Selective oxidation catalyst for ammonia from biomass gasification gas

advertisement

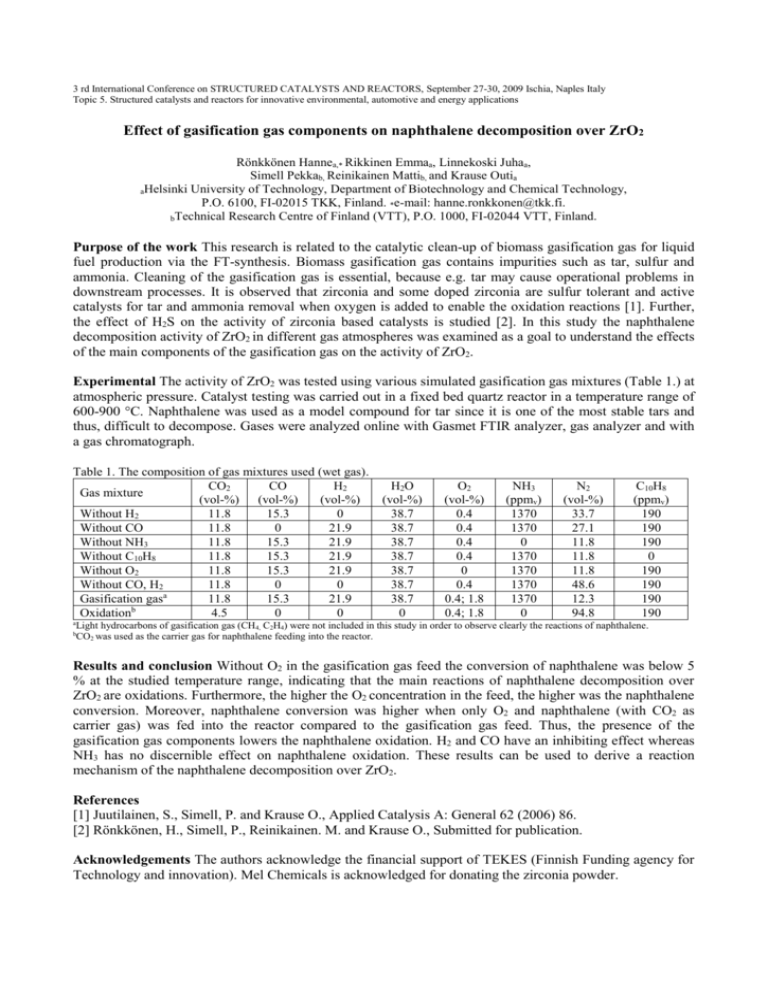

3 rd International Conference on STRUCTURED CATALYSTS AND REACTORS, September 27-30, 2009 Ischia, Naples Italy Topic 5. Structured catalysts and reactors for innovative environmental, automotive and energy applications Effect of gasification gas components on naphthalene decomposition over ZrO2 Rönkkönen Hannea, Rikkinen Emmaa, Linnekoski Juhaa, Simell Pekkab, Reinikainen Mattib, and Krause Outia aHelsinki University of Technology, Department of Biotechnology and Chemical Technology, P.O. 6100, FI-02015 TKK, Finland. *e-mail: hanne.ronkkonen@tkk.fi. bTechnical Research Centre of Finland (VTT), P.O. 1000, FI-02044 VTT, Finland. Purpose of the work This research is related to the catalytic clean-up of biomass gasification gas for liquid fuel production via the FT-synthesis. Biomass gasification gas contains impurities such as tar, sulfur and ammonia. Cleaning of the gasification gas is essential, because e.g. tar may cause operational problems in downstream processes. It is observed that zirconia and some doped zirconia are sulfur tolerant and active catalysts for tar and ammonia removal when oxygen is added to enable the oxidation reactions [1]. Further, the effect of H2S on the activity of zirconia based catalysts is studied [2]. In this study the naphthalene decomposition activity of ZrO2 in different gas atmospheres was examined as a goal to understand the effects of the main components of the gasification gas on the activity of ZrO2. Experimental The activity of ZrO2 was tested using various simulated gasification gas mixtures (Table 1.) at atmospheric pressure. Catalyst testing was carried out in a fixed bed quartz reactor in a temperature range of 600-900 °C. Naphthalene was used as a model compound for tar since it is one of the most stable tars and thus, difficult to decompose. Gases were analyzed online with Gasmet FTIR analyzer, gas analyzer and with a gas chromatograph. Table 1. The composition of gas mixtures used (wet gas). CO2 CO H2 Gas mixture (vol-%) (vol-%) (vol-%) Without H2 11.8 15.3 0 Without CO 11.8 0 21.9 Without NH3 11.8 15.3 21.9 Without C10H8 11.8 15.3 21.9 Without O2 11.8 15.3 21.9 Without CO, H2 11.8 0 0 Gasification gasa 11.8 15.3 21.9 Oxidationb 4.5 0 0 a H2O (vol-%) 38.7 38.7 38.7 38.7 38.7 38.7 38.7 0 O2 (vol-%) 0.4 0.4 0.4 0.4 0 0.4 0.4; 1.8 0.4; 1.8 NH3 (ppmv) 1370 1370 0 1370 1370 1370 1370 0 N2 (vol-%) 33.7 27.1 11.8 11.8 11.8 48.6 12.3 94.8 C10H8 (ppmv) 190 190 190 0 190 190 190 190 Light hydrocarbons of gasification gas (CH4, C2H4) were not included in this study in order to observe clearly the reactions of naphthalene. CO2 was used as the carrier gas for naphthalene feeding into the reactor. b Results and conclusion Without O2 in the gasification gas feed the conversion of naphthalene was below 5 % at the studied temperature range, indicating that the main reactions of naphthalene decomposition over ZrO2 are oxidations. Furthermore, the higher the O2 concentration in the feed, the higher was the naphthalene conversion. Moreover, naphthalene conversion was higher when only O2 and naphthalene (with CO2 as carrier gas) was fed into the reactor compared to the gasification gas feed. Thus, the presence of the gasification gas components lowers the naphthalene oxidation. H2 and CO have an inhibiting effect whereas NH3 has no discernible effect on naphthalene oxidation. These results can be used to derive a reaction mechanism of the naphthalene decomposition over ZrO2. References [1] Juutilainen, S., Simell, P. and Krause O., Applied Catalysis A: General 62 (2006) 86. [2] Rönkkönen, H., Simell, P., Reinikainen. M. and Krause O., Submitted for publication. Acknowledgements The authors acknowledge the financial support of TEKES (Finnish Funding agency for Technology and innovation). Mel Chemicals is acknowledged for donating the zirconia powder.