H&S Guidance for Design Technology, Art & Design

advertisement

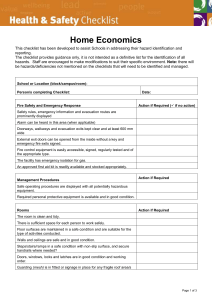

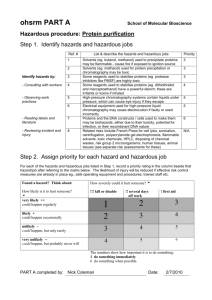

Health and Safety Guidance for Design Technology, Art and Design, Ceramics, Textiles and Food Technology Date: September 2015 Document summary This guidance is for subject leaders and staff within Design Technology, Art and Design and includes Graphics, Ceramics, Textiles and Food Technology. It sets the general standards required by East Sussex Children’s Services Department that schools must follow and should be read in conjunction with the relevant subject specific Code of Practice. Contents 1. 2. 2.1 2.2 2.3 2.4 2.5 2.6 2.7 2.8 2.9 2.10 2.11 3. 3.1 4. 4.1 4.2 4.3 5. 6. 7. 7.1 7.2 7.3 8. 8.1 8.2 8.3 8.4 8.5 9. 10. Introduction ............................................................................................................... 4 Management of safety .............................................................................................. 5 Risk assessments ....................................................................................................... 5 Health and safety policies............................................................................................ 6 Responsibilities ........................................................................................................... 7 Class sizes .................................................................................................................. 8 Using workrooms ......................................................................................................... 8 Maintenance of Equipment .......................................................................................... 9 Inspections ................................................................................................................ 10 Safety signs, notices and displays ............................................................................. 10 Making artefacts ........................................................................................................ 10 Guards and interlocks ............................................................................................... 10 Moving and handling ................................................................................................. 10 Accidents and incidents ......................................................................................... 10 Investigating and monitoring accidents ..................................................................... 11 Adhesives ................................................................................................................ 11 Hot-melt glue guns .................................................................................................... 11 Cyanoacrylates (superglues) ..................................................................................... 11 Wall-paper paste ....................................................................................................... 12 Buying safe goods and equipment ....................................................................... 12 Cleaning rooms ....................................................................................................... 12 Electricity................................................................................................................. 13 Mains leads, plugs and sockets................................................................................. 13 The fixed installation (the building wiring up to the power socket) ............................. 13 Room electricity emergency stops ............................................................................. 13 Checking and using equipment ............................................................................. 14 Approved equipment ................................................................................................. 14 Maintenance of equipment ........................................................................................ 14 Home-made mains apparatus ................................................................................... 14 Low voltage ............................................................................................................... 14 Rechargeable batteries ............................................................................................. 14 Fire safety ................................................................................................................ 15 Fumes and dust ...................................................................................................... 15 10.1 10.2 10.3 10.4 11. 11.1 11.2 12. 13. 14. 15. 16. 16.1 16.2 17. 17.1 17.2 17.3 18. 18.1 18.2 18.3 19. 19.1 19.2 19.3 19.4 20. 20.1 20.2 20.3 21. 22. 22.1 22.2 22.3 22.4 Cleaning dusty areas ................................................................................................. 16 Hazardous materials ................................................................................................. 16 Risk assessments and control measures .................................................................. 16 Prohibited substances ............................................................................................... 17 ICT equipment ......................................................................................................... 17 Safe use of laptop computers .................................................................................... 17 Interactive whiteboards.............................................................................................. 18 Ladders, steps and other access equipment ....................................................... 19 Lifting operations and lifting equipment .............................................................. 19 Lone working........................................................................................................... 20 Noise ........................................................................................................................ 20 Pressure systems ................................................................................................... 21 Hired pressure systems ............................................................................................. 21 Model steam engines ................................................................................................ 22 Protective clothing and safety equipment ............................................................ 22 Clothing ..................................................................................................................... 22 Eye protection and guards......................................................................................... 22 First aid...................................................................................................................... 22 Services: water and gas ......................................................................................... 22 Gas supplies.............................................................................................................. 22 Using gas burners ..................................................................................................... 23 Water ......................................................................................................................... 23 Storage .................................................................................................................... 23 Flammables ............................................................................................................... 24 Corrosives ................................................................................................................. 24 Shelving..................................................................................................................... 24 Storage-life ................................................................................................................ 24 Tools: hand tools and portable power tools ........................................................ 24 Hand tools ................................................................................................................. 24 Portable power tools .................................................................................................. 24 Glue guns .................................................................................................................. 25 Training .................................................................................................................... 25 Waste ....................................................................................................................... 25 Disposable items ....................................................................................................... 26 Combustible swarf ..................................................................................................... 26 Metal swarf, sharps and glass ................................................................................... 26 Chemically hazardous materials ................................................................................ 26 About this document: Enquiries: Health and Safety Team Version number: 02 Author: Related information Health and Safety Team Telephone: 01273 481938 Design Technology Code of Practice Email: Food Technology Code of Practice Art and Design Code of Practice paths@eastsussex.gov.uk Download this document From: https://czone.eastsussex.gov.uk/schoolman agement/healthsafety/curriculum/pages/prim ary.aspx Accessibility help Zoom in or out by holding down the Control key and turning the mouse wheel. CTRL and click on the table of contents to navigate. Press CTRL and Home key to return to the top of the document Press Alt-left arrow to return to your previous location. Health and Safety Guidance for Design Technology, Art and Design, Ceramics, Textiles and Food Technology 1. Introduction This guidance is for subject leaders and staff of Design Technology, Art and Design, and includes Graphics, Ceramics, Textiles and Food Technology. It sets the standards required by East Sussex Children’s Services Department that schools must follow. The purpose of this document is to ensure safe practice in technology at KS3 and higher. The document applies not only to teachers but also to others who work within the relevant departments, including technicians, teaching assistants and other support staff and trainees. This document must be made available to all staff involved in teaching these areas and they must use the information in planning practical work. There are other essential documents to this one: East Sussex Children’s Services Department Codes of Practice for Design Technology, Food Technology and Art and Design CLEAPSS documentation - Design Technology (relevant to Design Technology, Art and Design, Ceramics, Textiles, and Food Technology) BS4163:2014 Health and safety for design and technology in educational and similar establishments: British Standards A Guide to Safe Practice in Art and Design (updated version on NSEAD's website) . These documents, in conjunction with this guidance, form the basis of the policy arrangements and any risk assessments for health and safety in Design Technology, Art and Design, Ceramics, Textiles, Food Technology, Graphics, etc. Design Technology Departments must have copies of this information readily available for staff to use, and for inspection by the local authority advisers/officers, OfSTED inspectors, and the Health and Safety Executive. There are two further useful documents issued by the DfE. These are for design technology areas, Building Bulletin 81 "Design and Technology Accommodation in Secondary Schools: A Design Guide”, and for Art and Design areas, Building Bulletin 89, Art Accommodation in Secondary Schools (both documents are available from the CLEAPSS website). The School Standards and Framework Act and the precursor, the Local Management of Schools, has given schools increased delegated powers and duties in running schools, including health and safety responsibilities for staff, students and visitors. This document explains these health and safety responsibilities and the principles of successful health and safety management. As a guide to what is reasonably practicable, the word should in this document is used to mean something that is recommended but not compulsory; these are usually actions that are considered to be good working practices, but the school is free to choose other actions if it has good reasons for doing so. Conversely, the word must is used to mean something that is compulsory, usually something statutory, and a failure to implement would be breaching a law, or breaching a duty of care. Page 4 of 26 This document is specifically for health and safety matters relating to the technology curriculum areas, including art and design. For general health and safety matters relating to Children’s Services, refer to the A-Z of Health and Safety on Czone. 2. Management of safety The Children’s Services Department acknowledges that good design and technology involves a significant amount of practical work. Practical experience provides opportunities to introduce students to the concepts of risk assessment and safe working methods. Students should be encouraged to develop their understanding of risk assessment processes. It is essential that staff are fully conversant with hazards in their work area and that they plan, organise, and monitor the work so that the risks can be controlled. This document will support staff by providing advice and guidance on legislation and best practice as well as promoting a positive health and safety culture by the identification of hazards and implementing control measures to adequately reduce and control the risks. In the event of an accident, it is important that immediate interim measures are taken (if needed) to prevent a recurrence. Accidents must be reported in accordance with both the school and County Council reporting procedures. 2.1 Risk assessments Risk assessment is a process for looking at what can cause harm, how likely and severe the harm could be, and what can be done to prevent it. There is no such thing as zero risk - risk assessment is a way of reducing the risks to an acceptable level, so the benefits of the activity far outweigh them. All activities that involve foreseeable significant hazards must have a risk assessment before it is undertaken. Do not carry out any such activity without a risk assessment. This document, along with BS 4163:2014, contains information on the hazards that may be created by equipment and materials and a series of model risk assessments have been developed by CLEAPSS that will help schools to undertake their own risk assessments. A school specific risk assessment should be developed to ensure that all activities with foreseeable significant hazards are assessed. One practical way of ensuring that appropriate assessments are in place, would be to undertake a risk assessment for all equipment, materials and hazardous substances that are used in school. Before starting a new project the relevant risk assessments should be reviewed to identify if there are special local conditions that create hazards, not already on the risk assessments. You should adapt the risk assessment accordingly, adding steps to reduce the local hazard. If there are any activities containing significant hazards that have not been assessed, these can be included as part of the overall project risk assessment. When students are planning projects and coursework, staff should help them to identify the hazards that are likely to be encountered and the steps they will take to reduce the risks adequately. Do not forget to involve any Teaching Assistants and voluntary staff in your risk assessments. They should be consulted when considering students with special needs so that all students and staff have adequate levels of protection from the hazards in the practical curriculum. Page 5 of 26 Further information is contained in the Risk Assessment Policy, available via Czone. If you need further advice on risk assessments, for example if you are undertaking or supervising a special project, contact the Health and Safety Team. 2.2 Health and safety policies To achieve good management of health and safety, subject leaders and staff are expected to co-operate with the senior management of the school or college on health and safety matters. Each school has an overall Health and Safety Policy that explains how adequate standards of health and safety will be achieved and is prepared by the Headteacher and Governing Body. Subject leaders will normally have delegated responsibility for ensuring adequate health and safety standards in their departments. It is a requirement of the Children’s Services Department that those departments undertaking practical work (which includes Design Technology, Art and Design, Ceramics, Textiles and Food Technology) have a written subsidiary health and safety policy that clearly and concisely explains the departmental health and safety arrangements. This could be a combined policy that covers a range of practical curriculum areas, or individual policies in which each covers a specific practical curriculum area. In larger departments, many health and safety functions will be delegated. It must be clear from the department’s safety policy what safety functions have been delegated, and to whom. The policy should have four sections: A general statement of commitment and intent This is a short paragraph that expresses the departments’ commitment to health and safety and the intent to make teaching as safe as is reasonably practicable Department's organisation This is a description of the department’s organisation for achieving their commitment. This should explain the structure of the department and the line management from the Senior Leadership Team member to the subject leader to all staff who work in the department. This section should explain the formal ways in which health and safety information is communicated to and from staff. It is recommended that time be allocated formally at staff meetings to exchange information on health and safety. Minutes of a meeting can form a record of information passed to staff The particular arrangements for implementing the policy This should state the arrangements for undertaking risk assessments. This will include the use of documentation from CLEAPSS, BS 4163:2014, and “A Guide to Safe Practice in Art and Design”, as appropriate. This section should also explain all health and safety duties delegated by the head of department, such as the person responsible for ensuring schemes of work have appropriate risk assessments, the person who oversees the induction for new staff including technicians, the people who check the machinery, tools and rooms, etc. The arrangements for testing of particular items should also be explained, such as checking fume extraction, gas appliances, pressure systems, gas cylinders and regulators, and protective equipment such as goggles and face shields. There must be a procedure for making sure the health and safety functions are undertaken; part of the procedure must be a plan of what will be done to rectify faulty equipment and machinery Monitoring and reviewing This section should detail the department’s arrangements for monitoring and reviewing the health and safety of the department. Page 6 of 26 The document should be signed and dated annually (at the beginning of each academic year) by the member of the Senior Leadership Team with line management responsibility for the department, as well as the subject leader, and approved by the headteacher and governing body. The policy length will depend on the departmental complexity, but try to keep it to a few sides of A4. The document should not include particular risk assessments or other codes of practice - it is not a document on the particular safety measures for each piece of practical work undertaken. Practical activities must be assessed for risk, and safety measures used to keep the risks low. If you are undertaking any new activities, it is essential that a risk assessment is carried out beforehand. Please contact the Health and Safety Team to help you determine the significant hazards and the risk of them happening. From this, decide on suitable control measures to minimise the risks. 2.3 Responsibilities Health and safety is an integral part of the management of schools and its implications need to be considered whenever related decisions are made. Governors and headteachers are responsible for everything over which they have control and are expected to take all reasonable measures within their authority to avoid or minimise problems. It is the responsibility of the headteacher, as the day to day manager, and governors to ensure that: work is planned and organised safely staff receive adequate health and safety training, including specialist design technology training plant and equipment are regularly checked, inspected and maintained to recognised standards and records kept electrical installation is to current applicable requirements and in good order space allocation for machines, furniture and overall working arrangements and numbers of students working in a design technology area contribute to safe and healthy working what technology staff are asked to do is reasonable and has regard for their accredited skills level and the student’s health and safety. This document provides guidelines on safety in technology practical work. Subject leaders have a duty to organise the department so that staff have access to the safety information and understand the system for reporting defects in safety equipment. Specific health and safety responsibilities for all groups of staff are included in the school health and safety policy and the subject leaders must ensure that all members of staff are aware of their individual responsibilities. All staff within the line management structure, including the governing body, are accountable for the implementation of this document and regular monitoring arrangements must be put in place to ensure that the measures outlined within this document are an integral part of the day to day management of the department. No activity may be carried out unless the requisite safety apparatus is available and in good working order. Every technology department must have procedures for: Page 7 of 26 ensuring that risk assessments are undertaken and implemented communicating information to the people who need it ensuring regular safety checks are undertaken keeping rooms clean and tidy reporting defective equipment ensuring apparatus receives necessary maintenance ensuring only suitably qualified staff use restricted machinery or processes. A safety policy is a good way of showing how these procedures are organised in the department (see section 2.2 on Health and safety policies). 2.4 Class sizes There is no statutory limitation on class size in any subject in schools in England and Wales. British Standards recommend class sizes of no more than 20 per competent, qualified teacher. For numbers higher than this, follow the British Standards guidance (BS 4163:2014 section 4, part 9) and carry out a risk assessment. Use the guidance in Building Bulletin 81, ‘Design and Technology Accommodation in Secondary Schools: A Design Guide’, or DfEE Building Bulletin 89, ‘Art Accommodation in Secondary Schools’, as appropriate for planning class sizes and work space, and take into account: room size and layout the equipment in the room the type of activities to be undertaken competence and experience of the teacher bench space, space between benches class behaviour students with special needs. Any members of staff who are concerned that class sizes presents an unacceptable risk to health and safety should report their concerns to their subject leader and, if necessary, the headteacher. Use alternative methods if possible for particular practical activities to reduce the risks, but if they cannot be lowered to an acceptable level, the activities must not be undertaken until the health and safety matters have been resolved. The Health and Safety Team can give advice. 2.5 Using workrooms Staff are expected to leave workrooms in a safe condition. When starting a practical lesson, staff should check that rooms are clear, all thoroughfares and room exits are free from obstruction, floors are dry and in a safe condition, and the lighting is adequate for the work being undertaken. Fire doors must be unlocked and clear. Only staff accredited to use the equipment are permitted to switch on the electricity and gas mains isolators, students may not switch these on - not even under supervision. The department must ensure that students do not use utensils, tools, machines or other equipment until they have been taught how to use them correctly. Only one person may operate a machine or piece of equipment at a time (there are some exceptions and some machinery is restricted to use by qualified staff, see the Design Technology Code of Practice). Students are required to clear away at the end of each practical session as instructed. Page 8 of 26 Workshops, food technology rooms and other specialist practical rooms should be locked when not in use. A specialist room should only be used for the purpose for which it was designed. Supply or cover teachers must be given information on the room hazards; this could be a laminated A4 sheet for the room explaining the location and operation of main services such as electrical isolators, any local hazards, and where help can be obtained. Cover teachers may supervise practical work only if they are competent, experienced and accredited to the appropriate standard e.g. DATA certification for the equipment to be used, and understand the relevant safety procedures. There have been a number of instances where schools have asked non design technology trained staff to undertake practical resistant materials classes due to a shortage of a trained design technology staff. The subject leader and headteacher should ensure that any teaching staff practicing design technology in school have the following experience and qualifications: DATA H&S Accreditation in core secondary and every specialist level that the teacher may be required to teach Completion of a recognised design technology teacher training course. Machine workshops or rooms where machinery and tools are left accessible must not be used as tutor or form rooms. 2.6 Maintenance of Equipment Employers have a legal duty to ensure that equipment/plant that their employees and nonemployees (e.g. students/students) use is safe. A Safe Condition Survey has been produced to assist establishments in complying with this duty in design technology areas /workshops. The subject leader or other persons designated by them should complete the survey at the start of each academic year. The person (or persons) completing the survey cards must be competent to undertake the task (e.g. it would be inappropriate for a food technology teacher to check the condition of metalworking machinery, unless they were able to demonstrate competence in this area, such as DATA certification for the machines and experience). Where suitable qualifications are not available for machine types, the subject leader will need to assess the persons competence based on their experience and understanding of the manufacturer’s instructions on safe use of the machine. Sheets have been provided for details of competent persons to be recorded. A file should be developed and contain a survey sheet for each piece of machinery/ equipment in the establishment (e.g. if the establishment has 6 pillar drills there should be 6 “Drilling Machine” survey cards). Completion of the survey cards does not allow for other daily monitoring and maintenance procedures to be neglected. Where survey cards refer to the machine and its accessories having been maintained by a competent person/organisation, the level of competence required would normally be different to that of someone completing the survey cards. The person/organisation undertaking the maintenance would need to be competent to undertake checks, servicing and repairs whereas the holder of DATA accreditation should be competent to use and instruct on the operation of the machine. For machines which use gas the maintenance contractor must be a Gas Safe Registered engineer who has the appropriate certification to work on the type of installation and gas type. Page 9 of 26 2.7 Inspections Each workroom should be inspected three times per year by a person who understands the nature of the hazards associated with the activities carried out in the room. A model inspection checklist is available on Czone. 2.8 Safety signs, notices and displays Each workroom must have a set of safety rules and the fire procedure displayed clearly. Cautionary notices and signs must be displayed where appropriate, these can be homemade provided they conform to current standards and standard pictograms and are made of a durable material. Details are available on CLEAPSS in the sign catalogue which is adjustable and printable, and when laminated gives a useful and compliant workshop sign. 2.9 Making artefacts Items made at school must be safe to use. In many cases, there are regulations or guidelines such as the Toys (Safety) Regulations 1995. Items must not be dangerous on account of their flammability; they should be made inflammable or, if they can ignite, should burn slowly with a small rate of flame spread. 2.10 Guards and interlocks Keep machine guards in clean and good condition, those that have safety interlocks must be checked regularly to ensure that they work efficiently. 2.11 Moving and handling Moving and handling covers any form of lifting, pushing, pulling or carrying loads, by hand or using bodily force. Handling loads using incorrect techniques can cause strains, particularly back strain, fractures, cuts and other injuries. These can mean lost working days, and in severe cases even permanent disablement. Injuries caused by bad document handling are a big cause of absence in education. Therefore headteachers must make sure that each line manager is responsible for arranging to: avoid equipment and material handling where there is a risk of injury, wherever reasonably practicable risk assess all material handling operations record all relevant risk assessments review the risk assessments regularly provide adequate information, instruction and training for staff. 3. Accidents and incidents In health and safety, an accident is an event that causes ill-health or injury, and possibly damage to property or the environment. An incident is an event that nearly causes illhealth, injury, damage to property or the environment (so it can be called a near miss). Never ignore a near-miss. It gives important information on how to prevent a similar event happening again. If ignored, the consequences could be much worse next time. Page 10 of 26 It is essential to report accidents and incidents, as it is an important way of monitoring health and safety performance and identifying trends so that resources can be targeted towards tackling specific areas of concern. The law says that employers have to report serious accidents and incidents. There are two levels of reporting and recording accidents and incidents: using your local school minor injuries form and reporting to East Sussex County Council via the online incident system, available on Czone. 3.1 Investigating and monitoring accidents Unless they are minor accidents where the cause is obvious, accidents and incidents need to be investigated. The main reason for the investigation is to find the cause of the accident to prevent it happening again. You should record any findings and recommendations. The investigator should be the person responsible for the area where the accident occurred or the person in charge of the curriculum area if it happened in a lesson and should be carried out in liaison with the Health and Safety Co-ordinator. More serious accidents, where the injured person was taken to hospital, must be investigated by a senior manager and Health and Safety Co-ordinator. Accidents and incidents are usually caused by failures in control, and often have several causes, both direct and indirect. Although the direct cause may be human or technical failure, the indirect cause may be down to organisational failings or oversights that managers are responsible for. When investigating an accident it is important to look for both direct and indirect causes. 4. Adhesives Follow the guidance on CLEAPSS for Design and Technology to create a substance assessment for safe use of all adhesives. Do not use hazardous adhesives (for example, epoxy resins, cyanoacrylates and formaldehyde resins) when safer ones would do just as well. It is recommended that non-solvent based products are used where possible. All glues must be used in accordance with the manufacturer’s instructions. Be aware that some solvent-based adhesives are used by glue-sniffers. 4.1 Hot-melt glue guns Use the trigger-type only. Wear a protective glove on the hand holding the work. Consider the use of an appropriate stand to keep glue gun clear of drips. Before use, teach users the first aid procedure should hot glue come into contact with the skin; immerse the hand in clean cold water for at least five minutes. Ensure that there is a source of cold water available; it should be at least two metres away from the glue gun (preventing the risk of water being spilled onto the glue gun). 4.2 Cyanoacrylates (superglues) These may be used by teachers, technicians and under strict guidance and control, students Y10 and above. Students must be under direct supervision. Be very careful not to get this glue on anyone’s skin. This glue should be kept locked away when not in use. Page 11 of 26 4.3 Wall-paper paste Avoid the use of paste which has fungicide in it, as this is an irritant and can cause an allergic skin reaction. 5. Buying safe goods and equipment When you buy goods and equipment, you want to be sure that you get what you pay for, and that they will not cause any harm to staff or students. If possible, schools should avoid using hazardous substances. Non or less hazardous substances should be chosen in preference. The quality and performance of equipment must be suitable for educational use. For example, items meant for DIY enthusiasts may not be suitable for students to use. Please refer to BS 4163:2014 prior to purchasing any equipment to ensure its suitability and to identify any training requirements, etc. Buy from reputable suppliers, and avoid second-hand equipment unless you are sure it is in good condition and suitable. The CE mark on equipment is not a guarantee of safety - it says the manufacturer is claiming the machinery complies with the law. It’s up to the school to check the equipment is safe before use. To help you choose safe and good value products: research what you need - contact other educational establishments for recommendations don’t be misled by sales staff into buying unnecessary extras ask for written confirmation that the goods or services will comply with relevant safety standards check for hidden costs or small print clauses check to see if the goods or services are covered by a code of practice, or if the company is a member of a trade association if fitting or installation is involved, check to see that the person who will carry this out is suitably qualified (e.g. an electrician or gas fitter) if the equipment has replaceable parts, check that they are easily available at a reasonable cost, and preferably that you can get them from a range of suppliers. When ordering the goods, make sure your order identifies the exact goods, specifications and standards required, cross-referencing to the suppliers’ literature where necessary and only sign off if these are correct. When arranging installations, these should only be signed off when the equipment is proved to be working correctly. Be aware of interlock switching with machines and local exhaust ventilation (LEV) equipment. 6. Cleaning rooms Staff must keep the practical rooms clean and tidy. Walkways and work areas should not be cluttered. Equipment and materials must be stored appropriately. You need suitable equipment to clean dust. See the section (11) on fumes and dust. Page 12 of 26 School staff must leave practical rooms, offices and preparation rooms in a safe state so the rooms can be cleaned safely. Cleaners must have induction training before cleaning in hazardous areas such as machine workshops; the cleaning staff must have been trained to use the appropriate cleaning methods, particularly in ceramics areas, wood and metal machine workshops. You must explain to cleaners clearly if there are areas or equipment that should not be cleaned. Do this in liaison with the site manager or caretaker. 7. Electricity 7.1 Mains leads, plugs and sockets Plugs, leads and sockets must be checked regularly. Worn or damaged mains flex must be replaced. All 230 volt mains plugs must be the standard 13 amp square pin type with partly shrouded line and neutral pins, the older style plugs with bare line and neutral pins should not be used. Staff should not wire plugs until they have received adequate training. 7.2 The fixed installation (the building wiring up to the power socket) No one is allowed to work on the fixed installation without agreement from BSD Property (maintained schools). If they have agreed the work, it can only be done by an ESCCapproved contractor, a NICEIC contractor, or an ECA or JIB recognised electrician. The work must comply with the latest edition of the Institute of Electrical Engineers (IEE) regulations for electrical installation, and when it is finished, a completion certificate must be sent to BSD Property. The mains wiring in workshops (single phase and three phase) must conform to the requirements specified in section 3 (part 7) of BS 4163:2014. The mains isolator and emergency stops must be labelled clearly. No student or unauthorised person is permitted to turn on the mains isolator. Often you have to connect more than one device to a mains socket, particularly with computer equipment - do not use socket adapters, use fused 13A rated trailing distribution blocks. Extension leads may only be used as a temporary method of powering portable equipment; they must not be used as permanent fittings. Cable drum flex must be fully unwound before use. All flex must be routed, guarded or protected so that it does not cause a danger of tripping people. Portable mains equipment used outdoors must be protected by a residual current device (RCD). 7.3 Room electricity emergency stops Rooms with high power electrical machines should be fitted with adequate emergency stops around the room. Design technology workshops must have them installed. See section 3 (part 7.2.5) of BS 4163:2014. The stops must be tested regularly; if any malfunction, the machine should be taken out of use and they must be repaired by a qualified electrician without delay. Preparation rooms for staff use only do not need emergency stops and should not be affected if emergency stops within the workshops are activated. Page 13 of 26 8. Checking and using equipment All users of portable mains equipment should carry out a simple and quick five -point visual check before plugging a device into a socket and switching it on: Are the plug and mains socket in good condition with no damage or missing screws? Does the equipment have a current PAT label? Is the flex in good condition - the flex outer sheath must go fully into the plug and fully into the equipment? Does the mains equipment appear in good order, free from dampness and no obvious damage? If the equipment has a switch, is it switched to off? Remember, damp or wet mains conductors are dangerous. Do not attempt to remove damp plugs from sockets, isolate the supply first. 8.1 Approved equipment All mains electrical equipment used in schools must conform to relevant British Standards specification or equivalent European standards. Do not use equipment meant for domestic light use. 8.2 Maintenance of equipment The electricity at work regulations requires that periodic tests are made to ensure electrical equipment is in a safe condition. Portable electrical equipment should be formally tested annually. The checks include examination for integrity of connectors, correct fusing and flex, tests for earth bonding and for line-earth insulation. The electricity regulations apply to the whole school, not just to the technology department. Check with your school management for the arrangements for electrical testing. 8.3 Home-made mains apparatus Teachers/technicians are not permitted to construct mains equipment for school use. 8.4 Low voltage Students are not permitted to use power supplies with more than 33 volts on open terminals; for younger students (under Y10) it is preferable to keep the supply below 25 volts. Higher voltages are permitted if they are current limited to 5mA or less, or if the terminals are suitably shrouded to prevent accidental contact with a live conductor. Students must not be allowed to work on TV sets, open mains etc. 8.5 Rechargeable batteries Rechargeable batteries (nicad, nickel metal hydride, lithium or lead-acid) may not be used by young students in school (Y8 or lower) unless either the battery holder and all electrical connections are completely inaccessible to students, or some current limiting device is inserted between the batteries and the accessible connections. This restriction is necessary because of the dangers of using these batteries. If they are short-circuited, the conducting wires can become red hot and the plastic insulation will burn. If the short circuit is severe, high-capacity batteries may explode. Page 14 of 26 The risk of injury outweighs any cost-saving benefit. Nicad or nickel metal hydride rechargeables may be used by students in Y9 or above under suitable supervision when a low internal resistance power source is necessary for a project to work. The students must be made aware of the hazards. Owing to the risk of explosion, no attempt should be made to recharge primary (nonrechargeable) batteries. 9. Fire safety Follow the school procedure for fire evacuation. Each room should have a notice explaining the evacuation procedure and muster points. If there is more than one exit, and one may lead people in the wrong direction to escape safely, a fire exit sign with pictogram must be placed over the correct exit(s). Each workroom should have the correct type and number of extinguishers and other firefighting equipment as laid down by the local fire risk assessment. Access to the equipment must not be hindered. Staff are advised to read the instructions on using the equipment. Fire hazards from highly combustible material require a specific risk assessment. You need to look at how the fire could start, and put in specific safety measures to reduce the likelihood of it happening and spreading. 10. Fumes and dust The COSHH regulations require that fumes and dust are kept below limits specified. This can be done in several ways. If a health and safety risk is anticipated refer first to the HSE document HSG 258 about LEV, then follow these steps. 1) Change the process Sometimes a simple change of technique can reduce dusts. Avoid keeping and mixing fine powders if it is safe to keep them in paste or pellet form. Brush on paints, glazes etc. rather than spray them. Consider hand-cutting plastics rather than machining them 2) Use natural ventilation Activities which produce low levels of fumes, such as gluing with household glues, soldering and painting with solvent based paints, can be done with no special precautions other than ensuring good natural ventilation. This may mean working near a window or working outside 3) Use local exhaust ventilation (LEV) systems Some processes produce high levels of fumes and dust and may only be done with an adequate local exhaust ventilation system, also known as LEV, or fume extraction or dust extraction. Where LEV has been installed, it must be tested to check it meets the design criteria every 14 months. It is the responsibility of the subject leader to make sure the tests are undertaken and that records kept 4) Use dust masks and respirators These may only be used where it is impracticable to use methods 1-3, or when methods 1-3 are not sufficient by themselves. It is not an alternative cheaper method. Page 15 of 26 Refer to CLEAPSS Design and Technology guidance on LEV for dust and fume control for specific hazardous materials. Machines that produce high levels of fine dust, such as disc sanders, belt-facers, circular saws, band saws and powered fret saws must be fitted with suitable LEV. 10.1 Cleaning dusty areas It is important that workspaces which are prone to the build up of dust - like wood machining rooms and pottery rooms - are cleaned regularly, particularly in the not-soaccessible places. Vacuum cleaners may only be used if they have adequate dust filtering, (stage 3) ordinary vacuum cleaners will only disperse very fine dust and cause a greater risk. Surface cleaning should be done damp or wet, particularly silica dust in ceramics rooms. You may need to wear a disposable dust mask (grade FFP2) if dust becomes airborne while cleaning. See section 6 on cleaning rooms. 10.2 Hazardous materials If possible, schools should avoid using hazardous substances. Non or less hazardous substances should be chosen in preference. The Control of Substances Hazardous to Health (COSHH) Regulations require risk assessments and control measures to be provided for employees and others affected who have to work with hazardous substances, for example solvents, acids, bleaches, dyes, etc. which could be harmful if used wrongly. This includes fumes and dusts (COSHH is not concerned with dangers due to extremes of temperature or pressure. Asbestos and lead are also excluded from the regulations because there are separate regulations for these). COSHH is not designed to prevent teachers from using hazardous materials; it should be regarded as a more systematic approach to sensible safe practice which has developed in schools and colleges over the years. Reference must be made to the COSHH risk assessments before using hazardous materials, but there is no need for repeated referrals once they are familiar with the hazards and safety procedures. Be aware that the COSHH information is updated as new hazards are recognised. You must not use a hazardous material if a safer substitute is reasonably practicable. 10.3 Risk assessments and control measures Model COSHH risk assessments for the materials used in practical subjects are available from the CLEAPSS online pages for Design and Technology. These should be crossreferenced with the material safety data sheets to develop COSHH assessments. Do not use a hazardous material without an assessment. You must follow the guidance given on the assessment. To each risk assessment, you should add notes on any local conditions and hazards. Every employee has a duty to make full and proper use of the safety equipment and safety information provided by the school or the Local Authority. The COSHH information must be used in the planning and organising of technology activities. People handling hazardous materials are also required to follow the manufacturer’s or supplier’s instructions for its use. Page 16 of 26 LEV systems have to be checked every 14 months. Refer to the section fumes and dusts (11). 10.4 Prohibited substances Some of the following materials may have been used in the curriculum in the past, but they are no longer considered suitable. It is unlikely that these are in schools now, but sometimes they are discovered when clearing out old cupboards and stores. Do not use them. The below list is not exhaustive; no hazardous material may be used unless it has been assessed carefully. Prohibited Substance Asbestos Likely use Solvent Benzene Heat insulation Barium powder pigments Paint/glaze colouring Cadmium powder pigments Paint/glaze colouring Chromium powder pigments Paint/glaze colouring Fehling’s solution Food test Hydrofluoric acid Etching glass etc. Methanal (formaldehyde, formalin) Fungicide, lithography Million’s reagent Food test Phenol (solid) Anti-bacterial investigations Raw lead glazes Glazing ceramics Tetrachloromethane (carbon tetrachloride) Solvent, stain remover 11. ICT equipment Although working with display screen equipment is not generally high risk, users can get musculoskeletal and other physical problems, eye fatigue and mental stress if they do not follow the precautions laid down in the Display Screen Equipment (DSE) Regulations. These regulations are relevant to staff, particularly those in information technology areas. Students are not normally classed as users because they do not use the DSE equipment for long enough. Nonetheless, the general principles in setting up comfortable and low-risk workstations for students should still be followed. 11.1 Safe use of laptop computers Laptops and similar portable computers are not suitable as office workstations for administrative support staff. These styles of computers have smaller keyboards and screens than desktop computers and this makes them less comfortable to use, especially over longer periods. The hazards are aches and pains caused by poor posture, eyestrain and headaches from looking at a poor contrast screen, and arm and finger strains caused by poor keyboard technique. There is also an electrical hazard if the laptop external power unit becomes damaged. Page 17 of 26 Follow these points to reduce the health hazards: avoid using laptop computers for long periods; use a full-sized PC if one is available or consider using a docking station with a plug-in full size mouse and keyboard when you use mains power, only use the a/c adaptor provided by the manufacturer, not any others, to avoid incompatibility and damage to the laptop look at the adaptor, power cables and plug, and check that they are in good condition before plugging in. Keep the power cables free from twists if possible, choose software that allows you to adjust image size and colour be careful that power cables do not cross walkways because it may cause someone to trip when you use a laptop for more than a few minutes, make sure you are sitting comfortably with good posture, and adjust the screen to give the best viewing position without screen reflections. It is better to use the laptop on a table rather than on your lap take regular breaks from using the laptop if the work is prolonged. As a guide, do something else for five minutes every thirty minutes of laptop use. Practical rooms are far from ideal for ICT equipment, so extra care is needed. Ensure that the equipment is placed in a dust-free area and well away from water, hazardous liquids etc. Dust and dirt will damage DVD/CD drives. Do not place the equipment close to radiators or other heat sources. Ensure that the ventilation holes remain unobstructed. Arrange the equipment so that users are able to sit down and operate it comfortably. Refer to the section on electricity (8). Computer equipment is likely to have many trailing leads used for connecting the peripheral equipment. Route these leads to minimise the risk of someone becoming entangled in them. Some desktop PCs have a significant earth leakage to cause nuisance tripping of sensitive RCDs. Double insulated equipment such as laptops will not cause this problem. 11.2 Interactive whiteboards The height of the board from the floor should be set to give good visibility and ensure users can reach all areas of the board without having to bend excessively; the height should also give students access to a sufficient area of the board. Avoid using platforms to give younger students access to the board. The light from projectors is very bright and can cause eye damage. Follow these guidelines to prevent this: never stare directly into the beam of the projector. Warn students of the dangers too when entering the beam, you should not look towards the class for more than a few seconds as much as practicable, keep your back to the projector beam when you move into the beam students should be supervised when the projector is in use. Interactive whiteboards can be very difficult to see when direct sunlight shines on the board. If the board is in direct sunlight, you will need to fit window blinds. Staff adjusting or cleaning a high-mounted or suspended projector must use an appropriate step ladder to access it safely. Projectors should be allowed to cool down before cleaning. Page 18 of 26 All cabling must be safely secured for the whole of the cable length. 12. Ladders, steps and other access equipment You must have suitable ladders and other portable access equipment for staff who need to work at heights, for instance to put up displays or reach upper shelves. Chairs, tables and other items of furniture must not be used. Stepladders, ladders and scaffold towers must be suitable for the tasks. Metal ladders must meet BS 2037:1994, or the European equivalents. Ladders should be Class 1, designed for industrial use. Avoid ladders designed for light or domestic use. The headteacher must ensure that: the access equipment is in good condition the access equipment is stored safely and securely so unauthorised people cannot use it staff and other users know how to use it properly. Follow the guidance in the Stepladders user guide available on Czone. Access equipment must be checked every three months and records kept. One way of arranging this is to make sure each item of equipment has an ‘owner’ responsible for checking it regularly, and taking it out of service if it becomes defective. Staff that are expected to use ladders or stepladders more than 4 rungs high should attend a ½ day training session. All staff who are expected to use a mobile tower scaffold (either equipment owned or hired by the school) should attend a one day certificated training session prior to using the equipment. The qualification should be to a PASMA (Prefabricated Access Suppliers and Manufacturers Association) standard. 13. Lifting operations and lifting equipment These are regulated by the Lifting Operations and Lifting Equipment Regulations (LOLER). These regulations apply to all hoists, jacks or other lifting equipment that may be used in technology. If you have any such equipment, then you must ensure that the lifting equipment is: of adequate strength and stability for each load, particularly regarding the stress at its mounting or fixing point positioned or installed to reduce to as low as is reasonably practicable the risk of the equipment or a load striking a person; or from a load drifting, falling freely, or being released unintentionally either marked to indicate its safe working load, or has information kept with the machine that clearly indicates its safe working load for each configuration, or both if it applies thoroughly examined regularly. The regulations specify that lifting equipment to lift persons (including accessories for lifting persons) must be examined every 6 months. Other lifting equipment must be examined every 12 months (as a minimum), or in either case, in accordance with an examination scheme, and each time that exceptional circumstances have occurred that could have damaged the lifting equipment. Page 19 of 26 The examination must be done by a competent person, and will normally involve a load test. Records of dates and results of the examination must be kept. See the section on moving and handling (2.11). 14. Lone working Lone working means working when there is nobody else around to help or to raise the alarm if you need it. For example, a teacher might come into school on their own at the weekend to prepare some work. If staff need to work alone, you must consider what precautions you need to take for their health and safety. This begins before they even arrive for work: it is important that someone else knows that they will be working alone, and approximately when they should be home. For practical purposes, this could be a relative, friend or neighbour. When they are at work, the normal standards apply so that potential harm is kept to a minimum. But lone workers also have to remember that they are responsible in law for their own health and safety - they must not take risks or short cuts. They must not try to do anything they are not adequately trained for, or which needs more than one person to do it safely. Anyone with supervisory responsibilities must do a risk assessment identifying the hazards, assessing the risks involved and putting the measures in place to avoid or control them. This means identifying situations where their staff work alone, and considering a number of questions: Does anything about the environment present specific risks to staff – e.g. the location, weather conditions or time of year? Is there safe access in and out? Can the equipment be safely handled and used by one person? Does the job involve handling loads? Is there a risk of violence? Do the staff concerned have any medical conditions? What forms of communication are available? The risk assessment may point out a need for more staff, equipment, information, instruction and training, greater supervision, or new safer systems of work such as a checking-in system. Personal safety courses are available via the Children’s Services Workforce Development Team – sistraining@eastsussex.gov.uk. 15. Noise Noise levels at work are regulated by The Noise at Work Regulations 2005. Some machines can produce high levels of sound, for example circular saws, planers, and percussion drills. Page 20 of 26 In general, if persons about 2 metres apart are required to raise their voices to carry out a normal conversation, it might be necessary to implement controls under these Regulations. Further information on the exposure limits are contained in BS4163:2014. If you notice regular ringing in your ears after being in a noisy environment, reduce the noise if possible and obtain advice from the Health and Safety Team. 16. Pressure systems Large compressed air systems (in which the pressure multiplied by the internal volume of the air receiver exceeds 250 bar litre) are regulated by the Pressure Systems Safety Regulations 2000. It is the policy of this local authority to have the examination carried out by inspectors from Zurich using a written scheme of examination provided and record of these inspections must be kept. All pressure systems must be maintained in good repair to prevent danger. Users must know what action is needed in the event of an emergency, in most cases this will be to remove the source of energy (switch off the electrical supply, turn off the heat etc.) and leave the area. Users of any pressure system should carry out pre-start checks; they should understand under what circumstances the system should be shut down and know how to vent any residual pressure safely before removing lids, filler caps, hoses etc. If the pressure vessel shows any signs of significant pitting, corrosion, damage from drops or knocks or bowing from over-pressure, it should be considered sufficient grounds for replacing the apparatus. Regardless of the size of the system, it would still be wise to make regular spot-checks. Ensure that all hoses and pressure pipes are in good condition and securely fitted. The compressed air vessel should be free from corrosion or other visible signs of damage. Check that the pressure gauges are working and the pressure cut-out switch operates. Filters should be serviced regularly and water/oil trap bowls should be clear and free from cracks. Where appropriate, the compressed air vessel should be marked clearly with the maximum safe working pressure. Do not neglect the non-pressure hazards like power cables, drive belts and guards. If portable air compressors are mounted above the floor surface, they must be secured before they are used. Under no circumstances should compressed air be used for blowing away dust. 16.1 Hired pressure systems The owner has the responsibility for carrying out the formal examination and the hirer has the duty to use the system in accordance with the manufacturer’s instructions. Page 21 of 26 16.2 Model steam engines Under the Pressure Systems Safety Regulations, regular checks must be made on all pressure vessels, including model steam engines, using a written scheme of examination (WSE). It is the policy of this authority to have the examination carried out by inspectors from Zurich, using WSEs provided by the insurance company. A record of the examinations must be kept. 17. Protective clothing and safety equipment 17.1 Clothing Protective clothing such as aprons or overalls must be used in any ‘messy’ practical work, or where hazardous materials are being used. Do not use nylon or other plastic protective clothing in high-temperature work. Leather aprons and heat-resistant spats, gloves, boots and gaiters must be used when pouring molten metal in foundry work. People wearing bandages on the hand or forearm are not permitted to use machinery which has exposed moving parts. 17.2 Eye protection and guards Eye protection must be used if there is any significant risk of eye injury in the work being carried out or observed. Don’t overlook the risk when working with stretched materials. Eye protection must conform to BS EN166, except for welding shields which must conform to BS EN175. There are various grades within BS EN166, 3 protects against liquid splashes, 4 protects against large dust particles, 5 protects against gas and fine dust particles, 9 protects against molten metals and hot solids, B protects against medium energy impact, and F protects against low energy impact. B grade is generally sufficient for protecting eyes from particles produced by normal machining techniques, but grade 9 must be used for protection against hot metal splashes or sparks. Select the type of eye protection suitable for the practical work. Eye protectors must be kept clean and scratch-free, periodically they must be washed in a mild household disinfectant. 17.3 First aid Each workroom must have easy access to a first aid kit. It should be in a cabinet marked with a green cross. It must be stocked and used in accordance with the guidelines available on Czone. At least one person holding a First Aid at Work certificate must be available when design technology rooms are in use. 18. Services: water and gas 18.1 Gas supplies Refer to BS 4163:2014 section 3. There should be a gas isolating valve into each area of use. The valve must be labelled clearly and the off position indicated. If it is outside the workroom, a notice must be displayed near the entrance explaining where it is located. The valve must be accessible at all times. Make sure the gas isolators are off when the gas is not being used. Page 22 of 26 In emergencies, shut off the gas at the isolator. If you think there is a gas leak, or are worried about carbon monoxide, call the National Gas Emergency Service on 0800 111 999, 24 hours a day, and keep all unauthorised people away from the area. All gas equipment must be checked and maintained regularly. Gas pipe work and controls should be visually checked to ensure that they are corrosion free. Check that the gas flexible hoses and joints are in good condition and restraining cables, straps or chains are secure. The equipment must be stable, all fixing straps and bolts must be secure. Gasfired equipment fed with pressure air or any other extraneous gas must have an approved non-return valve fitted into the gas supply to each teaching area or group of areas. Staff and technicians may carry out simple maintenance such as unblocking nozzles and cleaning user-serviceable parts, but they may not otherwise dismantle or modify gas equipment; this must be done by a competent Gas Safe Registered contractor. All gas appliances must be formally checked at least once a year by a competent Gas Safe Registered contractor. Keep records of the checks and maintenance. 18.2 Using gas burners Do not situate gas burners in a position which can be illuminated by strong sunlight, the flame becomes very difficult to see. Utensils and tools must be placed so that you do not need to lean over the burner to reach them. Students must not be allowed to light gas burners until they have received adequate training on how to do it safely. The danger is particularly great with large burners like those fitted to brazing hearths and forges, where it is possible for large amounts of gas/air mixture to be released in a short time. 18.3 Water There should be a water stopcock in the water pipes into each area of use. The stopcock must be labelled clearly and the off position indicated. If it is outside the workroom, a notice must be displayed near the entrance explaining where it is located. In workshops and other ‘non-clean’ rooms, warm water, soap and hand drying facilities must be provided for hand washing. 19. Storage Workshop storage must be in accordance with section 3 of BS 4163:2014. Sharp tools and utensils must be stored so that accidental contact with the sharp part is unlikely. All materials that are hazardous, for example they may be toxic, flammable or corrosive, must be clearly labelled. The labelling must state the material and the nature of the hazard(s). Keep all working quantities of these materials to a minimum. Access to hazardous materials must be restricted to authorised users only. Storage must be kept well organised and tidy. Large items should not be stored at a high level and proper step ladders or similar must be available for reaching high shelves safely. Standing on benches, chairs, tables etc. is not permitted. Suitable storage for clothing, school bags, etc. should be provided away from the main practical area. Walkways must be kept clear at all times. Page 23 of 26 19.1 Flammables Stocks of flammable liquids must be stored in a lockable fire-resistant cabinet in a well ventilated stockroom. The maximum amount of flammable liquids you are allowed to store is 50 litres, no more than 5 litres of any one type. This is a large quantity and schools should not normally store such large amounts. A large storage of flammable liquids requires a specific fire risk assessment. 19.2 Corrosives Stocks of corrosive liquids must be placed in secondary containers, e.g. plastic buckets, so that the liquid can be retained if the primary container leaks. Stocks of corrosive liquids must be stored in a secure and well ventilated storeroom. 19.3 Shelving Make regular checks to ensure that shelving is in a safe condition. Shelves must not be overloaded and heavy materials must not be stored high up. Ensure that the shelf space is used sensibly with no items stacked precariously. Proper stepladders must be provided for access to shelving beyond easy reach from the floor. 19.4 Storage-life All materials and chemicals with limited shelf-lives must be dated, either with the purchase date or with the dispose-of-by date; it must be clear what the date refers to. Ensure that such chemicals or materials are disposed of safely before they deteriorate into a dangerous state. See the section on waste (22). See the separate Food Technology Code of Practice document for information on food storage. 20. Tools: hand tools and portable power tools Tools must be used in the correct manner and for operations that they are designed for. Follow the manufacturer’s instructions. Arrangements must be put in place to ensure that all tools are returned at the end of each practical lesson. 20.1 Hand tools These must be kept in a clean safe condition. Ensure handles are secure. Cutting blades must be kept sharp. Hammers must be checked to ensure the head is secure and the handle is in a safe condition. Sharp tools and utensils must be stored so that people cannot easily come into contact with the sharp edge or point. 20.2 Portable power tools All work equipment must be regularly checked and maintained. Power tools designed for machining materials must be a single-purpose type; power-tool attachments are not permitted. This does not apply to non-machining tools such as food processors and sewing machines. Students are not permitted to use portable power tools with exposed rotating cutters (except drills not exceeding 13 mm bits). This prohibition includes power gardening tools, circular saws, routers and planers. There are restrictions on the use of Page 24 of 26 food processors and liquidisers with exposed blades (see section 2 of the Food Technology Code of Practice: cookers and domestic machinery). High-power portable machining tools are not recommended for the technology curriculum. Schools are not permitted to use off-hand grinders, chain saws or any other very dangerous portable highpower tools. Keep the external surfaces free from water; better still, keep the tool well away from water (this does not refer to internal water reservoirs in steam irons etc.). All electrical equipment must be visually checked. At least once a year it must undergo formal checks for earth bonding and line insulation. Refer to the section electricity (8). 20.3 Glue guns Refer to the section on adhesives (4). 21. Training Subject leaders must assess their own health and safety training needs and that of their staff, and make arrangements for those who need training to attend suitable courses. Training is not just for employees; if you use voluntary workers, they are also entitled to training if they need it to carry out their role safely and without undue risk to themselves or others affected by their work. Some types of practical work using dangerous machinery may not be carried out unless the person holds current accreditation from DATA. Subject leaders should assess their staff periodically; training does not last indefinitely and refresher training will be needed. DATA accreditation must be updated every five years with the individual’s portfolio’s being subject to review by the Health and Safety Team as part of the audit programme. 22. Waste You have a strict duty to make sure your waste is managed properly. You must make sure waste is disposed of legally. You must always have it taken by a registered carrier to a properly licensed waste disposal facility, and always provide the necessary documentation. Waste material can be difficult and expensive to dispose of. If possible, avoid using processes that produce significant quantities of toxic waste - change the process to produce less waste, or a less harmful kind. When comparing the cost of materials, it is important to take into account the cost of disposing of them. It’s also important to avoid accumulating waste. Don’t buy more of a material than you are likely to need, particularly if it has a limited shelf life. Often a small amount can be treated then disposed of as household waste. However, if it is allowed to accumulate into a large amount, it becomes a problem to treat. There are extra regulations for some materials - such as asbestos, hazardous chemicals and oil. If you have to dispose of any such wastes, the Environment Agency must be told beforehand, and it will need a consignment note - the contractor will normally deal with this. Page 25 of 26 22.1 Disposable items The practice of reclaiming disposable items for re-use is bad and should be avoided. It saves very little money in return for lowering standards of hygiene and safety. 22.2 Combustible swarf Combustible swarf such as plastic shavings, wood shavings and dust must not be allowed to accumulate. They should be swept up into a sack and placed in a metal bin. The bin should be emptied regularly into the school dustbins. 22.3 Metal swarf, sharps and glass A bin, suitably labelled, should be reserved just for this type of waste. The cleaning staff must be made aware of this so that the contents can be handled correctly. 22.4 Chemically hazardous materials This must be disposed of as a special waste. It is important that schools avoid producing large quantities of hazardous waste. This may mean selecting a safer process that does not use or produce toxic materials. Page 26 of 26