Air Quality - National Environment & Planning Agency

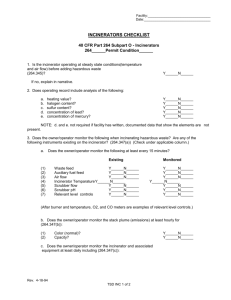

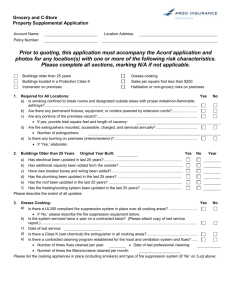

advertisement