Regulation PM- 8.0 Ports Operations (on shore)

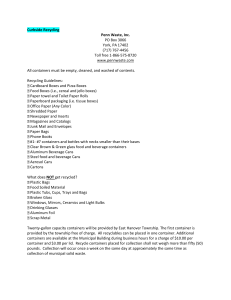

advertisement