Nitrous Oxide – Manufacturing Process

advertisement

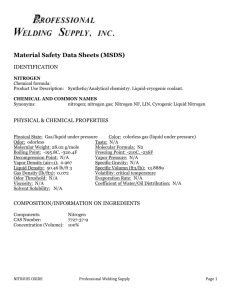

NITROUS OXIDE – MANUFACTURING PROCESS PROCESS: Nitrous Oxide is manufactured by decomposing molten Ammonium Nitrate at a temperature of 250º - 260º C, to generate Nitrous Oxide and steam. CHEMICAL REATION:NH4NO3 ---------> N2O | + 2H20 | The first step in the process is to melt and decompose Ammonium Nitrate. The melting is carried out in an Aluminium Pot provided with Electrical Heaters and Temperature Controllers. The molten material flows into a decomposition pot of Aluminium, which is also heated by Electrical Heaters and temperature is controlled by Controllers. In order to ensure smooth operation, catalyst like Ammonium Di hydrogen Phosphate is added in very small quantities. The gas evolving from decomposition pot carries with it fumes of undecomposed Ammonium Nitrate, steam and other reacted products like Ammonia, Oxides of Nitrogen, etc. Since the gas is very hot at a temperature of 250º / 260º C it is passed through a condensing coil where steam condenses which is used as a reflux in the Primary Scrubber. The Primary Scrubber is packed with ceramic rings and water that is condensed trickles down. This gas passes through a water scrubber, where water soluble impurities are removed. The gas then passes through a caustic scrubber where a solution of Caustic Soda with additives is being circulated to remove oxides of Nitrogen. The scrubber is packed with steel rings and is made of mild steel construction. After removal of oxides of Nitrogen, the gas still contains impurities such as Ammonia and Nitrogen. The gas coming out of the caustic scrubber is passed through an acid tower where battery grade sulphuric acid is being circulated by a pump, to remove traces of Ammonia. The gas is then stored in a gas holder, preferably rubber balloon type of holder. In order to remove the impurity of Nitrogen, the gas is compressed in a three stage Compressor which is water lubricated, to a pressure of 60-65 kg/cm2 when -2- -2- Nitrous Oxide gets liquefied. The liquefied Nitrous Oxide then passes through a set of driers before storing in a series of storage vessels. In these storage vessels, the liquid is allowed to settle so that Nitrogen which is not liquefied is vented out. The Liquid Nitrous Oxide, free from Nitrogen is then filled into cylinders either by a pump or directly. The cylinders are placed in a weighing scale during filling. As this is a liquiflable gas, it is filled by weight only. Purity is checked as the gas is compressed and also stored in cylinders. All the tests are done as per I.P. / International Standards to ensure the correct quality of gas by drawing samples from filled cylinders. *****