Nano 230-Nano 220 lab NSCC EDS analysis of Cu film

advertisement

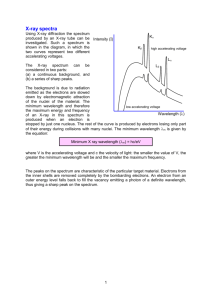

North Seattle Community College Nanotechnology 230 Lab 1 EDS Analysis of a Penny Introduction In class lectures we have discussed SEM analysis and energy dispersive spectroscopy (EDS) for analyzing what materials are present in a sample. EDS works by measuring the energy of emitted x-rays that are caused by electrons transitioning between the K, L, M and N quantum energy levels. Each element has a unique set of energy peaks that identify it. In SEM analysis the electrons do not bounce off of the surface but actually penetrate some distance into the material being imaged. The penetration depth is a function of the energy of the incoming electron beam above the 10 KeV energy level. In this lab we will analyze the Cu film that was sputter deposited in a previous lab and change the accelerating voltage to see how this affects amount of silicon and copper that is detected. The previously deposited film was about 200 nm of Cu on a Si wafer. Equation 1 below gives an estimate of the electron penetration depth as a function of accelerating voltage for voltages of 10 KV and above. Using this equation you will estimate the electron penetration depth when the accelerating voltage is varied between 10, 15, 20, 25 and 30KV. We will then use the counts per second (cps) of the Si Kα peak at 1.74 KeV and the Cu Lαβ peak at 0.933 KeV to determine the relative amounts of Cu and Si in the sampled region. R 4120 E (1.265 0.0954*ln E ) Equation 1 R electron penetratio n depth ( m) E Accelerati ng voltage (MeV) Density (g/cm 3 ) R Materials and Equipment Leica Stereo scan 420 with x-ray detector. Sample of silicon wafer with Cu thin film. North Seattle Community College Nanotechnology 230 Procedure 1. Place a piece of silicon wafer with Cu thin film in the SEM chamber and pump the chamber to operating pressure. 2. Obtain an image on the SEM, move to the Cu film and set the following operating parameters: Beam current = 400µA Collector Bias = 0V Probe current (I Probe) = 100nA Accelerating voltage (EHT) = 10KV Optibeam = On Working distance = 25mm 3. Check that there is liquid nitrogen cooling the x-ray detector by removing the plug from the top of the detector LN2 dewar and looking for a frozen section at the end of the dip stick. 4. Activate the Link ISIS software by accessing programs from the start bar and selecting “Oxford Instruments”, “Link ISIS”. When the software starts select “Chris Sanders” and click the lab notebook icon. Jobs should be set to HRGpaintchip”. 5. Select the icon of peaks to open the x-ray analysis window. 6. Click the button with a circle to start the acquiring x-rays. The button with a square will stop the analysis. 7. Adjust the probe current on the SEM to obtain an optimum x-ray count rate around 1.5 Kcps. 8. Within the x-ray analysis window click on the magnifying glass icon to see an enlarged view (zoom window) of the acquisition spectrum and zoom in near the 1.0 – 2.0 KeV section that we are interested in. 9. From the main x-ray analysis window you can also click on the “?” icon to see select elements from a library to see all of the emission peaks for a given element. 10. When the acquisition is finished bring up the zoom window as scale it using the left mouse button and cursor so that the 0.933 peak touches the top of the window. The count rate for that peak can then be read from the “Full Scale” chart in the upper left corner and entered into the data table. 11. Scale the window so that the 1.74 KeV peak touches the top and enter the count rate in the data table. 12. On the SEM adjust the accelerating voltage (EHT) to 15KV and repeat steps 6 – 11 to take data accelerating voltage. 13. Repeat step 12 for accelerating voltages of 20, 25 and 30 KeV to complete the table. 14. Close all of the x-ray analysis windows in the Link ISIS software. 15. Return the SEM to the operating conditions in step 2. 16. Place the SEM at a low magnification and return the screen image to the grid structure. 17. Obtain a clear low magnification image of the grid structure and shut the SEM down by selecting “SEM Shutdown” from the drop down menu obtained from the box in the upper left hand corner of the screen. 18. A “SEM Shutdown” dialog box will appear. With the question “Save operating conditions?” click “Yes”. North Seattle Community College Nanotechnology 230 Data Name:__________________________ Beam accelerating voltage (KV) Counts per second for Si Kα at 1.74 KeV Counts per second for Cu Lαβ at 0.933 KeV Ratio of Cu Lαβ / Si Kα 10 15 20 25 30 Analysis 1) Use equation 1 to estimate the electron beam penetration depth into a copper film at: A) 10 KV accelerating potential. B) 20 KV accelerating potential. C) 30 KV accelerating potential. 2) Using the estimates from question 1, what percentage of the beam penetration depth will be within the first 200nm of a Cu specimen for a: A) 10 KV accelerating potential. B) 20 KV accelerating potential. C) 30 KV accelerating potential. 3) Based on question 2A and the assumption that the Cu film is 200nm thick, what value would you expect for the Si Kα peak at 10 KV? North Seattle Community College Nanotechnology 230 4) Using equation 1 for a copper film at what accelerating voltage would half of the beam penetration depth be within 200nm of the surface? A more direct way to ask this question would be to find the accelerating potential for a 400 nm penetration depth. Hint: there are two ways to approach this, you can manipulate and solve the equation or guess the answer until you get it right. 5) For our sample with a 30KV accelerating voltage will the actual beam penetration be greater or less than that estimated in question (1). Why? Hint: think about the situation that equation one is estimating penetration depth for and what our sample actually is. 6) Draw a graph with accelerating voltage on the x-axis and ratio of Cu Lαβ / Si Kα on the y-axis and include it with your lab write-up. Be sure to put a title on the graph and label the axes with proper titles and units. Using Excel to plot the graph is recommended but not required.