pressure-volume-temperature and two

advertisement

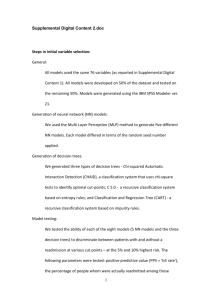

World Journal Of Engineering PRESSURE-VOLUME-TEMPERATURE CHARACTERISTIC OF GLYCEROL PLASTICIZED POLYVINYL ALCOHOL AND CASSAVA STARCH BLENDS Low Chong-Yu, Lee Tin-Sin Department of Chemical Engineering, Faculty of Engineering & Science, Universiti Tunku Abdul Rahman, Jalan Genting Kelang, 53300 Setapak, Kuala Lumpur, Malaysia While phosphoric acid acted as heat stabilizer to prevent occurrence of pre-processing thermal degradation. The mixtures were then compounded using a twin screws co-rotating extruder to produce plasticized PVOH (PPV). The composition of PPV is shown in Table 1. All heating zones were set at 160 oC while the screw speed was set at 250 rpm. After that, PPV, CSS and glycerol were mixed again in a high speed mixer as PPV-CSS mixtures at the composition shown in Table 2. The mixtures were compounded again in similar twin screws co-rotating extruder. All heating zones were set at 140 oC. Then, the extruded compounds were palletized and immediately sealed in polyethylene bags. Introduction The continual depletion of landfill space and environmental pollution of non-degradable or partially degradable petroleum based polymers have led the scientists to develop alternatives polymers compound based on agricultural resources. Starch as one of the cheapest and available abundantly agricultural resource is a good choice to blend with polymers for improvement of biodegradability while lowering the cost of the polymer compounds. In this study, cassava starch (CSS) is blended with polyvinyl alcohol (PVOH). PVOH is a biodegradable type of polymer possesses high polarity due to the existing of hydroxyl functional groups (-OH). Previous papers [1,2] have reported that the blending of starch and PVOH is highly compatible due to the presence of hydrogen bonding between the hydroxyl groups of starch and PVOH. The objective of the presence study is to characterize the pressure-volumetemperature (PVT) characteristic of PVOHcassava starch compound. PVT is able to provide the crystallinity and compressibility information of polymer compound subsequently leads to the estimation of shrinkage in injection moulded articles. Thermal transition measurement The specific volumes of the polymers as a function of temperature at 200 bars to 2000 bars were measured by pressure-volume-temperature (PVT) apparatus- SWO pvT 100. Initially, the known amount of specimen was filled into the cylindrical test cell with the piston inserted. Hydraulic pressure was applied to the specimens via the piston with an inert polytetrafluoroethylene (PTFE) seal to avoid potential leakage of molten specimen during testing. After precompression, the sample was heated in the test cell until equilibrates at the desired temperature of 200 oC for 5 minutes. The tests were conducted at low cooling rate of 5 oC/min to ensure sufficiently uniform temperature distribution within the specimen. The position of the piston was recorded continuously with decreasing temperatures. Finally, the specific volumes were calculated and plotted as a function of temperature as shown in Fig. 1. Experimental Materials Fully hydrolysed PVOH grade BF-17H (viscosity 25-30 cps, hydrolysis 99.4-99.8 mole %, ash < 0.7 %) was supplied by Chang Chung Petrochemical Co., Ltd.. CSS was obtained from Thailand- Cap Kapal ABC. Glycerol (C3H8O3) at 99.5 % purity was purchased from Fisher Scientific. Calcium stearate was provided by Sun Ace Kakoh Sdn. Bhd. and phosphoric acid at 85% purity was obtained from Merck. All materials were used as received. Table 1 Compositions of glycerol plasticized PVOH (PPV) Specimen Glycerol PVOH CaS Phosporic (phr) (%) (phr) acid (g) PPV 40 100 2 4.18 Table 2 Compositions of PPV blending with CSS Specimen PPV CSS Glycerol (wt %) (wt %) (phr) PPVCSS 40 60 20 Specimens Preparation PVOH, glycerol, calcium stearate (CaS), and phosphoric acid were physically mixed in a high speed mixer for 15 minutes. Glycerol and CaS were used as plasticizer and internal lubricant. 729 World Journal Of Engineering morphology in PPV where different molecular sizes and structures of starch and PVOH have disrupted the crystallinity morphology. Starch is denser than PVOH due to high branched of amylopectin structures resist the mobility of polymer chains and promote formation substantial amount of hydrogen bonds [5]. CSS is among the starch that has been found to possess semicrystalline long-branched structures [5]. Furthermore, the transition of onset melting points of PPV and PVOH-starch as identified at line A-B showed an agreement with previous DSC study that onset melting points were detected at the range of 160-180 oC [6]. Incorporation of starch has eliminated the crystalline content of PPV to an extent approaching the behaviour of amorphous polymer. In short, PVOH has significantly changed the processing behaviour of starch by influencing the blending morphology and interactions. PPV-starch compounds are preferable to be melt processed at temperature > 180 oC in order to achieve absolute molten state. The amorphous structure of starch filled PVOH has lower changes of specific volume subsequently leads to lower in shrinkage when injection moulded. Results and Discussion Fig.1 shows PVT diagram of PPV and PPVCSS measurements at pressure 200-2000 bar. As expected, when the pressure increased, the specific volume reduced gradually. This is because higher pressures have compressed the samples. Meanwhile, the PVT outcomes of PPV showed within the range 0.75-0.84 of neat PVOH as reported by Zoller and Walsh [3]. However, the extent decrements of PPV’s specific volume at decreasing temperature were lower than neat PVOH. This condition is obviously visible at molten state (above line A-B). Addition of glycerol as plasticizer has disrupted the crystallinity of neat PVOH. Glycerol has acted as external disturbance which disrupts the PVOH molecular chains to rearrange in compact structure. Hence, the amorphous structure in PPV reduced the changes of specific volume during cooling process. A Specific volume, v (cm3/g) 0.84 Conclusion 0.82 200 bar 0.80 500 bar Blending of CSS has reduced the crystallinity of the PPV by lowering the transition of specific volumes at melting stage and further rendering lower shrinkage when injection moulded. 800 bar 0.78 1000 bar 1200 bar B 0.76 1500 bar 2000 bar 0.74 0.72 20 40 60 80 100 120 140 160 180 200 References 220 Temperature, T (oC) 1. Lee, T. S., Rahman, W. A. W. A., Rahmat, A. R., and Samad, A. A. (2010). Computational modeling and experimental infrared spectroscopy of hydrogen bonding interactions in polyvinyl alcohol-starch blends. Polymer. 51, 1206-1211. 2. Lee, T. S., Rahman, W. A. W. A., Rahmat, A. R., and Khan, M. I. (2010). Detection of synergistic interactions of polyvinyl alcohol-cassava starch blends through DSC. Carbohydrate Polym.. 79(1), 224-226. 3. Zoller, P. ang Walsh, D. (1995). Standard PressureVolume-Temperature Data for Polymers. USA: CRC Press. 4. Abbès, B., Ayad, R., Pruhdommed, J. C., and Onteniente, J. P. (1998). Numerical Simulation of Thermoplastic Wheat Starch Injection Molding Process. Polym. Eng. Sci.. 38 (12), 2029-2038. 5. Liu, J., Xie, F., Yu, L., Chen, J., and Li, L. (2009). Thermal processing of starch-based polymer. Prog. Polym. Sci.. 34, 1348-1368. 6. Salleh, M. S. N., Rahman, W. A. W. A., and Lee, T. S. (2009). Tensile behaviour and thermal analysis of biodegradable injection grade tapioca starch filled plastic poly(vinyl alcohol). Proc. Env. Sci. & Tech. Conference (ESTEC2009). 7-8 December. Terengganu- Malaysia, 485-493. (a) 0.78 Specific volume, v (cm3/g) 0.77 A 0.76 200 bar 0.75 500 bar 0.74 800 bar 0.73 1000 bar 1200 bar 0.72 1500 bar B 0.71 2000 bar 0.70 0.69 0.68 20 40 60 80 100 120 140 160 180 200 220 Temperature, T (oC) (b) Fig.1 PVT diagrams of (a) PPV and (b) PPVCSS Generally, it was found that addition of starch also disrupted the crystallinity of PVOH. The thermal transition state at line A-B declined at high starch contains. This indicated that blending different molecule structure- i.e. starch into PVOH has deteriorated the crystal rearrangement during cooling process. High amount of starch in PPV caused the entire blending transformed into amorphous phase. This outcome agrees with previous study conducted by Abbes et al. [4] that thermoplastic starch is not very compressive with obvious thermal transition only found at 0.1 and 40 MPa PVT tests. This is due to the incorporation of starch has affected the 730