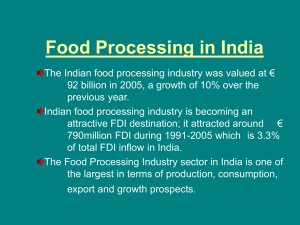

Food Processing Industry in India

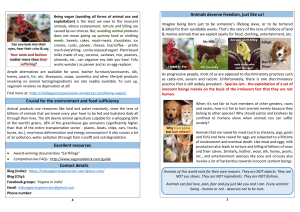

advertisement