synthetic polymers lab

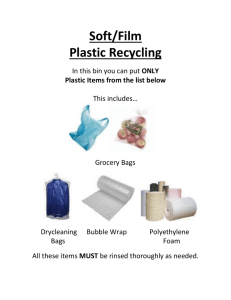

advertisement

PLASTIC BAGS Plastic bags are not created equal because they are meant for different purposes Have you ever wondered why some plastic bags are stronger than others? Why bags from clothing stores at the mall tend to be strong and thick, whereas those from your local grocery store are flimsy and thin? And then there are those wispy, clear bags you get back with your dry cleaning. There are many types of plastic bags, all designed for different purposes. The plastics we use today have come a long way since Alexander Parkes first introduced them to the world at London's Great International Exhibition in 1862. Parkes's material was an organic derivative of cellulose that could be molded when heated and then maintained its shape upon cooling. But it wasn't until 1909 that the word "plastic" was coined. Leo H. Bakeland used the term to describe a new class of materials that included "bakelite," a substance he created from coal tar. Bakelite was used to produce many items, including telephones, cameras, and even ashtrays. Although a key component in these items, plastics did not become really popular until after World War I, when petroleum, a more easily processed substance than coal, became readily available. Petroleum and natural gas are the primary sources of the key ingredients in plastic. Plastics are composed of polymers--large molecules consisting of repeating units called monomers. In the case of plastic bags, the repeating units are ethylene, or ethene. When ethylene molecules are polymerized to form polyethylene, they form long chains of carbon atoms in which each carbon also is bonded to two hydrogen atoms. Many kinds of polyethylene can be made from ethylene. Plastic bags typically are made from one of three basic types: high-density polyethylene (HDPE), low-density polyethylene (LDPE), or linear low-density polyethylene (LLDPE). Those thick, glossy shopping bags from the mall are LLDPE, while grocery bags are HDPE, and garment bags from the dry cleaner are LDPE. The major difference between these three materials is the degree of branching of the polymer chain. HDPE and LLDPE are composed of linear chains, while LDPE chains are branched. Branching can influence a number of physical properties including tensile strength and crystallinity. The more branched a molecule is, the lower is its tensile strength and crystallinity. That's why garment bags from the dry cleaner are so weak and flimsy. They are made from highly branched LDPE. Laboratory Investigation – Student Materials 1 What else do plastic bags contain? According to William F. Carroll Jr., a polymer chemist at Occidental Chemical Corp. and president-elect of the American Chemical Society, "With the possible exception of a little lubricant to help in extrusion, plastic bags are pretty much just the native polymer." However, different pigments may be added to produce colored bags. Plastic bags have made our lives easier in many ways. Unfortunately, they are often not disposed of properly. We see them blowing around in the streets and they often end up in streams and the oceans. These bags can be dangerous to animals, such as turtles, that ingest them or are strangled by them, especially in marine environments where plastic bags resemble jellyfish and other food items. One solution to this problem is to make degradable bags, such as those from starch. Starch, obtained from corn or potatoes, can be converted into lactic acid, which can be polymerized to the biodegradable plastic known as polylactide. Another solution is to add an ultraviolet-light absorber to make the material degrade when exposed to sunlight. Unfortunately, these solutions can make the plastics more expensive, so they haven't caught on with consumers. Plastics have been around for more than 100 years, and they will be around for many more. Without a doubt, they are extremely useful. But when it comes to shopping, some environmentally conscious consumers prefer to avoid plastic bags, opting instead for paper bags. And some go even further, just reusing the same cloth bag over and over again. http://pubs.acs.org/cen/whatstuff/stuff/8238plasticbags.html PLASTIC BAGS – QUESTIONS 1. Why are there so many different types of plastic bags? 2. What are the primary sources of the key ingredients of plastic? 3. What is the monomer of plastic bags? Draw it. 4. Write out what each of the following stand for, AND one example of each: HDPE- ______________________________________________________________________________________________ LDPE-_______________________________________________________________________________________________ LLDPE- ______________________________________________________________________________________________ 5. What is the MAJOR difference between these three materials? 6. What are the two qualities affected by branching? 7. What happens when a molecule is MORE branched? 8. To what are plastics dangerous? 9. What are 2 solutions to the bags not being biodegradable? 10. Why haven’t these caught on? 11. What are some other options to plastic bags that some people use? Which one is ‘better’ and why? Laboratory Investigation – Student Materials 2 Synthetic Polymers Polymers are large molecules consisting of chains of small molecules called monomers joined together in a repeating pattern. In the early 1900s, scientists began to understand the chemical makeup of natural polymers and how to make synthetic polymers with properties that complement those of natural materials. One simple synthetic polymer which chemists developed is polyethylene from repeating units of the monomer ethylene (H2C=CH2). Polyethylene is a very large zigzag-shaped molecule and one small part of a polyethylene chain is shown below. -(CH2- CH2)-n H | ---C | H H | C | H H | C | H H | C | H H | C | H H | C | H H | C | H H | C | H H | C | H H | C--| H Chemists and engineers have learned to process and modify molecules of polyethylene in different ways to manufacture common household products with a variety of characteristics. Polyethylene is used to make plastic trash bags, dry cleaning bags, milk jugs and soda bottles. In industry, materials made from polyethylene are tested for what are called “stress-strain behaviors.” Stress-strain behaviors include: Tensile strength - the amount of pulling force placed upon a material before it breaks Abrasion resistance - toughness of material against scraping, scuffing or scarring Puncture resistance - ability of a material to keep moving objects from perforating the surface YOUR TASK FOR THIS LAB: is to design an experiment that investigates ONE of these stress-strain behaviors among various plastic products made of a synthetic polymer. You have been provided with the following materials and equipment. It may not be necessary to use all of the equipment that has been provided. SUGGESTED materials and equipment: plastic dry cleaning bag plastic kitchen wrap plastic sandwich bag plastic grocery bag sandpaper markers coffee can rubber bands ruler ball bearings (different masses) scissors Designing and Conducting Your Experiment LIST THE FOLLOWING: Independent variable (what you change): ______________________________________ Laboratory Investigation – Student Materials 3 Control (the set up without the i.v., so that you know it was, in fact the i.v. causing the change): _____________________________________________________________________________________ What materials would you use to test the “tensile strength” of the plastic? _____________________________________________________________________________________ _____________________________________________________________________________________ What about to test the “abrasion resistance” of the plastic? _____________________________________________________________________________________ _____________________________________________________________________________________ And “puncture resistance”? _____________________________________________________________________________________ _____________________________________________________________________________________ The Dependent variable (the effect of the I.V.) must be MEASURABLE (data) So, what types of data would you collect for each test? (For example: the number of times the ball bearing is dropped on the plastic before it punctures, etc) THIS WILL TELL YOU YOUR D.V. Tensile strength - the amount of pulling force placed upon a material before it breaks (the more tensile strength, the more weight/pulling it can withstand before it breaks) Type of data collected: __________________________________________________________________ ______________________________________________________________________ (this is your D.V.) Name 3 or 4 controlled variables for this test: ______________________________________________ _____________________________________________________________________________________ _____________________________________________________________________________________ Abrasion resistance - toughness of material against scraping, scuffing or scarring (the more abrasion resistance something has, the more it resists being scuffed or scraped) Type of data collected: __________________________________________________________________ ______________________________________________________________________ (this is your D.V.) Name 3 or 4 controlled variables for this test: ______________________________________________ _____________________________________________________________________________________ _____________________________________________________________________________________ Puncture resistance – ability of a material to keep moving objects from perforating the surface (the stronger the material, the harder it is to puncture it) Type of data collected: __________________________________________________________________ ______________________________________________________________________ (this is your D.V.) Name 3 or 4 controlled variables for this test: ______________________________________________ _____________________________________________________________________________________ _____________________________________________________________________________________ *see this site for help http://www.americanchemistry.com/hops/activities/industrial_testing_lesson/industrial_testing_lesson.html Laboratory Investigation – Student Materials 4