Swimming Pools - Norfolk Schools

advertisement

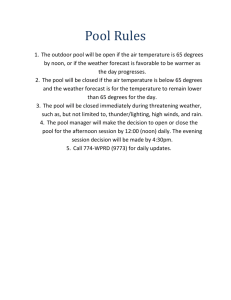

CODE OF PRACTICE Reference HS7 HEALTH AND SAFETY IN SWIMMING POOLS PART TWO: MAINTENANCE OF POOL AREA AND WATER TREATMENT Reissued: June 2006 Children’s Services Health and Safety Manual CONTENTS Introduction About this Code Responsibilities - Headteacher - Pool Carer - Children’s Services Technical Adviser (Swimming Pools) - NPS Property Consultants Ltd (NPS) or other Building Maintenance Contractors Training Pool Maintenance: Hazards and Control of Risks - Heating and Ventilation of Pool Area - Hard and Soft Water - Water Contamination - Microbiological Monitoring Emergency Procedures Pool Water Pollution – Emergency Measures - Solid Stools - Loose, Runny Stool (Diarrhoea), Vomit or Blood - Blood Spillages on Pool Surrounds Supplies and Equipment Supply and Storage of Pool Treatment Chemicals Personal Protective Equipment (PPE): Inspection, Maintenance and Storage Commissioning and Decommissioning of Outdoor Pools Appendix 1 - Assessments of Pool Plant Chemicals - Liquid Algaecide - Tile and Line Cleaner - Sodium Hypochlorite - Stabilised Chlorine Granules - Ground Aluminium Sulphate - Hydochloric Acid - Sodium Bisulphate - Calcium Hardness Tablets Appendix 2 – Water Treatment Procedures - Objectives of Water Treatment - Chlorination - Water Testing - pH Value - Chlorine Testing - Total Alkalinity Testing - Water Temperature - Water Clarity - Skimmer/Strainer Baskets - Filter Backwash - General Poolside Tasks Appendix 3 – Problem Solving Tables and Glossary Pool Water Testing Record Form ii 7-1 7-1 7-3 7-3 7-3 7-3 7-4 7-4 7-4 7-4 7-5 7-5 7-6 7-7 7-7 7-7 7-7 7-8 7-8 7-8 7-10 7-10 7-11 7-12 7-14 7-16 7-18 7-20 7-22 7-24 7-25 7-26 7-27 7-27 7-27 7-28 7-29 7-31 7-31 7-32 7-33 7-33 7-33 7-35 Children’s Services Health and Safety Manual INTRODUCTION Swimming pools are potentially high risk environments. Therefore it is essential that premises operating swimming pools and swimming activities plan and manage them effectively to ensure the safety of pupils, staff and other pool users. Where schools have arrangements to allow others such as Parent/Teacher Associations and other community groups or hirers to use the pool facility, it is essential that the school management ensures that safety measures are in place and hire/letting agreements define clearly what the safety parameters and responsibilities are . ABOUT THIS CODE This Code has been prepared to reflect health and safety legislation and relevant national standards and guidelines which include: Managing Health and Safety in Swimming Pools - Health and Safety Commission and the Sports Council 2003 Swimming Pool Water Treatment and Quality Standards - Pool Water Treatment Advisory Group 1999 Safe Practice in Physical Education - British Association of Advisers and Lecturers in Physical Education (BAALPE) 2004 The Code is complementary to, and forms part of, the Children’s Services Health and Safety Manual. The Health and Safety in Swimming Pools Code of Practice has been split into two parts: Part One - deals with the management and use of the pool facility and sets out responsibilities for day to day operation and emergency arrangements Part Two - deals with the maintenance of the pool facility in respect of water treatment, pool housekeeping, handling of chemicals, etc. The overriding principles contained in this Code are to ensure that all swimming activities and pools operated by Children’s Services are properly managed and maintained to specified standards and that: All swimming activities, both teaching and recreational, are conducted within recognised safety standards for tuition, supervision, life-guarding and first aid. In addition, management controls are provided and maintained Staff, teachers, carers, life-guards and pool plant operators are suitably trained to an appropriate standard and are fully aware of their responsibilities Isssed June 2006 COP 7 – 1 H&S in Swimming Pools: Part Two Children’s Services Health and Safety Manual Water hygiene standards are met and maintained by regular testing and recording of results Chemicals are stored, used and handled safely in line with recognised safe practices and procedures complying with Control of Substances Hazardous to Health Regulations (COSHH) 2002. DISTRIBUTION OF CODE OF PRACTICE Headteachers and other managers should ensure that relevant personnel are provided with copies of this Code or the relevant parts. They should ensure that a copy is available in every pool office and that all staff are aware of it. FURTHER INFORMATION Further information is available from the following people: General Health and Safety issues – Children’s Services Health and Safety Advisers on 01603 223470 or 01603 223989. Pool Plant issues – Children’s Services Technical Adviser (Swimming Pools) on 01603 224489. Swimming Curricular issues - PE Adviser on 01603 723697. Isssed June 2006 COP 7 – 2 H&S in Swimming Pools: Part Two Children’s Services Health and Safety Manual PART TWO: MAINTENANCE OF POOL AREA AND WATER TREATMENT INTRODUCTON Part Two of the Code contains information to protect the health and safety of employees who maintain school swimming pools. It covers all aspects of maintenance likely to be encountered under normal circumstances. The document is intended to be a guide to good practice as well as being an instruction manual for swimming pool carers. RESPONSIBILITIES Staff involved in this area of work have the following responsibilities: Headteacher Any pool being operated within their premises is managed, used and maintained in accordance with the guidance contained in Parts One and Two of Health and Safety in Swimming Pools Code of Practice All persons allocated responsibilities as defined in this code are suitably trained to carry out those responsibilities Normal and emergency operational procedures are written and appropriately distributed Where required records are kept of all training given to staff and others and for ensuring records are kept of maintenance and water treatment Ensuring adequate arrangements are in place for use of the pool by community groups or other users. Pool Carer Ensuring that the pool, surrounding area and changing rooms are kept clean and free from hazards Ensuring the quality of the pool water by dosing, testing and record keeping Visual inspection of plant and equipment Ensuring the security of pool plant room and chemical storage areas Handling chemicals appropriately as defined in this Code Wearing appropriate personal protective equipment when dosing pools. Children’s Services Technical Adviser (Swimming Pools) Providing advice and instruction to Pool Carers to ensure the safe and efficient operation of their pool Regularly monitoring all pools to ensure correct water treatment is being carried out and recorded Advising Pool Carers on corrective action required to achieve optimum water quality Isssed June 2006 COP 7 – 3 H&S in Swimming Pools: Part Two Children’s Services Health and Safety Manual Visual inspection of chemical storage, signing and personal protective equipment (availability and condition). Reporting findings to Pool Carer and Headteacher for corrective action. Visual inspection of plant and ancillary equipment and reporting findings to the Pool Carer and Headteacher for corrective action Carrying out regular microbiological sampling and testing of pool water Providing advice to Pool Carers on availability of certificated Pool Plant Operators training courses NPS Property Consultants Ltd (NPS) or other Building Maintenance Contractors The maintenance of plant and electrical and mechanical equipment TRAINING The operation and maintenance of swimming pool plant and water treatment processes must only be carried out by people who have been adequately trained and who have the requisite knowledge and experience. Informal instruction on pool operation and maintenance is provided by the Children’s Services Technical Adviser (Swimming Pools) to all pool carers on appointment. In addition, Pool Carers must attend formal certificated training on pool plant operation. Contact the Children’s Services Technical Adviser (Swimming Pools) on 01603 224489 for details of courses, dates and venues. POOL MAINTENANCE: HAZARDS AND CONTROL OF RISKS A great many hazards are inherent in maintaining a pool. The following paragraphs identify and explain the hazards and give advice on how to control the risks to staff and others. Pool Carers and others should follow this best practice at all times. Heating and Ventilation of Pool Area All indoor pools should be appropriately heated and ventilated to: Minimise pool water evaporation Protect the building from excessive condensation Provide comfort for bathers Ventilate any toxic gases released from water treatment Plant must be operated to maintain a pool hall air temperature approximately 1 C above pool water temperature. Isssed June 2006 COP 7 – 4 H&S in Swimming Pools: Part Two Children’s Services Health and Safety Manual Water Water used in swimming pools is supplied by the local water companies after being extracted from wells, lakes, rivers or reservoirs. Depending on which part of the country the water comes from will determine whether it is Hard or Soft. Hard Water Hard water is determined by the amount of calcium and magnesium salts it contains. As it evaporates, calcium and magnesium salts are left behind which increases the water's hardness making it 'hard' for soap to make suds, hence the name. Hardness affects the 'water balance' in a pool. If it is too hard it will be cloudy. Hard water (alkaline water) causes: Scale on pipe-work, reducing the flow and causing blockages Scale on heating surfaces, reducing heat transfer Scale in showers, causing cleaning problems Soft Water Soft water is low in calcium and magnesium salts. However, it does contain acids dissolved from peaty and moorland ground. Soft water (acidic water) causes: Corrosion in pipe-work and plant Damage to tiles, cement finishes and erodes grouting and concrete paving slabs It is therefore important to maintain the pH value of water (the scale of alkalinity and acidity) at a neutral level. Water Contamination No matter how well a pool is maintained, contamination is constantly being introduced into the water. This has to be dealt with to protect the health of users. There are 3 types of water contamination: - Physical Biological Chemical Physical Contamination This type of contamination consists of suspended solids like fluff, grit, plasters, hair, toenails, goggle straps, leaves, etc and occasionally sand from the pool filters. Isssed June 2006 COP 7 – 5 H&S in Swimming Pools: Part Two Children’s Services Health and Safety Manual These items are removed by the following methods: Manually with nets Skimmers or overflow channels which are positioned around the sides of the pool Strainer pots in the pump or the filter Rubbish at the pool bottom may need to be vacuumed or brushed into the pool bottom outlet Very bad contamination may be vacuumed directly into the waste drain without going through the filter Biological Contamination Living organisms can multiply in water very quickly. These are: Pathogenic bacteria - disease carrying bacteria harmful to humans Non-pathogenic bacteria - harmless to humans Algae - plant life If organisms are allowed to grow vigorously in the pool, then the water could turn green or become very cloudy. The pool then becomes unsafe for bathers. The most dangerous layer is the top 16 centimetres (6 inches) of the water surface. Bacteria are added by bathers, the most hazardous coming from urine, noses, throats, sores and infections. Algae grows from spores carried in the air from vegetation and from people's feet or occasionally from the water supply. It is essential that such contamination is controlled by disinfection and that these living and dead particles are removed. To disinfect water in pools we use chlorinebased products. Chemical Contamination Chemical contamination can arise from: Chemicals in natural raw water and those added by the Water Company Urine, faeces, sputum, cosmetics, skin creams and lotions, other human additives Chemicals added to the water for disinfection Microbiological Monitoring All Norfolk pools are monitored twice a term by the Children’s Services Technical Adviser (Swimming Pools). Water samples are collected and results of microbiological tests are faxed to the school. The most recent test result should be held on site by the Pool Carer. Isssed June 2006 COP 7 – 6 H&S in Swimming Pools: Part Two Children’s Services Health and Safety Manual EMERGENCY PROCEDURES Emergency procedures should be created and detailed in the Pool's Emergency Action Plan. Guidance on creation of Normal Operating Procedures and Pool Emergency Procedures is contained in Part One of this Code of Practice. In the event of toxic gases being produced, usually by mixing of two or more pool chemicals, the area should be evacuated immediately and the emergency services informed. Under no circumstances should an attempt be made to enter such an area to rescue someone. A safe rescue will require the wearing of breathing apparatus used by the emergency services. If this happens you should inform the Children’s Services Health and Safety Adviser and complete a County Council Incident Report Form filling in details in Part A of the dangerous occurrence. POOL WATER POLLUTION – EMERGENCY MEASURES Swimming pool water must be adequately disinfected at all times to control infection risk to bathers. However, there are some circumstances in which Pool Carers must take immediate action – to cope with stools, diarrhoea, blood and vomit. Because of the risks involved, a Pool Carer faced with a release of faeces into the pool must decide on an appropriate course of action very quickly. The following procedures are national best practice and must be followed in our pools. Solid Stools Retrieve the stools immediately they are seen using a scoop and disinfect the scoop after use Close pool for 24 hours Maintain disinfectant levels at the top of the range, i.e. no more than 4 parts per million of chlorine Filter for three turnover cycles of the pool, backwashing after each cycle Ensure any particles have been removed from the pool Pool carers should confirm that disinfectant residuals and pH values are within the recommended ranges Re-open pool Loose, Runny Stool (Diarrhoea), Vomit or Blood Close pool Empty pool Wash down pool sides and pool bottom and sweep to remove any deposits Backwash the filter to remove particles Isssed June 2006 COP 7 – 7 H&S in Swimming Pools: Part Two Children’s Services Health and Safety Manual Filter for 6 turnover cycles Refill the pool and ensure that disinfectant residuals and pH values are within the recommended ranges Re-open pool Blood Spillages on Pool Surrounds The same procedures for large blood spillages as for diarrhoea should apply. Any blood spillage on the poolside should not be washed into the pool or poolside drains. Instead it should be dealt with using strong disinfectant. The blood should be covered with paper towels, gently flooded with the disinfectant and left for at least two minutes before it is cleared away. On the poolside the affected area should be washed with pool water The person clearing up the spillage must wear gloves. SUPPLIES AND EQUIPMENT This section refers to the equipment required by the Pool Carer to look after and maintain the pool and not plant and equipment maintained by NPS or other pool maintenance contractors Equipment consists of: Pool vacuum equipment Sweeping brush Wire brush Water test set Chemical measuring equipment Skimmer nets Equipment Inspection This equipment must be maintained in a serviceable condition and should be inspected regularly to ensure that it is satisfactory to protect users from risk. Replace equipment as required. SUPPLY AND STORAGE OF POOL TREATMENT CHEMICALS The chemicals required for the treatment of pool water are detailed in Appendix 1, together with assessments required by the Control of Substances Hazardous to Health Regulations (COSHH) 2002. Isssed June 2006 COP 7 – 8 H&S in Swimming Pools: Part Two Children’s Services Health and Safety Manual Supply of Pool Treatment Chemicals Chemicals supplied for the treatment of pool water and cleaning surrounding areas must not be used for any other purpose. No chemicals other than those listed in this document should be used. These can be ordered through ESPO contract No 204 via BioLab UK Ltd. Do not order more chemical than required. The temptation to order large quantities to gain discounts must be balanced against the ability to store and handle the quantity safely. No more than 2 months supply should be ordered at one time. Storage of Pool Treatment Chemicals Good housekeeping and maintaining storeroom cleanliness are essential when storing pool treatment chemicals. Chemicals must be kept in containers that are correctly labelled with the details of the chemical they contain. Do not remove labels from containers or transfer chemicals to other containers that are not labelled or bear other product names or labelling. Chemicals must be stored in appropriate areas and bunded. Storage is not permitted in plant rooms, boiler rooms, changing rooms or the general pool area. It is essential that chemicals are kept separately to prevent accidental mixing or contamination. Toxic gases can be generated by inadvertent or inappropriate mixing of some chemicals. Exposure to heat, damp or direct sunlight should be avoided. Smoking is prohibited in chemical storage areas. The following markings will appear on the packaging: All chemical stores must have the following sign displayed: Isssed June 2006 COP 7 – 9 H&S in Swimming Pools: Part Two Children’s Services Health and Safety Manual PERSONAL PROTECTIVE EQUIPMENT (PPE) Where there is a foreseeable risk of contamination from chemicals, the following protective clothing and equipment may be required and where provided must be used. Goggles or face-shields Hard-toe rubber boots Overalls supplemented by full length aprons of rubber or acid-resistant plastic Rubber elbow-length industrial gloves You should consult the COSHH assessment in Appendix 1 to check requirements for safe handling and use of particular hazardous pool treatment chemicals. Gloves and eye protection should be worn however small a quantity of chemical is being handled. There are various standards for PPE. Within the standards there may also be subdivisions to denote the standard of protection or type, i.e. BS (British Standard) or EN (European Norm). All PPE must be ‘CE’ marked. The CE mark signifies that the PPE satisfies certain safety requirements. PPE Inspection, Maintenance and Storage An effective system of maintenance will be needed to ensure that the PPE continues to provide the user with the level of protection for which it was designed. Maintenance will include cleaning, disinfecting, examination, replacement, repair or testing. This equipment must be safely stored and kept clean and maintained in a serviceable condition. Each item should be inspected regularly to check for damage or deterioration. PPE must be replaced immediately when found to be unserviceable. PPE should also be checked by the user prior to use. If PPE is found to be faulty or in need of repair it should not be used until these repairs/maintenance have taken place or, alternatively, replacement PPE should be obtained. The PPE Issue Record Form contained in Section 13 of the Children’s Services Health and Safety Manual should be used to ensure all issues of PPE are recorded. The form must be signed by the recipient of the PPE and retained on the premises. COMMISSIONING AND DECOMMISSSIONING OF OUTDOOR POOLS Outdoor pools must be commissioned in May/June and decommissioned in July/August. Such work requires a specialist contractor to be employed. Schools can use NPS or employ the services of a specialist contractor direct. The contractor must be competent to carry out such work. Isssed June 2006 COP 7 – 10 H&S in Swimming Pools: Part Two Children’s Services Health and Safety Manual Appendix 1 ASSESSMENTS OF POOL PLANT CHEMICALS INTRODUCTION The Control of Substances Hazardous to Health (COSHH) Regulations 2002 are concerned with protecting people from hazardous substances. They require employers to carry out a risk assessment and on the basis of the assessment to prevent exposure or, if that is not possible, to control exposure to hazardous substances. A number of hazardous substances are used in the maintenance of swimming pools. This appendix lists these substances. COSHH assessments have been carried out for these substances and are included here. The assessments contain a number of items of information about the substance and the process in which it will be used. The assessments will dictate the controls that Pool Carers will adopt when using such substances. All staff using these substances must be familiar with the assessments as they appear in this appendix. COSHH ASSESSMENTS OF SUBSTANCES USED Substance Page Algicides Liquid Algaecide 7- 13 Cleaning Agents Tile and Line Cleaner 7- 15 Disinfection Chemicals Sodium Hypochlorite Stabilised Chlorine Granules 7- 17 7- 19 Filter Aids Ground Aluminium Sulphate 7- 21 Water Balance Chemicals Hydrochloric Acid Sodium Bisulphate 7- 23 7- 25 Water Testing Re-Agents Calcium Hardness Tablets 7- 26 Low risk substances used in Norfolk pools not requiring a written risk assessment: Cyanuric Acid Test Tablets; DPD No 1 Test Tablets; DPD No. 3 Test Tablets; Light Sodium Carbonate (Soda Ash); Phenol Red (Photometer) Tablets; Sodium Bicarbonate; Sodium Thiosulphate (Chlorine Reducer); Total Alkalinity Tablets. Isssed June 2006 COP 7 – 11 H&S in Swimming Pools: Part Two Children’s Services Health and Safety Manual Liquid Algaecide Substance or Preparation Trade Name BioLab Sunspot Liquid Algaecide Uses/Processes Substance is added to pool water by hand to combat fungal growth. Assessment The substance is corrosive and causes burns. Harmful if swallowed or if vapour is inhaled. Controls Avoid contact with skin and eyes. Use in a well ventilated area. Avoid contact with strong oxidising agents and strong reducing agents. Wear suitable chemical resistant protective clothing, gloves and eye/face protection. Wear chemical proof goggles or face shield. Spillage Contain and collect spillage with non-combustible absorbent material, e.g. sand, earth or a spill kit and place in container for disposal. Do not flush into surface water or sanitary sewer system Storage and Disposal Keep locked up and out of the reach of children. Keep container tightly closed. To maintain product quality, do not store in heat or direct sunlight. Keep in a dry, cool and well-ventilated place. Dispose of this material and its container to hazardous or special waste collection point. Isssed June 2006 COP 7 – 12 H&S in Swimming Pools: Part Two Children’s Services Health and Safety Manual First Aid Inhalation: move to fresh air. If breathing is irregular or stopped, administer artificial respiration. Give oxygen. First aider needs to protect themselves. Call professional medical attention immediately. Ingestion: call professional medical attention immediately. Clean mouth out with water and drink afterwards plenty of water. Do not induce vomiting without medical advice. Never give anything by mouth to an unconscious person. Eye contact: rinse immediately with plenty of water, also under the eyelids for at least 15 minutes. Call professional medical attention immediately. If spilt on the skin or clothes: take off all contaminated clothing immediately. After contact with skin, wash immediately with plenty of soap and water. Call professional medical attention immediately. Fire Fighting Dry powder, water spray, foam, carbon dioxide. Heating or fire can release toxic gas. Isssed June 2006 COP 7 – 13 H&S in Swimming Pools: Part Two Children’s Services Health and Safety Manual Tile and Line Cleaner Substance or Preparation Trade Name Tile and Line Cleaner Uses/Processes Hand application or spraying. Dilute in bucket to clean tiles and pool surrounds. Applied by hand with cloth. Assessment The substance is an irritant and causes eye and skin irritation. Controls Avoid contact with eyes, skin or clothing. Use in a well ventilated area. Wear rubber gloves, goggles or safety glasses with side shields when handling. Spillage Do not allow to enter surface water courses. Neutralise small amounts with an alkali such as Soda Ash and flush into sewer. Absorb or contain larger amounts and dispose of as hazardous waste. Storage and Disposal Keep locked up and out of reach of children. Small quantities created by the products normal use, wholly or partly neutralised with hard water salts may be disposed to the sewer. First Aid Inhalation: unless inhaled in steam, this product is unlikely to present problems by inhalation. Remove from contaminated atmosphere. Seek medical attention if irritation persists. Skin contact: remove all contaminated clothing, taking care not to transfer the material to unaffected areas. Wash affected area with copious amounts of water. Seek medical attention if burn persists. Isssed June 2006 COP 7 – 14 H&S in Swimming Pools: Part Two Children’s Services Health and Safety Manual Eye contact: immediately wash the eyes for at least 15 minutes with water, holding the eyelid open. Seek immediate medical attention. Ingestion: rinse mouth and give plenty of water to drink. Do not induce vomiting. Seek immediate medical attention. Fire Fighting Dry powder, water spray, foam, carbon dioxide. Isssed June 2006 COP 7 – 15 H&S in Swimming Pools: Part Two Children’s Services Health and Safety Manual Sodium Hypochlorite Brand Name Sodium Hypochlorite 14-15% Uses/Processes Disinfection agent (liquid bleach) pumped automatically into pool. Assessment The substance is corrosive and causes burns to skin and eyes. Harmful by ingestion, inhalation and through skin contact. Skin irritant. Contact with acids releases poisonous gas (chlorine). Controls Do not breathe mist. Do not mix with acids. Avoid contact with other cleaning agents. Use in well-ventilated areas only. Protect eyes. Do not mix with acids. Wear suitable protective clothing, gloves and eye/face protection - PVC is recommended. Keep locked up and out of the reach of children. Spillage Small spillages - wash the spillage area with water. Large spillages - contain spillages with sand, earth or any suitable adsorbent materials. Transfer to a container for disposal. Wash the spillage area with water. Storage and Disposal Keep away from heat and direct sunlight. Keep away from acids, ammonia solutions, amines and methanol. Dispose of substance and container via an authorised waste disposal contractor to an approved waste disposal site. Isssed June 2006 COP 7 – 16 H&S in Swimming Pools: Part Two Children’s Services Health and Safety Manual First Aid Inhalation: remove from exposure, rest and keep warm. Administer oxygen if necessary. Obtain medical attention. Skin contact: take off all contaminated clothing immediately. After contact with skin, wash immediately with plenty of water. If symptoms develop, obtain medical attention. Eye contact: speed is essential. Immediately irrigate with eyewash solution or clean water, holding the eyelids apart, for at least 10 minutes. Obtain immediate medical attention. Ingestion: remove patient from exposure, rest and keep warm. Administer oxygen if necessary. Obtain medical attention. Fire Fighting Dry powder, water spray, foam, carbon dioxide. Toxic fumes are produced when substance is involved in a fire. Isssed June 2006 COP 7 – 17 H&S in Swimming Pools: Part Two Children’s Services Health and Safety Manual Stabilised Chlorine Granules Substance or Preparation Trade Name Stabilised Chlorine Granules. Also known as Sodium Dichloroisocyanurate Dihydrate and Dichlor Granules. Uses/Processes For manual disinfection of pool water. Assessment The substance is harmful if swallowed. Can cause severe irritation to eyes and respiratory system and / or burns characterized by redness, swelling and scab. Contact with acids releases poisonous gas (chlorine). Controls Keep container dry. Mask in normal conditions. Wear suitable chemical resistant gloves. Wear protective clothing. Wear chemical splash goggles. Spillage Isolate area and warn others. Do not introduce water or other liquids to the spillage site. Sweep up and deposit in dry plastic sacks or drums. Do not put into bins or skips. Dispose of in accordance with appropriate local regulations. Storage and Disposal Store in a cool, dry place away from direct sunlight and heat. Damp or slightly wet conditions may slowly liberate hazardous gases. Keep locked up and out of reach of children. Avoid storage or contact with: organic materials, oil, grease, saw dust, reducing agents, Nitrogen containing compounds, Sodium Hypochlorite, Calcium Hypochlorite, other oxidisers, acids and alkalis. Isssed June 2006 COP 7 – 18 H&S in Swimming Pools: Part Two Children’s Services Health and Safety Manual This material and/or its container must be disposed of as hazardous waste. Avoid release to the environment. First Aid Inhalation: remove from exposure, rest and keep warm. In severe cases, or if recovery is not rapid, or complete, seek medical attention. Skin contact: wash thoroughly with plenty of water. Remove contaminated clothing and wash before reuse. If large area of skin is damaged or if irritation persists seek medical attention. Eye contact: flush immediately with water for at least 15 minutes. If irritation persists seek medical attention. Ingestion: wash out mouth with water. Do not induce vomiting. If patient is conscious, give water to drink. Seek immediate medical attention Fire Fighting Water, Carbon dioxide, dry powder, or appropriate foam. Isssed June 2006 COP 7 – 19 H&S in Swimming Pools: Part Two Children’s Services Health and Safety Manual Ground Aluminium Sulphate Substance or Preparation Trade Name Ground Aluminium Sulphate or Aluminium Sulphate or Sparkle Tabs Uses/Processes Coagulant for water treatment. Assessment May be harmful if inhaled. Material is irritating to mucous membranes and upper respiratory tract. May be harmful if swallowed. Causes skin irritation. May be harmful if absorbed through the skin. Causes severe eye irritation. On contact with water product will hydrolyse to produce Sulphuric Acid and Aluminium Hydroxide. Controls Use in well ventilated area. Avoid exposure to moist air or water. Wear suitable chemical resistant gloves. Wear appropriate chemical apron to prevent skin contact. Safety goggles or glasses with side shields. Have equipment for eye rinsing available. Spillage Damp down slightly then vacuum or shovel up into labelled containers for disposal. Do not let product enter drains. Contain the material and sweep up. Storage and Disposal Keep product in supplied container when not in use and replace lid after use to prevent absorption of moisture. Keep locked up and out of reach of children. Unused material and container should be considered hazardous waste. Dilute with water, neutralise with lime. Dispose of via an authorised waste disposal contractor. Isssed June 2006 COP 7 – 20 H&S in Swimming Pools: Part Two Children’s Services Health and Safety Manual First Aid Inhalation: not normally applicable but as a precaution remove to fresh air and keep patient warm. Skin contact: remove contaminated clothing immediately and wash affected area thoroughly with soap and water. Seek medical attention if skin appears damaged. Eye contact: wash out eye with plenty of water for at least 15 minutes and seek medical attention. Ingestion: rinse mouth out thoroughly with water, give plenty of water to drink and obtain medical attention immediately. Fire Fighting Water spray, carbon dioxide. Isssed June 2006 COP 7 – 21 H&S in Swimming Pools: Part Two Children’s Services Health and Safety Manual Hydrochloric Acid Substance or Preparation Trade Name Hydrochloric Acid 32% Uses/Processes Used to lower pH and /or total alkalinity. Assessment Extremely corrosive. inhalation of vapour can cause serious injury. Ingestion may be fatal. Liquid can cause severe damage to skin and eyes. Inhalation of mists and vapour will cause irritation of the upper respiratory tract, high concentrations may cause corrosion, pulmonary oedema may occur up to 48 hours after exposure. Irritating to skin, eyes and mucous membranes. Ingestion may cause damage to the gastrointestinal tract. Repeated exposure to low levels may cause erosion of the teeth and ulceration of the nasal septum and gums. Attacks most common metals liberating hydrogen, which can form explosive mixtures with air. Can react violently with oxidising agents liberating chlorine. Controls Good general ventilation required. Avoid heat, flames. Incompatible with most common metals, amines, metal oxides, acetic anhydride, propiolactone, vinyl acetate, mercuric sulphate, calcium phosphide, formaldehyde, alkalis, carbonates, strong bases, sulphuric acid, chlorosulphonic acid. Use safety glasses or face mask, gloves. Spillage Bund spill area, dilute with plenty of water and neutralise with lime slurry or sodium carbonate. Flush away with plenty of water. Isssed June 2006 COP 7 – 22 H&S in Swimming Pools: Part Two Children’s Services Health and Safety Manual Storage and Disposal Suitable Storage Media - rubber lined mild steel, PVC, high density polyethylene. Keep locked up and out of reach of children. Do not allow undiluted material to enter drains, sewers or water courses. Unused material and container should be considered hazardous waste. Dispose of substance and container via an authorised waste disposal contractor to an approved waste disposal site. First Aid Inhalation: remove from exposure, rest and keep warm. In severe cases, or if recovery is not rapid, or complete seek immediate medical attention. Skin contact: drench the skin with plenty of water. Remove contaminated clothing and wash before reuse. If large areas of the skin are damaged or if irritation persists seek medical attention. Eye contact: irrigate thoroughly with water for at least 10 minutes. Obtain medical attention. Ingestion: wash out mouth with water. Do not induce vomiting. If patient is conscious, give water to drink. Seek immediate medical attention. Fire Fighting Use extinguisher suitable to cause of fire. Isssed June 2006 COP 7 – 23 H&S in Swimming Pools: Part Two Children’s Services Health and Safety Manual Sodium Bisulphate Substance or Preparation Trade Name Sodium Bisulphate (Dry Acid) Uses/Processes Reduces alkalinity in pool water. Assessment Corrosive - causes burns. Very destructive of mucous membranes. Harmful if swallowed, inhaled or in contact with skin. Incompatible with strong bases, strong oxidizing agents, sodium carbonate and sodium hypochlorite. May decompose upon exposure to moist air or water. Controls Avoid contact with skin and eyes. Wear suitable protective clothing - safety glasses and suitable gloves. Spillage Collect into container and close lid. Storage and Disposal Keep locked up and out of reach of children Dispose of via an authorised waste disposal contractor. First Aid Inhalation: remove to fresh air and rest. Ingestion: do not induce vomiting; give plenty of water to drink; get prompt medical attention. Skin contact: wash with soap/cleanser and rinse with plenty of water. Eye contact: irrigate with water for at least 15 minutes. If irritation persists, consult a doctor. Isssed June 2006 COP 7 – 24 H&S in Swimming Pools: Part Two Children’s Services Health and Safety Manual Calcium Hardness Tablets Substance or Preparation Trade Name Calcium Hardness Tablets Uses/Processes Water testing re-agent. Assessment The tablets are corrosive, due to the lithium hydroxide content, and may cause burns or irritation to skin and eyes etc. Controls Use only as instructed in the test method. Avoid handling the tablets where possible to maintain analytical purity. Wash hands after contact. The use of thin disposable gloves and eye protection are recommended. Spillage Sweep up and wash away with plenty of water. Storage and Disposal Store in original container. Keep cool and dry. Keep away from children. In the small quantities associated with the correct use of these tablets there is no hazard to the environment. First Aid Eye contact: irrigate thoroughly with water. If discomfort persists, obtain medical attention. Skin contact: wash with plenty of water. Ingestion: wash out mouth thoroughly with water. If possible give water to drink. In severe cases, or if you feel unwell, obtain medical attention. Fire Fighting Water and all types of extinguishers may be used. Isssed June 2006 COP 7 – 25 H&S in Swimming Pools: Part Two Children’s Services Health and Safety Manual Appendix 2 WATER TREATMENT PROCEDURES INTRODUCTION To ensure that pool water is of a high quality the Pool Carer needs to take a number of actions. The table below lists the individual tasks which will be routinely required and how often they should be performed. Following the table are details of why some tasks are necessary and procedures for carrying them out. All water tests carried out by the Pool Carer must be recorded on the ‘Pool Water Test Record Form.’ Task How Often? 3 times a day Test water pH value Test water free chlorine value Test water combined chlorine value Test water total alkalinity Test water calcium hardness Record water temperature Check water clarity Remove skimmer/strainer baskets and clean Remove and clean chlorine pump injectors Backwash filter(s) Hose or mop out changing rooms, showers and toilet areas Scrub down pool surrounds and disinfect Check pool for debris, algae etc – brush and vacuum Remove and refit pool covers/blankets Remove pool scum line deposits Clean pool area walls and windows Inspect pool area for defects, including loose and broken tiles, security of hand rails, steps, springboards, lifting equipment etc General inspection of plant room Check availability and condition of PPE Record number of bathers Isssed June 2006 Daily Weekly Twice Weekly As required COP 7 – 26 H&S in Swimming Pools: Part Two Children’s Services Health and Safety Manual WATER TREATMENT Objectives of Water Treatment It is essential that pool water is: Crystal clear and inviting to bathers Sufficiently disinfected to kill bacterial pollution Clean and hygienic Free from surface contamination Of a comfortable temperature To achieve these objectives pool water has to be cleaned and treated with chemicals to counter the types of physical, biological and chemical contamination described earlier. Chlorination The main method of disinfecting pool water is by chlorination. The majority of pools have an automatic dosing system which feeds a chemical disinfectant into the water on demand. The disinfectant used is usually sodium hypochlorite. Manual dosing is required in some pools. This involves the addition of a disinfectant to the water by hand. Chlorine granules (Sodium Dichloroisocyanurate) is the disinfectant used. Pool Carer should ensure the correct methods of dosing are used in accordance with training and manufacturer's instructions. For COSHH assessment whilst handling these substances, refer to Appendix 1. Water Testing After disinfection the water should be checked and tested to ensure it remains at the quality desired. Samples for testing should be taken from the body of the pool water about half way between the return and draw-off points of the water circulation system. Tests should be made using the comparator or electronic apparatus provided to every pool. The following tests are required: - pH value of water Free chlorine level Combined chlorine level Total alkalinity Calcium hardness Water temperature Water clarity Isssed June 2006 COP 7 – 27 H&S in Swimming Pools: Part Two Children’s Services Health and Safety Manual PH Value pH is a scale from 0 to 14 which measures the acidic or alkaline condition of a substance, in this case the water in the pool. ACID Allowable Range ALKALI Ideal Range 14 0 6 6 6 6 7 7 7 7 7 7 7 7 7 8 8 8 8 . . . . . . . . . . . . . . . . . 6 7 8 9 1 2 3 4 5 6 7 8 9 0 1 2 3 pH Scale pH 7 is the neutral area, with pH 0 being the most acidic and pH 14 the most alkaline. For pool water the allowable range is between 7.2 and 7.8. However, the Ideal Range is between 7.4 and 7.6. Pool Carers should be aiming to ensure the Ideal Range in their pool. When the water falls below pH 7.2 a number of problems can occur, e.g. Smarting of bathers' eyes Corrosion of metals and pool finish (tiles, grouting etc.) Reduced efficiency of chlorine allowing unpleasant compounds to form When the water goes above pH 7.8 the following problems can occur: Smarting of bathers' eyes Ineffective disinfectant Formation of scale causing reduced filter efficiency pH Values: Water Testing pH values must be checked by water testing 3 times per day. This will require use of the Pool Water Test Kit and Phenol Red Tablets. Manufacturers' instructions and training must be followed when carrying out this procedure. The following is a quick reference guide for carrying out the water testing procedure: Fit pH disc into comparator Fill 2 test tubes with sample from pool Isssed June 2006 COP 7 – 28 H&S in Swimming Pools: Part Two Children’s Services Health and Safety Manual Leave one filled to 10ml mark and place in left hand compartment to act as a blank, behind colour standards Fill the other test tube to 10ml mark and add Phenol Red tablet Wait 2 minutes for the tablet to disintegrate Place in right hand compartment and match colour against disc, immediately, reading the value from the bottom right hand aperture. This is the pH value. If the value is outside the above parameters, the following actions will be necessary: If too acidic, add light sodium carbonate (soda ash) If too alkaline, add sodium bisulphate (dry acid) Please follow the instructions on the container regarding the appropriate quantity of sodium bisulphate to add to the water. Both of these substances should be handled with care. They are both white powders and can be introduced by either of the following methods: i) automatically injected in solution form by small metering pumps into the pool water circulation system or ii) by hand as follows: - wear appropriate personal protective clothing ensure bucket is washed before any chemical is added to the bucket measure out required amount of substance with scoop and measure mix in a clean bucket with water using a suitable mixing stick disperse into the pool water by walking around the poolside do not splash do not mix chemicals ensure at least 60 minutes have passed after addition of chemical before bathers enter the water record results on ‘Pool Water Testing Record Form’ Chlorine Testing Two types of chlorine testing are required - free chlorine and combined chlorine. Free chlorine is the amount of chlorine which is pure and ready to attack contamination. Once the chlorine goes to work it mixes with bacteria and algae and then changes composition, becoming combined chlorine. Combined chlorine is much less effective and slower to react in the disinfection process. Free Chlorine Testing Free chlorine testing should be carried out 3 times each day. This requires use of the Pool Water Test Kit and DPD No.1 Tablets. Manufacturers' instructions and training must be followed when carrying out this procedure. Isssed June 2006 COP 7 – 29 H&S in Swimming Pools: Part Two Children’s Services Health and Safety Manual The following is a quick reference guide for carrying out the free chlorine testing procedure: Fit chlorine disc into comparator Rinse 2 test tubes thoroughly with sample from the pool Leave one filled to 10ml mark and place in left hand compartment to act as a blank behind colour standards Fill the other test tube to 10ml mark and add a DPD 1 tablet Wait for the tablet to disintegrate Place in right hand compartment and match colour against disc immediately reading the value from the bottom right hand aperture. This is the free chlorine reading Record results on ‘Pool Water Testing Record Form’ If a colour appears when the tablet is added but disappears quickly a high level of chlorine is present. When this happens another test is required using 90% tap water and 10% pool water in a 10ml test tube. Add DPD 1 tablet to test tube and match the colour against the value on the disc. Multiply answer by ten to find the free chlorine reading. This technique also applies if the colour is deeper than the highest value on the disc. The free chlorine reading should be between 1.5mg/l and 3.0mg/l. If the chlorine level is below 1.5 mg/l increase level to 3.00mg/l by increasing the flow through the chlorine pump. If the chlorine level is above 4.00mg/l reduce level by adding Sodium Thiosulphate (Chlorine Reducer) to the pool water. Please follow the Instructions on the container regarding quantity. It is important that if the chlorine level is above 4.00 mg/l swimming must cease until the level is between the set parameters of 1.5 mg/l to 3.0 0mg/l. Combined Chlorine Testing The combined chlorine test should be carried out once a day immediately after a free chlorine test. The same equipment should be used as follows: Add a DPD 3 tablet to the test tube still containing the dissolved DPD 1 tablet Allow to disintegrate and mix After two minutes match against disc The answer is the total residual chlorine Subtract the free chlorine reading from the total chlorine reading and this will be the combined chlorine value The combined chlorine reading should be no more than 1 part per million above the free chlorine reading Record reading on ‘Pool Water Testing Record Form’ Isssed June 2006 COP 7 – 30 H&S in Swimming Pools: Part Two Children’s Services Health and Safety Manual If the combined level is above 1.00 mg/l reduce by large backwashes until level is below 1.00mg/l. Total Alkalinity Testing Total alkalinity refers to the total concentration of several basic (alkaline) chemicals in the pool water. This is known as the ‘buffer’. Total alkalinity affects the water's pH. For example, if the total alkalinity is too low, the pH level will be very sensitive and may suffer major changes. This makes it difficult to hold in the ideal range 7.4 to 7.6. If the total alkalinity is too high the water can become cloudy and scale producing. A high value can keep the pH value rigid and difficult to alter without excessive chemical addition. Total alkalinity should normally be between 80mg/l to 140mg/l. Pool water should be tested daily to ensure it remains in this range. This will require the use of the Pool Water Test Kit and Total Alkalinity tablets. Manufacturers' instructions and training must be followed when carrying out this procedure. The following is a quick reference guide for carrying out the total alkalinity testing procedure: Fill shaker bottle with pool water to 50ml mark Add one total alkalinity tablet Shake the bottle until the tablet dissolves Continue adding tablets one at a time until the colour of the solution changes from straw yellow to bright red. Ignore any intermediate orangepink colours Note the number of tablets used and calculate as follows - no. of tablets x 40 - 20 = total alkalinity in mg/l Record result on ‘Pool Water Testing Record Form’ If the Alkalinity is above 140mg/l reduce with sodium bisulphate (dry acid). Mix the dry acid and water and pour in one area of the pool only. This is known as spot dosing. Do this each day in a different area until the alkalinity is below 140mg/l. Calcium Hardness Testing The total hardness of water is measured by the amounts of calcium and magnesium salts contained in it. Calcium Hardness is the part of total hardness which measures calcium salt levels. The level will have a bearing on the pool water balance. If these levels are too low the water may become corrosive causing damage to pipe-work. Calcium Hardness should normally be between 250mg/l and 550mg/l. Pool water should be tested weekly to ensure it remains in this range. This will require the use of the Pool Water Test Kit and Calcium Hardness Tablets. Manufacturers' instructions and training must be followed when carrying out this procedure. Isssed June 2006 COP 7 – 31 H&S in Swimming Pools: Part Two Children’s Services Health and Safety Manual The following is a quick reference guide for carrying out the calcium hardness testing procedure: Fill shaker bottle with pool water to 50ml mark Add one calcium hardness tablet Shake the bottle until the tablet dissolves Continue adding tablets one at a time until the colour of the solution changes from pink to violet Note the number of tablets used and calculate as follows - no. of tablets x 40 - 20 = calcium hardness in mg/l Record result on ‘Pool Water Testing Record Form’ If the calcium levels rise above 550mg/l contact the Children’s Services Technical Adviser (Swimming Pools) on 01603 224489 for advice. Water Temperature Pool water is heated by pumping water through a heat exchanger and back to the pool tank. There has been a trend towards higher water temperatures, but this can create a number of problems: Bathers get hotter limiting serious swimming and increases sweat and other body oils release Micro-organisms grow faster the hotter the water Energy costs are higher as temperatures increase As water temperature rises, so does ambient temperature making the air uncomfortable Risk of condensation, corrosion and deterioration on the building Gases may be released creating bad smells The recommended water temperatures are: - Recreational and school swimming sessions: 28C (82.4F) Hydrotherapy pools: up to 37C (96F) Water temperature should be taken once a day (ideally in the morning). The thermometer used should be suitable for use in pools, i.e. one not containing mercury and which, in the event of damage, will not shed glass into the water. Readings should be recorded on the ‘Pool Water Testing Record Form’. Water Clarity So that the pool water looks inviting, but more importantly for reasons of safety, the pool water must be clear. It should be possible to see the pool floor from any point on the pool surround. If this cannot be achieved you should take the action detailed in the problem solving tables that follow. Isssed June 2006 COP 7 – 32 H&S in Swimming Pools: Part Two Children’s Services Health and Safety Manual Skimmer/Strainer Baskets The pool water flows over one or more weirs at the side of the bath and is then drawn by the pump through a strainer basket situated behind the weir. These baskets must be inspected daily and emptied as required. Skimmers will only work properly if the pool water is at the correct level. This is approximately half way up the skimmer aperture. Filter Backwash In normal operation filters will become clogged and will need to be backwashed. The frequency of backwashing will depend on the usage, i.e. numbers and type of bathers. The following procedure should be adopted: Turn off power to filter Ensure any necessary valves are opened and/or closed Move lever on filter to backwash Turn on power Backwash for 3-5 minutes or until sight glass (if fitted) is clear Turn off power Move lever to rinse Turn on power and rinse for ten seconds Turn off power Move lever back to filter position Turn on power. The number of times a pool requires backwashing will depend on the following factors: - Clarity of water Number of bathers Hours of daily use Type of swimming, e.g. babies, lifesaving Type of activities, e.g. canoes It is recommended that a pool should be backwashed at least three times a week. GENERAL POOLSIDE TASKS In addition to the water treatment tasks, several activities are required with regard to the pool surrounding area. Plant Room These areas must be secured from unauthorised access. They should be marked by appropriate signs. Isssed June 2006 COP 7 – 33 H&S in Swimming Pools: Part Two Children’s Services Health and Safety Manual Plant rooms should not be used to store combustible materials. They should be kept clean and tidy and easy access and egress must be maintained at all times. The following actions will be required in the plant room each day: Ensure pump is working and check strainer basket Check all gauge readings, in particular filtration plant pressure/vacuum gauges Record and report any abnormalities Check correct operation of dosing equipment, clean injectors weekly Check operation and efficiency of extract ventilation system Ensure pool water heating plant is operating effectively Inspect all plant for obvious water leaks Check visually for slack or frayed belt drives, ensure all guards to moving parts are in place Listen for and report any unusual noises from mechanical plant, report any unusual smells. General Inspection of Pool Area Daily checks should be made of the pool area. Defects should be recorded and reported to the school’s Property Surveyor or the Children’s Services Technical Adviser (Swimming Pools). Local immediate actions should be taken to remove a defective item or area from use until rectified. A general inspection of the pool surrounding area should look in particular at: Condition of pool surrounding flooring, i.e.cracked or loose tiles, etc. Security of pool handrails, steps, springboards, equipment storage mechanisms Condition of pool cover and storage mechanism Security and functioning of poolside hoist (if fitted) Condition of poolside aids or equipment, i.e. ropes, life-belts, buoyancy aids, etc. Pool Covers (Thermal Blankets) These are used primarily to conserve heat and so prevent evaporation. It is estimated that they can save up to 60% of heating costs. They are also useful in preventing unwanted debris from contaminating the pool water. They do, however, need careful handling. These points should be considered: Pools larger than 10 x 5 metres should consider having the cover in sections Care is needed to prevent debris falling back into the pool when removing 2 people will be required to fit and remove Consider the installation of rollers to assist in fitting and removing blankets Remove covers from outdoor pools in winter months to avoid deterioration Isssed June 2006 COP 7 – 34 H&S in Swimming Pools: Part Two Children’s Services Health and Safety Manual Appendix 3 PROBLEM SOLVING TABLES AND GLOSSARY The following tables will act as a quick reference problem solver for Pool Carers. Problem pH too high Possible Reason Suggested Action Mains water is alkaline (hard) Add more acid Alkaline disinfectant being used Consider changing to acid disinfectant. Adjust regularly by acid dosing. Mains water is acidic (soft) Add more alkali Acidic disinfectant used Consider changing to alkaline disinfectant. Adjust regularly by alkali dosing. Water is not buffered alkalinity too low Check and raise alkalinity Dosing erratic Check dosing accuracy and frequency pH difficult to change Water too buffered - alkalinity too high Check and lower alkalinity Cloudy, dirty water Bathing load too high Reduce bathing load Filtration inadequate Check filter, flow rate, backwash pH too low pH erratic Isssed June 2006 COP 7 – 35 H&S in Swimming Pools: Part Two Children’s Services Health and Safety Manual Problem Possible Reason Cloudy, clean water Hardness salts coming out of solution Suggested Action Check and where necessary correct pH, alkalinity, hardness Entrained air or coagulant Check on coagulant dosing. Check air release on filters; air leaks on suction side of pump Cloudy, coloured water (outdoor pools mainly) Algae - sunlight, poor hydraulics Increase residual level, backwash Slimy coloured growth on pool walls, floor, black on grouting Algae - sunlight, poor hydraulics Without bathers, brush or vacuum off algae, increase residual level, backwash Water has a bad taste or smell irritates eyes and throat High combined chlorine Check combined chlorine levels and type; be prepared to dilute or correct free chlorine level pH wrong Check and correct as necessary Sunlight Consider a stabiliser (cyanuric acid) Bather pollution Reduce bathing load Filter blocked, turnover reduced, hydraulics poor Check filter, strainer, flow rate, and valves Too infrequent backwashing/cleaning - or scale Check and improve backwash effectiveness; consider replacing sand Incorrect coagulant dosing Check coagulant dosing; inspect filter Chlorine level difficult to maintain Filter blocked (pressure across it too high) Isssed June 2006 COP 7 – 36 H&S in Swimming Pools: Part Two Children’s Services Health and Safety Manual Problem Water clarity generally poor Possible Reason Suggested Action Wrong filter or incorrect use Check filtration type and rate, sand condition, procedures (backwashing etc.) Insufficient chlorine Check and correct free chlorine residual Incorrect or no coagulant Check coagulant usage Hard scale on surfaces, fittings, pipes, etc; water may feel harsh Hardness salts coming out of solution Check and where necessary correct pH, alkalinity, hardness Cannot get test kit readings for free chlorine residual Chlorine levels too high Test a 50:50 diluted water sample Chlorine levels too low Check chlorine dosing Air circulation poor Check air handling introduce more fresh air Combined chlorine too high Restore recommended chlorine levels Temperature too high Reduce to recommended levels Water has a salty taste Dissolved solids too high Dilute Staining at water inlet Iron salts coming out of solution Check pH, water balance, coagulation Dull water, no sparkle Could be anything Check everything disinfection, water balance, filtration, coagulation, etc. Poor air quality Isssed June 2006 COP 7 – 37 H&S in Swimming Pools: Part Two Children’s Services Health and Safety Manual GLOSSARY Acid Chemical which lowers pH when added to water. Algae Microscopic aquatic plant life that can grow in water where there is a combination of warmth and light. Most commonly green or brown in appearance. Left unchecked algae multiply quickly causing considerable problems such as cloudy and discoloured water. Algaecide Chemical compound used to kill or prevent the growth of algae. Alkali A term applied to carbonates and hydroxides. Alum Chemical used to aid filtration. It produces a gel in the upper region of a sand filter bed which traps particles that are smaller than the gaps between the sand grains. Backwash The process where filter beds are cleaned with pool water by reversing the flow of water through the filters and dumping to waste. Bacteria Microscopic organisms – some of which can cause disease. They are introduced to a swimming pool by bathers, wind, dust, rain and surface drainage. Bather Load The number of bathers using a pool – the principal source of contamination. Breakpoint Chlorination A method of chlorination where sufficient quantities of chlorine are added to water to oxidise most of the ammonia and organic matter while still leaving a residual of free chlorine. Calcium Hardness The measure of calcium salts dissolved in pool water. Chlorine A disinfectant that kills or inhibits algae and bacterial growth. Chlorine Demand Chloramines The amount of chlorine that is required to kill bacteria and organic matter before a residual of free chlorine is produced. As well as reacting with ammonia, chlorine reacts with organic nitrogen compounds that are derived from proteins in pollution from bathers. The resultant chlorinated organic amines contribute to combined chlorine readings. If the combined reading is too high only dilution significantly reduces them. Isssed June 2006 COP 7 – 38 H&S in Swimming Pools: Part Two Children’s Services Health and Safety Manual Combined Chlorine Free chlorine that has been used up and combined with waste products. The product of this reaction is chloramines, which are measured as combined chlorine. It has very poor disinfecting properties and is measured by subtracting the figure from a free chlorine test (DPD 1 tablet) from the figure from the total chlorine test (DPD 3 tablet). Chlorine Lock A condition where the residual of chlorine has become ineffective due to excessive levels of cyanuric acid. Cyanuric Acid A stabiliser added to pool water to protect the active chlorine against loss by ultra violet radiation from the sun. Dechlorination If it is necessary to reduce the chlorine residual in a pool due to accidental over-treatment, Sodium Thiosulphate can be used. DPD Short for Diethyl-p-Pheneylene Diamine. Dry Acid A more common name for sodium bisulphate which is used to reduce pH and total alkalinity levels in a pool. Filter A vessel containing a media that removes particulate matter as water passes through it. Filter Media Material used inside the filter to trap oxidising matter and debris. Backwashing releases the dirt by reverse-flowing water through it and leading off to drain. Filtration Rate The volume of water that passes through a filter bed in litres per square metre per hour. As the filter bed becomes blocked with debris the flow rate slows down and the volume of filtered water reduces. This can have a significant effect on water quality in a busy pool as it also affects the speed with which disinfection chemicals are distributed. Flocculant Material used to aid filtration by trapping smaller particles to form larger particles that are more easily removed by the filter. Flow Rate The flow of water in litres per minute, or gallons per hour. Free Chlorine The residual amount of chlorine left over after the chlorine demand has been met. Hydrochloric Acid An acid used to lower the pH and /or total alkalinity. Isssed June 2006 COP 7 – 39 H&S in Swimming Pools: Part Two Children’s Services Health and Safety Manual Inorganic Chloramines Compounds resulting from the chlorination process. These are removed by shock dosing with chlorine. Organic Chloramines Nitrogen bearing compounds such as saliva, urine, perspiration, body oils and sun tan lotions that are continually being introduced into pool water by swimmers. Organic chloramines cannot be shock dosed or filtered out and therefore must be removed by dilution. Oxidation The process whereby contaminants are burned up by causing them to combine with free available chlorine. pH Solution pH is the measure of the hydrogen ion concentration. A pH of 1 is a strong acid with many hydrogen ions. A pH of 14 has few hydrogen ions and is a strong alkali. A pH of 7 is a neutral solution. The pH of the human eye is around 7.4 – 7.5. Anything higher or lower will irritate. Phenol Red A chemical reagent used in the measurement of pH. ppm 1 part per million = 1 milligram per litre – measure of a chemical’s concentration in water. Residual Chlorine The free chlorine element in water that is still available for disinfection. Shock Dosing The process of adding extra chlorine to kill excessive bacterial or algae (algal growths) and to bring about the chemical destruction (oxidation) of organic wastes. Soda Ash Sodium carbonate. Used to increase the pH of pool water. Sodium Bicarbonate Baking Soda. Used to increase the alkalinity of pool water. Sodium Bisulphate Commonly known as Dry Acid. Used to decrease pH levels and/or alkalinity in pool water. Sodium Thiosulphate Used to neutralise excessive chlorine in pool water. Stabilised Chlorine Chlorine that contains cyanuric acid to condition against the effects of the sun. Lasts up to 5 times longer than un-stabilised chlorine. Total Dissolved Solids The total amount of dissolved materials in the water. High TDS in pool water can cause poor disinfectant efficiency, cloudy water and odours. Isssed June 2006 COP 7 – 40 H&S in Swimming Pools: Part Two Children’s Services Health and Safety Manual Total Alkalinity A measurement of the total amount of alkaline (basic) chemicals such as bicarbonates, carbonates and hydroxides in the water. Alkalinity buffers the pH and prevents sudden changes caused by addition of chemicals. High total alkalinity may result in difficulty adjusting the pH. Total Chlorine A measurement of all the active and inactive chlorine compounds in pool water as measured by a combination of DPD 1 and DPD 3 tablets. Turbidity This occurs where particles are suspended in solution and cause a loss of clarity. Turnover The time taken for a volume of water equivalent to the total volume of the pool to pass through the treatment plant once. Isssed June 2006 COP 7 – 41 H&S in Swimming Pools: Part Two