Ultra-thin Nano-layer Shrink-Stretch films

advertisement

Ultra-thin Nano-layer Stretch-Shrink Films

Henry G. Schirmer, BBS Corporation, Spartanburg, SC

Tom Schell, Curwood, Inc., Oshkosh, WI

Abstract

Clear ultra-thin polyolefin films based on nano-layers

composed of PP/EVA have been made and characterized.

These films exhibit shrink properties as well as stretch

properties and are surprisingly tough in spite of thinness

as low as 0.1mil total. In order to avoid unmanageable

tack, a high degree of slip was used. Surprisingly the high

slip films made did cling well to food dishes and bowls

making it highly useful as a lidding film. The high degree

of shrink shown in the film makes it also useful for shrink

packaging soft materials. Overlap seals were made during

the shrinking process.

room temperature. Therefore, any stretch orientation of PP

should have to be done immediately.

The quickest way to orient is as the PP containing film is

being blown. Fortunately, the specific material

composition used was very amendable to long stalk

processing where a very high blow up ratio (BUR) of 5:1

was obtained. Picture 1 below shows the first attempt.

Introduction

Oriented shrink films are another film type that has shown

unique improved properties through the use of nano-layers

within the film structure. Tough thin shrink films as low

as 0.3mil thick have been seen performing as well as

thicker films for packaging applications. The work

reported here is still another example of an even thinner

shrink film showing stretch properties as well. Ultra-thin

films as low as 0.1mil have been made because of the

high melt strength imparted by nano-layers.

The tool for creating nano-layers within the films

described in this work is the Layer Sequence Repeater

(LSR). As film research continues so does our knowledge

of what the LSR can do. Nano-layer films create many

surprises that we had not seen before and some of these

have been reported earlier at PO 2009, 2010, 2011 and

listed in the references. Some of the knowledge gained

has been used to develop the LSR further but cannot be

reported at this time because of patent reasons.

Nylon 6/EVOH nano-layer films reported in the above

papers showed some surprises that eventually led to an

understanding that blown films containing crystalline

EVOH in nano-layer form had a lower density, lower

M.P. crystal structure that was consistent with the film

being easily deformed. We also suspected that similar

things were happening to N6 as well. To test this,

N6/EVOH nano-layer films were stretch oriented above

the Tg of both but below 100C. Stretching the film in this

low temperature range showed clearly how deformable

this new crystal structure actually was.

Polypropylene is another crystalline polymer that also

may experience a new crystal structure when in nanolayer form. But it has a Tg well below room temperature

and that means that any crystalline changes may only be

temporary. Both N6 and EVOH both have Tg above 60C

so the new crystal forms remained rather permanent at

PICTURE 1

LONG STALK BUBBLE PROCESS

High Density Polyethylene shopping bags gain much of

their strength and toughness through this method of

orientation. Generally, a high molecular weight polymer is

the key to successful processing and the EVA component

in the 11-60-70 series structure was of 0.3MI. However,

the nano-layer structure of this new stretch-shrink film

gave it far different properties from an opaque stiff HDPE

counterpart. These properties were indeed due to the

nano-layers within the microstructure of the film series

described here. Picture 2 shows the micro-structure of a

similar but thicker precursor film.

PICTURE 2

25 NANO-LAYER FILM

1

Definition of Terms

The Patented Modular Disk Die has produced films

containing 25 and more micro-layers independently of the

LSR. While it is generally true that as the number of

micro-layers increases, the individual layer thickness

decreases for a given total film thickness. But the

thickness of each of the structural micro-layers is

generally all in the same order of magnitude. This doesn’t

preclude that some thin micro-layers may contain the

same material to make what would appear to be fewer and

thicker micro-layers. The reason for doing this might be to

simply gain increased output or to gain some other

processing attribute.

The Layer Sequence Repeater (LSR) operates as an

independent unit within a Modular Disk Die and inserts

nano-layer bundles within the matrix of micro-layers

wherever desired. These are truly an order of magnitude

thinner than the surrounding micro-layers. So the term

nano-layers as depicted here will be used to differentiate

nano-layer thickness relative to micro-layer thickness and

the difference was very apparent in picture 2 above and

other microphotographs shown in this paper.

For the purposes of this paper, the number of nano-layers

issued by the LSR was set at 25 in alternating layers of

EVA/PP. This nano-layer bundle appeared to be well over

one third of the total thickness of the film in all microphoto’s taken. In fact, the measured proportional thickness

ratio was 2125/4625 or 0.46T where T=total thickness.

Since the bundle contained 25 nano-layers, then each

nano-layer averaged .46/25T or .018T. At a total thickness

T=0.1mil, each nano-layer averaged 0.0018mil thick.

That’s 45.7 nanometers and will be the average of each

PP/EVA nano-layer in this paper.

Oriented films can be biaxial or monaxial. The ultra-thin

films within this report are biaxial. Oriented films can be

made by either a reheat process or by a cooling process.

The ultra-thin films here are from a cool down process.

Generally oriented films from cool down processes are

tougher, stretchier and in a less stressed state (low shrink

force) than films derived from the heat up process (high

shrink force). Some processes share a little of both as is

seen in US Patent 5,456,979.

were made at 4mil because we first thought to orient them

using a reheat process. However, there were problems

with hot tack and open ability of the tubing. So that

approach was temporarily abandoned until we could

provide a means to prevent hot tack. Picture 3 shows the

nano-layer structure of the 4mil film. Other thinner films

in this series all have the same structure but become

increasingly harder to microphotograph.

PICTURE 3

SAMPLE 11-54

The above 4mil film blown film structures also had a

tendency to blow with a stalk. So to enhance the stalk

stability, the EMA was switched to an EVA with a 0.3

MI. This higher MW resin indeed made long stalk

processing more stable and processed well in the LSR

with PP.

Samples 11-57 through 11-60 were made at a high BUR

and increasing draw speeds. Sample 11-61 coupled this

with a drastically reduced delivery rate. The highest draw

speed for this lab equipment was 56 fpm. Picture 4 shows

the overall setup.

Ext. d

Ext. b, A, c

2” Die &

Air ring

Experimental Procedure

TEST FILM STRUCTURES

Samples 11/54 & 11-55=

LDPE/EMA/{EMA/PP.. 25nano..PP/EMA}/EMA/LDPE

The above structures were the start of the PP nano-layer

series. EMA having about a 2 MI was first chosen to

sequence with PP because it adheres well. These films

PICTURE 4

LABORATORY FILM LINE

Extruders d, b, c = 0.75”

Extruder A = 1.25”

Extruders b, A, c were all commonly driven at a fixed

output ratio of 20/60/20 referred as a triplex extruder.

2

Samples 11-62 to 69=

LDPE/EVA/{EVA/PP.. 25nano..PP/EVA}/EVA/LDPE

With the stability of the process well defined by the 11-54

to 11-61 samples, the parameters were set so that thinnest

and widest film could be obtained. All films made were

15-16” wide with the rate of the triplex extruder b, A, c at

29rpm and extruder d at 30.

Because the glass transition temperature (Tg) of PP is

below room temperature at about –10C, any deformable

crystalline state produced within the nano-layers during

cooling would only be temporary at room temperature and

would quickly revert to the more stable higher melting

more rigid state. As reported earlier this is similar to the

two crystalline forms of polybutene –1.

The DSC curves displayed in Fig.1 show the first heat to

be lower than the second annealed heat.

Samples 11-70 to 11-73

LDPE/EVA/{EVA/PP.. 25nano..PP/EVA}/EVA/LDPE

The triplex extruder b, A, c was then lowered in rate to 20

rpm while extruder d was also lowered to 20 rpm. All

sample rolls were 15-16” wide and in 4 increments the

draw speed was increased from sample to sample roll until

the fastest setting at Sample 11-73. Many rolls of this

were collected until the EVA ran out. This gave us enough

of this thinnest sample to test in several areas of

application.

162.55 C

111.92 C

CONTROL FILM STRUCTURES

In order to see the true effect of the nano-layer core in the

above test films, the die module was switched to a similar

module containing a three-layer core. Everything else

remained the same.

163.57 C

111.59C

Samples 11-74 & 75

LDPE/EVA/(EVA/PP/EVA)/EVA/LDPE

These films were also run with a high stalk high BUR

bubble into films of 14-16” widths. Attempts to draw 1175 to thinner film failed and the only stable processing

condition was close to 11-74. Both films were 1 mil thick.

Samples 11-76 & 77

LDPE/EVA/(EVA/PP/EVA)/EVA/LDPE

Extruder screw speeds were changed to lower rpm similar

to 11-73. Sample 11-76 was drawn to 0.5mil thickness at

16” width. Sample 11-77 was very unstable and could not

be blown much past 12” wide. This was 0.2mil compared

to 0.1mil for the 11-73 16” wide nano-test films. Clearly,

25 alternating nano-layers of EVA/PP/EVA imparted high

melt strength and pinhole resistance caused by an

occasional gel in the bubble as it was drawn very thin

biaxially. The 3-layer EVA/PP/EVA control films showed

no bubble stability as they were drawn thinner than

0.5mil.

Discussion of Results

DSC TESTS

ΔT=1.02C

FIG. 1 DSC CURVES FOR SAMPLE 11-73

This is consistent with having a less dense form of crystal

structure. The ΔT at 1.02C is surprising and may be a

result of the orientation of the film during processing. The

stretching of the film during the cooling from the melt

immediately oriented the PP layers that were being cooled

probably even before the LDPE layers solidified.

Orientation during the cooling from a melt usually takes

place at a lower temperature than heating from a solid as

is usually done. A lower density form of crystal structure

may very well be the signature of this difference.

Since at least the nano-structure of this film was oriented

as the melt was cooled, the stress involved in stretching

the film to high BUR was much lower than it would have

been for orientation by the reheat methods. This is seen in

the low shrink tension and force during the shrink process

that sample 11-73 displayed during shrink packaging tests

described below. It therefore seems plausible that the

lesser stressed oriented PP crystal may also display a less

densely packed but still stable crystal structure to account

for the ΔT between first and second heat.

3

Also notable on the DSC curves is the wide temperature

range that exists while there are still solid nano-layers of

PP remaining. So from room temperature all the way to

160C the film would have some degree of strength due to

the solid PP. This wide range of hot strength is in many

ways similar to x-linked PE shrink films.

STRETCH - SHRINK TESTS

Sample 11-73 was selected for shrink performance tests as

well as stretch lidding film because it was the thinnest that

was produced at 0.1mil. This ultra-thin film was

surprisingly tough and handled well in lidding trials where

it was drawn tight over the rim of a bowl. Although the

film was not tacky due to the slip added to the outer PE

layer, it had a tendency to cling to the bowl. This was

enhanced further if any moisture was present. There is no

question that the thinness and ease in draping of the film

also added to this good performance. Picture 5 shows the

lidded bowl along with a shrunk package showing overlap

seals made during shrinking.

Lap seals during shrink

PICTURE 6 - TRACED 10mm CIRCLE ON FILM

Tight lid cover

PICTURE 5 SHRINK-STRETCH OF 11-73

During the shrinking of 11-73, the heat strength became

noticeable when the lap seals were made during shrinking.

Obviously, the film temperature was above 111C in order

to make the seal but there were no burn through holes

observed as the film sealed and shrunk at the same time.

The presence of the PP nano-layers was no doubt

responsible for holding the film together over this wide

shrink temperature range especially in the range between

111C and 162C, the melting points of LDPE and PP.

Since the shrink took place in this tacky temperature

region, testing the film for ultimate free shrink and shrink

tension was complicated by the extreme thinness and film

tack. With the LDPE surfaces melted, the shrinking film

stuck immediately to itself on contact and the thinness

produced extremely low shrink force. Pictures 6 and 7

show how the ultimate free shrink was obtained by

draping the film with a 10x10mm traced circle from a

table. With a helper to keep the film from folding onto

itself, hot air was applied by means of a heat gun set at

low air flow. The result was free shrink in all directions as

shown in picture 7.

PICTURE 7 – FILM SHRUNK BY HOT AIR GUN

The better samples showed approximately 50% free

shrink in all directions and selected articles shown in

picture 8 were shrink-wrapped. These included an

answering machine and 2 rolls of tissue.

PICTURE 8 – 50% SHRINK, FILM & PACKAGES

4

Measurement of shrink force was also complicated by the

same things as free shrink. The film became tacky at the

measurement temperature and the shrink force was low.

By trial and error, we found that 2 paper clips and a strip

of wood weighing 24 grams provided enough weight to

counterbalance the longitudinal shrink so that no shrink

occurred in that direction. Picture 9 shows the results.

The free shrink film sample was held with paper clips on

all 4 corners. This was not truly free shrink because there

was some pendulum like resisting force to do this as the

device was heated within an oven.

Both sides of the device held suspended 3-1” strips of film

cut from the longitudinal and transverse directions. Each

strip was weighted with paper clips at 1.2 grams each and

progressed from one to three clips for increasing weight.

Each strip was marked with 10 cm measurement lines that

increased in length as the samples became heated and

stretched beyond the shrink force limit. The shrink tension

then was derived at the weight where the film shrink was

in balance with the weight suspended in a manner similar

to the above earlier crude measurements.

The stretch-temperature-weight tabulation below Graph 1

in the next column shows that this occurred in the 210220F-temperature range where the shrink was below 10%.

There was virtually no shrink force beyond this

temperature.

PICTURE 9 – SHRINK TENSION MEASURMENT

Since the film was 13” wide and averaged 0.1mil thick,

the shrink tension was calculated as follows:

24gms. /13”x 0.1mil x .001”/1mil =

24gms. /13” x 0.0001”= (1lb/454gms)24gms. /0.0013in2

Shrink Tension = 40.7 psi

All these were crude measurements and more control was

desired to obtain a better characterization. So a sample

holding device was assembled that overcame the film tack

problems. This is shown in Picture 10.

Free shrink was easier to measure and the results are

shown in Graph 1. Please note the difference between the

L & T free shrink was partially due to the slight pull of the

suspension clamps on the film corners during shrink and

is more of a reflection of the differences in the extremely

low shrink tensions i.e. the differences between the lower

transverse value and the higher longitudinal value.

Please note picture 8 again where the shrink was 50% in

both directions. This was a situation where there was a lot

less shrink tension influence on restraining free shrink in

the transverse direction. The less restraint on the film

means a truer value of free shrink, so we averaged both to

arrive at the 50% average free shrink in both directions.

% FREE SHRINK OF SAMPLE 11-73

3 shrink force strips with progressive wts.

Longitudinal

Average

Free shrink film

held with 4 clamps

Transverse

GRAPH 1 FREE SHRINK VS. TEMPERATURE

PICTURE 10 SAMPLE HOLDING DEVICE

Graph 1 shows that shrink began at about 200 F close to

the melting point of the LDPE outer surfaces. It then

5

progressed as the temperature rose to 260F where total

melting of the sample took place. Somewhere within this

region the shrink forces came into play but all test strips

measuring shrink force failed at 230F and higher.

Significant stretch occurred between 210 and 220F so

these 2 temperature readings were averaged and shown

tabulated and underlined below in blue.

Shrink force @ 210F

Longitudinal stretch

Transverse stretch

1.2gms. 2.4gms. 3.6gms

10.1

10.2

10.8

10.2

11.0

20.5

Shrink force @ 220F

Longitudinal stretch

Transverse stretch

Average stretch (long.)

Average stretch (trans.)

1.2gms.

10.0

10.1

10.05

10.15

decreased. Generally, as the stretching and cooling speed

increased the elongation decreased. This is a clear

indication of orientation taking place. Oriented films

simply have less elongation than blown films.

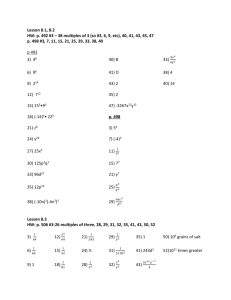

Table 1 TENSILE –ELONGATION (Instron, psi)

2” Span @ 20” per minute crosshead

Sample

Machine direction

Cross Machine

TEST

mils

T

E

T

E

11-63

1.06

4599

480%

4325

425%

11-64

0.41

4399

268%

3848

287%

11-67

0.26

4475

177%

4284

246%

Clearly the lowest shrink force occurred in the transverse

direction because there was more stretch occurring at the

2.4gm value. The transverse shrink force at 1.2 grams

resisted any significant elongation and the longitudinal

shrink force of 2.4 grams also resisted any significant

elongation. So in choosing these 2 values, the shrink

tension was calculated as follows:

11-73

0.15

4956

124%

1676

402%

1.2gms. /1”x 0.1mil x .001”/1mil =

1.2gms. /1” x 0.0001”= (1lb/454gms)1.2gms. /0.0001in2

2.4gms.

10.5

12.0

10.35

11.50

3.6gms.

11.4

11.4

11.10

15.95

Therefore between 210 & 220F:

Shrink Tension Transverse = 26.4 psi

Shrink tension longitudinal = 2(26.4) = 54.8 psi

As shown here, the more precise measurements of both

shrink and shrink tension were essentially a confirmation

of the less controlled measurements taken earlier.

OTHER FILM CHARACTERIZATION TESTS

Tensile – Elongation (Test Film)

We have seen from the shrink and shrink tension tests that

the more highly stressed orientation appeared to be in the

Machine Direction (MD) than in the Cross Machine

Direction (CDM) using the thinnest sample 11-73. Tensile

& Elongation tests, however, should help to confirm this

and show how the orientation behavior is influenced by

sample thickness. In other words the thinnest sample

should show the most orientation because of higher

stretch speeds and faster cooling.

The main point to note in looking at the test data is that

blown films usually have lower tensile strength and higher

elongation in most cases than oriented films. Table 1

above shows a summary of the T & E data as the films

were drawn faster and the thickness was accordingly

CONTROL

11-74

1.27

4554

494%

4451

479%

11-75

1.13

4850

516%

4642

479%

11-76

0.40

3612

315%

3095

306%

11-77

0.20

2993

105%

2768

326%

There was one exception in the cross machine direction of

sample 11-73 elongation. This may have been due to a

less oriented streak in the film. Cross machine direction

properties often can be less consistent than machine

direction properties because of film differences due to

streaks, die lines etc.

While the elongation goes down, the tensile strength goes

up as orientation increases. Again this is seen in the

machine direction with the same exception in the cross

machine direction particularly with the thinnest sample.

The least oriented sample appeared to be in the thickest

sample 11-63 with the highest elongation but its tensile

strength was also surprisingly high in both directions.

This probably was due to the differences in crystalline

size and coarseness of the aged polypropylene in the less

oriented state. Oriented polypropylene has a very fine

crystalline structure while unoriented polypropylene has a

course sphereulitic structure.

Tensile – Elongation (Control Film)

The control films containing EVA/PP/EVA instead of 25

nano-layers showed a marked decrease in tensile as the

films were drawn thinner showing that they were weaker.

Note the blue values in table 1 above. This is consistent

with the poor bubble stability shown during manufacture.

6

The machine direction measurements show this vividly

while the cross machine measurements were less

pronounced especially with the elongation. Sample 11-77,

the thinnest control sample, could not be blown as wide as

its test film counterpart 11-67. So, table 1 shows at a

glance the higher tensile and lower elongation of the more

oriented test films. While the control films became more

oriented during stretching, there was much less strength

developed.

Graph 2 details the test film data more vividly. Films

made below .4 mils have decreased elongation and

generally higher tensile strength. This implies higher

orientation is obtained with thinner test films.

Oriented Films

GRAPH 3 - TEAR STRENGTH (Gms)

Permeability

Blown Film

Permeability of the film to gases and vapors tends to

either get a bit lower or remain about the same with

respect to orientation. What truly counts is thickness. As

the films become thinner the permeability increases.

GRAPH 2 - TENSILE & ELONGATION DATA

Tear Strength

Graph 4 shows that both Oxygen and water vapor follow

the same path of increasing permeability as the films

became thinner.

Just as the ultimate elongation of the more oriented films

was lower than the less unoriented films in the above film

series, tear strength also was lower. Since the thinner

films had increasingly lower elongation (a sign of

increasing orientation) , we now can also follow the same

decrease in tear strength over the same film thickness

path. Graph 3 on the next column shows this relationship.

Please note the steep drop in tear strength as the film was

reduced in thickness from 1 mil to.41 mil. This .41mil

thickness value appears to be the threshold to the film

becoming truly oriented. This is also the thickness where

the tensile strength began to climb and the elongation

became lower.

7

although they could be made into 1-mil

films with a high stalk, high BUR process.

Summary and Conclusions

1.

Test film containing a core of 25 alternating

nano-layers consisting of Polypropylene and

EVA had a propensity to be blown into very

thin films at a blow up ratio of about 5:1with

a long stalk process. Low MI EVA stabilized

the process as would be expected.

1.

2.

The thinnest test films made with this

process were about .1mil thick.

3.

3.

The thinnest test films showed all the signs

of being oriented with free shrink at up to

50% and shrink tension about 25-50 psi.

4.

5.

DSC measurements showed the PE/EVA

melt peaks at 96-111C and the PP peak at

162.55C. This extra 50C temperature spread

gave the film more hot strength during

shrinking.

DSC measurements also showed a

difference in the PP crystallinity on 1 st heat

at 162.55C to 2nd heat at 163.57C or a

∆T=1.02C. This difference is usually

indicative of a lower density crystalline

structure due perhaps to orientation.

6.

The test films sealed during heat shrinking

using simple overlap seals as would be used

in film over wrapped trays or rolls of paper.

7.

The relatively high elongation of even the

thinnest test film was helpful in making it

very useful as a stretch lidding film for food

trays and bowls.

8.

Graphs of the tensile, elongation and tear

strength all showed a decided tendency to

higher and higher orientation as the test film

was drawn thinner and thinner.

9.

Permeability to Moisture Vapor and Oxygen

increased as the test film became thinner.

10.

A special shrink property device was needed

and assembled for use to avoid film-to-film

contact. The high tack of the test film due to

the melting of the polyethylene surfaces

made measurement difficult with standard

devices in the shrink temperature region.

11.

Control films containing 3 alternating

EVA/PP/EVA layers as a core could not be

blown with stability into ultra-thin film

REFERENCES

2.

4.

5.

6.

7.

8.

9.

10.

11.

12.

The Modular Disk Coextrusion Die –

Schirmer Polyolefins 2000

New Compositions of Matter from The

Modular Disk Coextrusion Die - Schirmer,

Love, Schelling, Loschialpo - ANTEC 2000

Micro-layer Coextrusion Technology Baer,

Jarus, Hiltner - ANTEC 1999

Modular Disk Coextrusion: Production Rate

Tests with the 9” flex-Lip Die Schirmer Future-Pak 1999

25 Micro-layer Blown Film Coextrusion Die

– Schirmer - Polyolefins 2008

Exploratory Experiments on Solid-State

Foaming of PLA films and COC/LDPE

Multi-layered Films - Lu, Kumar, Schirmer ANTEC 2009

Improved

Flexible

Packaging

Film

Performance via Layer Multiplication- Sam

Iuliano – Polyolefins 2009

Nano-layers in Blown film – Schirmer,

Jester, Medlock – Polyolefins 2009

Nano-layers in Blown Barrier Films –

Schirmer, Jester, Medlock, Schell – PO 2010

Oriented Blends of Polybutene –1 and

Polypropylene –Schirmer–US Pat. 3,808,304

A.M. Chatterjee, “Butene Polymers”,

Encyclopedia of Polymer Science and

Engineering, Vol 2, 2nd. Ed, 590 (1985)

Nano-layers in Blown Barrier Films (part 2)

– Schirmer, Schell, Pucci & Chatterjee

AUTHOR CONTACTS

Henry G. Schirmer

BBS Corporation

2066 Pecan Drive

Spartanburg, SC 29307

Tel: (864) 579-3058

E-Mail: hschirmer@att.net

Tom Schell

Curwood, Inc.

2200 Badger Avenue

Oshkosh, WI 54904

E-Mail: TASchell@bemis.com

8