California Tire Product Stewardship Final Action Plan

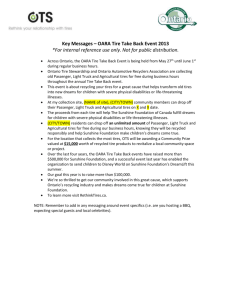

advertisement