pola27448-sup-0001-suppinfo01

advertisement

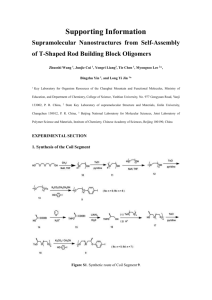

Supporting Information Ordered Nanostructures from Self-Assembly of H-shaped Coil-Rod-Coil Molecules Zhuoshi Wang1†, Keli Zhong2†, Yongri Liang3, Tie Chen1, Bingzhu Yin1, Junqiu Liu, Myongsoo Lee4* and Long Yi Jin1* Experimental Section 1. Synthesis of coil segment 8 Figure S1. Synthetic route of Coil Segment 8 Synthesis of compound 21: To a solution of Ethyl L-(-)-lactate (36.5 g, 0.308 mol), and 3,4-dihydro-2H-pyran (42.1 g, 0.5 mol) were slowly added 10 drops of concentrated HCl at 0℃. The solution was stirred for 10 h while it reached room temperature. Na2CO3 (3 g) was added, and stirring was continued for 10 h. The reaction mixture was then filtered, concentrated to small volume, and distilled to give 21 (51.9 g, yield 83%). Synthesis of compound 22: To a suspension of LiAlH4 (12.0 g, 0.316 mol) in dry diethyl ether (80 mL) was added a solution of 21 (51.9 g, 0.257 mol) in diethyl ether (40 mL) at 0 ℃ under nitrogen atmosphere over 8 h. After 12 h at room temperature, the reaction mixture was refluxed for 5 h. Methyl acetate (5 g), 10% NaOH (20 mL), and water (80 mL) were then added in that order to the mixture cooled at room temperature. The precipitate was filtered off, and the solution was concentrated, dried over K2CO3 and finally distilled to give 22 (35.2 g, yield 86%). Synthesis of compounds 16, 18, 23: These compounds were synthesized according to the same procedure, a representative example is described for 16. To a 250 mL two-neck flask compound tetraethylene glycol (4.07 g,21mmol), dry THF (100 mL) were added. After stirring for several min at 0 ℃, NaH (1g,23mmol) was added slowly. And then iodomethane (8g,22mmol) was added dropwise for 1.5 h at 0 ℃. The mixture was refluxed for 24 h. The reaction was concentrated by evaporation and extracted with dichloromethane. The combined organic portions were dried over MgSO4 and filtered. The residue was purified by flash column chromatography with EA/CH3OH=4/1 as eluent to give product 16 (6 g, 74%) as colourless liquid. 1 H-NMR (300MHz, CDCl3, δ, ppm): 3.44-3.73 (m, 18H), 3.36 (s, 3H). Compound 18a: 1 H-NMR (300MHz, CDCl3, δ, ppm): 3.44-3.73 (m, 26H), 3.36 (s, 3H). Compound 18b: 1 H-NMR (300MHz, CDCl3, δ, ppm): 3.44-3.73 (m, 34H), 3.36 (s, 3H). Compound 23a: 1 H-NMR (300MHz, CDCl3, δ, ppm): 3.44-3.73 (m, 24H), 3.36 (s, 3H) , 1.18 (s, 3H). Compound 23b: 1 H-NMR (300MHz, CDCl3, δ, ppm): 3.44-3.73 (m, 32H), 3.36 (s, 3H) , 1.18 (s, 3H). Synthesis of Compounds 17, 19, 24: These compounds were synthesized according to the same procedure, a representative example is described for 17. To a 250 mL round bottom flask Tetraethylene glycol monomethyl ether (8.24g , 40mmol), p-Toluenesulfonyl chloride (15.3g, 80mmol),pyridine (20ml), dry Dichloromethane (100ml) were added. After being stirred at room temperature for 18 h, 30 mL water was added into the reaction mixture, the aqueous phase was slowly acidified with cold 3 N HC1 to pH = 2-3 and extracted with dichloromethane (3 X 50 mL). And then the organic fractions were dried over MgSO4. After evaporation of the solvent 12.6 g (yield 87%) of clear oily 17 was obtained that was used without further purification. 1 H-NMR (300MHz, CDCl3, δ, ppm): 7.79 (d, J=8.2Hz, 2H), 7.33 (d, J=8.2Hz, 2H), 4.15 (t, 2H), 3.54-3.73 (m, 14H), 3.36 (s, 3H), 2.43 (s, 3H). Compound 19a: 1H-NMR (300MHz, CDCl3, δ, ppm): 7.79 (d, J=8.2Hz, 2H), 7.33 (d, J=8.2Hz, 2H), 4.15 (t, 2H), 3.54-3.73 (m, 26H), 3.36 (s, 3H), 2.43 (s, 3H). Compound 19b: 1H-NMR (300MHz, CDCl3, δ, ppm): 7.79 (d, J=8.2Hz, 2H), 7.33 (d, J=8.2Hz, 2H), 4.15 (t, 2H), 3.54-3.73 (m, 34H), 3.36 (s, 3H), 2.43 (s, 3H). Compound 24a: 1H-NMR (300MHz, CDCl3, δ, ppm): 7.79 (d, J=8.2Hz, 2H), 7.33 (d, J=8.2Hz, 2H), 4.15 (t, 2H), 3.54-3.73 (m, 24H), 3.36 (s, 3H), 2.43 (s, 3H), 1.18 (s, 3H). Compound 24b: 1H-NMR (300MHz, CDCl3, δ, ppm): 7.79 (d, J=8.2Hz, 2H), 7.33 (d, J=8.2Hz, 2H), 4.15 (t, 2H), 3.54-3.73 (m, 32H), 3.36 (s, 3H), 2.43 (s, 3H), 1.18 (s, 3H). Synthesis of compound 8: These compounds were synthesized according to the same procedure, a representative example is described for 15a. Excess K2CO3, 4-Iodophenol (0.88g, 4.02mmol), Compound 19a (1.3g, 3.2mmol) and 18-crown-6 (0.1g, 0.38mmol) were dissolved in absolute acetonitrile (50ml). The mixture was further refluxed for 24h. the solvent was removed in a rotary evaporator and washed by water. The mixture was extracted with ethyl acetate and dichloromethane and then dried over anhydrous magnesium sulfate and filtered. After the solvent was removed in a rotary evaporator, the crude product was purified by chromatography on silica gel chromatography (EA:CH3OH=20:1 as eluent) to yield 0.85g of a yellow liquid (62.0%). 1H-NMR (300MHz, CDCl3, δ, ppm): 7.72 (d, J=8.2Hz, 2H), 7.28 (d, J=8.2Hz, 2H), 4.16 (t, 2H), 3.87 (t, 2H), 3.44-3.73 (m, 26H), 3.36 (s, 3H). Compound 8b: 1H-NMR (300MHz, CDCl3, δ, ppm): 1H-NMR (300MHz, CDCl3, δ, ppm): 7.72 (d, J=8.2Hz, 2H), 7.28 (d, J=8.2Hz, 2H), 4.16 (t, 2H), 3.87 (t, 2H), 3.44-3.73 (m, 34H), 3.36 (s, 3H). Compound 8c: 1H-NMR (300MHz, CDCl3, δ, ppm): 1H-NMR (300MHz, CDCl3, δ, ppm): 7.72 (d, J=8.2Hz, 2H), 7.28 (d, J=8.2Hz, 2H), 4.58-4.64 (m, 1H), 3.44-3.80 (m, 26H), 3.36 (s, 3H), 1.18 (s, 3H). Compound 8d: 1H-NMR (300MHz, CDCl3, δ, ppm): 1H-NMR (300MHz, CDCl3, δ, ppm): 7.72 (d, J=8.2Hz, 2H), 7.28 (d, J=8.2Hz, 2H), 4.58-4.64 (m, 1H), 3.44-3.80 (m, 34H), 3.36 (s, 3H), 1.18 (s, 3H). 2. Synthesis of the rod precursors Synthesis of 2-amino-5-bromobenzoic acid methyl ester (4) Anthranilic acid methyl ester (16.6g, 0.11mol) was dissolved in glacial acetic acid (250 mL) and cooled below 16 ℃. Bromine (22.1g, 7.1mL, 0.138mol) was subsequently added dropwise, resulting in compound 4 as precipitates. After filtration, the residue was washed with glacial acetic acid, nd the crude product was purified by means of recrystallization to give the pure compound as a white solid (15.7g , 62.1%). 1H-NMR (300MHz, CDCl3, δ, ppm): 7.95 (d, J = 2.4 Hz, 1H), 7.30 (dd, J = 9, 2.4 Hz, 1H), 6.54 (d, J = 9 Hz, 1H), 5.75 (s, 2H), 3.95 (s, 3H). Figure S2. Synthetic route of the rod precursors 3, 4 Synthesis of methyl 5-bromo-2-iodobenzotate (5) 4 (1.15g, 0.005mol), H2O (5ml), H2SO4 (5ml), CH3COOH (5ml), were put into two-neck flask and cooled at 0 ℃ by an ice-water bath. A solution of NaNO2 (0.38g, 0.0055mol) in water (3ml) was added dropwise over a period of 2.0 h under constant stirring. Then the solution of KI (0.006mol) in water (2mL) was added by drops into the above mixture for 1 h under ice-water bath. The mixture was further stirring for another 1 h at 60℃. The crude product was filtered and washed with water, and then extracted with methylene chloride. The extract was dried with MgSO4 and concentrated by vacuum evaporation. The crude product was purified by silica gel chromatography to yield 1.19g of a white solid (70%). 1H-NMR (300MHz, CDCl3, δ, ppm): 7.94 (d, J = 2.4 Hz, 1H), 7.84 (d, J = 9 Hz, 1H), 7.30 (dd, J = 9, 2.4 Hz, 1H), 3.95 (s, 3H). Synthesis of (5-bromo-2-iodophenyl) methanol (6) To an oven-dried flask protected under N2 were charged methyl 5 (1.19g, 0.0035mol) which was dissolved in methylene chloride (15 mL) and slowly added DIBAL (1M in hexane, 12 mL) at 0℃. The reaction was gradually warmed up to room temperature and kept stirring overnight. The mixture was cooled to 0 ℃, treated with 15% aqueous citric acid slowly, and then extracted with CH2Cl2. The extract was dried with MgSO4 which was further puried by silica column chromatography (hexanes/ CH2Cl2, 1:1) to give the pure compound as a white solid (1.0 g, 92%). 1H-NMR (300MHz, CDCl3, δ, ppm): 7.74 (d, J = 8.5 Hz, 1H), 7.68 (d, J = 2.4 Hz, 1H), 7.16 (dd, J = 8.5, 2.4 Hz, 1H), 4.63 (d, J = 6 Hz, 2H), 2.13 (t, J = 6 Hz, 1H). Synthesis of 5-bromo-2-iodobenzaldehyde (7) 6 (1.0g, 0.0032mol) was dissolved in 20mL of methylene chloride. PCC (2.15g, 0.01mol) was added under nitrogen. The reaction mixture was stirred at room temperature under nitrogen for 4 h. The resulting solution was removed in a rotary evaporator, and the crude product was purified by column chromatography (silica gel, hexane/ CH2Cl2, 1:1) to give the pure compound as an oyster white solid (0.89g, 90%) . 1 H-NMR (300MHz, CDCl3, δ, ppm): 10.02 (s, 1H), 7.98 (d, J = 2.4 Hz, 1H), 7.76 (d, J = 8.5 Hz, 1H), 7.38 (dd, J = 8.5, 2.4 Hz, 1H). Figure S3. 1H-NMR spectra of molecules 1a, 2a in CDCl3 Figure S4. MALDI-TOF-Mass spectra of 1, 2 (matrix: CHCA) Figure S5. Wide-angle X-ray diffraction patterns of the rod-coil oligomers 1a and 2a measured in their solid state. The results clearly show that the intermolecular distance for 2a is longer than for the molecule 1a with no side methyl group, and prove that the methyl groups on the surface of rod and coil segments can lead to lowered interaction of π-π stacking and, subsequently, loose the packing of the H-shaped rod segments. Calculating process of pore size of the hexagonal perforated lamellar structure (molecule 2a) From the experimental values of the unit cell parameters (a, c) and the density of each segment (ρ = 1.01 g/ cm3, and ρcoil =1.0 g/ cm3 ), the perforation sizes in diameter are calculated to be 4.2 nm, according to following equations, where Mw is the molecular weight, and NA is Avogadro’s number. The densities of poly(ethylene oxide) coils (ρcoil ) were used as ρ peo =1.0 g/cm3. Mw = 2045, M coil = 1060, a =6.22 nm, c =8.1 nm, ρ =1.01 g/ cm3, ρcoil =1.0 g/ cm3, hrod = 3.26 nm (estimated by Corey-Pauling-Koltun (CPK) molecular model). V unit cell = √3*a2c/2 = 0.27139 * 10-18 cm3 m unit cell = ρ V unit cell = 0.27410 * 10-18 g m bundle = m unit cell / 2 = 0.13705 * 10-18 g n bundle = m bundle * NA/ Mw = 41 V coil = m coil / ρ coil = 2 n bundle * M coil / NA ρ coil = 0.14438 * 10-18 cm3 V rod = V unit cell -V coil =0.12701* 10-18 cm3 V coil ( perforated)= √3*a2h/2 - V rod / 2 =0.04572 *10-18 cm3 π r2 h =V coil (perforated) r =√V coil (perforated) / π h = 2.1nm D = 2r = 4.2 nm