Research on ERP and PLM Integration-Based on

advertisement

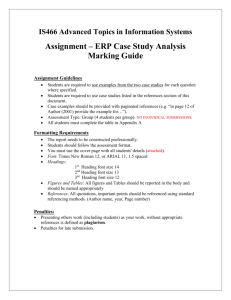

Research on ERP and PLM Integration Based on R&D Project Management Xu Zhao , Kai-chao Yu Faculty of Mechanical and Electronic Engineering,Kunming University of Science and Technology, Kunming,China (zhaoxu417@126.com, kmust.aaron@163.com) Abstract - Due to the uncertainty of characteristics of demand, technical and periodic progress of Product R&D projects, The conventional project management software is generally difficult to meet the demand of the product R&D projects management. The integration of PLM and ERP can make the project time, cost, task and resource integrated, in order to achieve the needs of R & D projects involving the effective management of costs, resources, and progress. In this paper, built a project management system architecture based on Windchill PLM and SAP ERP integration, and have been studied the key technologies of system implementation. Keywords - PLM,Product R&D, Project Management ERP, System Integration I. INTRODUCTION Under the aggressive process of globalization, more and more companies have recognized the importance of the success rate of new product R & D, continue to introduce competitive new products and improve the corecompetitiveness of enterprises are the fundamental way to ensure the sustainable development of enterprises[1]. Project management, as an advanced management methods, not only contribute to comprehensive management the progress, costs, resources of product R & D projects, but also improve product R & D efficiency and quality [2]. Therefore, the project management of product R & D has become a new research topic. Based on domestic and foreign research and application of IT project management, project management software can be roughly divided into project management and non-project management of two major categories. project management software is based on the project's construction methods, use of network planning techniques, integrated management of a class of application software during the construction progress, costs, resources, etc. [3], such as P3, (the Primavera the Project Planner), the MS the Project, Harvard Total the Project management,, Harvard Project Manager, and so on. At present, many types of project management software have a well developed. On the other hand, nonproject management software, is a business management project based on project management and enterprise management integration of enterprise management applications such as ERP (Enterprise Resource Planning) and PLM (product lifecycle management), project management is usually one of the core functionality[4]. Because of the uncertainty of demand, technical and periodic progress of R & D project management, the R & D enterprise is often use ERP and PLM project management software. However, due to the different focus of the ERP and PLM project management - ERP system focuses on the project time and cost management, while PLM system focus on the management of project tasks and resources. Therefore, ERP and PLM integration can be achieved effectively manage all the work involved in the project. In other words, based on the PLM and ERP integration project management can achieve the needs of product R & D projects, costs, resources, and the progress of a comprehensive, systematic management, it is worth in-depth study[5]. II. THE CHARACTERISTICS OF R&D PROJECT MANGEMENT R & D enterprise project management focuses on the whole process of management of R & D projects, R & D projects from the decision-making, project control, acceptance, trial production, the market reaction processes formed a large circle, while each of the specific implementation process a link composed of many small processes. R & D project has the following characteristics[6-8]: 1) The uncertainty of demand, R & D projects can only be a rough target, may be the entire development process is a learning process, it is difficult to take a whole consider of the project details in the feasibility analysis stage. 2) The technological uncertainty, R & D project needs to overcome one or more technical problems in the process of research and development. It requires repeated judgment established the feasibility of technology roadmap, and the need to rely on external forces, etc.; 3) R & D projects have characteristics of the type of material parts of many but a small number. The difficulty of R & D project management is: 1) R & D projects the need for timely follow-up market demand, resulting in a lot of R & D projects to the lack of overall R & D project strategy, in order to seize market opportunities, to accelerate the progress of the project, resulting in the increase in the rate of failure of the project. 2) R & D projects need in the project implementation process does not stop the overcome the technical problems and technical research, project progress is difficult to control, despite the project have a detailed project node program, but the actual implementation of it is difficult to achieve, and unable to timely carry out risk tips and alarm[9][10]. 3) R & D project process knowledge information, the need for careful knowledge management, need a reasonable knowledge management and sharing of ways to make that knowledge can be passed to improve the similar R & D projects in enterprises, and improve the efficiency of the Enterprise Project Management[11]. III. THE MAIN METHOD OF PLM AND ERP INTEGRATION There are three type methods of PLM and ERP integration. First, the public interface platform developed by PLM-owned or ERP-owned software company, such as SAP XI, SAP's exchange infrastructure is an application integration platform SAP NetWeaver middleware products the part is used to provide a platform for other heterogeneous systems with SAP data and processes interact. Public interface platform provides a variety of heterogeneous systems interface, easy to operate, but requires companies to purchase the module, and employ the module consultants for guidance, the costs incurred are generally spend so much, many enterprises to take difficult to apply,it is Applies to to large enterprises, and enterprises are involved in many kinds of information systems of the type of underlying database[12][13].The second way is direct database access, after the analysis of PLM and ERP systems database, direct access to the interaction between the two systems database[14].Third through business self-developed intermediate data in the middle of table conversion, real-time transmission of data, the investment in this way is small, quick, but generally only applies to data transfer between two systems. The multi-system will have a greater risk[15]. This study only involved in PLM and ERP systems, so choose the third approach for integrated design and development. IV.THE INFORMATION MODEL BASED ON PLM AND ERP INTEGRATION PLM and ERP integration module release the WBS and BOM data to the ERP system, publish the module to split the project to the specific tasks and split into parts data of material data, then integrated package in the form of release, release data stored as XML in the specified directory of the ERP system, ERP system conversion ERP WBS and BOM data. PLM and ERP integration information model in Fig 1. Working hours management The project cost control Project budget Purchasing Inventory Management Management ERP WBS BOM PLM Product R & D R & D projects Component data architecture Master Data management management Management Database Fig 1 the PLM and ERP integrated information model diagram The biggest difference between ERP -PLM integration based on Project management and general ERP-PLM integration is that the transfer of information between the two systems is not only based on the BOM information, but also require the transfer of the project WBS, and project task split and issued. The BOM transfer between ERP system and PLM system makes the enterprise as a whole to the parts in the process of R & D projects for the control of the whole process, from the drawings, digital to analog models, assembly drawings to the relevant parts procurement, vendor selection, inventory control, and overall management of the R & D projects in various parts. However, if the R & D projects as a whole control, the WBS elements are the important elements need to pass between two systems, In the PLM system to build the project in the project WBS structure to determine the time of the project node and key nodes, after the interface through the middle of the WBS architecture and the corresponding project node and transmission of information to the ERP project in the ERP project budget for the project funding programs, materials and working hours, consumption control. Thus, it is reasonable to control project costs and tasks of the various stages of time, reduce the cost of doing business risk, and improve enterprise efficiency. The data release from PLM to the ERP system: (1) The WBS structure of project and various stages of time node split the middle of the program WBS for specific tasks planned by the project management module of the ERP software implementation of the mandate. (2) parts, including the encoded version, the drawing version and the involved manufacturers model attribute information by the corresponding modules of the ERP software, parts procurement, and various parts inventory management. (3) BOM structure information, Cloth to ERP BOM structure information BOM three elements: the parent, the number of sub key and sub key. Data dissemination rules PLM-side data table to the three types of information from the ERP interface table one-to-one mapping, and ultimately through the program interface in the ERP software to create the appropriate project structure, corresponding to the procurement plan, the implementation of the project tasks[15]. V.THE KEY TECHNOLOGIES OF INTEGRATED DEVELOPMENT AND REALIZATION Establish a standardized and unified interface data structure design is a key technology integration and implementation of PLM and ERP, PLM integration output to establish a unified data structure of the base table, the other systems required to enter all the information classified in the base table in a seemingly close actually very flexible integration; implementation and development is fairly easy to do so in the application of the integrated system. Only need to create the same data structure and the same name of the base table view, this integrated approach and procedures designed to naturally have a comprehensive migration and inheritance. The integrated solution is the most important technical point is the data reorganization technology, construction code generator. (1)The data reorganization is one of the ultimate goal of PLM and ERP integration, data sharing and use of data reorganization to achieve data consistency, to reduce the complicated types of interfaces between systems; (2) When integration of the two systems using the middle of the table, the structure of the code generator is very important. Generally, the formation of the concept of parts and materials generated at the stage of product development and design, this time also generate the formation of the items code in the PLM system, production planning, procurement, use of the above items code. However, the heterogeneous ERP system and PLM system may exist to express the mutual opposite sex and multiplicity of the same items encoded. So in the design of the integrated program will generate a code translation table to construct a code generator translates the information of the two different encoding WBS coding, and data transfer between two systems. VI. Conclusion PLM solution of the product development process, data and process management, and R & D department, the relevant departments of the enterprise, collaborative applications on the product data between enterprises and R & D projects in the tasks and the cycle of detailed and accurate control; and ERP is overall balance and optimize the management of human, financial, material, information, time and other resources owned by enterprises. PLM and ERP integration, play to the strengths of the two management software, to solve a large number of special needs exist in the R & D projects. REFERENCES [1] Fang Wei,Sun Shulin,New product development project critical success factors for empirical research .2007,27 Research management (5) :102-109 [2] Project management institute project management body of knowledge guide. Lu jiechu, Wang Yong, Beijing: Publishing House of Electronics Industry, 2005.pp.33-35 [3] Coordination between oriented R & D enterprise, supplier evaluation and selection,Shanghai Tongji University, Master's Thesis .2010.pp.21-24 [4] Chen Kun,Product R & D project management applications. dissertation, Zhengzhou University, 2006.5 [5] Chuan Sheng, Luo Zhongxian, Dai Yuehong. Integration of PLM-based manufacturing enterprise applications,Manufacturing Information 2009:4 [6] Zhang Xiaodong, Zhang Dinghua,PDM and ERP integration technology research,Chinese manufacturing information .2008:4 [7] Qiu Yuan, Shen Jianming, Yang Aihua, Introduction to modern project management,Machinery Industry Press .2003:5.pp.22-26 [8] Bi star, Zhai Li, project management,after day University Press, 2000.pp.96-98 [9] Wu Yuanhong,enterprise innovation and product development management, the first edition,Guangzhou: Zhongshan University Press, 2000.pp.204-206 [10] PenerHerzum, Oliversims with Han Ke translation. Based on the components of enterprise-class development. Machinery Industry Press .2005:11 ~ 12 [11] Ren Yong,Project management,Beijing: Tsinghua University Press, 2004.pp.105-107 [12] Zhang Wenjie,Dynamic management of multi-project development companies,Xi'an Jiaotong University. 2002 [13] Zhang Bo,IT applications in the machinery manufacturing enterprises and research,Tianjin: Tianjin University in 2002.pp.74-77 [14] Hugh Woodward.Practice standard institute work breakdown structures,Project Management Institute.2001.pp.66-69 [15] Wang Wei. PLM and ERP in the end who integration,CAD / CAM and manufacturing information .2009:6