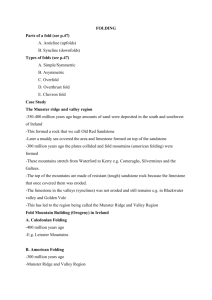

Integrierte Frontschnitteinrichtung

advertisement

fjj Successful Event at Herzog + Heymann Event unter neuen Ukraine, Finland, USA, Denmark, Sweden, Poland, Hungary, Austria, France, Switzerland, Germany – the visitors of the Herzog + Vorzeichen Heymann’s After Ipex Event could not be more international. They were rewarded with interesting highlights. 14 systems from the programme of MBO, Bograma, Sigma, Ehret and Herzog + Heymann were exhibited in three halls. Brand new within the H+H-programme are the fast Tape Dispenser (max. 15.000/h) and the new Window Patching Machine of Pro-Vision. An offer to newspaper- and commercialrotary printers For the half-or thirdfold of newspapers or commercial-rotary printers, two alternatives were introduced. The half-fold can be handled by a simple configuration consisting of rotary feeder TA 15, knife folding unit and a simple flat track delivery unit. Generally a compensating stacker would be used instead of the H+H flat track delivery unit to relieve the afterwards bundling. This system impresses by shortest preparation time, small space requirement and little investment costs. The capacity of approx. 10.000 up to 13.000/h is on an attractive priceperformance ratio. Automatically packed into paperboard The efficiently packing of small products is always a big problem , especially if it’s a question of high volume. For the first time there is the possibility to fill small sized products automatically into paperboards with the filling machine of Messrs. Sigma. World champion’s 50.000 small sized foldings directly into the paperboard Two plough-fold units are the principal items within the system for third-fold. Because of the possible capacity of up to 18.000/h the feeding and delivery of the products must occur properly. Buffer systems existing from customer’s side can be used for delivery. It is appropriate to also deliver by the compensating stacker. Herzog + Heymann-pre-pile system VS 450 with continuous stream suction feeder FBS. Window Patching Maschine and Tape Dispenser fixed on Herzog + Heymann-Transport System. With intermediate effect, the new Window Patching Machine permits absolutely new mailings. The Window Patching Machine can be used either inline with the rotative web punching machine from Ehret, the rotative Bograma sheet punching machine or with the Bograma inline punching machine, as the window will be punched inline before window patching. Also new scope of design will be offered concerning personalizing. The address of the covering letter is visible through the window, so this is also usable for dispatching. Surface glue for flexible application Previously, for application of surface hotmelt glue or remoistable glue, cutting units had to be costly considered. Newly, surface glue nozzles can be used at Herzog + Heymann flexibly at almost any place next to the vacuum belt of the transport system. Half- and thirdfold product. The flexibility of the Herzog + Heymann plough-fold units are featured by special features which allow to enclose advertising promoter to the printing products. Potential is to dispense products, to label, to personalise. The necessary units can be retrofitted within an add-on system. Pharmaceutical enclosures will get thicker Because of new regulations within the EU the manufacturer of pharmaceutical products is forced to create their enclosures more comfortable for reading by using larger type sizes. The volume of the text will be automatically higher but the end format must not, so the end product will get thicker. To occupy the non-stop process for higher net-capacity, previously the confinuous stream suction feeder was used for smallsizes. The problem was always to find the suitable air cushion in proportion to the pile height. Furthermore at high capacity 2 operators – one for the feeder, one for the delivery unit – are necessary. The new pre-pile system for the continuous stream suction feeder FBS is an alternative to the round pile feeder. Small sizes up to 65 mm width and wide, but short formats, which are bulky at pre-piling, are very reasonable on this pre-pile system in connection with the continuous stream suction feeder, the miniature folding machine KL 112.1 and the box delivery equipment within the vertical delivery. Up to 156 panel are currently possible with the Herzog + Heymann-Technology. To meet the target, waterscoring is necessary. Mailings with lateral label closing In any mailing house, today lateral closing with labels belongs to the feasible repertoire. For this purpose the cost effective transport system 091 ECO together with the Hermalabeller were introduced. The feeding of the pre-manufacured mailings ocurred by the cost effective friction feeder FRK. So, 20.000 products, accurately closed at both sides with lables were lying in the delivery after one hour. Miniature folding products are running directly into paperboards. Within the pause, a full paperboard can be changed against an empty one. Pharmaceutical enclosure with 156 panel and sealed with label. Three highlights from Bograma Rotative Sheet Punching Machine For the first time presented on IPEX in Birmingham, now on the After Ipex Event at Herzog + Heymann in Bielefeld. The new rotative sheet punching machine BSR 550 Servo from Bograma opens absolutely new scopes. Bograma-Rotary-Punch BSR 550 Servo. The interesting characteristics of this punching machine are: Formats of max. 550 x 750 mm Grammages up to 0,5 mm thickness Most complicated punching shapes in all feasible formats Inline waste brake-away After punching, Inline-processing with folding units. Front- and longitudinal cut inside a punching machine With the development of the new integrated front cutting equipment, a solution was found to produce three-side cut products more efficient and cost-effective with only one punching machine, without limitation within the tool area and with constantly high cutting quality. Through the integration of the front cutting equipment into the transfer, all tools still can be fitted within the punching area. The front cutting equipment can be ordered optionally to every new BS MULTI 450/750 Servo and Servo plus and to BSM 450 basic. The equipment is also available as retro-fit kit for all already delivered punching machines type BSM 450/750 Servo, Servo plus or BSM 450 basic. Piling up to 5 up with STA 550 The pile delivery STA 550 from Bograma allows to deliver flat folding products without considerable gapping or glued booklets. So the production of up to 5 up products can be considerably optimized. MBO with innovative novelties: MBO T 535/44 PERFECTION – fully automated (NEW) Patented features for half format: With the new pocket folding machine T 535 Perfection for the first time the users can benefit from the inimitable features of the Perfection series within the format of 50 x 70, as the T 535 Perfection already standardly comes with the patented MBO knifeshaft cassette within the folding unit I. Linke on a sliding carriage, the knife-shafts can be sidewise simply pulled out on the cassett, so the setting-up can occur in comfortable working position. Also on board are the vacuum- infeed and –alignment system VIVAS and the high-speed guide inside folding unit II. Both guarantee the precise alignment and the marking free sheet transport up to high speed. Equipped with the newest MBO controlgeneration VARIO-Control Plus including coloured touch screen, the T 535 Perfection allows amongst others the sheet target tracking through the complete machine. The possibility of modular automating of pockets, rollers and side-lays makes this folding machine to a very flexible and also fast and comfortable for setting-up high-power performer, absolutely precisely working. Insofar quality, equipment versions and operator convenience is concerned, the T 535 Perfection leaves nothing to be desired. MBO Pocket Folding Machine T 765 EFFICIENCY AUTOMATIC (NEW). With the Efficiency Automatic (EA) folding machines, MBO created a completely new series. It combines the attractive ratio of price and performance of the Efficiency series with the advantages of the automation. Equipment:: Model T 765 / 64 with round pile feeder, automated combi-folding pockets COMBIPLATE II, automated spiral folding rollers, palamides alpha700 plus pile delivery. MBO Combi Folding Machine K 800.2 S-KTZ Perfection – fully automated With following characteristics: Model K 800.2 / 4 S-KTZ, MWK knife-shaft cassette, swivelling cross-fold table, threefold extricable, cross-fold stop as waste paper ejector. Ehret with innovating novelties: Ehret Web Finishing Line (NEW) The roll sheeter can proceed every single format-cut with different length of 125 mm – 2032 mm. Additional highlights of this line: Max. production speed: 250 m/min. With variable cut-out (of 3,2 mm up to 80 mm) The split & merge-module allows to lead two webs register-true on top of each other. So doubling of one side printed or personalized webs is possible at highest speed. The plough fold module offers folding in longitudinal direction at maximum production speed. MBO DFT 560/6 folding unit with automated combi folding pockets and automated folding rollers MWK knife-shaft cassette palamides delta502 automatic delivery unit. Ehret Web Finishing Line for production of greeting cards with highspeed performance UW-52/520 Unwinder with web guide SVC-521 C fully automated electronical Digital-roll sheeter, 520 mm wide Herzog + Heymann-Transport System with belt guided plough fold. Ehret Web Finishing Line for pharmceutical enclosures Roll sheeter VC 400 C with integrated unwinder for paper reels with 80 cm diameter, reel width 400 mm, roll sheeter with cut-out. Folding unit M 7.46/52 6 pockets with lattice-type alignment table. Knife folding unit XS 300 for miniature formats. Perspective: The response of the visitors of this After Ipex Event was extremely big. The MBOGroup presented an interesting programme with important novelties, which are positively taken in by the professional audience. Through the impulse of this event, the responsible persons reckon with sustained incoming orders. www.herzog-heymann.com