World Journal Of Engineering Prediction of Mechanical and Barrier

advertisement

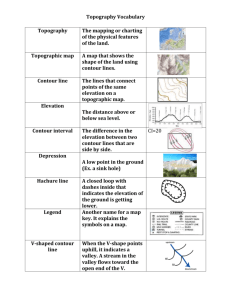

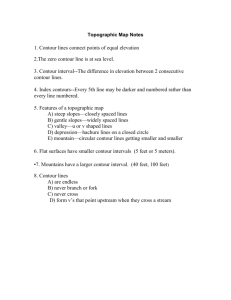

World Journal Of Engineering Prediction of Mechanical and Barrier Properties of Chlorobutyl Rubber/Natural Rubber Blend using Artificial Neural Networks Lin Li, Jin Zhang, Z X Zhang, Jin Kuk Kim* School of Nano & Advanced Materials Engineering, Gyeongsang National University, 660-701, South Korea Three important factors identified to have simulation. Fig.1a shows the contour plots maximum impact on the properties of the of the effect of CB and the CIIR/NR ratio blends are the CIIR/NR ratio, oil and carbon contents at constant of oil (10 phr) on break black contents. Three important levels are elongation. Fig.1b shows the contour plots identified to quantitate every factor of the effect of oil and the CIIR/NR ratio respectively. The three levels for the contents at constant of CB (55 phr) on break CIIR/NR ratio are 90/10, 80/20 and 70/30 elongation. We can find that break (The total weight of the blend is kept at elongation is maximum in the region 100phr). Carbon black is varied in three 10.50phr≤oil≤14.33phr, 7.12≤the CIIR/NR levels (40phr, 55phr and 70phr), and oil is ratio ≤8.78, 58.86phr≤CB≤68.5phr. varied in three levels (5phr, 10phr and 15phr). Although there are three factors and three levels involved for every factor, nine experimental runs are taken by orthogonal experimental design (L9(34))[1-2]. Mechanical properties a a b Fig. 2 Contour plots of the effect of the CIIR/NR ratio, CB and oil on ultimate tensile strength Fig.2a shows the contour plots of the effect of oil and the CIIR/NR ratio contents at constant of CB (55 phr) on ultimate tensile strength. Fig.2b shows the contour plots of the effect of oil and CB contents at constant of the CIIR/NR ratio (5.65) on ultimate tensile strength. We can find that ultimate tensile strength is maximum in the region 5.95phr≤oil≤9.10phr,2.30≤theCIIR/NRratio ≤7.12,56.00phr≤CB≤70.00phr. b Fig.1 Contour plots of the effect of the CIIR/NR ratio, CB and oil on break elongation The RCAD program gave two-dimensional contour plots after the 663 World Journal Of Engineering By examining the overall performance of each sample, the prediction of the optimum formula combination by RCAD is that rubber ratio of CIIR/NR is 87.50/12.50, the optimum concentrations of carbon black and oil are 66.25phr and 10.25phr for CIIR/NR compound, respectively. Table1 Comparison of experimental properties and those predicted by RCAD Predicted by Experimental properties RCAD value Tensile 4.62Mpa 4.55Mpa Strength Break 492.21% 481.87% Elongation Permeability 3.59 3.64 Table 1 shows the comparison of properties between the predicted and the experimental values. It is observed that the predicted and the experimentally determined properties are fairly close to each other and thereby confirming that orthogonal experimental design-based ANN–GA optimization procedure can be used for the prediction of properties with a fair degree of accuracy. Barrier property a b Fig.3 Contour plots of the effect of the CIIR/NR ratio, CB and oil on permeability Fig.3a shows the contour plots of the effect of oil and the CIIR/NR ratio contents on permeability (where CB content is constant at 55 phr). It additionally shows that at a fixed ratio of CB content oil has little effect on the permeability property compared to the CIIR/NR ratio. Fig.3b shows the contour plots of the effect of oil and CB contents on permeability (where the CIIR/NR ratio is constant at 9.0). It additionally shows that at a fixed the CIIR/NR ratio oil has little effect on the permeability property compared to CB level. So the result indicates that the CIIR/NR ratio and CB level are the important factors rather than the oil level in effecting on permeability of blends. We can find that permeability is maximum in the region 6.60≤the CIIR/NR ratio ≤9.00, 59.20phr≤CB≤70.00phr,5phr ≤oil≤10.60phr. Conclusion The predicted optimum formulation was found to be parallel to the experimental recipe, thereby validating the accuracy of the orthogonal design method-based ANN–GA optimization procedure. Reference [1]White, H. Artificial neural networks: approximation and learning theory. NewYork: Blackwell (1992). [2] Cook, D.F., Ragsdale, C.T., Major, R.L. Combining a neural network with a genetic algorithm for process parameter optimization. Eng Appl Artif Intell, 13(2000), 391–396. 664