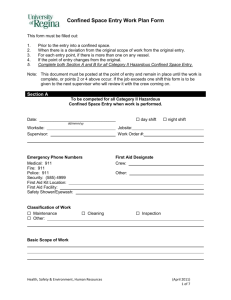

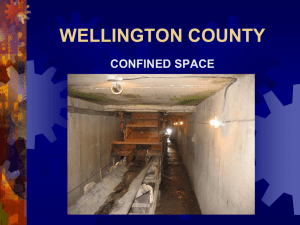

Confined Spaces

advertisement

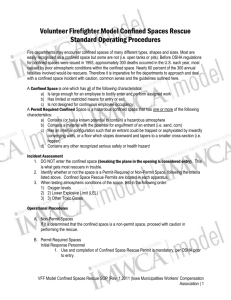

Confined Spaces Education Consultant Workshop Objectives At the end of this session, the participant will: Understand the legislation pertaining to confined spaces Identify the potential hazards Be aware of employer and employee responsibilities Be able to apply this information in the workplace 2 Course Outline 1. Health & Safety Legislation 2. Hazard Recognition 3. Safe Work Procedures 3 Definition: Confined Space Enclosed or partially enclosed Not designed or intended for continuous human occupancy Restricted access or egress 4 Definition: Confined Space May become hazardous because of : Materials or substances contained Construction Location Atmosphere Design 5 Examples of Confined Spaces • Tanks • Storage bins • Boilers • Double hulls • Vats • Pumping stations • Kilns • Pits, sumps • Vaults • Vessels • Silos • Manholes • Pipelines • Water reservoirs • Sewers • Other similar spaces • Manure pits 6 Confined Space Regulations 263(1) Where an employee is about to enter a confined space, an employer shall appoint a competent person to verify by tests that: 263(1)(a)the concentration of airborne chemical agents or airborne dust in the confined space is not hazardous…, 263(1)(b)the concentration of an airborne chemical or mixture of chemical agents or airborne dust in the confined space does not exceed 50% of its lower explosive limit, 7 Confined Space Regulations 263(1)(c)the level of physical agents in the confined space is not hazardous… 263(1)(d)the percentage of oxygen in the atmosphere in the confined space is not less than 19.5% by volume and not more than 23% in volume 8 Confined Space Regulations 263(1)(e) the concentration, level or percentage referred to in paragraphs (a) to (d) is able to be maintained during the period of proposed occupancy of the confined space by the employee 263(1)(h)all electrical equipment and machines have been locked out, with the machines being put in a zero energy state. 9 Confined Spaces - Hazardous 10 Employer’s Responsibilities Instruct and train workers Purge when necessary Provide PPE and emergency equipment To ensure the worker has read, dated and signed the report Appoint a competent tester 11 Competent Person According to the 91-191 I(2) regulation, ‘Competent’ means I. Qualified: ‘knowledge, training, and experience, to do assigned work in a manner that will ensure health and safety’ II. Knowledgeable: about the related act and regulations III. Knowledgeable: about the related potential for danger 12 Competent Person Do the tests (oxygen, flammability, toxicity, etc.) Be trained in the procedures Be in attendance outside Ensure constant communication Have a standard-level first aid and CPR 13 Competent Person Ensure continuous monitoring Set out procedures Set out the results (tests) Identify the proper PPE and emergency equipment Calibrate instruments 14 Employee’s Responsibilities Competent person follows procedures Install warning signs if there’s a traffic hazard Follow procedures Use PPE and emergency equipment Read and sign the report of the competent tester 15 Written Report 1. Sets out the Results (tests) Evaluation (hazards) 2. Sets out procedures to be followed 3. Identifies PPE 4. Sets out emergency procedures 16 Written Report 5. Identifies equipment and rescuer 6. Kept at the worksite 7. Kept for a period of 2 years 8. Available to an officer 17 Three People Are Needed… 1. Entrant: Read, date and sign report 2. Person outside the entrance (standby): Competent 3. Back-up: Near Vicinity 18 Safe Work Procedures Preplan the job Prepare and check equipment Ensure traffic control Test before opening and record Follow correct opening procedures 19 Safe Work Procedures Record results of re-test Ventilate and purge if required Set up an escape and rescue plan Ensure continuous monitoring if necessary 20 Protective Equipment Employer shall: Provide PPE in good condition Inspect regularly Ensure employee training 21 Protective Equipment Employee shall: Wear and use Use properly Inspect and test Report problems 22 Equipment In wet conditions, equipment should be: 1. Battery operated 2. Double insulated 3. Bonded or grounded *Be aware of other hazardous conditions Example: Chemicals, moving equipment, etc. 23 Oxygen Less than 19.5%: Use appropriate RPE Reserve 5 minutes More than 23%: No flammable, combustible or reactive material 24 Unsafe Conditions Safety Hazards Atmospheric Hazards Unsafe Actions 25 Hazard Recognition Solids (entrap) Liquids (drown) Atmospheric hazards Machines or equipment (trap, squeeze or crush) Bulk materials (shift or collapse) 26 Hazard Recognition Electrical shock Rescue equipment (nonfunctional) Size of entrance (too small) Rusted ladder 27 Hazard Recognition Traffic Hazards Temperatures Visibility Slippery Work Surfaces Lack of Education & Training Lack of enforcement *NOTE: Never put yourself in a position where you need to be rescued 28 Written Program 1. Identify Confined Spaces 2. Recognize Hazards 3. Testing and Controls 4. Emergency Procedures and Rescue 5. Responsible Parties 29 Written Program 6. Standby Procedures 7. Training Requirements 8. Permit Requirements 9. Pre-entry Requirements and Checks 30 Summary During this session, we have been made aware of: i. The legislation pertaining to confined spaces ii. The potential hazards iii. Employer and employee responsibilities iv. How to apply this information in the workplace 31