An Instrument for On-Site Detection of Pathogens in Food

advertisement

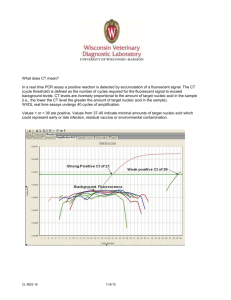

MEAM-ESE SENIOR DESIGN PROJECT - ADVISOR SUBMISSION FORM 1. Project Title: “An Instrument for On-Site Detection of Pathogens in Food” 2. Proposer's Name: Haim Bau (MEAM), Changchun Liu (MEAM), Shelley Rankin (Vet School), and Ken Laker (ESE) E-mail: laker@seas.upenn.edu, bau@seas.upenn.edu, srankin@vet.upenn.edu, lchangc@seas.upenn.edu 3. Brief Project Description: Foodborne diseases are common in developed and developing countries and cause human suffering, death, and significant economic cost in terms of healthcare, lost productivity, food destruction, halts in production, and recalls. Annually, foodborne pathogens cause over 48 million illnesses in the US alone. Foodborne diseases can be prevented and the associated damage minimized with appropriate food testing along the spectrum from farm to fork. Our objective is to design, develop, and validate a portable, inexpensive, diagnostic instrument for onsite, molecular detection of pathogens in various food matrices. The project is interdisciplinary and flexible. Based on team members interests, the project may involve (i) the development of a microfluidic system for sample preparation and isothermal enzymatic amplification of nucleic acids associated with target pathogens and/or a suitable sensor information acquisition system that will interface with a smart phone. The smart phone will be used for (in the order of priority) (i) fluorescent signal detection (with the phone camera) and data analysis; (ii) instrument control; (iii) transmission of test results to a central location; and (iv) the collection of pertinent information to assist health officials in identifying the source of contamination. Expertise unavailable to the team will be provided by the participating laboratories. The technology developed in this project can also be applied to detect pathogens in body fluids such as blood, saliva, and urine to diagnose various diseases and cancer markers. Reference: C. Liu, E. Geva, M. Mauk, X. Qiu, W. R. Abrams, D. Malamud, K. Curtis, S. M. Owen, and H. H. Bau, 2011, An Isothermal Amplification Reactor with an Integrated Isolation Membrane for Point-of-Care Detection of Infectious Diseases, Analyst 2011, 136, 2069-2076. C. Liu, M. G. Mauk, R. Hart, M. Bonizzoni, G. Yan, and H. H. Bau, 2012, A Low-Cost Microfluidic Chip for Rapid Genotyping of Malaria-Transmitting Mosquitoes, PloS One 7 (8), e42222. Liu, C., Mauk, M., Hart, R., Qiu, X., and Bau, H., H., 2011, Self Heating Cartridge for Molecular Diagnostics, Lab on Chip 11, 2686-2692. 4. Project Design Objectives: The project includes a few components. The scope of the project depends on the team’s size, expertise, and interests. Below, we describe the two main components of the project. Variants are also possible. The two main components of the project are: (a) The microfluidic cassette with a processor and (b) The smart phone interface a. The microfluidic cassette This part of the project will be carried out by individuals with a background in Mechanical Engineering. The basic chip design for the isolation and amplification of nucleic acids is depicted in Fig. 1. The chip is milled in acrylic and contains amplification reaction chambers equipped with flow through membranes for the isolation and purification of nucleic acids. The various reaction chambers can be used for multi-target detection, calibration, and discrimination between wild types and drugresistant bugs. Although functional, the chip is not yet fully automated. Opportunities are available to further develop the chip to accommodate sample preparation, reagent storage, pumping, and exothermic reaction-based self-heating (as an alternative to electrical heating) and to devise fabrication techniques consistent with low cost, mass production. The chip can operate either as instrumented with electrical heater or uninstrumented with the exothermic reaction-based heater. If an electrical heater is selected, the team will need to develop a processor to thermally control the chip’s temperature. If an exothermic reaction-based heater is selected, the team will need to develop appropriate thermal control scheme to isolate the chip temperature from varying ambinet conditions. Smart Phone – Based Interface The presence and quantity of target molecules is determined based on the amount of product (amplicon) generated by the enzymatic amplification process. Our detection method is based on monitoring fluorescent emission. We are, however, willing to consider other detection modalities such the monitoring of solution pH. Below, we focus on fluorescent emission. The emission intensity from the various reactors will be monitored with the cell phone camera either continuously (in real time) during the nucleic acid amplification process or after certain predetermined time (end-point detection). In a senior design project last year (Fig. 2), the team designed illumination to provide uniform excitation to the amplification reactors and filters to minimize the overlap between excitation and emission spectra. The work was not completed. It is necessary to debug the system, verify its performance, and complete the software to process the data and report test results. The data will be displayed, for example, in a graphical form as emission intensities (obtained from various reactors) as functions of time. The program will determine the threshold times needed for the emission intensities to exceed a predetermined value and provide estimates of the numbers of target molecules in the sample If the team selects to focus only on the smartphone interface, we will provide the team with the chip shown in Fig. 1 and with assays to generate the fluorescent signals to be detected. b. Fig. 1: A plastic chip containing three reactors for the isolation, purification, and amplification of nucleic acids associated with target pathogens. The chips are currently milled. There is a need to develop fabrication methods consistent with large quantity production. A prototype smartphone-based 5. Prior Experience: detection, processing, and Individuals interested in part (a) of the project would benefit communications. H, M, N, stand, from MEAM 575- Micro and Nanofluidics (Fall 2014) and respectively, for high, medium, and low CFU concentrations of target bugs. MEAM410/510 - Design of Mechatronic Systems or equivalent. Machine shop experience is a plus. Individuals interested in part (b) of the project would benefit from experience in smartphone (.e., android) programming, interest in applications development, and some knowledge of optics.