08621 - Plastic Skylights - Alberta Ministry of Infrastructure

advertisement

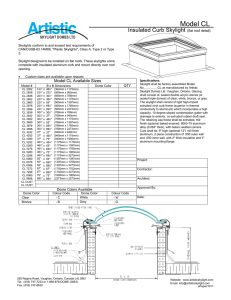

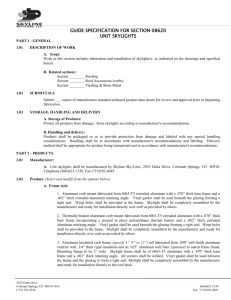

Section Cover Page Section 08621 Plastic Skylights 1999-09-27 This Master Specification Section contains: .1 This Cover Page .2 Specification Section Text: 1. 1.1 1.2 1.3 1.4 General Related Sections Design Criteria Shop Drawings Protection/Storage 2. 2.1 2.2 2.3 Products Materials Components Fabrication 3. 3.1 Execution Installation BMS Basic Master Specification Alberta Infrastructure Master Specification System Page 0 Section 08621 Plastic Skylights Page 1 Plan No: Project ID: 1. General 1.1 RELATED SECTIONS .1 .2 .3 1.2 Wood curbs: Roof flashings: Framed roof openings: Section 06100. Section [07625][07622]. Section [ ]. DESIGN CRITERIA .1 Skylight to be designed to withstand positive roof/snow load of [ ] [ kN/m2] and wind uplift of [ ] [ kN/m2] without damage to unit or permanent deformation to sealant or seals. .2 Skylight shall be installed weather and watertight. 1.3 SHOP DRAWINGS .1 Submit shop drawings and/or catalogue illustrations in accordance with Division 1. .2 Clearly indicate size and description of components, materials, attachment devices, description of frame and finish, and construction details. 1.4 PROTECTION/STORAGE .1 Prevent damage to components during handling and storage. .2 Apply protective coatings of paper or sprayed plastics to prevent any marring, scratching or damage to plastic and metal during handling and after installation. .3 Select suitable stripable coating which will not leave residue to collect dirt. 2. Products 2.1 MATERIALS .1 Dome: Acrylic plastic, bubble shaped convex, [clear] [white translucent] [clear outer unit and white translucent inner unit]. .2 Aluminum: extruded sections of 6063-T5 alloy, all components one piece without splices. .3 Gaskets: extruded resilient [vinyl] [neoprene], purpose made for location. .4 Seals: closed cell neoprene sponge, compressible, with full recovery after 50% compression. Section 08621 Plastic Skylights Page 2 Plan No: Project ID: .5 Insulation: fibrous glass. .6 Attachments: stainless steel purpose made screws. 2.2 COMPONENTS .1 Skylight Lid: single dome of [clear] [white translucent] plastic, of thickness governed by roof/snow and uplift loads, edges formed for gasket seal. .2 Skylight Lid: double dome, outer dome of [clear] [white translucent] plastic, inner dome of [clear] [white translucent] plastic, inner space air purged, gas filled and hermetically sealed at edges, thickness of plastic domes governed by roof/snow and uplift loads, edges formed for gasket seal. SPEC NOTE: Hermetically sealed domes in Alberta weather conditions may still produce inter dome condensation. .3 Operating Skylight: equip skylight unit with [ULC and FM listed thermal safety vent hardware, fusible link activated, spring operated, hold open device, with outside and inside cable release] [hydraulically dampened, fusible link activated] [mechanically dampened, fusible link activated] [chain activated, gravity operating lift] mechanism. [Provide aluminum insect screen in aluminum frame at lower part of skylight frame.] .4 Skylight Frame: extruded aluminum curb frame, [thermally broken,] integral sloped condensation gutter and curb frame counterflashing, extruded aluminum dome retaining frame, screw attached to curb frame, integral fit with dome compression gasket. [Notch] [Drill] holes for positive non-plugging drainage of condensation gutter. .5 Curb Frame: [ mm] thick x [ mm] high [insulated sandwich of aluminum sheets] 3 mm thick aluminum curb frame, insulation provided under roofing section [ ], with deck flange for attachment. .6 Curb Frame: Solid wood construction, refer to Section 06100. 2.3 FABRICATION .1 Cut to length and form all components, free of twists, bends or visual distortion. Miter, reinforce, rivet and seal all corner joints. .2 Fabricate all fittings and anchors required to fit skylight to curb. .3 The design and construction of skylight to conform to all codes and regulations in effect at place of building. Section 08621 Plastic Skylights Page 3 Plan No: Project ID: .4 Ensure continuity of weathertight seal and proper fit to building frame, so to transfer all loads and achieve weathertight installation. .5 Extrusions shall be designed to collect and lead off any condensate accumulation to the eaves without dripping, or plugging of weep holes. 3. Execution 3.1 INSTALLATION .1 Erect all the components plumb, square, level and in proper alignment. .2 Securely anchor frame to curb for rigid installation. .3 Coat aluminum in contact with dissimilar materials, with bituminous paint. .4 Co-ordinate and install exterior flashing. Secure and seal frame to curb. Seal with sealant specified in Section 07920. .5 Install dome with compression gaskets installed. .6 Install retaining frame and secure assembly with machine screws. Ensure even clamping pressure on gasket. .7 Adjust and seal assemble to achieve weathertight installation, with provision for expansion and contraction of components. .8 Remove protective materials from dome. Wash with mild soap and water solution and rinse clean. END OF SECTION