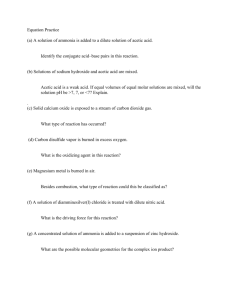

Assay of the intestinal enzymes sucrase, maltase and

Mannitol

Glacial acetic acidUsed as 2M solutionSodium phosphate (monobasic)Sodium phosphate (dibasic)

Potassium hydroxideL-alanine-p-nitroanilide hydrochloridep-NitroanilineSodium hydroxideUsed as 1M solutionSucrosemaltosemaleic acid (as 0.1M buffer)Hydrochloric acid (5M solution)TRISGlucose 500 trinder(sigma-aldrich)

Hazardous

Substances Policy - Assessment

CHEMICAL HAZARD AND RISK ASSESSMENT

School of Biosciences

Name of supervisor

Assessor

Professor Pat Butler

Signature

Emma J. Watkins

Assessment Number*

Date of Assessment

2057

16/07/2002

Signature

Notes A School COSHH form in Word is available on the School Server.

Available from the Health and Safety Unit.

Guidance on making an assessment is given in Making a Chemical Hazard and Risk Assessment .

Guidance is also available from Guidance on Completing the Chemical Hazard and Risk Assessment Form .

Use a continuation sheet to expand any section of this form in hard copy version.

1 LOCATION OF THE WORK

ACTIVITY

W119

2 PERSONS WHO MAY BE AT

RISK

List names where possible Emma J. Watkins

3 ACTIVITY

ASSESSED

Assay of the intestinal enzymes sucrase, maltase and aminopeptidase-N.

Attach copies of data sheet(s) 4 MATERIALS

INVOLVED

NAME HAZARD RISK PHRASES HAZDAT NO***

Mannitol

AMOUNT max/stored

500g 4159

BIOSCIENCESNO***

Glacial acetic acid

Used as 2M solution

Sodium phosphate

(monobasic)

Sodium phosphate

(dibasic)

2.5 litres

100ml

250g

250g

Not hazardous by CHIP

Corrosive

Flammable

Irritant

Irritant

R: 10, 35

Flammable and causes severe burns

R: 36/37/38

Irritating to eyes, respiratory system and skin

R: 36/37/38

Irritating to eyes, respiratory system and skin

2

1285

641

693

Potassium hydroxide

L-alanine-p-nitroanilide hydrochloride p-Nitroaniline

Sodium hydroxide

Used as 1M solution

Sucrose maltose maleic acid (as 0.1M buffer)

Hydrochloric acid (5M solution)

TRIS

Glucose 500 trinder

(sigma-aldrich)

500g

500g

500g

500g

1litre

1kg

2.5 litre

500g

100mg

50mg

Corrosive

Irritant irritant

Corrosive

‘Hazards have not been thoroughly investigated

’

Toxic

Irritant

Corrosive

Not hazardous by CHIP

Not hazardous by CHIP

Harmful

R: 35; 22

Causes severe burns and harmful if swallowed

May be harmful by inhalation, ingestion or skin absorption; may cause irritation.

R: 23/24/25 and

36/37/38 and 63 and

33

Toxic by inhalation, in contact with skin and if swallowed; irritating to eyes, respiratory system and skin; possible risk of harm to the unborn child; danger of cumulative effects

R: 35

Causes severe burns

R: 22; 36/37/38

Harmful if swallowed;

Irritating to eyes, respiratory system and skin.

R: 34; 37

Causes burns; irritating to the respiratory system

R: 36/37/38

Irritating to eyes, respiratory system and skin.

R: 36/37/38

Irritating to eyes, respiratory system and skin.

316

911

381

302

308

5 INTENDED

USE**

Give brief details and attach protocol/instructions

Aminopeptidase-N assay Tissue samples are diluted 8:1 with mannitol buffer (0.0596g hepes

+ 0.3M potassium hydroxide + 15.925g mannitol) and homogenized. 10 microlitres of the homogenized sample are diluted 1:1, again with mannitol buffer, and placed in a test tube. To this tube is added, 1ml of the assay mix (0.5mg/ml L-alanine-p-nitroanilide + 0.2M phosphate buffer. After 20 minutes incubation at 40 o C, the reaction is stopped by the addition of 3ml 2M glacial acetic acid. The absorbance of each of the resulting solutions is read at 384nm.

In order to construct a calibration curve, 0.25g p-nitroalinine are dissolved in 1litre distilled water. Four dilutions (1:1 with distilled water) are performed. From each of these dilutions,

1ml of the solution is mixed with 3ml glacial acetic acid. The absorbance of each of the resulting solutions is read at 384nm.

Sucrase and Maltase assay Tissue samples are diluted 8:1 with mannitol buffer (0.0596g hepes + 0.3M potassium hydroxide + 15.925g mannitol) and homogenized. 100µl of tissue homogentae is incubated at 40 o

C with 100µl of substrate buffer solution (56mM sucrose/maltose solution in 0.1M sodium-maleate buffer). After 10 minutes, reactions are arrested by the addition of 3ml of stop/develop reagent (one bottle of glucose-trinder 500 reagent (Sigma-aldrich) in 250ml of 1M TRIS/HCl plus 250ml 0.5M sodium dihydrogen phosphate/disodium phosphate). Absorbance of the resulting solution is read at 505nm after

20 minutes.

6 RISKS to HEALTH and SAFETY from

INTENDED USE

From personal exposure or hazardous reactions. Refer to OELs, flash points, etc., as appropriate. Are pregnant women, breast-feeding mothers especially at risk?

p-nitroalinine poses a threat to the unborn child; there is a danger of cumulative effects. The following substances are irritating to the eyes, skin and respiratory system: sodium phosphate

(monobasic and dibasic), p-nitroalinine, TRIS and maleic acid.

Potassium hydroxide and sodium hydroxide can cause severe burns; a 2M solution of glacial acetic acid is irritating to the eyes and skin.

HCl poses the following hazard: contact with common metals produces hydrogen gas which may form explosive mixtures in air. TRIS yields the following combustion products: carbon monoxide, carbon dioxide and nitrogen oxides.

HCl solutions and mist with a pH of 3 or below pose a significant risk to health. Vapour or mist from concentrated solutions can cause severe nasal irritation, sore throat, choking, coughing and difficulty breathing. Prolonged exposures can cause burns and ulcers to the nose and throat. HCl liquid can cause severe irritation (redness, swelling and pain) and corrosive skin damage with permanent scarring. Repeated exposures to low concentrations of HCl mist can cause brownish discolouration and damage to tooth enamel.

Maleic acid mists (solution) or dusts can cause mild to severe irritation or tissue damage, depending on the severity of acid exposure. Symptoms of exposure include sore throat, nasal irritation and coughing. Prolonged or repeated contact with dusts or very dilute solutions may result in redness, swelling and thickening of the skin (dermatitis).

7 CONCLUSIONS ABOUT

RISKS

Is level of risk acceptable? Can risk be prevented or reduced by change of substance/procedure? Are control measures necessary?

Yes, the level of risk is acceptable.

Only small volumes of each solution are used during enzyme assays.

8 CONTROL

MEASURES

Additional to Good Chemical Practice

Proper labeling of storage containers which should be appropriately stored in a corrosionresistant bin and, if necessary, transported in special containers. Glacial acetic acid should be kept well away from any sources of ignition. Protective gloves and clothing should be worn at all times to prevent personal contact with any substances that are toxic/irritant and or cause

(severe) burns. The preparation of the p-nitroalinine solution for the enzyme assay and the use of glacial acetic acid, maleic acid and hydrochloric acid should be carried out in a fume cupboard. Care should be taken to avoid generating dust when using all chemicals.

Soap, water and paper towels should be available. Protective gloves and face mask should be worn when carrying out the homogenisation.

9 INSTRUCTION/TRAIN

ING

Specify course(s) and/or special arrangements.

Training in enzyme assay techniques: given by Enrique Caviedes-Vidal, Wildlife Ecology

Department, University of Madison, USA (November 2001).

10 MONITORI

NG

Performance of control measures,

Review every 5 years unless list of chemicals or quantities change.

Personal exposure Health Surveillance

11 WASTE DISPOSAL

PROCEDURE

See School Server for Approved Procedure Document on specific Chemical Waste

Disposal.

The following substances can be disposed of in small quantities by diluting with water (until any reaction is complete) and then pouring down the sink, with plenty of water: 2M glacial acetic acid (dilute to <5% concentration), sodium phosphate (monobasic) and (dibasic), potassium hydroxide (dilute to <2%), sodium hydroxide, maleic acid and hydrochloric acid.

Contaminated gloves, paper towels e.t.c. (Hazardous waste for collection) can be placed in a sealed bag. This bag can then be placed inside a yellow bin liner labeled ‘clinical waste’ for collection by cleaning staff.

After the cleanup of a large spillage containing ‘flammable-extremely flammable’ substances, or ‘irritant’ (R35≥1% or R35≥5%), waste should be treated as ‘Special Waste’ and advice sought from the Health and Safety Unit. TRIS should always be disposed of as ‘Special

Wa ste’.

12 REVIE

W

Enter the date or circumstances for review of assessment (maximum review interval 5 years)

Review in five years time or in the event of a change to the protocol.

13 EMERGENCY

ACTION

To stabilize situation eg spread absorbant on liquid spill; eliminate sources of ignition, etc. TO CONTROL

HAZARDS

Where necessary, carry out work in the fume cupboard; eliminate sources of ignition; ensure access to water and appropriate fire extinguishers. In the event of spillage, wear protective clothing, keep personnel not involved in practical work away from the area, mop up spillages with an inert absorbant material e.g. paper towels; scoop up solid spill and place in a labeled container; avoid generating dust; afterwards, thoroughly wash the area with plenty of water; ventilate the area. Prevent materials entering drains or watercourses. Acids and alkalis may be neutralized to reduce contamination before disposal. A large spill of either maleic acid or p-nitroaniline should be disposed of as Special Waste.

For further details see attached safety data sheets.

N.B. neutralizing a spill of 2M glacial acetic acid with sodium hydrogen carbonate, sodium carbonate or calcium carbonate will produce large amounts of carbon dioxide gas; ensure adequate ventilation.

University emergency service tel: 44444 report accidents and or incidents immediately.

Evacuation, protection for personnel involved in clean-up, Special First Aid TO PROTECT

PERSONNEL

For any of the listed solutions in the event of: SKIN CONTACT: Drench the affected area with clean running water for at least 10 minutes and until no chemical remains in contact with the skin. Remove contaminated clothing, which is not stuck to the skin, as soon as practicable after commencement of washing. If there is any injury or if skin absorption is suspected obtain medical attention.

EYE CONTACT: Flush the eye with clean running water for at least 10 minutes; obtain medical examination of the affected eye.

INGESTION: Do not make the casualty vomit; wash out the mouth with water. If the casualty is conscious, give 0.5 litre water to drink. For maleic acid and sodium hydroxide, follow this with 0.5 litre milk. Seek medical attention.

INHALATION: Remove the casualty from exposure; rest and keep warm. If the casualty has been seriously affected, obtain medical attention.

For full details of first aid measures, see attached safety data sheets.

Clean-up/decontamination TO RENDER SITE OF EMERGENCY

SAFE

Wearing protective clothing, gloves and eyeshield, mop up spillages and place contaminated waste in a sealed ‘hazardous waste’ labelled bag. This can be stored in the fume cupboard until collection. The area should be well ventilated and personnel not involved in cleaning up, should be kept well away from the area.

CONTACT : Norman Day TEL: 45474

* Prefix T is used for Teaching Assessment Number.

** Please include amount of chemicals used and how.

*** Hazdat No is the UNICOSHH datasheet report number.

Biosciences No is the Biosciences data sheet number.

UNICOSHH IS A CHEMICAL DATABASE ON THE HEALTH AND SAFETY UNIT SERVER.

BIOSCIENCES DATA SHEETS ARE AVAILABLE IN THE SCHOOL SAFETY OFFICE.

10.10.00