction is less than 0,1%. In the third case- group C, the difference between warp and weft fineness is of 20 tex and the between warp and weft density 20 threads/cm. Low warp fineness 20 tex is substituted with high warp density

40/cm, and low weft density is substituted with high weft fineness 40 tex. But as the change of fineness can’t influence on construction as the change of density, the fractions of warp and weft threads differ from each other and they are: U o

=0,644, U w

=0,354, but cover factor remains high

0,998. The density of initial woven structure of each group than changes for 10%, and the influence of this change is observed on colour values of simulations.

5.2 Influence of weave on colour values at different densities

Figures 3, 4 and 5 are presenting the curves of the calculated and measured colour values of simulations from groups A, B and C in different weaves and densities. It is evident that the colour values L*, a*, b*, h ab

and C* ab change differently with the change of the weave from plain through rep 2/4 and 2/8 to twill 4/4, basket 4/4 and twill 8/8, basket 8/8. It can be observed, that influence of weave depends on warp and weft thread density and fineness.

The changes of colour values from weave 1 to 7 are different in groups A, B and C, due to different constructional parameters of initial simulations. In generally patterns of group A have the highest lightness, patterns of group B are the most reddish (highest a* values) and patterns of group the most yellowish (the highest b* values), Table 3. The influence of weave is the most obvious by the patterns of group B, where the difference between fineness and density is very high and

E* ab

values between plain and other weaves are from 2,28 to 18,77 by twill 8/8. In this group is the most evident the similarity of patterns with the same numbers of warp and weft points in one colour repeat. This is shown in Figure 4, where twill 4/4 and basket 4/4 have similar colour values and the same is with twill 8/8 and basket 8/8. The influence of weave is lower by simulations of group A, where density and fineness are numerically equal and

E* ab values between weaves reach 11,89 by basket 8/8. The lowest influence of weave and the lowest

E* ab

values are by C group, where small influence of one constructional parameter is substituted with higher influence of other constructional parameter in a thread system and colour differences are from 0,70 up to 11,04 by twill 8/8.

In all three cases lightness L* is a little increasing when the weave changes. Yellow colour parameter +b* is increasing too and red parameter +a* is decreasing. So in all cases different disposition of interlacing points by twill 4/4 and basket 4/4 with 8 warp and weft points in weave repeat and twill 8/8 and basket 8/8 with 32 warp and weft points in repeat, brings to higher lightness L* and yellow value +b*. These weaves look lighter with more yellow. Moreover, it seems that with agglomeration of red and yellow interlacing points on the surface, the influence of yellow colour is higher in comparison with red colour and the consequence is increasing of lightness and parameter b* by weaves with 4 or more agglomerated points. But from Table 1 it can be seen also that a* value of red thread is 57,65 and of yellow negative –7,29 and b* value of

red is 17,49 and yellow 69,69. So the values b* sum up with the change of weave and points agglomeration, but the values a* subtract because of negative –a* value of yellow thread.

Consequently the changes in hue-h ab

values are very high in basic fabrics in all three groups, because of the relationship h ab

= arc

tg (b*/a*)

.

With reduction of warp and weft threads density, the fractions of warp and weft threads and cover factor reduce as well. By threads density 27 threads/cm in group A the warp and weft fractions are 0,484 and cover factor is 0,968, by density 36 threads/cm in group B are U o

= U w

=

0,494 and cover factor is 0,989 and in group C by density g o

=36 and g w

=18 the fractions are U o

=

0,611 and U w

= 0,35 and cover factor 0,961. By these constructional parameters the influence of weave on colour values of simulations is smaller, what can be seen on right sides of Figures 3, 4 and 5, where the curves are more regular and the values of colour differences

E* ab

between weaves are lower, Table 3.

5.3 Differences between calculated and spectrophotometrically measured colour values

On Figures from 3 to 5 are presented theoretically calculated colour values as hatched straight lines and measured colour values as full curves for simulations of groups A, B and C. The ratio between the number of warp and weft interlacing points and warp and weft fractions are equal for all presented weaves and in consequence the theoretically calculated colour values are equal for all weaves too. But spectrophotometrical determination finds out that different weaves show quite a big colour differences in all colour values, so disposition and agglomeration of interlacing points influence on colour measurements.

Colour measurements considerably differ from theoretical calculation in the case of group B, where patterns have high threads density and very low fineness, above all in colour parameters a*, b* and consequently h ab

. Theoretical calculations predict all colour values better in the case of group A and especially in group C, so, when threads fineness and density are of same number or when low density is substituted with high fineness or vice versa. However the differences are still the biggest in colour parameters a*, b* and h ab and nearly insignificant in colour parameter

C* ab

. This can be observed in smaller colour differences between calculated and measured values in Figures 3-group A and 5-group C.

Deviations between calculated and measured colour values become smaller with a reduction of density of 10% in all three groups. Here the cover factors of fabrics are smaller and for group A is 0,968, B 0,989 and group C 0,961 in comparison with initial A 0,992, B 0,9994 and C 0,998.

Moreover with a reduction of threads density there is a bigger influence of foundation reflectance, which is white. Apart from lower colour differences between weaves, bigger foundation reflectance causes lower differences between calculated and measured colour values and so, better colour prediction for these constructional parameters.

6. CONCLUSIONS AND FURTHER RESEARCHES

The influence of different weaves on colour values of fabric simulations at different threads density is investigated in the experimental work. It is found out that by agglomeration of threads on the fabric surface, i.e. by increasing of individual colour areas in a particular colour repeat

(threads grouping), the colour values L*, a*, b*, h ab

and C* ab

change differently in dependence on the colour of the warp and weft threads and the relation between fabric density and fineness

(group A, B and C):

threads fineness and density influence on fractions of warp, weft, foundation and fabrics cover factor and with their change the influence of constructional parameters on colour values of woven fabrics can be achieved;

predicted colour values of weaves with the same relation between number of warp and weft interlacing points are the same, although the constructions of these weaves are very different, but spectrophotometrically colour deviations between different weaves are high, because of different dispositions and agglomeration of interlacing points on fabrics surface;

with the reduction of fractions U o

, U w

and U f

and cover factor, their influence on colour values of fabric is reduced too, and at the same time there are not such colour differences between different weaves;

the influence of weave is bigger in the patterns with higher density in both thread system and in the patterns, which have big numerical difference between threads fineness and density

(group B), with the decrease of density the influence of different weaves on colour values is reduced;

the biggest deviations between different weaves occur in values, which determinate the hue of a surface, that are values a*, b* and h ab

, but on the other hand the change of weave play almost no role on values of C* ab

and L*, not regarding the density;

theoretical calculations of colour values match better spetrophotometrically determined values by patterns with lower density, where the cover factor is smaller and the foundation reflectance in higher;

the comparison of calculated and measured colour values at changing density indicates that in some weaves at certain density colour values can be better theoretically predicted.

During the further researches in this field the experimental work could be enlarged on other weaves too and detailed investigation of increasing or decreasing, grouping and agglomeration of interlacing points should be done. Consequently, this would provide analysis of deviations between the calculated – theoretically and spectrophotometrically determined colour values and the reason for such deviations.

7. REFERENCES

1

Božič, P. (2002). Vpliv vezave na barvne vrednosti tkanin iz različno obarvanih niti ,

Diplomsko delo, Univerza v Ljubljani, Naravoslovno tehnična fakulteta, Oddelek za tekstilstvo,

Ljubljana

2

Dimitrovski, K. & Gabrijelčič, H (2001). Izračunavanje i mjerenje boja tkanina iz različito obojenih niti, Tekstil , Vol. 50, No. 11, November 2001, pp. 558-567

3

Dimitrovski, K & Gabrijelčič, H. (2002). Napovedovanje barvnih vrednosti žakarskih tkanin =

Predicting of colour values of jacquard fabrics. Tekstilec , Vol. 45, No. 7/8, pp.179-194., ISSN

0351-3386

4

Mc Donald, R. (1997). Colour Physic for Industry , Society of Dyers and Colourists Bradford,

(2 nd

5

ed.), England

Arah Weave

3.2 User’s Manual

1993-2002 Arahne. Available from: http//www.arahne.si

Accessed: 2002-01-15

6

Kožuh, M. (2002).

Vpliv gostote in finosti na barvne vrednosti tkanin iz različno obarvanih niti , Diplomsko delo, Univerza v Ljubljani, Naravoslovno tehnična fakulteta, Oddelek za tekstilstvo, Ljubljana

7

Kysselef, I. (2002). Vpliv gostote na barvne vrednosti tkanin iz različno obarvanih niti ,

Diplomsko delo, Univerza v Ljubljani, Naravoslovno tehnična fakulteta, Oddelek za tekstilstvo

8

Bregar, N. (2002).

Vpliv finosti na barvne vrednosti tkanin iz različno obarvanih niti

,

Diplomsko delo, Univerza v Ljubljani, Naravoslovno tehnična fakulteta, Oddelek za tekstilstvo,

Ljubljana