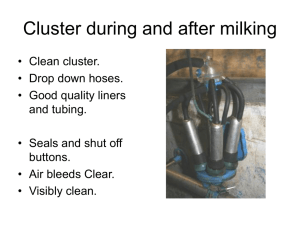

line identification of freshly collected milk

advertisement

TITLE PAGE Quality of Life and Management of Living Resources Robust chemical Sensors and biosensors for rapid on - line identification of freshly collected milk ROSEPROMILK Key Action n. 1 – Food, Nutrition and Health. Theme 1.1 “Development of safe and flexible and new and improved manufacturing processes and technologies”. 1 OBJECTIVES AND EXPECTED ACHIEVEMENTS Objectives This proposal addresses issues of quality management, traceability and safety during the production of milk. It is proposed to design and develop novel sensing devices for a range of key analytes, selected as indicators of either: a) contamination b) safety and quality control The overall objective is then to combine these sensors into integrated and robust on-line systems for rapid quality assurance monitoring. The detailed objectives are as follows: Contamination monitoring in the milking parlour The hygienic quality of milk has improved with successful harmonisation of hygiene directives. However, concerns over milk contamination are growing as the labour available for milking cows diminishes. In conventional milking systems where one person often milks 100 cows/hour and in robotic milking systems new technology is required to replace manual systems. Companies and research institutions within the EU lead the world in the development and introduction of robotic milking. High standards have been set for animal welfare and milk hygiene. The technical means of achieving these standards are still lacking. Close control, in real time, of milk contamination markers will improve the milking system by allowing operators to make fast decisions about milk quality; by minimising or eliminating the contamination it will be possible to classify freshlycollected milk as hygienically acceptable for human use. 1.1 Faecal contamination As a result of the cow’s anatomy and environment, faecal contamination during the production of milk is an enduring problem. There is a need to avoid introducing undesirable colour and flavouring taints into the milk, combined with the ever-present risks associated with introduction of faecal pathogens. It is proposed to develop a sensor to detect faecal contamination in milk and/or teat wash water based on an electrochemical procedure, to detect chlorophyll, which has been shown to undergo electrochemical oxidation processes at a platinum disc electrode. A further target analyte of faecal contamination, unrelated to the porphyrins, is the ammonium ion which will be detected in freshly collected milk and teat wash water. This goal will be achieved by developing cost-effective instrumentation, which can be incorporated into automated robotic milking machines. 1.2 Mycotoxin contamination Milk is susceptible to contamination from external sources; one key analyte is aflatoxin M1. Aflatoxin M1 is a hepatocarcinogenic mycotoxin, that could occur in milk of cows fed with aflatoxin B1- contaminated feedstuffs. It is proposed to develop a sensor for aflatoxin M1. The procedure we have to develop is totally innovative consisting in the development of an electrochemical procedure, which allows the sensitive detection of aflatoxin M1 directly on a probe surface using commercially available antibodies to aflatoxin M1. This procedure requires simple steps, can be carried out directly in the milking parlour with the use of inexpensive instrumentation, also the probes are strips which will be disposable to avoid problems with probe regeneration and calibration. By extension of the ROSEPROMILK project a flow analysis system based on solenoidal valves for aflatoxin M1 detection will be developed Different techniques will be studied and optimised: continuously flow-analysis (CF), flow injection analysis (FIA), sequential injection analysis (SIA). This system will be fully automated in order to assure a rapid quality monitoring of milk 2 Expected achievements i. Faecal contamination sensor based on electrochemical detection (of chlorophyll, carotenoids, bile pigments, or ammonium) using screen printed electrode technology. ii. Immunosensor for aflatoxin M1. iii. Laboratory validation for faecal contamination and aflatoxin M1 detection. iv. Integration of (i) and (ii) into robotic milking machine. v. Validation of (iv) in operational milking parlour. 3