Assiut university researches Hydrogen production from acid

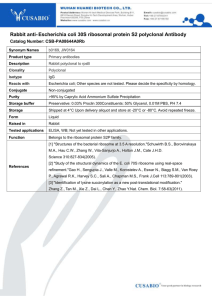

advertisement

Assiut university researches Hydrogen production from acid hydrolyzed molasses by the hydrogen overproducing Escherichia coli strain HD701 and subsequent use of the waste bacterial biomass for biosorption of Cd(II) and Zn(II) Fatthy Mohamed Morsy Abstract: This study was devoted to investigate production of hydrogen gas from acid hydrolyzed molasses by Escherichia coli HD701 and to explore the possible use of the waste bacterial biomass in biosorption technology. In variable substrate concentration experiments (1, 2.5, 5, 10 and 15 g L 1), the highest cumulative hydrogen gas (570 ml H2 L 1) and formation rate (19 ml H2 h 1 L 1) were obtained from 10 g L 1 reducing sugars. However, the highest yield (132 ml H2 g 1 reducing sugars) was obtained at a moderate hydrogen formation rate (11 ml H2 h 1 L 1) from 2.5 g L 1 reducing sugars. Subsequent to H2 production, the waste E. coli biomass was collected and its biosorption efficiency for Cd2þ and Zn2þ was investigated. The biosorption kinetics of both heavy metals fitted well with the pseudo second-order kinetic model. Based on the Langmuir biosorption isotherm, the maximum biosorption capacities (qmax) of E. coli waste biomass for Cd2þ and Zn2þ were 162.1 and 137.9 (mg/g), respectively. These qmax values are higher than those of many other previously studied biosorbents and were around three times more than that of aerobically grown E. coli. The FTIR spectra showed an appearance of strong peaks for the amine groups and an increase in the intensity of many other functional groups in the waste biomass of E. coli after hydrogen production in comparison to that of aerobically grown E. coli which explain the higher biosorption capacity for Cd2þ or Zn2þ by the waste biomass of E. coli after hydrogen production. These results indicate that E. coli waste biomass after hydrogen production can be efficiently used in biosorption technology. Interlinking such biotechnologies is potentially possible in future applications to reduce the cost of the biosorption technology and duplicate the benefits of biological H2 production technology. Key words: Hydrogen production Biosorption Cd2þ Heavy metals Zn2þ Waste Escherichia coli biomass a b s t r a c t This Published in: international journal of Hydrogen Energy ,Vol. 36,PP.1438114390