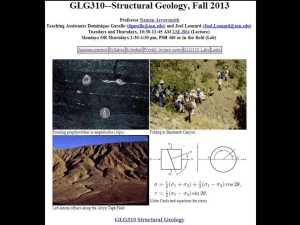

Mohr-Coulomb failure

advertisement

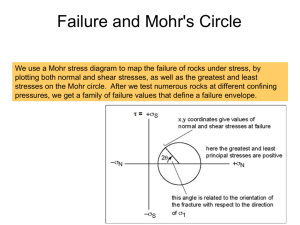

Mohr-Coulomb failure Goal: To understand the relationships between stress, brittle failure, and frictional faulting and to use this relationship to predict rock behavior 1. Review of principal stresses and introduction of shear stress and normal stress Stress resolved into three principal vectors at right angles to each other σ1, σ2, and σ3 where σ1 ≥ σ2 ≥ σ3 σ1 is the maximum principal stress direction, σ2 is the intermediate principal stress direction, and σ3 is the minimum principal stress direction We also define the differential stress (σd) as (σ1 - σ3) The confining pressure is defined as σ2 = σ3 under compressive stress and σ2 = σ1 under tensile stress Lithostatic stress as static stress generated by mass of overlying rocks Lithostatic stress for a 1-m2 area = ρGh where: ρ = density of the overlying rocks G = acceleration due to gravity h = thickness of column of overlying rocks For any plane with strike parallel with σ2, stress is resolved into 2 components: a. Shear stress (σs), acting parallel with the plane b. Normal stress (σn), acting perpendicular to the plane The stress components are related by: a. σs = ½(σ1 - σ3)sin(2θ) b. σn = ½(σ1 + σ3) - ½(σ1 - σ3)cos(2θ) where θ is the angle between the plane and σ1 2. Mohr diagram for stress Relationship between σ1, σ3, σs, and σn is plotted graphically in Cartesian coordinates where the y-axis = σs and the x-axis = σn, σ1, σ3, and σd The mohr circle for stress is a circle with diameter = σd plotted on the mohr diagram with its center on the σn-axis at a point = ½(σ1 + σ3) 3. For any plane with strike parallel with σ2: σs and σn can be found using a graphical construction if we know σ1, σ3, and θ Plot a line from the center of the mohr circle to the edge of the circle so that the line is at an angle 2θ (clockwise) from the x-axis. By definition, the length of this line = ½σd The intersection of this line with the circle defines a point who’s ycoordinate = σs and who’s x-coordinate = σn on the plane 4. Coulomb’s failure criterion: On a Mohr diagram, every homogeneous material has a characteristic failure envelope for brittle shear fracturing Combinations of σs and σn that plot outside of the envelope will result in fracture. Those inside the envelope are stable. Failure envelopes are derived experimentally. Rock samples are placed in a piston rig with σ1 > σ2 = σ3 (compressive stress) or σ3 < σ2 = σ1 (tensile stress). σ1 is increased, or σ3 is decreased until the sample fractures. Then, the sample is removed, the angle θ is measured, and the results are plotted on a Mohr diagram. Hundreds of these experiments will define the Coulomb failure envelope. — Describe this graphically on the board Failure envelopes are parabolic in tensile stress and straight lines in compressive stress Under compressive stress, the failure envelope at any point is defined by the Coulomb law of failure σc = σ0 + tan(φ)σn where: σc = the critical shear stress, or the shear stress at failure σ0 = the cohesive strength, or the σs value on the failure envelope where σn = 0 (where failure envelope crosses the y-axis) φ = the angle of internal friction. φ = 90-2θ Tan(φ) is known as the coefficient of internal friction Most rocks have an angle of internal friction ≈ 30°. Therefore, θ at failure is also ≈ 30°, even though σs is greatest when θ = 45°. Can use the mohr circle and the Coulomb failure envelope to determine if a given state of stress is stable for a given rock type Describe this graphically on the board 5. Byerlee’s law and slip on pre-existing fractures Pre-existing fractures have no cohesive strength. In other words, σ0 = 0 Failure envelopes for pre-existing fractures (envelope of sliding friction) are also derived experimentally using same methodology used to define Coulomb failure envelopes. Describe this graphically on the board Except: the envelope of sliding friction is almost the same for every rock type. The angle of sliding friction (φf) is the angle between the failure envelope and the x-axis a. For low confining pressures, φf ≈ 40° b. For medium-to-high confining pressures, φf ≈ 35° Sliding envelope is described by Byerlee’s Law: σc = tan(φf)σn Can use the mohr circle and Byerlee’s failure envelope to determine if a given state of stress is stable for a given fracture orientation (θ) Describe this graphically on the board 6. Effect of pore-fluid pressure on stress regime Pore-fluid pressure (Pf) effectively reduces the stress equally in all directions We define the effective stresses (σ1eff, σ2eff, and σ3eff) as: σ1eff = σ1 - Pf σ2eff = σ2 - Pf σ3eff = σ3 - Pf Note that σ1eff - σ3eff = σ1 - σ3 so that pore fluid pressure does not change the differential stress, it only lowers the confining pressure Increased pore fluid pressure moves the Mohr circle to the right, closer to the failure envelopes.