06_SWP_Colony supression assay_JS

advertisement

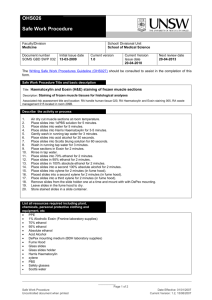

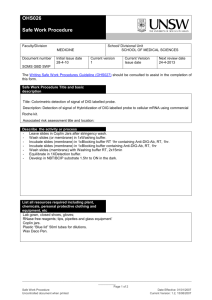

OHS026 Safe Work Procedure Faculty/Division Medicine Document number SOMS.CGM.SWP006 Initial Issue date 23rd June 2009 School/ Divisional Unit School of Medical Sciences Oncology Research Unit/Neuromuscular and Regenerative Medicine Unit Current version Current Version Next review date 1.0 23rd June 2012 Issue date 23rd June 2009 The Writing Safe Work Procedures Guideline (OHS027) should be consulted to assist in the completion of this form. Safe Work Procedure Title and basic description Title: Clonogenic-colony suppression assay Description: Procedure for measuring a compound/proteins ability to suppress colony formation in mammalian cell lines. Associated risk assessment title and location: 06_Colony Suppression Assay_JS Describe the activity or process Introduction to the procedure: The clonogenic survival assay is the most commonly used assay to assess growth inhibition in vitro. Cultured cells are seeded into tissue culture dishes at low densities to allow the formation of individual clonogenic colonies. In this circumstance this method is used to determine the effect on cell growth of either knocking down a protein of interest (siRNA) or in the presence of cytotoxic drugs. Procedure: SETTING UP ASSAY PLATES FOR CYTOTOXICITY ASSAYS 1. Mammalian cell lines are maintained in T75 tissue culture flasks 2. Prior to use cells are trypsinized and counted using a hemocytometer. 3. For a 6-well plate cells are seeded at ~ 500 cells/well/2ml for a 12 well plate cells are seeded at 100 cells/well/0.5ml (this needs to be optimized for each cell line being used). 4. 24hrs post plating cells are incubated in media containing increasing concentrations of drug/ compound and a well for a vehicle control. Drug dose is specific to the compound being used and needs to be optimized for each compound. Cells are treated for 72hrs with cytotoxic drug. Drug containing medium is then removed and is replaced with fresh culture media. Media is then changed every 3days for seven to ten days until visible colonies form. FOR siRNA 1. Mammalian cell lines are maintained in T75 tissue culture flasks and plated into 6-well culture dishes at a density of 1.0X105 cells /well/2mls 24hrs prior to siRNA transfection. 2. Cells are transfected with siRNA (as described in the ORU_NRMU_siRNA transfection SWP). 3. 72hrs post transfection cells are harvested and reseeded into 6-well plates at ~ 500 cells/well/2ml for a 12 well plate cells are seeded at 100 cells/well/0.5ml (this needs to be optimized for each cell line being used). 4. Media is changed every 3days for seven to ten days until visible colonies form. STAINING CELLS FOR ANALYSIS 1. After 10-15 days media is removed and colonies washed twice with 1XPBS. 2. Colonies are then fixed for 15 min at RT with 10% Acetic acid and 10% methanol. 3. Colonies are stained with 0.4% Crystal violet and 20% Ethanol at RT for 40 mins. 4. Staining solution is then removed and plates are washed once with distilled water and air dried. Plates can then be photographed or scanned to visualize and count colony numbers. Surviving fraction can then be determined as follows: colony number/ (number of cells seeded X plating efficiency). Plating efficiency is determined by the colony number divided by the number of cells seeded at the beginning of experiment (control condition). ___________________________________________________________________________________________________________ ___________ Page 1 of 3 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007 List all resources required including plant, chemicals, personal protective clothing and equipment, etc Chemicals/buffers: Fixing solution 10 mls Acetic acid 10mls 100% Methanol 80mls dH20 Staining solution 0.4g Crystal violet 20mls 100% Ethanol 80mls dH20 1 X DMEM complete media 1 X DMEM media 10% FBS Equipment: Sterile 6-well tissue culture dish, 12 well tissue culture dishes, Sterile pipettes (5,10 and 25ml), Pipette gun, Pipettes and pipette tips Large equipment Tissue culture biohazard hood, Tissue culture incubators, 37 water bath, 4C fridge, dissecting microscope/scanner. PPE: Latex Gloves Gown Safety Goggles Enclosed shoes List potential hazards and risk controls including specific precautions required Chemicals and reagents: Crystal violet: Hazardous in case of eye contact (irritant), of ingestion, of inhalation. Slightly hazardous in case of skin contact (irritant). PPE to be worn. Methanol: Highly flammable, keep away from naked flames and ignition sources. Toxic by inhalation, in contact with skin and if swallowed. Methanol used for the preparation of fixation buffer is decanted within the laboratory in a well ventilated area. PPE to be worn. Ethanol: Highly Flammable, keep away from flames and ignition sources. Irritating to eyes. Repeated exposure may cause skin dryness. Vapours may cause headaches, nausea and vomiting. Use in a well ventilated area and PPE to be worn. Acetic acid: Very hazardous in case of skin contact (irritant), of eye contact (irritant), of ingestion, of inhalation. Hazardous in case of skin contact (corrosive, permeator), of eye contact (corrosive). Liquid or spray mist may produce tissue damage particularly on mucous membranes of eyes, mouth and respiratory tract. Skin contact may produce burns. Inhalation of the spray mist may produce severe irritation of respiratory tract, characterized by coughing, choking, or shortness of breath. Decanting acetic acid must be done in a fume hood wearing PPE. List emergency shutdown instructions Methanol: Do not turn on, or extinguish any ignition source - no smoking. Take precautionary measures against static discharges. Use dry chemical or foam to extinguish if there is a naked flame. Ethanol: Do not turn on, or extinguish any ignition source - no smoking. Take precautionary measures against static discharges. Use dry chemical or foam to extinguish if there is a naked flame. List clean up and waste disposal requirements Crystal violet: Disposal of general crystal violet waste is in a liquid tissue culture biohazard waste container located in the laboratory. For spills: Use appropriate tools to put the spilled solid in a biohazard waste disposal container. Finish cleaning by spreading water on the contaminated surface and dispose of in appropriate biohazard waste container. Methanol: Used methanol is discarded in marked liquid biohazard waste containers within the laboratory. For spills: Contain spills as much as possible. Liquid spills should be absorbed prior to disposal. (“Silicate” type absorbent materials are suggested). Minimise dilution water to control spill volume. Ethanol: Used ethanol is discarded in the general laboratory liquid biohazard containers. For spills: Contain spills for salvage or disposal. Liquid spills should be absorbed prior to disposal. (“Silicate” type absorbent materials are suggested). Minimise dilution water to control spill volume. Acetic acid: Used acetic acid is disposed of in a marked acid waste biohazard waste container in the laboratory. For spills: Dilute with water and mop up, or absorb with an inert dry material and place in an appropriate general laboratory waste disposal container. If necessary: Neutralize the residue with a dilute solution of sodium carbonate. In the event of an emergency people to contact include: Fire Wardens: Dr Justine Stehn and Dr Anthony Kee ___________________________________________________________________________________________________________ ___________ Page 2 of 3 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007 First Aid: Renee Szokoli List legislation, standards and codes of practice used in the development of the SWP NSW OHS Act 2000 NSW OHS Regulation 2001 Code of Practice for the Labelling of Workplace Substances AS/NZS 2243.2:2006. Safety in laboratories. Part 2: Chemical aspects AS/NZS 2243.3: 2006 Safety in laboratories Part 3: Microbiological aspects and containment facilities AS/NZS 2243.6-1990. Safety in laboratories. Part 6: Mechanical Aspects. AS/NZS 2243.3:2006 Safety in Laboratories Part 7 Electrical aspects AS/NZS 2161.1:2000 Occupational Protective Gloves – Selection, Use and Maintenance AS/NZS 1336:1997 Recommended Practices for Occupational Eye Protection Supervisory approval, training, and review Supervisor: Peter Gunning Signature: Plant custodian: Signature List competency required – qualifications, certificates, licencing, training - eg course or instruction: Training as per Training Needs Analysis, Induction to Lab, Training in this SWP ___________________________________________________________________________________________________________ ___________ Page 3 of 3 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007