XII- ()

advertisement

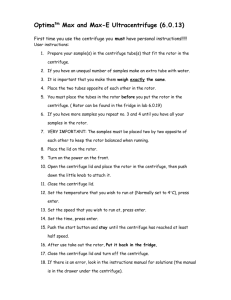

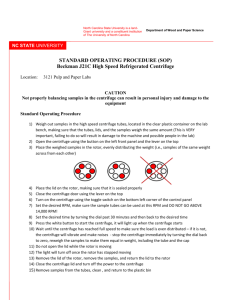

XII. USING A CENTRIFUGE INTRODUCTION A centrifuge is a mechanical device that can subject an experimental sample to a sustained centrifugal force. Tubes containing experimental samples either in suspension or dissolved in a fluid can be "spun" at high speeds for particular lengths of time to achieve particular objectives. In bioresearch labs, these objectives include the separation, concentration, clarification, characterization, and purification of biological and biochemical materials. Material that has accumulated on the bottom of a tube after centrifugation (if any) is called the "pellet", and the overlying fluid is called the "supernatant solution" or simple the "supernate". Material comprising the pellet is said to have "sedimented". The force that the sample is subjected to is expressed as some number times the force of gravity, or relative centrifugal force (RCF). This might be 100 x g or 50,000 x g, etc. The lowest such force attainable in the laboratory (on Earth!) is 1 x g. In this case, a centrifuge is not required; rather, a sample can be left standing in a vertical tube on the lab bench, with gravity causing material to move slowly downward and settle onto the tube bottom. The first isolation of cell nuclei was in fact done in this manner! However, use of a centrifuge dramatically decreases the time required, and provides control over the process. Two major components of a centrifuge are the drive mechanism, and the rotor. The drive mechanism is the source of rotary motion, and is powered by an electric motor, by air pressure, or by oil turbines, depending upon the type of centrifuge. The rotor is the large rotating element of a centrifuge into or onto which samples are loaded. It is driven about a fixed axis (or shaft) by the drive mechanism, with expenditure of large amounts of energy. A loaded rotor must be well-balanced about its axis of rotation, so as to minimize vibration and strain on the shaft and bearings. It is also important for rotors and their associated components to be kept clean and free of debris, both to avoid contamination of samples and to minimize possible rotor corrosion. TYPES OF CENTRIFUGES: (A) SPEED The "speed" of a centrifuge is measured in revolutions per minute, or rpm. Centrifuges are generally divided into 3 categories based on their maximum attainable speed: 1. "Low-speed": to maximum of ~ 5 x 103 rpm. 2. "High-speed": to maximum of ~2 x 104 rpm. 3. "Ultracentrifuges": to maximum of ~105 rpm. (B) TEMPERATURE Centrifuges are either refrigerated or not refrigerated. Refrigerated centrifuges have a built-in refrigeration unit surrounding the rotor, with a temperature sensor and thermostat permitting selection of a particular temperature or a permissible temperature range that is maintained during centrifugation. Many biological samples are temperature sensitive, and centrifugation in the cold (say, 1-4oC) is frequently required. Centrifuges that are not refrigerated are normally used at whatever temperature the room they are in happens to be. This is typically described in research reports as "room temperature" or "ambient temperature", which sounds somewhat scientific. In fact, such terminology means that the temperature was probably somewhere above 20oC but is actually unknown! For purposes of repeatability, it is a good idea to measure "room temperature" in your room with a thermometer. It should be noted, however, that such measurement will provide only an estimate, because the spinning of the centrifuge itself can generate heat that warms up the centrifuge and any samples contained within. If samples must be kept cold and a refrigerated centrifuge is not available, a non-refrigerated centrifuge is frequently pre-cooled and run in a temperature controlled room ("cold-room"). TYPES OF ROTORS There are two fundamental types of rotors: "fixed angle" rotors, and "swinging bucket" rotors. Fixed-angle rotor: In fixed angle rotors the tubes containing samples are placed into shields or openings in the rotor at one particular pre-set angle. The tubes are thus tilted with their tops closer to the shaft than their bottoms, and remain in that fixed position during the run, regardless of rotor speed. Swinging-bucket rotor: In swinging bucket rotors, the tubes are initially vertical. The bottoms of the sample tubes then swing outward freely as the shaft rotates, and the tubes are actually horizontal during the run. By the time the centrifuge stops, however, the tubes have returned to their starting vertical position. Swinging-bucket rotors are particularly useful for sedimenting a sample through a density gradient (see below). A major advantage is that the density gradient solution (usually sucrose or cesium chloride) can be put into the centrifuge tubes vertically, while centrifugation takes place with the tubes in a horizontal position. Sedimented materials then appear as parallel bands running across the width of the tube, whereas, in a fixed angle rotor, the bands would be diagonal. In the latter case there is reorientation of contents upon removal of tubes from the rotor, whereas no reorientation of tube contents occurs with swinging bucket rotors. RATES OF SEDIMENTATION The rate at which a particular type of biological specimen will sediment during centrifugation depends on several factors, including (a) the imposed force (RCF; no. X g), (b) the density (= weight per unit volume) of the specimen, (c) the density of the medium, (d) frictional forces, and (e) the size and shape of the specimen. Regardless of the other factors, a specimen (say, a "particle") will continue to move toward the bottom of a tube at some rate during centrifugation so long as its density is greater than that of the medium through which it is moving. If its density is less than that of the medium, it will not move downward through the medium at all, and, under certain circumstances, the particle might actually move upward! If the density of the particle is equal to that of the medium, the particle will not move in either direction. Enhanced separation and purification of specimens from a mixture can be achieved through use of density gradients. Use of one type of density gradient is illustrated in an exercise below. PARAMETERS OF A CENTRIFUGE "RUN" In lab jargon, the entire process of putting samples into a centrifuge, carrying out the centrifugation itself, and removing samples from the centrifuge is called a centrifuge "run". Every "run" is performed under specified conditions of force, time, and temperature, which constitute the variables or "parameters" of a run. The force as RCF (no. x g) is not always known, and thus parameters sometimes also include the speed setting (RPM), rotor type, and centrifuge model, i.e., all of the information needed if one wanted to repeat the procedure. THE TECH. FACILITY LOW-SPEED "CLINICAL" CENTRIFUGE (Manufacturer: International Equipment Corp., = IEC) In the Tech. Facility you will be using an IEC "low-speed" general purpose clinical centrifuge. This bench-top centrifuge is equipped with an IEC Model No. 215 Rotor (4-Place Rotor). READ THE FOLLOWING INFORMATION ON COMPONENTS OF THE TECH. FACILITY CLINICAL CENTRIFUGE BEFORE PROCEEDING TO THE EXERCISES. CLINICAL CENTRIFUGE COMPONENTS, SUMMARY: shields - cylindrical metal cups that hang downward from the trunnion rings, into which the centrifuge tubes are placed. trunnion rings - metal rings with bar-like extensions on two opposing ends through which the shields are placed, holding them in position while allowing them to swing up and outward once the centrifuge is in motion. rubber cushions - rubber pads placed at the bottom of the shields, acting as cushions for the centrifuge tubes, to prevent breakage during centrifugation. drive mechanism - the source of the rotary motion, either electric motors or air or oil turbines, depending upon the type of centrifuge, that turns the shaft. rotors - centrifuge component, around the periphery of which the sample holders are arranged, that is accelerated to very high rotational speeds. EXERCISE #1: CENTRIFUGE COMPONENTS Locate the centrifuge station in the Tech Facility. Examine and familiarize yourself with the components of the IEC "table-top" clinical centrifuge (see Figure 1). First, make sure that the centrifuge is not running. Then, unlatch the lid if it is not already unlatched by pulling the knob toward you and lifting the lid. Look inside at the rotor, trunnion rings, and shields (do not remove anything!), then re-latch the lid. EXERCISE #2: USING A CENTRIFUGATION NOMOGRAPH A centrifugation "nomograph" is a graphic device that relates rpm, RCF, and "rotating radius" for use in determining centrifugation parameters. Knowing any two of the three, you can determine the third by lining the two known values up along a straight edge and reading the unknown value where the edge passes through its scale. In the Tech. Facility you will be using the IEC "low-speed" clinical centrifuge equipped with a No. 215 Rotor. According to the manufacturer the maximum rpm for this rotor is 4000 rpm, and the maximum relative centrifugal force (RCF) is 1975 x g. Using the Nomograph in your Tech. Facility workbook (next page), plus the given rpm and RCF values for the 215 rotor, determine the rotating radius in centimeters and inches. (Use a straight edge or ruler.) EXERCISE #3: USING A NOMOGRAPH TO DETERMINE RCF Assume that a rotor has a rotating radius of 9.0 cm. Using the centrifugation Nomograph, once again, determine what the RCF will be for the rotor at a speed setting of 10,000 rpm. (Use a straight edge or ruler). EXERCISE #4: WEIGHING TRUNNION RINGS AND SHIELDS Several examples of shields and trunnion rings of various weights and different design are in the drawer labeled "matched pairs - shields and trunnion rings". Take all of these shields and trunnion rings out of the drawer and bring them over to the electronic balance. Prepare a Table in your Tech Facility notebook, in which you record the weight already inscribed on each component. Then weigh each piece on the electronic balance, record these measurements (in same Table), and put all of the components back in the proper drawer. According to the manufacturer (IEC), the shields and trunnion rings have been weighed and matched to 0.5 grams or less. The weight in grams is stamped on each component. Examine the data in your Table. Does the inscribed weight and the measured weight of each piece match exactly? What is the difference in weights? Do the weights of matched components match exactly? Are all of the measured weight variations within the 0.5 gram error limit specified by the manufacturer for matched components? EXERCISE #5: BALANCING CENTRIFUGE COMPONENTS ON THE BEAM BALANCE When using any type of centrifuge, all opposing components should be balanced against each other. For the IEC Clinical Centrifuge with swinging bucket rotor, this means that you should, ideally, check the balance of the opposing sets of trunnion rings, shields, and centrifuge tubes as units (all together). This will detect weight differences due to errors such as possible presence of fluid accidentally dripped into one of the shields, or a missing rubber cushion. In practice, opposing sets of trunnion rings and their shields (with cushions inside) are usually given a balance check without the tubes, and placed into the centrifuge. Later, the tubes containing samples are balanced against each other in a separate operation, before being placed into the shields. If, during a centrifuge "run", there is significant vibration, shaking, or other movement of the centrifuge, this means that opposing components have not been balanced properly. The run must be stopped immediately, otherwise the tubes may break or the centrifuge may be damaged. In this exercise you will check whether trunnion rings and shields of the same labeled weight do indeed balance each other, using the beam balance. Procedure: Remove an opposing set of two trunnion rings with their shields from the Table-top centrifuge. Zero the beam balance, place each ring on a platform with its shield (with cushion inside) standing up in the middle. Without moving any of the sliding beam weights, determine whether they balance one another. If the pointer is only slightly off the mark, that is satisfactory. If not, carefully check that each shield contains one rubber cushion, and that there is no liquid in them (or foreign object). If they do not balance and you cannot determine why, tell the instructor. After balance of opposing sets is verified on the beam balance, weigh each trunnion ring-shield set on the electronic balance. The allowable maximum difference in the weight of opposing sets is 0.5g. Do the weights of the sets match within 0.5g? Carefully place each trunnion ring-shield set back in the centrifuge (IN OPPOSING POSITIONS!). EXERCISE #6: BALANCING SAMPLE TUBES All tubes to be centrifuged must have an opposing tube. The weight of the tube plus its shield and trunnion ring must match that of its opposing tube plus its shield and trunnion ring. The balance of opposing sets of trunnion rings and shields has already been verified. In this exercise you will balance two "sample tubes" against each other. (1) Obtain two 250 ml glass beakers, and balance them against each other on the beam balance. Use the slide weights as necessary, and leave the beakers on the balance. (2) Obtain two blue-cap 15 ml plastic centrifuge tubes. Number the tubes: (1) and (2). (3) Into tube #1, add water using a squirt bottle, up to the 8 ml mark. Cap the tube and place it into one of the beakers on the balance. (4) Uncap the second tube, which is empty, and place it into the other beaker. Also place its cap on the same platform. (5) Using a squirt bottle, fill the empty tube with water until pointer reads zero. (i.e., the two side balance). (6) Once the tubes are balanced, remove the beakers from the balance and move the slide weights back to the zero position. (7) Compare the volumes of water in the two tubes. Are they the same? How do account for the differences, if any? GENERAL INSTRUCTIONS FOR USING A "TABLE-TOP" LOWSPEED CLINICAL CENTRIFUGE Note: This is not an exercise but a general guideline on how to use a clinical centrifuge. Read this carefully. (1) Before using centrifuge, check to see that all opposing trunnion rings and shields are of the same weight. This can be done easily since the weights are inscribed on the trunnion rings, shields. (2) Check that the shields contain rubber cushions. (3) Check that opposing sets of trunnion rings and shields (with cushions) balance each other. (4) Place experimental sample into the centrifuge tube and balance it against another "water balance" tube using the beam balance and squirt bottle (don't forget tube cap!). (5) Place into trunnion rings, positioning balanced tubes opposite one another. (6) Once tubes are in place and all rotor positions are filled, close lid of centrifuge. (7) Set the desired time on timer. (8) Select appropriate speed setting on centrifuge with the speed selection knob; this simultaneously turns on the centrifuge. (9) Once centrifuge is turned on, lid must be kept closed. (10) Do not reopen it until rotor has come to a complete stop at end of run. (11) When centrifuge has stopped, carefully remove tubes without agitating contents. (12) Close lid of centrifuge. (13) Properly dispose of any waste material in appropriate receptacles. (14) Clean up area around the centrifuge. EXERCISE #7: CENTRIFUGATION OF CELLS; PELLET AND SUPERNATE Materials: Two blue-cap conical centrifuge tube One small tube of WARD'S simulated blood (in refrigerator) Pasteur pipet and bulb Digital lab timer Your bottle of PBS (phosphate buffered saline, in refrigerator) 1) Fill a blue-cap conical centrifuge tube to the 4 ml mark with your PBS solution. 2) Look in refrigerator for plastic beaker marked "WARD'S simulated blood", which has already been diluted into PBS (phosphate buffered saline). Take one aliquot (i.e., one microfuge tube with sample) out of beaker to use in this and the next two exercises. 3) Shake the tube of simulated blood to thoroughly mix contents, and add contents to the tube containing 4 ml PBS. Cap tube and mix thoroughly. Save microfuge tube for later use. 4) Using the beam balance, pre-balance the two plastic beakers marked "BB" (located near the beam balance), then balance your tube of "cell" suspension against a similar tube of water (don't forget to include the tube caps). 5) Once tubes are properly balanced remove beakers from beam balance and move slide weights back to the zero position. 6) Check balance of opposing trunnion rings and shields, if necessary. Place the tubes into shields in the centrifuge, positioning them opposite one another. 7) Close lid of centrifuge, and set a digital lab timer (timer labeled "TF-1" or "TF-2") to 3 min. Timers should be in drawer labeled "Timers"! "Punch in" time of 3 min and 00 seconds. If you have not used a timer like this before, practice setting it in advance. 8) Turn on the centrifuge by turning up the speed selection dial stepwise to the #7 setting. Then quickly start timer (push "start" button). 9) Once the timer goes off the centrifugation "run" is complete. Turn off the timer ("Stop/Reset" button) and the centrifuge (set speed selector back to "OFF" position. DO NOT LIFT OPEN THE LID OF THE CENTRIFUGE AT THIS TIME - THE ROTOR IS STILL SPINNING AND THERE IS POTENTIAL DANGER (AS FROM A TUBE BREAKING). IT MUST COME TO A COMPLETE STOP BEFORE OPENING LID! 10) When the rotor is at a complete stop, lift the lid and carefully remove the tube containing the experimental sample from its shield. Place it carefully in test tube rack near centrifuge (do not shake it up). What do you see (exactly)? Is there a distinct pellet? A clear supernate? Record observations in your Tech. Facility Notebook. (NOTE: REAL cells stick to centrifuge tube walls too!) EXERCISE #8: USING A MICROCENTRIFUGE ("MICROFUGE") The Tech Facility microcentrifuge, located near the Table Top centrifuge, is one of the smaller and simpler models available. It has a 6-place fixed angle rotor that holds six 1.5ml microfuge tubes. This particular instrument has a maximum speed of 6,000 RPM, corresponding to 2,000 x g. Most microfuges can be classified as "High-speed"; what speed classification would you give the Tech Facility microfuge? A "run" is started by positioning tubes containing equal volumes opposite each other (each tube must have a balance partner!), and closing the lid. This microfuge will start when the lid is closed, and will begin to stop when the lid is unlatched. NEVER lift the lid up until the microfuge has stopped spinning. Procedure: (1) Draw off and dispose the clear supernatant solution ("supernate") from the tube of "cells" remaining from the previous experiment. Remove fluid down to just where the tube starts to taper. (2) Resuspend the "cell pellet" in the fluid remaining in the tube by squirting fluid up and down with Pasteur pipette and rubber bulb. (3) Using Pasteur pipette, transfer the "cell" suspension into your microfuge tube. (4) Fill another microfuge tube (obtained from drawer labeled "Microcentrifuge Tubes") to the same level (as judged by eye) as the experimental tube, close both caps tightly, and place in opposite positions in Microfuge rotor. (Lid will be unlocked when microfuge is not running). (5) Set timer to 1 minute. (6) Press lid closed to start microfuge "run" and start timer. (7) When timer alarm goes off, press latch that opens lid (and turn off timer). (8) When rotor has stopped spinning completely, open lid, remove both tubes gently and place them in microfuge tube rack (nearby). (9) Examine "experimental" tube. Is there a distinct pellet and a clear supernate? Record observations in your Tech. Facility Notebook. (10) Save the microfuge tube of "cells" for use in a later exercise. EXERCISE #9: CENTRIFUGE VIDEOTAPE View the videotape on "Principles and Practices of Centrifugation". The tape can be found in the file drawer marked "Tech. Fac. Videotapes". Ask for assistance on the use of the Tech Facility VCR and monitor. This video presentation introduces many more aspects of centrifugation and types of centrifuges available, are not covered in this Module. When completed, eject the tape and re-wind it in the separate tape winder. Place tape back into its jacket, and return to file drawer. PREPARATION OF GRADIENTS There are two types of gradients used in centrifugation of cells and subcellular components: continuous gradients and discontinuous gradients. In a continuous gradient, the concentration of the gradient agent (usually sucrose or cesium chloride) varies smoothly from highest at the bottom of the tube to lowest at the top. Production of continuous gradients requires use of special mixing devices. The discontinuous or step gradient is a simpler form of gradient. It involves the addition of successive layers of solutions of various densities/concentrations to a centrifuge tube. The densest solution is first layered (by pipetting) at the bottom of the tube. Slowly and carefully the other successive layers are added in decreasing density, so that there is no mixing between the adjacent layer interfaces. This is facilitated by placing the pipette tip up against the wall of the tube close to the meniscus of each successive layer and moving it gradually upwards with the rising meniscus. Once this is completed, the sample to be fractionated or separated is layered at the top of the gradient in the centrifuge tube. The density of its medium should be less than that of the uppermost gradient layer. Sucrose is a gradient medium commonly used for fractionation and purification of subcellular organelles (e.g., mitochondria, ribosomes) and viruses. Advantages to this type of gradient include: (a) simplicity of preparation, requiring only a series of pre-prepared stock solutions; (b) adjustable layer heights to provide for sufficient spacing between the adjacent densities/concentrations, thus allowing for good separation and easier recovery of fractions that collect at each layer. In density step gradient centrifugation, particles in the sample layer will move downward until the density of the surrounding medium matches or exceeds their own. They will then form a layer or band at that position, and further centrifugation will have little effect. EXERCISE #10: USING A SUCROSE STEP GRADIENT Procedure: 1. If you have not already done so in an earlier module, make up 10 ml of 0.5M and 0.25M sucrose solutions in PBS (phosphate buffered saline). (Use bottle labeled: Tech. Fac. Sucrose; bottle of PBS can be found in the refrigerator) 2. Obtain a blue-cap 15 ml conical centrifuge tube. Using disposable 5 ml pipettes, carefully layer solutions (3 ml each) with the denser one at the bottom. Tip: When layering, hold tube at a slight angle, dribbling the solution down the side of the tube. Layering must be done carefully to minimize mixing of solutions at interfaces. 3. Once the step gradient is prepared, carefully set the tube into a test tube rack. 4. Use your microfuge tube of "cells" from the previous exercise, resuspending the "cells" in PBS by squirting as previously. 5. Layer the sample suspension carefully on top of the sucrose step gradient. 6. Balance the tube containing the gradient against a "water balance" tube (use one already marked "Water Bal" if possible) before placing into the centrifuge. (Refer to Exercise #7, Steps 4-5) Do the volumes in the two tubes match exactly? If not, why not? 7. Once a pair of tubes have been properly balanced, lower them carefully into shields, positioning them opposite one another. Set speed selection dial at setting 7 and centrifuge for 5 min. Remove tube carefully, examine it, and record observations in Tech. Facility Notebook. 8. Return tube to shield and run centrifuge again for 5 min, at setting 7. What do you observe? Explain. 9. When finished, pour tube contents down drain and discard only tubes that had "cells" in them (in proper waste container!). SAVE all water balance tubes for re-use by others (put into rack near centrifuges).