Removal of Chloride and Iron Ions from Archaeological Wrought Iron

advertisement

Removal of Chloride and Iron Ions from Archaeological Wrought Iron with Sodium Hydroxide and

Ethylenediamine Solutions

L.S. Selwyn and V. Argyropoulos

Results are presented on the effectiveness of treating archaeological iron by immersion in an

aqueous sodium hydroxide (NaOH) solution (2% w/v, pH 13.5, room temperature) followed by

immersion in an aqueous 1,2-diaminoethane (ethylenediamine, EN) solution (5% v/v, pH 11.5,

50°C). This study was undertaken to determine the effectiveness of these solutions in removing

dissolved chloride ions and to explain the occasional observation of rapid iron corrosion. Thirtytwo archaeological wrought iron pieces were treated. Some were immersed in NaOH followed by

EN, and, for comparison, others were treated first in EN, then NaOH. Each artifact was treated

separately and solutions were changed on a regular basis. The chloride ion concentration was

determined by potentiometric titration with a silver nitrate solution. For nine artifacts, solutions

were analysed quantitatively for 26 different dissolved elements using inductively coupled plasma

atomic emission spectrometry. The results demonstrate that chloride ions are more effectively

removed from archaeological iron by immersion in NaOH than by immersion in EN. The results

also demonstrate that heavily mineralized iron is more likely to remain unbroken if immersed in EN

before immersing in NaOH. Unfortunately, the corrosion of iron can be stimulated by EN because

it forms soluble complexes with iron(II) ions.

INTRODUCTION

In the early 1980s, James Argo developed a new treatment for archaeological iron at the Canadian

Conservation Institute (CCI) in response to the need to treat iron recovered from a wet, saline, land

site in Red Bay, Labrador [1-4]. This treatment is based on the immersion of iron in a 2% w/'v

aqueous solution of sodium hydroxide (NaOH) at room temperature followed by immersion in a 5%

v/v 1,2-diaminoethane (ethylenediamine, EN) solution heated to 50°C [5]. It was developed to

preserve the shape of the object and to promote long-term stability by removing soluble salts. This

treatment has been applied successfully at CCI. as determined by collection surveys after treatment

[6, 7], Elsewhere, however, there has been only limited use ot EN solutions to treat archaeological

iron [8. 9], In general, this treatment has not found favour because EN is toxic [10] and because

some objects lost their corrosion layer and corroded rapidly [8. 9, 11]. The authors felt that there

was still a need for further study of this treatment approach because several questions remained

unanswered. Was the success of the treatment due to the primary use of aqueous NaOH or was it

due to the combined effect ot using both NaOH and EN solutions? How effective was each of these

solutions in removing chloride ions (Cl-) and in preserving the corrosion layer? Why were there

occasional examples of rapid corrosion problems?

We wanted to evaluate the CCI treatment approach using archaeological iron objects without using

any destructive methods such as exposing the iron to high relative humidity after treatment [11-14],

or dissolving the piece to detect residual chlorides after treatment [12, 15, 16], It was decided to

treat objects separately and analyse individual NaOH or EN treatment solutions quantitatively for

dissolved Cl- ions. One drawback of this approach is that it does not provide any information about

the quantity of Cl- ions remaining in the object. It was also decided to monitor a limited number of

treatment solutions for trace elements using inductively coupled plasma atomic emission

spectrometry (ICP-AES) analysis to find out whether ions other than Cl- were being removed bv the

alkaline treatment solutions.

ICP-AES is a relatively inexpensive technique that is routinely used to analyse quantitatively for

many elements in a solid sample simultaneously. Applications include the analysis of

archaeological material such as ceramics [17], glass [18] and metals [19]. The technique is popular

because it can analyse simultaneously for major, minor and trace elements.

Thirty-two objects were obtained from Ferryland and Renews, two terrestrial sites in Newfoundland

with wet, saline environments similar to the Red Bay site [10]. To find out if the immersion order

made a difference, some objects were immersed first in a 2% w/v NaOH solution followed by

immersion in a 5% v/v EN solution; for other objects, the order was reversed. Treatment was

continued until low Cl- ion levels were measured in successive changes of the treatment solution.

For all 32 objects, the Cl- ion content was determined at each solution change using a

potentiometric titranon with a silver nitrate solution [20, 21]. In addition, tor nine artifacts, each

solution change was analysed quantitatively for 26 different dissolved elements using ICP-AES.

This paper reports the results from the assessment of the effectiveness of these two alkaline

treatment solutions in stabilizing archaeological iron.

BACKGROUND INFORMATION

As iron corrodes during burial, the iron dissolution reaction (Fe → Fe2+ + 2e-) takes place at the

interface between the metal and its corrosion products. In aqueous solutions with pH greater than

about 4. this half-reaction is counterbalanced by the reduction of dissolved oxygen (O2 + 2H2O +

4e- → 4OH-) [22]. At the iron surface. iron(II) ions dissolve, accumulate, and undergo hydrolysis,

Fe2+ + H2O ↔ Fe(OH)+ + H+. which causes local acidification [23, 24]. Electrical neutrality must

be maintained and this is achieved by anions (e.g., Cl-) diffusing in from the surrounding

environment to balance the charge of the Fe2+ cations. Chloride ions, in particular, tend to

concentrate at the interface because of their high mobility and because they are often the

predominant environmental anions, especially in a manne environment. The net result is that the

cracks, pores and open spaces within the corrosion layer on archaeological iron are filled with an

acidic iron(II) chloride (FeCl2) solution, with the Cl- ions strongly concentrated inside the corrosion

layer at the surface of the corroding iron [22, 25, 26].

Immersion treatments for archaeological iron are designed to remove the acidic FeCl 2 solution,

making it less likely to corrode [25], Such immersion treatments

involve placing excavated iron in a liquid, which is usually near-neutral or alkaline, and waiting for

the Cl-ions to diffuse out [27, 28]. Immersion in sodium hydroxide (0.1 to 0.5 M) is recommended

[27, 29-32], and has been noted as more effective than other treatment methods [6, 7, 11, 16, 28, 33,

34], The main driving force for Cl- ion removal is diffusion, with the Cl- ions diffusing from a

region of higher concentration (at the metal/corrosion interface) to one of lower concentration (the

treatment solution).

The corrosion layer and its porosity play an important role in the ability of Cl- ions to diffuse away

from the metal surface into a treatment solution. Inside the corrosion layers, the Cl- ions are

dissolved in the solution filling the interconnecting pores and channels [26]. When an object is

immersed in a treatment solution, it is the porosity within the solid that allows the treatment

solution to diffuse in and the Cl- ions to diffuse out. The rate at which the Cl- ions diffuse out of the

solid depends on the size of the open spaces within the solid, how well they are linked together, and

if continuous pathways exist from the metal/corrosion interface to the outer surface of the object. If

the treatment solution can diffuse in, then the Cl- ions can diffuse out. If the Cl-ions are isolated in

discrete pores, they will be trapped and unable to diffuse out. If Cl- ions are still trapped after

treatment, they may cause problems in the future, especially if a channel opens up, allowing water

and oxygen to enter [25].

ETHYLENEDIAMINE (EN)

Ethylenediamine (H2N-CH2-CH2-NH2) contains two amino groups (-NH2) separated by a twocarbon chain. It dissolves readily in water to form an alkaline solution; the lone pair of electrons on

each nitrogen atom in EN interacts with protons (H+) in water to form either ENH+ (singly

protonated H2N-CH2-CH2-NH3+) or ENH22+ (doubly protonated +H3N-CH2-CH2-NH3+), as

described by:

Whether the predominant species in solution is neutral or protonated depends on pH, as determined

by:

At 25°C, the formation constants K1,H+ for equation (3) and K2,H+ for equation (4) are [35, 36]:

The predominant species is ENH22+ below pH 6.9. ENH- between pH 6.9 and 9.9, and neutral EN

above pH 9.9. In the 5% v/v EN solution (pH 11.5) used in this study, the predominant species is

the neutral EN molecule.

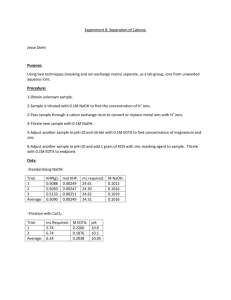

EXPERIMENTAL PROCEDURE

Samples

Thirty-two freshly excavated wrought iron artifacts from the Renews and Ferryland sites in

Newfoundland) were selected by Cathy Mathias, Memorial University, for use by CCI. The 32

objects (identified by their accession numbers) consisted of nails, handles, hooks, knife blades and

other tools. They were all relatively light (10-120 g), except for a hinge (400 g) and a large axehead (2000 g), and had been stored wet after excavation. Many were stored in water at room temperature and the others in 1% w/v NaOH; prior to shipping to CCI, those pieces stored in NaOH were

rinsed with hot tap-water for two days. Additional details about these 32 pieces are available

elsewhere [10]. All the artifacts were shipped wet to CCI and, on arrival, they were stored in a

refrigerator at about 7°C and 70% relative humidity for either seven or 56 weeks, depending on

when they underwent treatment at CCI. (Wet artifacts tend to dry out if stored in a refrigerator with

a freezer that lowers the relative humidity.) The artifacts were photographed and X-radiographed.

The iron pieces were divided into three groups, based on site and storage history. Group 1 contained

12 Renews nails, previously stored in water; in the radiograph, these pieces appeared to be

extensively mineralized. Group 2 contained 10 Ferryland iron tools, previously stored in water; in

the radiograph, these pieces appeared to have a substantial metal core, except possibly artifact

number 94191. Group 3 contained 10 Renews iron tools and scrap iron that had been stored first in

water, then in 1% w/v NaOH; in the radiograph,

these pieces showed substantial metal cores, except for No. 3013 and possibly No. 2995.

Samples from the surface of six artifacts (two from each group) were analysed by X-ray

diffractometry using iron-filtered cobalt radiation, 45 kV, 160 mA [37]. Their colour ranged from

orange to brown to black with one instance of red. Group 1 pieces (Renews 6554 and 6566) were

covered with lepidocrocite [(γ-FeO(OH)], quartz (SiO2). and muscovite [KAl2(Si3Al)Ol0(OH,F)2].

Group 2 pieces (Fern-land 94991 and 97018) contained goethite [α-FeO(OH)], akaganéite [ßFeO(OH)], lepidocrocite, magnetite (Fe3O4), quartz, and albite (NaAlSi3O8). Group 3 pieces

(Renews 3013 and 4859) were covered with lepidocrocite, goethite, quartz and muscovite. Quartz,

albite and muscovite are typical soil minerals; albite is a type of feldspar, and muscovite a type of

mica [38], The iron compounds goethite, akaganéite, lepidocrocite and magnetite have most likely

formed from the corrosion of the iron artifacts, although goethite is also common in soil.

Treatment

Each iron artifact was treated by one of the following three chemical treatments:

Treatment 1, NaOH/EN. Artifacts were immersed first in aqueous 2% w/v NaOH (0.5 M, pH 13.5 ±

0.5) at room temperature for eight to 13 weeks. Next, they were immersed in aqueous 5% v/v EX

(0.75 M, pH 11.5 ± 0.5) and heated to 50°C on working days. Immersion lasted until the Cl- ion

concentration in the last solution change was less than 20 parts per million (ppm), typically between

six and 18 weeks. The decision to transfer an object from NaOH to EN was based partly on the

degree of mineralization and not necessarily on a low chloride ion concentration in the treatment

solution. If, for example, the object had a substantial metal core and the shape of the object was

retained by the inner corrosion layer (e.g., the magnetite layer), then it was left in NaOH until the

outer corrosion layers fell away easily. If, on the other hand, the object was extensively mineralized

and the shape of the object was retained somewhere in the mineralized layer, then these objects

were removed from NaOH after the outer corrosion had softened (as determined by feel) but before

the corrosion started to fall off. There was concern that the shape of the object could be destroyed or

irreparably damaged by continued immersion in NaOH. It lumps ot corrosion products fell off the

object that were required to preserve its shape, they were retained for consolidation.

Treatment 2, EN/NaOH. Artifacts were immersed first in aqueous 5% v/v E.V heated to 50°C on

working days for five to 29 weeks. Next, they were placed in aqueous 2% w/v NaOH at room

temperature, typically for 10 to 23 weeks. The objects were removed from E.V it continued

immersion appeared not to be removing large numbers of Cl- ions or if prolonged immersion in E.V

resulted in the dissolution ot the corrosion layers. Artifacts were removed from NaOH when the Cl ion concentration was less than 20 ppm. or it the mineralized regions were becoming soft and the

outer corrosion layers started to come off.

Treatment 3. EN. Artifacts were immersed in aqueous 5% v/v EN heated at 50°C. Immersion lasted

until the Cl- ion concentration measured in the last solution change was less than 20 ppm, typically

from 17 to 25 weeks.

Table 1 lists the chemical treatment used on each artifact. Treatment 1 was used on five iron pieces

randomly selected trom Group 1, six pieces randomly selected from Group 2. and one piece (3004a)

chosen trom Group 3. Treatment 2 was used on six pieces randomly selected trom Group 1, tour

pieces randomly selected from Group 2, and one piece (3004b) chosen from Group 3. Treatment 3

was used on 10 pieces from Group 3.

Artitacts were immersed in the first treatment solution, each in a separate container. All the

treatment solutions were changed at the same time, usually weekly during the first month (because

many of the objects became obscured as dirt, soil and other material dissolved and coloured the

treatment solutions), then monthly thereafter. For Cl- ion analysis, a 30 mL sample was collected

prior to each solution change: for ICP-AES analysis, 300 mL samples were collected prior to

solution changes for nine artifacts. The Cl- ion content in the samples was determined using a

potentiometric titration with silver nitrate [20, 21]. These were usually analysed over a one- or twoday period, after standards had been prepared and the titration checked, with up to 30 samples being

analysed per day [10]. The samples and standards for ICP-AES analysis were prepared and

analysed for 'total metals' by Seprotech Laboratories in Ottawa [10]. The decision to change

treatment solutions from NaOH to E.V (or vice versa), or to stop treatment.

was usually based on the detection of low Cl- ion concentrations (e.g., below 20 ppm) from several

consecutive treatment solutions.

The treatment solutions were made up with deion-ized water (pH 6.0 ± 0.2) and with NaOH pellets

(Fisher Scientific, American Chemical Society (ACS) certified) or anhydrous ethylenediamine

(Fisher Scientific, 98-100%). Artifacts were always completely immersed in the solutions. Table 1

lists the solution volumes and the ratios of solution volume to surface area used for each artifact.

For practical reasons, a 5:1 mL:cm2 ratio (treatment solution volume : estimated surface area) was

used where possible, although a ratio of 20:1 mL:cm2) is often recommended to avoid appreciable

changes m solution composition during experiments [39]. The containers (glass for EN solutions,

plastic for NaOH solutions) were covered with plastic lids or sealed with a polyethene-based plastic

wrap secured with a rubber band. All the containers were placed in a large fume-hood. The EN

containers were placed on hot plates and the temperature was adjusted to maintain 50 ± 10°C for

about eight hours during working days. For safety reasons, the hot plates were turned off during the

night or at weekends. The NaOH solutions were left at room temperature (about 22°C).

After chemical treatment, the objects were rinsed for two to nine weeks in hot (~50°C) deionized

water to remove residual chemicals and to lower the pH of the surface of the artifact to 7. Whenever

the water was changed (about once every two weeks), the surface pH was checked with pH

indicator paper. After hot washing, the artitacts were immersed in an acetone (propa-none) bath for

three to 12 days to remove residual water. After air-drying, most of the artifacts were mechanically

cleaned to reveal the shape of the object, using hand tools and/or an air-abrasive unit (abrasives:

aluminium oxide 27 µm, silicon carbide 50 µm, glass beads 27 µm). Following cleaning, most of

the artifacts were coated with tannic acid [40]. Artifacts that had broken into two or more pieces

were glued together using either a cellulose nitrate adhesive (H.M.G. Heat and Waterproof

Adhesive, H. Marcel Guest Ltd) or a mixture of approximately equal amounts of Acryloid B-72

(Rohm & Haas) and acetone. Treated artifacts were packed in Ethafoam, placed in perforated

polyethene or polypro-pene bags, and returned to Newfoundland.

EXPERIMENTAL RESULTS

Artifacts from Group 1 (Renews) were extensively mineralized; the outer material consisted of a

mixture of

Table 1 Experimental details of the chemical treatmentsa

Notes

a. The times are listed for each treatment step, including the initiai storage in water at CCI the

alkaline treatment, rinsing, and dewatering in acetone.

b. A single value refers to both treatment solutions, and two values refer to solution 1. then solution

2

c. After the treatment in the acetone bath, additional treatment comprised one day in 5% v/v EN

followed by three weeks hot washing (water, 50°C) and eight days in acetone.

small rocks, sand (quartz), soil minerals and iron corrosion products. For Group 1 objects, it was

important to retain the outer corrosion layers during the chemical treatment and then rely on the

later use of controlled mechanical cleaning to expose the shape expected to lie beneath the outer

material in a dense zone of magnetite (and not retained by what little metal remained). Artifacts

from Group 2 (Ferryland) and

Group 3 (Renews) contained substantial iron cores. The outer material, thinner than that of Group 1,

also consisted ot a mixture of small rocks, sand, soil minerals and iron corrosion products. For these

Group 2 and 3 objects, it was not so important to retain the outer surface material because the shape

of the object was expected to be well outlined by the remaining metal core.

Table 2 summarizes the experimental observations and results from Cl- ion analysis. The second

and third columns list information about how well an object survived immersion in NaOH and/or

E.V solutions, determined by noting whether or not the object remained in one piece. The core

refers to the main object, describing the number of pieces of remaining metal with attached inner

and outer layers. The clumps refer to pieces detached from the original. When the number of pieces

was greater than four, the number is listed simply as 'many'. The behaviour of the objects in NaOH

and in EN solutions is discussed in more detail below.

Effect of NaOH solutions on objects

During immersion ot the extensively mineralized Group 1 objects in NaOH first (treatment 1), the

outer corrosion and soil layer softened, sometimes in as little as two weeks. In four of the five

pieces, large clumps broke from the main piece during their 10-13 weeks in NaOH. In two of these,

large clumps of outer material fell otf to reveal evidence ot a hollow interior and a thin strip ot

metal at the centre. The detached clumps usually maintained their shape in NaOH solutions. In

object 6554, a crack was noted in the outer layer after eight weeks in NaOH and so it was removed

trom NaOH to prevent further damage. During immersion of Group 2 and Group 3 objects with

substantial metal cores in NaOH (treatment 1), the outer layer ot corrosion and soil usually softened

and tell off as many small pieces. The inner corrosion layer and the metal core appeared to remain

unchanged. For these objects, the removal of the outer layer was considered beneficial because it

uncovered the layer that approximated to the shape ot the object.

During immersion of Group 1 objects in NaOH second (treatment 2), an interesting result was

observed. Five of the six objects remained unbroken during immersion in NaOH for 10-23 weeks.

These objects remained unchanged in shape even though the hard outer layer ot corrosion and soil

softened during immersion in NaOH. Object 6749 broke in half, but the outer layers on each half

remained intact. During immersion of Group 2 and Group 3 objects with substantial metal cores in

NaOH second (treatment 2), the objects usually remained unchanged.

Effect of EN solutions on objects

During immersion in EN solutions, part of the outer corrosion fell off some objects to reveal an

underlying

black layer which was easily removed during handling; sometimes black material settled at the

bottom of the container. Table 2 lists those objects where the loss of the black layer in E.V was

observed. For object 94991, so much ot this inner layer came off that the metal surface was

revealed; the black sludge that formed at the bottom ot the container was analysed and identified as

magnetite [37].

For some iron objects immersed in EN, the solutions became murky, with what looked like an

orange or red-brown suspension of colloidal or particulate material. Those objects tor which the E.V

solutions appeared murky are also listed in Table 2. Sometimes, an orange sediment formed at the

bottom of the container. For objects 94549 and 97018, samples of the cloudy EN solutions were

collected, centnfuged for 15 minutes, and the solid was analysed by x-ray diffraction (XRD). Lepidocrocite was identified from 94549 and lepidocrocite, goethite and magnetite were identified from

97018 [41].

During immersion of Group 1 objects in EN in treatment 2, the outer layer of corrosion and soil did

not soften as was noted for similar material when placed in a NaOH solution. As listed in Table 2,

five out of the six Group 1 pieces remained complete and no clumps of corrosion fell off. even after

immersion in EN for up to 29 weeks. This was desirable because the shape of the object was

expected to be preserved within the layers of corrosion and soil. None of the solutions were murky.

During immersion of Group 2 objects in EN in treatment 2, object 99441 remained unchanged but

the other three suffered varying degrees of loss of their corrosion layers. Most of the solutions

became murky. For object 99440, which remained in an EN solution for six months, most of the

outer layer remained in place with only a small loss of the black inner layer. For object 94191, some

bare metal was exposed after five weeks in EN: when this object was transferred to NaOH, the

black layer stopped coming off and a brown layer started to form. Finally, for object 94991, after 13

weeks in an E.V solution, it was decided to stop treatment because bare metal was exposed. During

immersion of Group 3 objects in E.V in treatment 2, typically for 17-25 weeks, these pieces

remained essentially unchanged. (Group 3 objects had been pre-treated for two months in 1% w/v

NaOH in Newfoundland.) None of them fell apart, none of the solutions became murky, and no

inner black layer was exposed; only one clump of corrosion fell off object 2995.

During immersion of Group 1 objects in EN second in treatment 1, further disintegration of the

objects was observed. Many of the clumps of corrosion and soil

Table 2 Experimental observations and results from chloride ion analysis.

Notes

a. The number of pieces after each treatment solution. The first figure is the number of core pieces

and the second the number of outer clumps.

b. Entry indicates whether the inner black layer wiped off easily in EN.

c. Entry identifies murky EN solutions.

d. Total weight of Cl- removed in either NaOH or EN. The '=' symbol is used where the chloride

content is approximate because one NaOH solution was not analyzed.

e. Percentage of chloride ions removed in NaOH

f. Initially black material came off. but this eventually stopped

g. Broke in half during hot wash h. Disintegrated during hot wash

i. Active corrosion noted after treatment

broke apart into smaller pieces. Object 6554 (which cracked m NaOH; lost one clump from its shell

but otherwise remained intact. Most of the EN solutions turned murky, and the inner black

corrosion could be easily wiped off. During immersion of Group 2 objects in EN in treatment 1, five

of the six EN solutions became murky and the inner black layer (exposed during earlier immersion

m NaOH) started to come off. The EN solutions remained murky and the black continued to come

off for objects 94549 and 97018 (six-weeks in EN) and for object 94546 (18 weeks in EN). For

objects 94419 and 99429, the black material stopped coming off the objects during their eight

weeks in EN, but it was difficult to tell if the solutions were murky or just highly coloured. After

object 94549 had finished treatment, including hot washing, rinsing m acetone and air-drying for

eight days, it was returned to an EN solution for 24 hours to find out how the object reacted to EN

after it had been rinsed and dried in air. For the first few hours, the surface remained unchanged but

then the black material started to come off again.

Dissolved chloride ions

Table 2 summarizes the total weight of Cl- ions released into either the NaOH or the EN solutions

for each artifact. The final column lists the percentage of Cl- ions released in NaOH relative to the

total released. Figures 1, 2 and 3 show (for objects in Groups 1, 2 and 3, respectively), the weight of

Cl- ions (in milligrams) in the treatment solutions as a function of time. Data points in the graphs

are the sum of the weights of Cl- ions in each solution. The error in each data point was calculated

by summing the squares of the error for each measurement and then taking the square root [42]. The

concentration of Cl- ions (in ppm) was determined by titration of samples collected prior to each

solution change. Because individual objects were not all treated in the same volume of treatment

solution, it was necessary to convert from Cl- ion concentration (ppm) to Cl- ion weight (mg) to be

able to compare Cl- ion results between objects. The conversion was made by multiplying the

concentration in ppm by the volume of the treatment solution (in litres). The errors in weight of Clions were calculated by multiplying the error in ppm (±3 ppm [10]) by the appropriate sample

volume (in litres).

In general, when objects were immersed in NaOH first, it took about three months before the Cl- ion

concentration dropped to low levels. When the objects were then transferred to an EN solution for

another two months, only a small additional weight of Cl- ions was

removed. In contrast, when objects were immersed in EN first, many of the objects needed about

seven months before the Cl- ion level dropped to low values. Furthermore, when these objects were

transferred to a NaOH solution, it was often observed that roughly the same weight of Cl- ions was

released into NaOH during immersion for three to six months as had already been released in EN.

Figure 1 graphs the Cl- ion results for the 11 extensively mineralized Group 1 objects; Figure 1a

shows the results for objects treated first in NaOH and Figure 1b shows the results for objects

treated first in EN. Comparing the overall slopes for objects in NaOH with objects in EN shows

that, in general, the Cl- ions are released faster into NaOH than into EN solutions. For the five

objects treated first in NaOH, over 87% of the total Cl- ions were released into the NaOH solution.

For the six objects treated first in EN, only part of the total Cl- ions was released into the EN

solution, with

Figure 1 Weight of chloride ions removed from the objects as a function of time for Group 1

objects from Renews: (a) objects treated first in NaOH; (b) objects treated first in EN. Error bars

are approximately the same height as or smaller than the symbol size. The numbers refer to the

accession number of the object.

more released into NaOH. For object 4824. 8% of the total Cl- ions were released in EX, with the

remaining 92% released in NaOH. For objects 6737, 6741 and 6749, approximately equal weights

of the total Cl- ions were released in EN and NaOH. For objects 6566 and 6569, the results are not

considered meaningful because such a small total weight of Cl- ions was removed.

Figure 2 graphs the Cl- ion results for the 10 Group 2 objects with substantial iron cores; Figure 2a

shows data for objects treated first in NaOH and Figure 2b shows data for objects treated first in

EN. In general, the Cl-ions appear to be released into NaOH faster than into EN solutions. For the

six objects treated first in NaOH. over 89% of the total Cl- ions were released into the NaOH

solutions. For the three objects treated first in EN, then NaOH, roughly equal weights of Cl- ions

were released into each solution type.

Figure 3 contains the Cl- ion results for Group 3 objects with substantial iron cores; Figure 3a shows

the results for object 4859 which is representative ot the other objects in the group. All the graphs

have similar

Figure 2 Weight of chloride ions removed from the objects as a function of time for Group 2

objects from Ferryland: (a) objects treated first in NaOH; (b) objects treated first in EN. Error bars

as Figure 1.

shapes, with the weight of Cl- ions removed generally increasing with time; only rarely did a curve

flatten (as often seen in Figures 1 and 2). For all 10 objects, the total weight of Cl- ions removed

was always less than 40 mg: these objects had been pre-treated tor two months in 1% w/v NaOH in

Newfoundland. Figure 3b graphs the Cl- ion data for Group 3 objects 3004a and 3004b, each ot

which contained a substantial amount of metal, was covered with similar outer crusts and, in

common with other Group 3 objects, had been pre-treated in NaOH. Pieces 3004a and 3004b were

treated differently from other Group 3 objects and differently from each other. Object 3004a was

treated first in NaOH, then EN while object 3004b was treated first in EN, then NaOH. Almost six

times more Cl- ions were removed from 3004a than 3004b. suggesting that, over the same penod of

time, the 2% w/v NaOH solution was more effective than the 5% v/v EN solution in promoting the

release of Cl- ions.

Figure 3 Weight of chloride ions removed from the objects as a function of time for Group 3

objects from Renews: (aj results for one object fthe other nine objects nave similar curves) treated

only in EN solutions at CCI; Ib) results for object 3004a and 3004b, Where error bars are not

shown, they are approximately the same height as or smaller than the symbol size.

The decision to stop treatment was usually made when the Cl- ion concentration reached low levels

in successive changes of the treatment solutions, typically <20 ppm. This approach should be used

with caution because the concentration of Cl- ions depends on the volume of the treatment solution

used. Compare, for example, two treatment volumes, one 500 mL and one 200 mL. each containing

20 ppm Cl-. More Cl- ions (10 rag) will have been removed from the object immersed in 500 mL

than from the object immersed in 200 mL (4 mg). The final Cl- ion data were not analysed and

graphed until after the treatments had been stopped. In hindsight, the data should have been

analysed and plotted before making the decision to stop treatment. It is possible that some of these

objects (particularly Group 3 objects) still contain residual Cl- ions and may suffer corrosion

problems in the future.1

Dissolved metal ions

The concentrations (in micrograms per litre, µg.L-1) of 26 elements were analysed by ICP-AES and

reported by Seprotech Laboratories. For each solution, the weight of each element analysed was

calculated by multiplying the concentration by the appropnate solution volume. The errors in weight

for each element were calculated from the appropriate percentage error provided by Seprotech. No

correction was made for background level of the elements in treatment solutions because they were

assumed to remain constant, given that all solutions were prepared from stock solutions of NaOH or

EN. The weight of each element removed by each solution change of NaOH or EN was added

together to calculate a total weight removed by either solution. For each element, the results were

then plotted against time. For many of the elements analysed, there was an initial increase followed

by a flattening of the curve. The ICP-AES results for the five elements detected in significant

amounts are listed in Table 3. For each object, the results are reported as the total weight and

percentage of an element removed into NaOH or into EX. Except for iron, the general trend for

these elements was for more of an element to be dissolved into the first treatment solution in which

the object was placed.

The results for iron are particularly interesting (Figure 4); remarkably little iron was detected in the

NaOH

1

In 2003, Cathy Mathias surveyed the condition of these artifacts and found that they were stable

except for two from Group 1 13346, 6563), one from Group 2 (9944V), and two from Group 3

13007, 4859).

solutions while more was detected in EN solutions. In Figure 4a (NaOH first), there was relatively

little iron detected in the NaOH solutions. But when the objects were transferred to EN, the weight

of dissolved iron increased. For objects 94419 and 99429, more iron was dissolved in the first EN

solution than in the second. In Figure 4b (EN first), the iron level increased and then levelled oft in

subsequent EN baths as less iron dissolved in later solution changes. Once the objects were

transferred to a NaOH solution, very little additional iron dissolved.

DISCUSSION

Diffusion of chloride ions

In this study, the approach was to treat each of the 32 iron objects in separate solutions, with regular

changes in the treatment solution, and quantitatively monitor the Cl- ion concentration over time.

The overall observation was that more Cl- ions were removed more quickly from iron treated in a

NaOH solution than from iron treated in an EN solution. When NaOH was used first to treat Group

1 and 2 objects, immersion for about three months was needed before low Cl- ion levels were

achieved, with relatively few additional Cl- ions removed in the following two or three months of

immersion in an EN solution. In contrast, when EN was used first to treat Group 1 and 2 objects, an

immersion of up to seven months was often needed to achieve low Cl-ion levels in solution and, for

many of these objects, this only accounted for about half of the total chloride ions removed. The

remainder were removed when the objects were transferred to NaOH solutions.

The authors wanted to use the diffusion model developed in 1978 by North and Pearson to assess

the Cl- ion data [28], For their diffusion model, North and Pearson assumed the Cl- ions were

initially evenly distributed within the corrosion layer and no Cl- ions were present outside the

corrosion layer (i.e., in the treatment solution). They also assumed that the Cl- ions were diffusing

through a constant distance (i.e., the corrosion layer) and that the solid matrix remained physically

unchanged. Their model provided a general expression for the diffusion of Cl - ions from objects of

any shape over a short time. The expression predicted that when the amount of Cl - ions in solution

was plotted against the square root of time (t1/2), the resulting graph would comprise a straight line

(passing through the origin) with a slope proportional to the Cl- ion diffusion constant. For Cl- ions

diffusing through the solution in

Table 3 Experimental results from ICP-AES analysis. a

Notes

a. Table gives the weight and percentage of the elements phosphorus (P), ron (Fej. aluminium (AI),

calcium (Caj. and potassium (K) removed in NaOH or EN; n.d. indicates that the element was not

detected. b. Objects are from Group 1 13346, 4824, 6569), Group 2 (94419. 99429. 99441). and

Group 3 (2279, 3004a. 3004b).

the pores of a corrosion layer, the magnitude of the diffusion constant reflects the rate at which Clions move through this solution, which in turn depends on the pore size, channel size, and their

connectivity- within the solid [27]. Diffusion constants are smaller for ions diffusing through a

solution within the pores of a solid (e.g., a corrosion layer) than for ions diffusing through an open

solution.

In our Cl- ion data, the authors often observed a delay before any Cl- ions were detected in solution,

and many curves of Cl- ion versus square root of time were S-shaped instead of linear. Figure 5

contains several examples of our data, showing that the extrapolated lines did not pass through the

origin, but instead crossed the x-axis at a specific time. For most objects from Groups 1 and 2

treated first in E.Y, approximately linear results were observed. In contrast, however, tor most

objects from Groups 1 and 2 treated first in NaOH, and Group 3 objects treated in EN, non-linear

curves were observed. Elsewhere, however, the authors have provided another diffusion model,

different from that of North and Pearson, that can be used, at least qualitatively, to

describe the S-shaped behaviour and the delay time observed m some of our data [43]. This other

model is based on the solution to the diffusion equation for the limiting case where the Cl- ions are

initially concentrated at the interface between the iron and the corrosion layer. This abrupt starting

distribution can be viewed as the opposite to the uniform starting distribution used by North and

Pearson. These diffusion models were not use to interpret the results because of the wide variation

in the Cl- ion data as a function of time for the different artifacts. Another reason was that many of

the objects in this study underwent a significant physical change (e.g., pieces broke open) during

immersion, and diffusion models can only be applied when the conditions under which they are

derived (e.g., fixed diffusion distance) remain unchanged.

Other dissolved ions

High levels of phosphorus were detected in the treatment solutions and these are most likely due to

twentieth-century contamination by agricultural activity.

Figure 4 Weight of iron removed from the objects against time for six objects: (a) objects treated

first in NaOH; (b) objects treated first in EN. Error bars as Figure 3

Figure 5 Weight of chloride ions removed from the objects against the square root of time: (a)

results for Renews objects, two from Group 1 (6563, 6741) and one from Group 3 (2995); (b)

resuits for two Group 2 Ferryland objects. Error bars as Figure 3.

The phosphorus is probably present in solution as phosphate (PO43-) ions which are known to be

adsorbed onto soil particles, especially acidic soils, and are not easily removed by leaching with

rainwater [44. 45]. However, exposure to high levels of hydroxyl ions during treatment in NaOH or

EN probably displaces the adsorbed phosphate ions, leading to the high levels in solution.

Relatively high levels of aluminium were also detected; these are probably the result of the

dissolution of soil minerals associated with the outer corrosion layers; muscovite was identified on

Group 1 and 3 objects, and albite was detected on Group 2 objects. The higher levels of aluminium

from Group 2 objects may reflect a higher solubility of albite than muscovite in alkaline solutions.

Higher levels ot magnesium, calcium and potassium were detected and are probably from seawater

contamination of the burial environment. It is not known whether the other trace metal ions detected

in sample solutions are from the burial environment or from the metal itselt. More analvsis of the

metal content of the objects and a more detailed study of the burial environment would be needed

for a better understanding of the ICP-AES results.

Effect of temperature

The solubility of iron oxides and oxyhydroxides increases with increasing temperature in alkaline

solutions (because of the increased solubility of anionic species such as Fe(OH)3- [23, 46]) and so

the use of higher treatment temperatures may dissolve more material from the corrosion products

and increase the porosity of the remaining material. Higher treatment temperatures will also cause

the metal and corrosion products to expand and this may also increase the porosity of corrosion

layers. In our experiments, the use of EN treatment solutions at ~50°C rather than at room

temperature may

have expanded the corrosion layers and dissolved additional iron corrosion products. The etfects ot

using a higher treatment temperature are probably responsible for additional chloride being

removed from objects placed in EN at ~50°C after a long immersion in NaOH at room temperature.

Role of Fe(II) ions

Turgoose predicted that placing archaeological iron into an alkaline solution would cause Fe2+ ions

to precipitate within the corrosion layer, thereby restricting the diffusion of Cl- ions out of the object

[22, 26]. More recently, Turgoose et al. have shown that Cl- ions diffuse out more easily after

archaeological iron has been immersed in a NaOH solution [47. 48], They attributed this beneficial

effect to rapid electrochemical reactions occurring at the iron/corrosion interlace which cause

fissures and cracks to develop in the corrosion layer on a microscopic scale. It is likely that the

cracks and fissures are caused by the precipitation of small amounts of solid corrosion products

within the corrosion layer. These rapid processes are thought to be oxidation-reduction reactions

involving iron metal, magnetite. and iron(II) species. The reactions occur on electronically

conducting surfaces (e.g., magnetite) and cause irreversible changes and softening of the corrosion

layer [48].

Recent electrochemical studies of iron in NaOH solutions (pH 11-13) have detected electrochemical

activity in passive iron oxide films and confirmed that oxidation-reduction reactions occur easily

between the iron(II) and iron(III) oxidation states [49-53], These studies have also shown that there

is little or no dissolution ot the corrosion products in the passive layer (e.g.. FeO(OH), Fe3O4 and

Fe(OH)2) in these NaOH solutions under oxidizing or reducing conditions. Under reducing

conditions, the passive film does not dissolve but instead undergoes a solid-state conversion from

Fe(III) compounds to lower oxidation-state compounds (perhaps including Fe(OH)2) which have a

porous structure.

The advantage ot these irreversible changes and softening of the corrosion layer is the increased

ease with which Cl- ions are removed from archaeological iron. But there are disadvantages, too. An

increase in porosity tends to decrease the mechanical integrity of the corrosion crust, making it

more likely that the corrosion products can break off. The authors observed this problem with

artifacts placed first in NaOH treatment solutions, especially the extensively mineralized Group 1

artifacts.

Effect of pH

One reason that alkaline solutions have proved more effective than near-neutral solutions for

removing Cl-ions from archaeological iron is an increased dissolution of material at higher pH.

Alkaline solutions tend to be good at dissolving both inorganic and organic material. The solubility

of quartz, for example, increases markedly above pH 9 [54, 55]. Greasy dirts, fatty compounds, oils,

and other organic material (e.g., cellulose and protein) are broken down in alkaline solutions by

saponification into water-soluble compounds such as soaps and alcohols [56].

Another reason tor the effectiveness of alkaline solutions is their ability to passivate an iron surface.

The corrosion rate of iron slows significantly if the pH at the metal surface is high enough to

precipitate Fe2+ ions as Fe(OH)2 (which has a minimum solubility at pH 11 [24]) and, once formed,

is easily oxidized and hydro-lysed to Fe(OH)3 [57]. In general, the iron corrosion rate slows as the

pH is increased above nine and drops to a negligible rate above 12 [58]. As long as archaeological

iron is corroding during immersion, the Cl- ions are prevented from diffusing out because they are

attracted to the Fe2+ ions being generated by the corrosion process. If the corrosion can be stopped,

for example by passivating the iron at high pH, then the potential gradient generated by Fe 2+ ions is

removed. The Cl- ions no longer act as counterions and are able to diffuse out ot the corrosion layer

into the treatment solution [43]. In this study, archaeological iron was immersed in an alkaline

solution of either NaOH (pH 13.5) or EN (pH 11.5). Considering only the influence of pH, the

NaOH solution should be more effective than the EN solution in passivating the iron and allowing

the Cl- ions to diffuse out.

The pH of the solution also affects whether or not Cl- ions are adsorbed. Under acid conditions, Clions are adsorbed onto iron oxide surfaces which have a net positive charge because of the excess

H+ ions in solution [24]. The adsorption of Cl- ions onto iron oxide surfaces decreases in neutral and

alkaline solutions because the rising pH shifts the net surface charge on the iron oxide surface to be

negative [59, 60]. Therefore, when archaeological iron covered with iron oxides or oxyhydroxides

is placed in highly alkaline solutions (e.g.. NaOH or EN solutions), the number ot Cl- ions that

remain adsorbed on an oxide surface is expected to below.

Duprat et al. have compared the effectiveness of NaOH and EN solutions (each solution at pH 11

and containing 3% w/v NaCl) for inhibiting iron corrosion

[61. 62]. Thev observed that the EN solution was more effective than the NaOH solution in slowing

iron corrosion. They attributed the overall effectiveness of these two solutions to their alkalinity and

their ability to form a passivanng film on iron. They attributed the increased effectiveness of EN

over NaOH (at the same pH and Cl- ion concentration) to the EN molecule contributing an

additional inhibiting effect by being adsorbed onto the metal surface [63, 64].

Adsorption of EN

Ethylenediamine can act as a corrosion inhibitor for iron (slowing the corrosion rate of iron)

because EN can be adsorbed onto oxide-free [65] and oxide-covered [66] iron surfaces.

Ethylenediamine slows corrosion by forming a new layer when adsorbed onto bare iron or by reinforcing an existing oxide film when adsorbed onto oxide-coated iron. The ability of EN to act as a

corrosion inhibitor has been demonstrated for iron in strong acid solutions where the iron metal is

oxide-free [65, 67-71]. EN has also been shown to be an effective corrosion inhibitor for iron in

alkaline solutions where the surface is covered with a corrosion layer [61-64, 72-75].

Chemisorption is thought to be the main mechanism responsible for the adsorption of EN onto iron.

Chemisorption (also called specific adsorption) involves the formation of coordinate bonds between

neutral EN molecules and the iron surface [76, 77]. These bonds, also called donor-acceptor bonds,

involve the sharing of the unpaired electrons on the nitrogen atoms in the neutral EN molecule with

empty d-orbitals on iron. The bonds are relatively strong and chemisorbed molecules are not easily

removed by rinsing. McCafferty and Hackerman studied the effectiveness of diamines for slowing

iron corrosion in 6 M hydrochloric acid (HC1) [67, 68]. For EN, they suggested that both nitrogens

were adsorbed onto iron, with the molecule lying parallel to the surface. Of the diamines studied.

EN was one of the least effective corrosion inhibitors. In neutral or alkaline conditions, with an

oxide film present. EN is thought to be chemisorbed onto the surface (either onto the metal at flaws

in the existing oxide film, or onto iron oxyhydroxide corrosion products); this incorporation into the

film serves to reinforce it [61, 62, 66).

Another mechanism, physisorption, may be responsible for additional EN adsorption. Physisorption

(also called physical adsorption) involves adsorption of charged inhibitor ions by the formation of

relatively weak electrostatic bonds between inhibitor ions and an electrically charged iron surface

[76, 77]. In certain

acids, especially those containing halogens, such as HCl, the halogen ions chemisorb onto the metal

and these negative ions attract and electrostatically bond positive ions (e.g., protonated EN) [68]. In

general, organic amines tend to be more effective corrosion inhibitors in acids if halide ions are

present because of this joint adsorption process [78, 79], Under alkaline conditions, where chloride

ions are much less likely to be adsorbed, it is possible that a few protonated EN species (minor

constituents in alkaline solutions) may be electrostatically bonded to the oxide-covered surface with

its negative surface charge [63, 66].

The effectiveness of EN as an iron corrosion inhibitor depends on concentration and temperature.

Zaritskii studied iron corrosion in EN solutions using weight-loss measurements [73]. He observed

that the iron corroded rapidly for the first few days and then the corrosion rate slowed to a steady

rate. He found that, at room temperature, the corrosion rate of the iron decreased with increasing

concentration of EN between 1-20% EN. Zaritskii also studied the effect of temperature on the iron

corrosion rate in EN solutions and noted (for the same EN concentration) a higher corrosion rate at

80°C compared to room temperature. Zaritskii's result suggests that the effect of temperature should

be included in any future studies of EN as a treatment for archaeological iron. Sokolova et al.

studied the effectiveness of EN as a corrosion inhibitor tor iron using weight-loss measurements

[72]. It took about 10 days for their iron samples to reach a steady-state corrosion rate. They varied

the concentration of EN from 10-5 M to 1.5 M; the corrosion rate started to slow significantly at 0.1

M EN and became negligible at 1 M EN (The authors used 5% v/'v (0.75 M) EN in the present

study.)

Soluble [Fe(EN) ]2+ complexes

As Duprat et al. have shown, ethylenediamine can act as a corrosion inhibitor for iron because of its

alkalinity and its ability to be adsorbed onto an iron surface [61, 63]. Unfortunately. EN also has the

ability to form soluble complexes with Fe2+ ions and this property can make its use dangerous.

Neutral EN molecules interact with Fe2+ ions to form iron-ligand complexes; the EN ligand replaces

some or all of the water molecules that normally surround iron ions in solution [80. 81]. Bonds are

formed between the unpaired electrons on the two nitrogens in EN and the d-orbitals of the iron

ions. Both nitrogen atoms on an EN molecule are capable of interacting with the same metal ion

simultaneously, acting as a bidentate ('two-toothed') ligand, replacing two water molecules and

forming a five-membered ring. This process is known as chelation and the ligand involved is called

a chelating agent [81].

Ethylenediamine is well known for its ability to form complexes with transition metal ions in the

divalent (+2) oxidation state [10, 80, 82]. The stability constants for these complexes are often

determined using acid solutions (to avoid precipitation of metal hydroxides) and inert atmospheres

(to avoid oxidation of divalent ions to higher oxidation states) [80]. Ethylenediamine is also known

to form complexes with certain monovalent ions (e.g., Ag+) and trivalent ions (e.g.. Co3+), as well

as a range of other divalent ions (e.g., Sn2+. Cd2+, Pb2+, Pd2+ and Pt2+) [80, 83], In aqueous

solutions, transition metal ions typically have six water molecules associated with the central metal

atom (i.e., a coordination number of six), giving it octahedral symmetry, and these six water

molecules can be replaced with up to three EN molecules. Iron(II) ions, for example, can form three

different complexes with ethylenediamine: [Fe(EN)x]2+ with x = 1, 2 or 3 [80]. A schematic diagram

showing an Fe2+ ion surrounded by three EN molecules is shown in Figure 6. Information about the

reactions and formation constants for these three complexes is summarized elsewhere [10].

Iron(III) ions can form complexes with various ligands, but they are usually stable only under acid

conditions or other controlled conditions. Iron(III) ions can react with EN to form [Fe(EN)x]3+

complexes but they are difficult to isolate. The complex [Fe(EN3]Cl3, for example, is made by

adding EN to anhydrous FeCl. in absolute ethanol [84]. In general, iron(III) complexes are unstable

under alkaline conditions because the iron(III) ions react with hydroxyl ions and precipitate as

insoluble iron hydroxides and oxyhydroxides [85, 86], For example,

Figure 6 Schematic diagram of the compiex ion [Fe(EN)3]2+ showing each ethylenediamine

molecule occupying two coordination positions on Fe2+.

the iron(II)-EDTA complex (where EDTA is ethylene-diaminetetraacetic acid) is stable under

alkaline conditions, but the iron(III)-EDTA complex is not [85].

In this study, relatively high levels of iron were detected in EN treatment solutions compared to

NaOH treatment solutions. This behaviour is attributed to the reaction of EN with Fe2+ ions within

the corrosion layer to form soluble [Fe(ENx)]2+ complexes which then diffused into the treatment

solution. The Fe2+ ions inside the corrosion layer may have been present at excavation, may be the

result ot ongoing corrosion of iron metal, or may arise from the dissolution of corrosion products

(e.g., dissolution of Fe(OH), or magnetite). As the soluble [Fe(EN)]2+ complexes diffused into the

treatment solution, they encountered higher levels of dissolved oxygen. The authors believe that the

Fe2+ ions in the complexes are oxidized to Fe3+ ions which then precipitate as insoluble iron

hydroxides and oxyhydroxides [87]. The intense colour observed in EN treatment solutions

compared to the paler NaOH treatment solutions may be due to either the soluble [Fe(EN)x ] 2+

complexes or their oxidation to colloidal Fe3+ material.

For many objects, it was observed that if the outer iron(III) oxyhydroxide layer had fallen off and

the inner black layer (presumably magnetite) was exposed to EN, then this black layer became easy

to remove and sometimes collected as black sludge at the bottom of the containers. The exact

mechanism for this process is not known. It may be that if magnetite is exposed to an EN solution,

then the EN molecule can adsorb on its surface, interact with Fe2+ ions to form soluble [Fe(EN)x]2+

complexes, and destabilize the magnetite by making it less cohesive and less adherent to the

underlying metal. It may also be that EN is stimulating iron corrosion beneath the magnetite. If the

iron is corroding in the presence of EN then newly formed Fe2+ ions will react with it to torm

soluble [Fe(EN)x]2+ complexes and prevent the iron from passivating. This will undermine the

magnetite and it will fall off. The ability of EN to stimulate iron corrosion has been studied by

Sakakibara et al. in anhydrous methanol containing 0.1 M LiClO4 [88, 89]. They showed that bare

iron passivated in this electrolyte in the absence of EN but continued to corrode in the presence of

EN (10-4 M) because of the formation of soluble [Fe(EN)x]2+ complexes [88, 89].

Passivation versus corrosion of iron in EN solutions

When archaeological iron is placed in an EN solution, there are competing factors at work because

EN can stimulate as well as inhibit corrosion. The main advantage of using an EN solution to treat

archaeological iron is its ability to act as a corrosion inhibitor, either by being adsorbed onto the

metal surface or by reinforcing a preexisting iron(III) oxyhydroxide film. When freshly excavated

archaeological iron is placed in an EN solution, it is expected to be corroding because of the

presence of an acidic FeCl, solution trapped next to the metal surface. Over time, the iron surface is

expected to passivate in EN solutions, mainly because of the increase in pH but also because of the

adsorption of EN molecules on the metal surface. The limited results from ICP-AES analysis

(Figure 4) suggest that, at least in some cases, the iron eventually passivates because the level ot

iron in EN solutions usually stops increasing.

The main disadvantage of using an EN solution to treat archaeological iron is its ability to stimulate

corrosion by reacting with Fe2+ ions to form soluble [Fe(EN)x]2+ complexes. The results from the

ICP-AES analysis of a few of the treatment solutions clearly indicated an increase in dissolved iron

in EN solutions compared to NaOH solutions. Rapid corrosion of iron metal in archaeological

objects treated in EN solutions has been reported in the conservation literature [8, 9, 11]. The

authors also noted instances where exposure of the magnetite layer on an artifact to EN resulted in

what appeared to be the dissolution ot magnetite. We interpret this as a reaction between EN and

Fe2+ ions (from magnetite or from corroding iron metal beneath the magnetite) to form soluble

[Fe(EN)x ]2+ complexes.

Our results suggest that heavily mineralized archaeological iron (Group 1 objects) is seriously

damaged by immersion in NaOH (2% w/v. pH 13.5) because of the high pH and the cracking

caused by rapid oxidation-reduction reactions occurring inside the corrosion layers. Our results also

suggest that heavily mineralized archaeological iron does not experience such serious damage when

immersed in EN (5% v/v, pH 11.5) prior to immersion in NaOH. The neutral EN molecule may be

adsorbed onto the existing iron(III) oxyhydroxide corrosion layer where it acts as a corrosion

inhibitor by helping to reinforce the corrosion layer. The EN molecule may also be removing Fe2+

ions as soluble [Fe(EN)x ]2+ complexes from within the corrosion layers, thereby removing their

contribution to the rapid oxidation-reduction reactions that cause cracking within the corrosion

layer. If the Fe2+ ions are removed during immersion in EN, then they can no longer participate in

electrochemical reactions when the artifact is transferred into NaOH. Unfortunately, with less

cracking, Cl- ions are more likely to remain trapped within the corrosion layer.

CONCLUSIONS

Results have been presented from a systematic assessment of a treatment approach for

archaeological iron developed at the Canadian Conservation Institute in the early 1980s. Thirty-two

archaeological wrought iron objects from Ferryland and Renews, Newfoundland, were treated by

immersion in individual treatment solutions containing an aqueous solution of either NaOH (2%

w/v, pH 13.5) or EN (5% v/v, pH 11.5). Treatment solutions for all 32 objects were analysed

quantitatively for dissolved Cl- ions. Treatment solutions for nine objects were analysed by ICPAES for 26 additional dissolved elements. This systematic approach provided specific information

about the quantity and time-dependence of Cl- ion and other dissolved elements as they diffused out

of each object into a given treatment solution.

The results demonstrate that immersion of archaeological iron in an aqueous sodium hydroxide

solution is an effective way to treat archaeological iron with a substantial metal core where removal

of chloride ions is important; the softening of the corrosion layers and the passivation of iron metal

are contributing factors. The results also demonstrate that immersion of archaeological iron in an

aqueous ethylenediamine solution is not particularly effective at removing Cl- ions although it is

effective in preserving the corrosion layer on heavily mineralized iron; removal of dissolved iron(II)

ions and minimal softening are contributing factors. The use of EN solutions in conjunction with

NaOH solutions may provide an effective way to treat archaeological iron without a substantial

metal core where maintaining the outer corrosion layers is important.

Unfortunately, immersing archaeological iron with a substantial amount of remaining iron metal in

EN solutions can be dangerous because of the ability of EN to form soluble complexes with iron(II)

ions. If the iron metal is still corroding and forming new iron(II) ions at anodic sites, then the iron

may continue to corrode (because of the reaction ot Fe2+ ions with EN to form soluble complexes)

rather than passivate (through the reaction of Fe2+ ions with hydroxyl ions to precipitate iron(II)

hydroxide). Finally, ICP-AES analysis of treatment solutions provided a better understanding of

what other elements were being removed from the archaeological iron by treatment in alkaline

solutions.

ACKNOWLEDGEMENTS

The authors thank Cathy Mathias and Dr James Tuck from Memorial University of Newfoundland

and Steve Mills from Parks Canada for supplying the iron artifacts tor treatment. We also thank statt

at the Canadian Conservation Institute (CCI) for their help, particularly Kimberly Figures and Judy

Logan for help with the treatment, Nancy Binnie for help with chloride ion analysis, Jane Sirois for

X-ray diffraction analysis and Carl Bigras for photography. Comments on the final draft from Jane

Down. David Grattan, Cathy Mathias. Gavie McIntyre and Susanne Sutherland were also greatly

appreciated. Finally, funding for Vasilike Argyropoulos by the CCI Fellowship Program is

gratefully acknowledged.

REFERENCES

1 Argo. ].. 'The treatment oí corrosión with amines'. Conservation Sews 17 (1982) 7-9.

2 Argo, J., and Turgoose. S.. "Amines and iron stabilisation: discussion', in Corrosion Inhibitors in

Conservation, ed. S. Keene. UKIC. London (1985) 31-32.

3 Argyropoulos. V7.. Sehvyn. L.S.. and Logan. J.A.. 'Developing a conservation treatment using

ethylenediamine as a corrosion inhibitor for wrought iron objects found at terrestrial archaeological

sites', in Metal 95. ed. I.D. MacLeod. S.L. Fennec and L. Robbiola. James & James. London (1997)

153-158.

4 Logan, J.A.. 'An approach to handling large quantities of archaeological iron', m ICOM

Committee for Conservation ~tli Triennial Meeting. Copenhagen (1984) 84.22.14-84.22.17.

5 McCawley. J.C., 'Current research in the corrosion of archaeological iron", in [COM Committee

for Conservation 7th Triennial Meeting. Copenhagen (1984) 84.22.25-84.22.27.

6 Costain, C. and Logan. J.. 'Survey ot iron artifacts from Red Bay, Labrador to assess the

effectiveness of various iron treatments', ¡COM Committee tor Conservation, Metal Uorkiug Croup

Sewsletterl (1985) 8-9.

7 Sehvyn, L.S.. and Logan. J.A.. 'Stability of treated iron: a comparison of treatment methods', in

¡COM Committee for Conservation 10th Triennial Meeting. Washington DC (1993) 803—807.

8 Busse, E.. 'The Manitoba North cannon stabilization project'. m Metal 95. ed. I.D. MacLeod. S.L.

Pennec and L. Robbiola. James & James, London (1997) 263-268.

9 Brown. CE., 'Ethylene-dmmine treatment of iron'. Conservation Sews 27 (1985) 38.

10 Sehvyn, L.S.. 'Supplementary information'. CPMR Report, Proteus 86672. Canadian

Conservation Institute. Ottawa (2004).

11 Costain. CG.. 'Evaluation of storage solutions for archaeological iron'. Journal of the Canadian

Association tor Conservation 25 (2000) 11-20.

12 Watkmson. D.. 'Degree ot mineralization: its significance for rhe stability and treatment of

excavated ironwork'. Studies in Conseivjtion 28 (1983) 85-911.

13 Sjogren. A.. Mathiesen. T.. van Lanschot.J.. Turgoose. S., and Hawkins. C 'Rapid lowtemperature hydrogen plasma treatment of archaeological iron'. Zeitschrift für Schweizerische

Archäologie und Kunstgeschichte 54 (1997) 34-40.

14 Van Lanschot. !.. Mathiesen. T.. Szalkay. CD., and Turgoose. S.. 'Non-destructive

electrochemical measurement of the stability of archaeological iron artifacts', in 4th International

Conference on Son-Destructive Testing ot Works of Art. Berlin (1994) 306-315.

15 Wafkmson. D.. 'Chloride extraction from archaeological iron: comparative treatment

efficiencies', m Archaeological Conserva-tion and its Consequences, ed. A. Roy and P. Smith, 1IC.

London (1996) 2118-212.

16 Al-Zahram. A.A.. "Chloride ion removal from archaeological iron and ß-FeOOH'. PhD thesis.

University of Wales. Cardiff" (1999).

17 Hart. F.A.. and Adams. S.J.. "Research notes and application reports: the chemical analysis of

Romano-British pottery from the Alice Holt Forest. Hampshire, by means of inductively coupled

plasma emission spectrometry". Archaeometry 25 (1983) 179-185.

18 Heyworth. M.P.. Hunter. J.R.. Warren. S.E.. and Walsh. J.N.. "ICPS and glass: the multielemental approach', in Seutron Activation and Plasma Emission Spectrometric Analysis in Arcliticology Techniques and Applications, ed. MJ. Hughes, M.R. Cowell and D.R. Hook. British

Museum Occasional Paper 82. London (1991) 143-154.

19 Giumha-Mair. A.R.. 'The composition ot copper-based small finds from a west Phoenician

settlement site and from Nimrud compared with the contemporary Mediterranean small finds'.

Archaeometry 34 (1992) 107-119.

20 Costain. C. 'Measurement of chlorides in treatment solutions', ICOM Committee tor

Conservation, Metals Hoiking Croup Seivslcrter 1 (1985) 4-7. and erratum in following

newsletter.

21 Seluyn. L.S.. 'Analysis of the chloride ion concentration in aqueous solutions by potentiometric

ritration". Canadian Conservation Institute Research Report. Canadian Conservation Institute,

Ottawa (2001) 1-14.

22 Turgoose. S.. "The corrosion of archaeological iron during burial and treatment . Studies in

Conservation 30 (1985) 13— 18.

23 Blesa. M.A.. Morando. P.J.. and Regazzom. A.E., 'Iron oxides', in Chemical Dissolution of

Metal Oxides. CRC Press, London (1994) 269-308.

24 Cornell. R.M.. and Schwertmann. U.. The Iron Oxides. VCH. Weinheim (1996).

25 Selwyn. L.S.. Sirois. P.I., and Argyropoulos. V.. "The corrosion of excavated archaeological

iron with details on weeping and akaganéite'. Studies in Conservation 44 (1999) 217-232.

26 Turgoose. S.. 'Structure, composition and deterioration of unearthed iron objects', m Current

Problems in the Cousen'atiou ot Mela! Antiquities. Tokyo National Research Institute of Cultural

Properties (1993) 35-52.

27 North. N.A.. 'Conservation of metals', in Conservation of

45 Mariut. Archaeological

Objects, ed. C. Pearson. Butterworths. London ¡1987; 207-252.

28 North. N.A.. and Pearson, C, "Washing methods tor chloride removal trom manne iron

artifacts*. Studies in Conservation 23 (1978) 174-186.

46

29 Oddy. W.A.. "A review of procedures tor the conservation oí cast and wrought iron tound on

the sea-bed . The International journal of \autical Archaeolooy ¿ind I. nderwaicr Exploration 2

(1975) 367-370.

3U North. N.A.. and Pearson. C. "Methods tor treating marine

47 iron', in ICOM Committee for

Conservation 5th Triennial Meeting, Zagreb (1978) 78/23/3. 1-10.

31 Pearson, C. 'On-site conservation requirements for marine archaeological excavations'. The

Intenidtional Journal of Xautical Archaeology and L'uderwater Exploration 6 (1977) 37-46.

48

32 Mathias, C, "A conservation strategy for a seventeenth century archaeological site at Ferryland.

Newfoundland'. Journal of the International Institute for Conservation — Canadian Group 19

(1994) 14-23.

49

33 Keene, S., "Real-time survival rates for treatments of archaeological iron', in Ancient &

Hisroric Metals: Conservation and Scientific Research, ed. D.A. Scott, J. Podany and B. Considme.

Gerry Conservation Institute. Marina del Rev (1994) 249-264.

50

34 Watkinson, D.. 'An assessment of lithium hydroxide and sodium hydroxide treatments tor

archaeological ironwork*, in Conservation of Iron, ed. R.W. Clarke and S.M. Blackshaw. National

Maritime Museum Monographs and Reports No. 53.

51 Greenwich (1982) 28-40.

35 Perrin, D.D.. Dissociation Constants of Organic Bases in Aqueous Solution. Butterworths.

London (1965).

36 Powell, H.K.J.. and Curtis, N.F., "The free energy, enthalpy.

52 and entropy changes for

the neutralisation of some C-l-substituted 1,2-diaminoethanes'. journal of the Chemical Society

(B) (1966) 1205-1211.

37 Sirois, {., 'Analysis ot iron corrosion products', Analytical

53 Research Services Report

So. 3356. Canadian Conservation Institute, Ottawa (1995).

38 Bear. F.E.. (ed.). Chemistry of the Soil, 2nd edn, Reinhold. New York (1964) 80-90.

39 ASTM Designation G31-72, 'Standard practice tor laboratory

54 immersion corrosion

testing ot metals', in 1992 Annual Book of ASTM Standards, Vol. 03.02. American Society for

Testing

and Materials, Philadelphia (1992) 102-109.

55

40 Logan. J., "Tannic acid treatment*. CCI Xotes 9/5, Canadian Conservation Institute. Ottawa

(1997).

56

41 Sirois, ).. "Analysis ot iron corrosion products'. Analytical Research Services Report Xo.

3380.B, Canadian Conservation

57 Institute. Ottawa (1995).

42 Taylor. J.R-, An Introduction to Error Analysis. University

58 Science Books, Mill Valley.

CA (1982) 56.

43 Selwyn, L.S., McKinnon. W.R., and Argyropoulos. V.. "Models tor chloride ion diffusion in

archaeological iron". Studies in Conseivation 46 (2001) 109-120.

59

44 Sjöberg. A., "Phosphate analysis of anthropic soils'. Journal of Fteld Archaeolooy 3 (1976) 447454.

Wagner. D.. Dakoroma. F., Ferguson, C, Fischer, W.R., Hills. C. Kars. H., and Meijers. R., ""Soil

archive" classification m terms of impacts of conservability of archaeological heritage", in Metal

95, ed. I.D. MacLeod, S.L. Pennec and L. Robbiola. James & James, London (1997) 21-26.

Townsend. H.E.. "Potential-pH diagrams at elevated temperature tor the system Fe—H,O*. in

Proceedings of the Fourth International Congress on Metallic Corrosion, ed. N.E. Hammer,

National Association ot Corrosion Engineers, Houston, Texas (1972) 477-487.

Turgoose. S.. Hawkins. C. Wrathall. N., Kalsbeek, N., van Lanschot. !.. Mathlesen. T., and Sjogren,

A., Development of Improved Conservation Procedures tor Archaeological Iron, Environment

Program CT94-0561. Corrosion and Protection Centre, UMIST and School of Conservation,

Copenhagen (1996). Hjelm-Hansen. N.. van Lanschot, J.. Szalkay, CD., and Turgoose. S.,

'Electrochemical assessment and monitoring of stabilisation of heavily corroded archaeological iron

artefacts', Corrosion Science 35 (1993) 767-774.

Amaral. S.T., and Müller. IX., 'A RRDE study of the electrochemical behavior ot iron in solutions

containing silicate and sulphate at pH 10-13', Corrosion Science 41 (1999) 759-771.

Virtanen. S.. Schmuki. P.. liuchler. M.. and Isaacs, H.S.. 'Electrochemical behavior ot Fe in

phosphate solutions studied bv in situ x-ray absorption near edge structure', Journal oj the

Electrochemical Society 146 (1999) 4087-4094. Schmuki. P.. Virtanen, S.. Davenport, A.J.. and

Vims, CM., 'In situ x-ray absorption near-edge spectroscopic study of the cathodic reduction of

artificial iron oxide passive films*, Journal of the Electrochemical Society 143 (1996) 574-582.

Schmuki, P.. Büchler. M.. Virtanen, S., Isaacs, H.S., Ryan, M.P.. and Böhm. H.. 'Passivity of iron in

alkaline solutions studied by m situ XANES and a laser reflection technique', Journal of the

Electrochemical Society 146 (1999) 2097-2102. Schmuki, P., Virtanen. S., Isaacs. H.S.. Ryan, M.P.,

Oblonsky, L.I.. and Böhni, H., 'In situ XANES study of the cathodic reduction behavior ot the

passive film on iron and artificial passive films'. Electrochemical Society Proceedings 97-26 (1998)

183-194.

Patterson, R.E., 'Silica: introduction', in Kirk-Othmcr Encyclopedia of Chemical Technology. 4th

edn, Volume 21, John Wiley & Sons. New York (1997) 977-1005. Dent Classer. L.S., and Kataoka,

N., 'The chemistry of "alkali-aggregate" reaction". Cement and Concrete Research 11 (1981) 1—9.

Mills. J.S.. and White. R., The Oroautc Chemistry of Museum Objects. Butterworths. London

(1987).

Nicholls. D.. "Iron", in The Chemistry ot Iron, Cobalt and Xiekel, Pergamon Press. New York

(1973) 979-1049. Whitman. G.W.. Russell, R.P., and Altien, V.J., 'Effect of hydrogen-ion

concentration on the submerged corrosion of steel". Industrial and Engineering Chemistry 16

(1924) 665— 670.

Blesa. M.A.. Regazzom. A.E., and Maroto, A.J.G., "Reactions of metal oxides with aqueous

solutions', Materials Science Forum 29 (1988) 31-98.

">o Hingston. F.J., Posner. A.M.. and Quirk. J.P.. 'Anion binding at oxide surfaces — the

adsorption envelope'. Search 1 (197(1) 324-327.

61 Duprat, M.. Shin. A.. Derbah, Y.. and Pebere, N.. 'An electrochemical impedance approach to

the corrosion inhibition of a carbon steel in neutral media', Materials Science Forum 8 (1986) 267279.

f

>2 Duprat. M., and Dabosi. F., 'Electrochemical impedance measurements applied to corrosion

inhibition study ot carbon steel in neutral media', m Proceedings ot die International Congress on

Metal Corrosion, NACE. Houston (1984) 104-109.

63 Duprat, M, and Dabosi. F., 'Corrosion inhibition of a carbon steel m 3% NaCl solutions by

aliphatic ammo-alcohol and diamine type compounds'. Corrosion 37 (1981) 89-92.

64 Dabosi, F.. Deslouis, C, Duprat, M., and Keddam. M.. 'Corrosion inhibition study ot a carbon

steel m neutral chloride solutions by impedance techniques'. Journal ot the Electrochemical Society

130 (1983) 761-766.

65 Incorvia, MJ., 'Stereochemistry in corrosion inhibition', in Proceedings of the 6th European

Symposium on Corrosion Inhibitors, Universita degli Studi di Ferrara (1985) 81-93.

66 Incorvia, M.J., and Contarim, S.. 'X-ray photoelectron spectroscopic studies of

metal/inhibitor systems: structure and bonding at the iron/amme interlace', ¡onrnal ot the Electrochemical Society 136 (1989) 2493-2498.

67 McCafferty. E.. and Hackerman, N.. 'Double layer capacitance of iron and corrosion inhibition

with polymethylene dia-mines', Journal ot the Electrochemical Society 119 (1972) 146—154.

68 Hackennan. N., and McCafferty. E.. "Adsorption and corrosion inhibition with flexible organic

diamines'. in Proceedings of the Fifth International Congress on Metallic Corrosion. Tokyo I9~2,

NACE, Houston (1974) 542-548.

69 Desai, M.N.. and Desai, M.B.. 'Polyamines as inhibitors of corrosion oí mild steel in

hydrochloric acid solutions', Journal of the Electrochemical Society of India 30 (1981) 345-350.

70 El-A\vady, A.A., Abd-El-Nabey. B.A., and Aziz. S.G.. 'Kinetic-thermodynamic and adsorption