Metal Oxide Modified Electrode for Ammonia Ion and the Application

advertisement

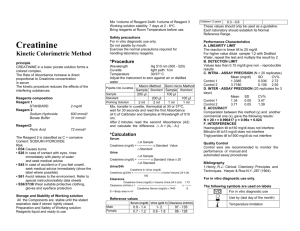

A Novel Copper(I) Oxide Based Creatinine Biosensor Meng Shan Lin* and Hoang Jyh Leu Department of Chemistry, Tamkang University, Tamsui 251, Taipei, Taiwan A novel creatinine biosensor was based on the measurement of ammonia by flow injection analysis(FIA). Using the immobilization of creatinine deiminase onto a copper(I) oxide mixed carbon ink composite electrode which effectively senses the ammonium ion in aqueous solution, a very sensitive creatinine biosensor was developed. All parameters, such as applied potential, buffer pH value, flow rate of carrier, that may affect the performance of the creatinine biosensor were carefully studied. For the optimum conditions of the creatinine biosensor, the detection limit as low as 25 μM and the response time of 45 s were obtained in this flow-injection system. A relative standard deviation of 3.2% (n =20) was obtained for the successive analysis of standard creatinine solution. And the linear range of this system was upto 5mM. Keywords: creatinine deiminase, copper(I) oxide, carbon ink, flow-injection system 1. Introduction It is an increasing requirement for easy, selective, accurate and reliable measurements for the important metabolites to be used as an index for the state of health in these years. Creatinine is a final product of creatine metabolism in mammals. Therefore, it is an important diagnostic substance in the biological fluids of renal, thyroid and muscle function and is very important in treatment with external dialysis. The physiologically normal concentration range for serum creatinine is 45-140μM and creatinine is 0.8-2.0g per day in urine. But the concentrations may raise to a value higher than 1000μM in serum during the case of kidney dysfunction or muscle disorder. Most creatinine determinations in clinical biochemical laboratories and commercially available analysers are based on spectrophotometric detection of Jaffe reaction(1). Creatinine reacts with alkaline picric acid to form orange–red complex which is a colored species that absorbs at 500 nm. However, there are many interferences may interfere with the formation of complex and lack specificity, such as glucose, pyruvate, acetoacetate, bilirubin, dopamine and others(2-3). Although several kinetic methods and different pre-treatments of the samples had been developed, the accurate determination of creatinine concentration in the biological samples remained a problem(4). Because of specificity requirements, biosensors with the inherent specificity from enzyme are seemed suitable tools for such analysis, and various types of the biosensors for creatinine detection have been developed(5-7). They are amperometric biosensors using mono or tri-enzyme system, potentiometric biosensors utilizing ISFET and ion or gas sensitive electrodes, optic fluorescent biosensors, impedimetric biosensors employing screen-printed carbon electrodes, and capacitimetric biosensors using Ir-metal oxide semiconducting capacitors(8-10). However, all these biosensors have some disadvantages such as low selectivity, unfavorable sensitivity, poor stability, bad reproducibility and low storage stability for parts of those biosensors. But enzyme based amperometric biosensors have the advantages of reducing time and cost than other methods, the rapid, simple and promising methods are more feasible than others. Most of the publications showed the amperometric creatinine biosensors which were based on the tri-enzyme catalytic sequence through creatininase, creatinase and sarcosine oxidase(11). They were coupled to convert creatinine to electrochemically detectable hydrogen peroxide. As the three enzymes were integrated, responses resulted from the sequencing catalytic reactions were decreased, and the sensitivity and detection limit of these methods were affected(12). Mono-enzyme based amperometric and potentiometric biosensors for creatinine determination had been also published(13-14), the enzyme were used creatinine deiminase to transform creatinine into NH4+ and N-Methylhydantoin below pH 9.2 buffer solution. By this way, the potentiometric methods were mainly based on the detection of NH4+ by ion selective electrode or ISFET, but the sensitivity and linear range were not always satisfied for biological real sample requirements. In order to manufacture the effectively chemical sensors, several redox-active metal oxide materials have shown considerable promise for application in the areas of electrochemistry and photochemistry. Well known materials used in metal oxide sensors are SnO2, ZnO, TiO2, Ga2O3 and WO3, but these oxides are mostly used for gas sensors. For the liquid sample determination, the pH value, oxygen and hydrogen peroxide are commonly used Ag, Pt, Pd, Ru, Ir, Cu and Rh oxide as the electrode modifiers to promote the electrochemical reaction. Regarding copper(I) oxide(Cu2O), it is a metal-oxide p-type semiconductor that has potential applications in solar energy conversion and catalysis, but there are still a few application for sensor. A lot of effort has been devoted to the synthesis of Cu2O thin films, nanoparticles, nanowires and whiskers. Ammonia is also a critical parameter in food and pharmacological analysis as well as in clinical chemistry. Furthermore, there is a need for an alternative measuring method for the rapid, easy, low-cost and ecologically beneficial determination of ammonia, which could be fulfilled by an amperometric determination. The conventional analytical technique for the detection of ammonia was developed using Pt electrode at a high overpotential of >1V vs. SCE. In order to reduce the overpotential for interferences avoided, a variety of electrode materials and configurations, such as polypyrrole, polyaniline, polyaniline-Nafion, and zeolite clinoptilolite have been reported. Nevertheless, a serious problem in using these electrodes is the stability and the interference. In this work, we utilized a new catalyst, copper(I) oxide, to develop a ammonia chemical sensor and apply to creatinine biosensor. This purpose was to construct a high sensitivity, less interferences, rapid and inexpensive analytical method by flow injection analysis. In order to improve the sensitivity and detection limit of the amperometric method, this copper(I) oxide modified electrode was used to catalyze the oxidation and reduction of the ammonia in aqueous solution. And the creatinine deiminase was paired for above ammonia sensor to construct this creatinine biosensor. The cross-link type enzyme immobilization methods for this system were also been discussed for the system. Characteristic of the proposed ammonia sensor and creatinine biosensor for this work were studied. 2. Materials and methods 2.1. Chemicals and reagents Creatinine deiminase (E.C. 3.5.4.21, Grade III from Microorganism), with specific activity of 13.7Umg-1, was obtained from TOYOBO (Osaka, Japan). Bovine Serum Albumin (96-99%), Creatinine (anhydrous) and Glutaraldehyde (50% Aqueous Solution) were obtained from Sigma (St. Louis, USA). Copper(I) Oxide (97%), Tetraethyl orthosilicate (98%) and Chitosan (medium molecular weight) were obtained from Aldrich (Milwaukee, USA). All other chemicals and solvents used were of analytical-reagent grade and were used as received. The buffer solutions were prepared from sodium salts aqueous solution with the addition of an appropriate amount of NaOH solution. Deionization-RO water prepared from Barnstead Easypure Ro and Easypure UV/UF (Dubuque, IA, USA) with a resistance of 18.3MΩ-cm was used for preparing the solution. 2.2. Apparatus A three electrode system was used for the flow injection analysis and the cyclic voltammetric(CV) studies. A piece of Pt wire or stainless flow cell body was used as the counter electrode. A commercial Ag/AgCl (with 3M NaCl solution) electrode was used as the reference electrode. And the glassy carbon electrodes with catalyst modifiers were used as the working electrode. CV measurements and amperometric FIA experiments were carried out with a model 750A electrochemical workstation (CH Instruments, Austin, TX, USA) and a model CC-5 flow-through thin-layer electrochemical cell (Bioanalytical System, West Lafayette, IN, USA) connected with the above electrochemical analyzer. The FIA measurements were conducted with a Cole-Parmer microprocessor pump drive (Vernon Hills, IN, USA), a Rheodyne 7125 injector with a 100 μL sample loop on the CC-5 flow device and the enzyme based electrochemical detection system. 2.3. Design and fabrication of ammonia chemical sensor and creatinine biosensor Design of the ammonia chemical sensor was carried out according to our experiences in the past. The Copper(I) Oxide modified electrode was fabricated by the weight ratio of 3:2:5 for Cu2O:carbon ink:cyclohexanone. A 3mg mixture was applied onto a glassy carbon disk electrode (3mm diameter) and 40 oC air–dried in convection oven to allow the solvent to evaporate. The first part of creatinine biosensor fabrications was followed the same procedures of ammonia chemical sensor on the down series partition of dual working electrode. The second part of creatinine deiminase (CD) immobilization was cross-linked on the up series partition of dual working electrode by a procedure similar to that reported in the literature. The mixed solution for creatinine deiminase immobilization was prepared by dissolving 5 units of CD in 10μL of pure water. A 2 % glutaraldehyde (GA) solution was used as the cross-linking agent. A portion of 1μL of the prepared CD solution was then mixed with 0.5μL of 2 % GA and 1μL of 1 % bovine serum albumin (BSA) solution. After applying the prepared CD immobilization solution on the bare glassy carbon electrode, it was allowed to 10 oC air–dried in incubator to form a creatinine biosensor. The finished biosensor was stored at 4 oC in run buffer solutionwhen not in use. 2.4. Analytical measurements The chemical sensor and biosensor were first washed thoroughly with de-ionized water, then set the electrodes in normal three electrode cell or flow-through thin-layer electrochemical cell. For FIA, the sensors were equilibrated in blank buffer solution at an optimized condition until the current became lower and constant. The quantification of ammonia or creatinine was achieved by measuring the reduction current from amperometric signals. All experiments were performed at room temperature (25 oC). 3. Results and discussion 3.1. Electrochemical oxidation and reduction behaviors of ammonia on the Cu2O modified electrode Cyclic voltammograms of the Cu2O modified electrode under optimum static condition in pH 10 phosphate buffer is shown in Fig. 1. An obvious peak at -0.4V (vs. Ag/AgCl) in a cathodic sweep with one anodic shoulder at 0.15V were observed. These two peaks indicate the redox transition of Cu(I)/Cu(0) and Cu(I)/Cu(II) when the scan rate was higher than 50mV. Based on earlier reports, the cathodic peak correspond to Cu2(I)O → Cu(0) and the anodic shoulder correspond to Cu2(I)O → Cu(II)O. It is worth noting that Cu2O is a semiconductor in nature because Cu(I) has a filled electronic configuration and is the key oxide of Cu in most electrocatalytic applications. The feasibility of using the Cu2O modified chemical sensor to measure ammonia ion was investigated. The increasing responses, from 0 to -0.6V and -0.2 to 0.3V showing five successive additions of 1mM ammonia chloride in the cyclic voltammogram in 0.05M pH 10 phosphate buffer, are demonstrated in Fig. 2. These successive cyclic voltammetric responses indicate the feasibility of utilizing this Cu2O catalyst to develop an effective electrochemical scheme for ammonia ion determination at potentials from 0.3 to -0.6V. Due to the ratio of sensitivity over background, we optimized the oxidation processes for the ammonia chemical sensor. The exact ammonia ion oxidation processes on the Cu2O modified electrode could be demonstrated with a serial electrochemical type reaction mechanism as shown in scheme1. 3.2. Optimizations for ammonia chemical sensor in FIA system Hydrodynamic voltammograms for 5mM ammonia chloride under various poised potentials (0.5 to -0.3 V), flow rate (0.15 to 1.5 mL/min) and sample loop (10 to 500 μL) are shown in Fig3. The optimized values were chosen based on the peak resolution (calaulated by dividing the peak current by the peak width) and current sensitivity. The poised potential of 0.15 V, flow rate of 0.5 mL/min and sample loop of 20 μL gave the best results and these conditions were therefore used to construct the calibration curve. It is important that the optimized poised potential of 0.15 V matches exactly the redox potential of the Cu(I)/Cu(II) transition and thus corresponds the reaction mechanism. Fig.4 shows the calibration plot for ammonia ion under the optimized conditions. The linear range is up to 10 mM and the sensitivity is 1334.2 nA mM-1 (r =0.997) with a detection limit of 18.7 μM (S/N = 3). The RSD obtained for continuous injection (n = 20) of 5mM ammonia chloride was 1.59 %, demonstrating the high precision of the present method. 3.3. Optimizations for creatinine biosensor in FIA system In order to understand the various immobilization method for this biosensor, several cross-linked methods were studied and evaluated. In this experiment, we chose BSA-glutaraldhyde, chitosan-glutaraldhyde and TEOS based sol-gel materials for the immobilization of creatinine deiminase. Table 1 shows the results of these three methods, we found the BSA-glutaraldhyde method had the best sensitivity and reproducibility. In the following optimization, we used this cross-linked method for the creatinine determination. The pH effect on the response of the biosensor was studied by varying the pH of the 0.05M phosphate buffer solutions from 6.00 to 11.00. Fig. 5 shows the plot of the responses of this enzyme based biosensor to the injection of solutions of 0.5mM creatinine at different pH values. As the highest current response was found for solutions with a pH of 10.00, the 0.05M phosphate buffer solution with a pH of 10.00 was chosen as the optimum carrier solution for creatinine analysis. The effect of sample loop of sample on the current response was also studied. In a sample loop ranging from 10 to 500 μL, the current response decreased gradually as the sample loop increased (from 100 to 500 μL). The optimized values were also chosen based on the peak resolution and current sensitivity, a compromised value of 100 μL was selected as the optimum sample loop volume for this experiment. Fig.6 shows the calibration plot for creatinine under the optimized conditions. The linear range is up to 5 mM and the sensitivity is 557 nA mM-1 (r =0.998) with a detection limit of 25.0 μM (S/N = 3) and the response time of 45 seconds. The RSD obtained for continuous injection (n = 20) of 0.5mM creatinine was 3.2 %, demonstrating the high precision of the present method. 4. Conclusions The creatinine deiminase based biosensor combined with FIA was successfully demonstrated to be suitable for creatinine detection by effective catalytic oxidation through Cu2O catalyst. The oxidation reaction mechanism was also be characterized. Since the oxidation process on this biosensor is diffusion-controlled, the electrode renewal is fast (45 s) with good repeatability (3.2%) and low signal-to-noise ratio. The detection limit is 0.025 mM (S/N = 3). It is worth noting that the most applications in clinical and pharmacological practice require ammonia ion determination at neutral pH, and this FIA method can obviously fit this requirement well. Furthermore, this biosensor can be constructed simply and inexpensively, and thus offers an easy route to extension to real application. Acknowledgement The authors gratefully acknowledge financial support from the National Science Council of the Republic of China and Department of Chemistry in Tamkang University. Fig. 1. Cu2O modified electrode under optimum condition in pH 10 phosphate buffer. Fig. 2. Cyclic voltammograms of Cu2O modified electrode under optimum condition in pH 10 phosphate buffer. There are five successive additions of 1mM ammonia chloride in the in the optimum conditions. Creatinine + H2O Creatinine Deiminase N-Methylhydantoin Electrode Cu2O (ox) NH3 0.15V - e Cu2O (red) NH3 (ox) vs. Ag/AgCl Scheme 1. A serial electrochemical type reaction mechanism for creatinine biosensor. (b) 11000 4000 10000 3000 9000 Current (nA) 5000 2000 1000 250 240 230 8000 220 7000 210 6000 0 200 5000 -1000 -400 -200 0 200 Operation Potential (mV) 400 600 -0.25 0.00 0.25 0.50 0.75 1.00 Flow Rate (mL/min) 1.25 1.50 1.75 Peak Resolution (nA/sec) Current (nA) (a) (c) 280 14000 260 Current (nA) 220 12000 200 180 11000 160 140 10000 120 Peak Resolution (nA/sec) 240 13000 100 9000 80 0 100 200 300 400 500 Sample Loop (L) Fig. 3. The optimized study of operation potential, flow rate and sample loop in ammonia chemical sensor. 18000 16000 14000 Current (nA) 12000 10000 8000 Up to 10mM (R = 0.997) 6000 4000 2000 0 -2000 0 10 20 30 40 50 Ammonia Conc. (mM) Fig. 4. The calibration plot for ammonia ion chemical sensor under the optimized conditions. Modified Method Sensitivity RSD BSA Cross-link 550 nA/mM 0.9 % Chitosan Cross-link 490 nA/mM 1.5 % Sol-Gel 410 nA/mM 1.7 % Table. 1. The results of the three cross-linked methods for creatinine biosensor in the optimized conditions. 600 18 600 550 16 Current (nA) Current (nA) 500 400 300 14 450 12 400 10 350 200 8 300 100 6 7 8 9 10 11 0 100 200 300 400 500 Sample Loop (L) Buffer pH Fig. 5. The optimized study of buffer pH and sample loop in creatinine biosensor. 4000 3500 Current (nA) 3000 2500 Up to 5 mM (R = 0.998) 2000 1500 1000 500 0 0 5 10 15 20 25 Creatinine Conc. (mM) Fig. 6. The calibration plot for creatinine biosensor under the optimized conditions. Reference 1. M. JAFFE, Z. Physiol. Chem., 1886, 10, 391. 2. S. Narayanan, H.D. Appleton, Clinical Chemistry, 1980, 26, 1119. 3. D. Heinegard, G. Tiderstrom, Clin. Chim. Acta, 1973, 43, 305. 4. N. Perakis, C.M. Wolff, Clin. Chem., 1984, 30, 1792. 5. M. Mascini, G. Palleschi, Anal. Chim. Acta, 1982, 136, 69. 6. V.K. Nguyen, C.M. Wolff, J.L. Seris, J.P. Schwing, Anal. Chem., 1991, 63, 611. 7. M.B. Madaras, R.P. Buck, Anal. Chem., 1996, 68, 3832. 8. G.F. Khan, W. Wernet, Anal. Chim. Acta, 1997, 351, 151. 9. J.Y. Sung, H.J. Huang, Anal. Chim. Acta, 1991, 246, 275. 10. W.J. Cho, H.J. Huang, Anal. Chem., 1998, 70, 3946. 11. C.M. Chang, H.J. Huang, Anal. Chim. Acta, 1995, 300, 15. Peak Resolution (nA/sec) 500 12. J. Wang, Talanta, 1994, 41, 857. 13. T. Yao, K. Kotegawa, Anal. Chim. Acta, 2002, 462, 283. 14. T. Smith-Palmer, J. Chromatogr. B, 2002, 781, 93.