Specifications of Optics table with linear stages A. Scope of Supply

advertisement

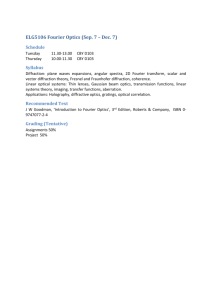

Specifications of Optics table with linear stages A. Scope of Supply An optics table having degrees of freedom in three orthogonal axes is required for characterization of micro optics. This table shall be installed in BL-07 beamline of Indus-2 synchrotron radiation source located at Raja Ramanna Centre for Advanced Technology (RRCAT), Indore. The supplier shall design, fabricate, supply and install the optics table as shown in Figure 1 at BL-07 experimental hutch. The necessary logistic (crane, utilities like gas, etc) support during installation shall be provided by the purchaser. 1. Design of the optics table. The values mentioned in this document shall be taken for actual design. 2. Solid and firm bottom support holding complete weight of working plate of optics table and load of ~500kg. 3. The dimensions of working plate of the table shall be 2000 mm along z–axis (along beam propagation) and 1200 along x –axis. There shall be three linear motion guides along z– axis (length 2000mm) for linear movement of three Aluminum alloy base plates of size 1000mm (length) x 200mm (width) x 25mm (thickness) that having linear movement range of 140025mm. 4. On top of the above three Aluminum alloy plates three linear stages shall be fixed with Aluminum alloy base plates of nominal size 300 x 200 mm that moves along x– axis (length 1000 mm) having linear movement of 700mm25mm. Total weight on the individual linear motion stage shall be ~100 kg. 5. On the working plate of the table, there shall be one additional linear motion stage with base plate of nominal size 150 x 150 mm along z –axis (length 2000 mm, for clarity it is called z1 axis) having linear movement of 180025mm. Total weight on this linear motion stage shall be ~50kg. 6. All above linear motion guides/stages shall have suitable ball screws and stepping motor arrangement. 7. Total height of the optics table shall be adjustable ~1000-1200 mm (y-axis). The height adjustment shall be through appropriate motorized lifting system. B. Specification of the Optics Table The schematic of the optics table is shown in Figure 1. The optics table consists of solid base (for rigid support), working plate for mounting various linear stages and motorized lifting system for changing the vertical height. The table 1 summarizes the required range, resolution and repeatability of the required degrees of freedom of the optics table. Page 1 of 6 Figure 1: Schematic of optics table with overall dimension of 2000 mm (length, z-axis) x 1200 mm (width, x- axis) and 1200 mm (height, y-axis)[nomenclature is added]. Table 1: Various requirements (range, resolution, repeatability) of the optics table. Movement X y z z1 Actuator Range [mm] Resolution [mm] Motor + Ball screw 0.010 700 2 5 Appropriate motorized 100 around 1 lifting system (jack) central height Motor + Ball screw Motor + Ball screw 1400 25 1800 25 0.020 0.020 Repeatability [mm] 0.015 1 0.025 0.025 1. Base of the optics table The base of optics table shall be made of high density cement composite (enclosed completely in metallic housing with surface painted with non-corrosive material) or synthetic granite of size ~ 2000 mm (length) x 1300 (width) x 300 mm (thickness). The use of base is to provide rigidity to the overall optics table and avoid any distortion. This base shall have provision of leveling to adjust level of the base in y direction to compensate the floor unevenness. 2. Working plate of optics table 2.1 The working plate of the optics table shall be made from sub-harmonic vibratory stress relieved gray cast iron material Grade FG-220 of IS: 210. The thickness and cross-section design of the base plate is such that it shall carry the uniform distribution load (excluding its own weight) of ~500kgf Page 2 of 6 with maximum bending or sagging limited to 50m. The surface shall be milled and its top surface shall have provision of mounting LM guide ways and ball screws and other required accessories to move and control the linear stages in x and z direction. Geometrical accuracies of LM guide ways mounting surfaces shall be as per standard recommendations given in Ball Screws and LM guide ways catalogues. The cast iron base plate shall be painted with epoxy paint on all non-machined surfaces having Graphite Black shade equal to RAL Color Chart No. 9011. There shall have arrangement of adjusting the leveling of working plate using Engineer’s level. 2.2 The above base plate (mentioned in 2.1) shall have the sufficient tapped holes for mounting the five linear motion (LM) guides and ball screw mechanism as per the schematic design shown in figure 1. The LM guides and ball screw considered in the optics shall be of reputed company make like THK/HiWin etc. The length of three LM guides along z –axis shall be 2000 mm and linear movement range is ~140025mm using ball screw actuated by the stepper motor. The straightness of the LM guides shall be in the range of ~50 m in 2000mm length. 2.3 Three Aluminum alloy base plate of cross-section 1000 mm (length), 200 mm (width) and 25 mm (thickness) shall be fixed on three LM guides through suitable fixtures/fasteners. 2.4 Three linear translation stages (along x-axis) with base plate (made of Aluminum alloy) of nominal size 300 mm x 200 mm shall be fixed on the above three Al base plate. The linear movement of the individual stage shall be of 70025mm actuated by stepper motor. The top surface of linear stages shall have M6 tapped holes in a linear bi-direction grid of nominal 25 mm to facilitate mounting of various vertical stages and the optical objects. All Aluminum alloy components shall be black / dark brown anodized. The straightness of the LM guides shall be in the range of ~30 m in 1000mm length. 2.5 One linear stage (along z1-axis) with base plate of nominal size 150 mm x 150 mm shall be fixed on working plate of optics table. The linear movement of the stage shall be of 180025mm actuated by stepper motor. The top surface of linear stage shall have M6 tapped holes in a linear bi-direction grid of nominal 25 mm to facilitate mounting of various vertical stages and the optical objects. The working height of stage shall be matched to the working height of other three linear stages (along x-axis) mentioned in 2.4. 3. Lifting system for Optics table 3.1 The overall height of optics table (distance between top working surface and the floor) is to be minimum ~1000 mm and adjustable upto 1200 mm using suitable hydraulic system or using screw jack lifting system with guide post. The height adjustment shall be through motorized operated hydraulic pump or through motorized operated screw jack system (of reputed company make like Nosen or duff Norton or Thomson etc.). 3.2 The lifting system shall be sturdy and shall able to handle the load of entire working plate and objects load thereof (total weight of ~2000 kg). 3.3 There shall be mechanical lockable screws to hold the table at its adjusted/desired height. 3.4 Supplier shall evaluate the requirement of guide mechanism for movement (adjusting the height) of working plate in vertical direction. Page 3 of 6 3.5 While height adjustment, the maximum tilt (height difference from highest point to the lowest point of the table) allowed is 0.3 mm in the entire height adjustment. 4. General requirements 4.1 The base and the working plate of the optics table shall have provision to level accurately (0.025 mm/meter) at RRCAT installation site. For this purpose integral cross base for locating precision Engineer’s level shall be provided. 4.2 The optics table having seven numbers of linear motion stages shall be linearly moved by independent stepping motor actuator through precision ground ball screw. The linear movements shall have accuracy within 30 microns. The lead of all ball screws shall be identical. Details of the bought out components (like ground ball screws, LM guides, couplings), make, part no, etc should be supplied with quotation. 4.3 Each stage shall have steel scale with zero pointers to set / locate each stage independently as and when required. The least count shall be 1.00 mm. On longer length (z-axis), two scales shall be fixed on either side. 4.4 All seven stages shall have ends of travel limit switches (NONC type) and also mechanical soft stoppers in case limit switch overrides fails. 4.5 All stages having working plate shall have M6 tapped hole in a linear bi-direction grid of nominal 25 mm to facilitate mounting of various components. All tapped holes on Al or Al alloy plates/structures shall be fitted with SS inserts of suitable length. 4.6 All required actuators based on ball screw/linear motion guides shall be through stepping motors. The suitable torque motor (double side shaft) shall be selected by the supplier of reputed company make (only Schneider or Sanyo Denki or Oriental). The stepper motor shall have inbuilt driver electronics and controlled remotely through communication cable (RS232/RS485). The motor shall have suitable step size to achieve the resolution/repeatability and sufficient torque for each linear stages. The supplier shall mention the make/model/step size and current rating of the individual motor in offered quotation. Supplier shall supply the zip-open type low noise cable drag chain to route the signal cables to each stage conveniently. The opening section of cable drag chain could be around 30 mm x 30 mm or similar and can be finalized during design phase. The controller and the control software are not under scope of supply. 4.7 Controller and software: Supplier will prepare the controller with driver for all stepper motors along with suitable GUI based control software. All signal cables, end lugs and connections thereof shall be arranged by supplier as per system requirement and industry standards. The entire wiring diagram and the cable layout shall be supplied to the purchaser. Supplier should quote separately for the controller electronics and the control software. 4.8 All technical documents and schematic design for the optics table shall be provided with quotation in order to evaluate the performance of the system and also to assess the capabilities of the supplier. 4.9 The supplier shall give the warranty for a period of 12 months from the date of commissioning and final acceptance. Page 4 of 6 4.10 The successful bidder shall supply the detailed engineering design including bills of materials to the purchaser and shall obtain the approval from purchaser prior to start the fabrication process. 4.11 The optics table shall be supplied, installed and commissioned by the supplier at RRCAT site. If supplier required any site preparation then it shall be clearly mentioned in the quotation with cost if required. 4.12 All engineering drawings/data taken during factory testing/raw files etc shall be supplied to the purchaser. 4.13 The purchaser reserves the rights to assess/evaluate the capability of the bidder by visiting their facilities if it is located in India. C. Manufacturing and test plan After awarding the contract, supplier shall submit detailed design, manufacturing and test plan for different stages of fabrication prior to the fabrication activities and list of methods that will be used for measurements of mechanical (movements of all axes and rigidity) test. The purchaser will review and approve the supplier’s manufacturing and test plan. The detailed design report and raw files of tests should be submitted to the purchaser. Any changes and deviation from plan should be intimated by supplier to purchaser and should take necessary approval from the purchaser. All engineering drawings of optics table including different sub-assemblies shall be provided in soft and hard copy. All the technical documentation, user instructions, drawings, handling instructions, troubleshooting, etc. should be provided in English. The purchaser will review the drawings and other documentation provided by the supplier and will inform to supplier of any discrepancies or errors or modifications. Supplier will take the approval on all the engineering drawings prior to fabrication of optics table. Also, any changes or corrections in the drawings/documents shall be submitted to purchaser for approval. The supplier will submit the design report of the optics table along with list of all standard items which will be used for fabrication of optics table. The supplier will arrange the presentation for design review at RRCAT once the design is completed. Vibrations if any produced during the movement shall be damped to 1m in 1 minute. The optics table during entire in its motion should not be deflected by more than 0.3mm. The working plate of the table should not deflect more than 0.3 mm if a 10kg force is applied sidewise (along z and x axes). The final assembly of the optics table shall be done in clean enclosed area isolated from manufacturing area. Supplier will assemble the all linear stages on the working plate and submit the test report as per acceptance criteria. The repeatability test of all the axes movements shall per international traceable standards, ISO 230, Part2. Supplier shall show the list components purchased for construction of table during the factory inspection with invoice. D. Acceptance criterion The acceptance criterion of the optics table is defined on the basis of satisfactorily performance of detailed specifications mentioned in section B (serial no 1-4). Before dispatch of equipment, the purchaser shall visit the factory site for inspection of the table. The supplier shall show the alignment Page 5 of 6 of base and working plate using engineer’s precision leveler. The vertical height and tilt adjustment of working plate shall be demonstrated using motorized lifting system in full (dummy) load condition. The motorized movement of all linear stages (7 numbers) shall be demonstrated in full load condition. The supplier will demonstrate motorized movement range, resolution and repeatability of all linear stages in front of purchaser’s representative. The supplier shall arrange suitable characterization tools for these measurements at his works and at RRCAT for acceptance. The resolution and repeatability of all linear stages shall be demonstrated using the linear module of laser interferometer system. The supplier shall also ensure the testing of motorized stages at RRCAT site during installation is done with laser interferometer system having the same accuracy. The endurance test of all the movement shall also be performed by moving the stages in continuous operation at least ~50 cycles. After PDI clearance, supplier shall ship the material to RRCAT, Indore. The supplier shall install the optics table and demonstrate the above mentioned criterion at RRCAT installation site. The results obtained during the factory acceptance test and during installation time shall be compared for final acceptance of the table. End of specifications Page 6 of 6