Extractive Distillation with Salt in Solvent

advertisement

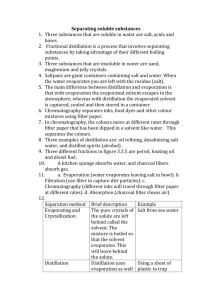

Extractive Distillation with Salt in Solvent Zhou Rongqi(周荣琪) Duan Zhanting(段占庭)1 Department of Chemical Engineering, Tsinghua University, Beijing 100084 ABSTRACT Extractive distillation with salt in solvent is a new process for producing anhydrous ethanol by combining the principle of “salt effect” and some traditional extractive distillation methods. Compared with the common extractive distillation the performance of solvent is improved, the recycling amount of solvent is reduced to 1/4—1/5, and the number of theoretical plates is reduced to 1/3. Energy consumption and cost of equipment are also reduced and continuous production is realized. High efficiency and low solvent wastage make this technique feasible. Key words extractive distillation, salt, solvent, anhydrous ethanol 1.Technical Traits of Extractive Distillation with Salt in Solvent Anhydrous ethanol is not only used as chemical reagent and organic solvent, but also used as the raw material of many important chemical products and intermediates. It has found diverse applications in many fields such as pharmaceutical, electronic and military industries. The method of manufacturing anhydrous ethanol has been ameliorated incessantly due to the increasingly strict requirements for quantity and quality of this product. As one of the most primitive ways, the dehydrating process was notorious for large intensity of labor and poor product quality. Dehydration by utilizing molecular sieve or ion exchange resin may provide high-quality products, but this operation can only be applied to some small-scale batch apparatus. It also has other drawbacks such as difficulty in refreshing, tremendous power consumption and low yield. Although azeotropic distillation with benzene was used in large-scale manufacture, the unacceptable number of tower plates and residual benzene in final product made it unsuitable for medical or chemical uses. Besides, poisoning of benzene happens occasionally in practical process. In recent years, pentane-combined azeotropic distillation has been reported with obvious advantages such as simple process, small number of plates and suitability for large-scale production. Because of the low boiling point of pentane and the azeotropic agent, it should be operated under artificial high pressure. Besides this substance is easy to evaporate in normal room temperature, and the consumption of azeotropic 1 Manuscript received: 1998-04-10 1 agent is unbearable. Another alternative method is extractive distillation with ethylene glycol as solvent. It has features of high quality of products and suitability for large-scale production, relatively less volatilization amount and lower consumption of solvent. However, the solvent ratio (the ratio of solvent to feed) is too large, normally 5:1. Because of the great amount of recycling solvent, the additional consumption of energy is high. At the same time, the high liquid-phase load and low plate Efficiency(20—40%) increase the number of plates and offset the effects of raising relative volatility and reducing the number of plates by introducing solvent to a great extent[1]. With salt dissolved in ethanol-water system, its relative volatility can be improved[1]. Salt added extractive distillation just makes use of this property[2,3]. This application can lead to satisfactory effect of dehydration, smaller number of theoretical plates and simplified process. In industrial operation, when a solid salt is used in place of a liquid separating agent, it is normally fed to the column by filling the dissoluble into the reflex stream immediately before the entry of the reflex at the top of the column. Because the salt is nonvolatile, it will remain entirely within the liquid phase and hence flow only downward. So it can elude the conventional stripping section. Pure product is achieved from the column top. However, dissolution, reuse and transport of salt is quite a problem. The concurrent tub-jam and erosion limit the industrial value of this technique. After comparing all kinds of techniques available at present, we put forward the novel extractive distillation with salt in solvent. This invention combines the principle of “salt effect” and the extractive distillation and it is called as extractive distillation with dissolved salt. The new technique avoids the defects of traditional processes, and is an ideal process for anhydrous ethanol production. Some characteristics are listed as follows: (1). Ameliorate the performance of solvent. Compared with common extractive distillation, the recycling amount of solvent is reduced to 1/4—1/5, number of theoretical plates is reduced to 1/3, energy consumption and equipment cost are also reduced. (2). Continuous production is realized. High efficiency and low solvent wastage make this technique feasible. (3). No pollution. Product shows extraordinary purity. 2. Experimental Research on Extractive Distillation with Salt in 2 Solvent We have performed experimental research, so as to collect relevant data of salt-added extractive distillation critical for industrial application. Properties of salts and solvents involved are listed in Table 1. Table 1 Properties of salts and solvents definition molecular formula molecular purity weight density (kg/m3) boiling point(℃) ethylene glycol C2H6O2 anhydrous ethanol C2H5OH 62.07 46.07 A.R. C.P. 1.11╳103 0.79╳103 198 78 95% ethanol C2H5OH sodium chloride NaCl anhydrous CaCl2 calcium chloride strontium chloride SrCl2·6H2O aluminum AlCl3 chloride potassium nitrate KNO3 Cu(NO3)2·3H2O copper nitrate aluminum nitrate Al(NO3)3·9H2O 46.07 58.44 110.99 C.P. A.R. A.R. 0.82╳103 265.62 133.34 A.R. A.R. 101.11 241.60 A.R. A.R. 357.15 98.14 A.R. C.P. 138.2 C.P. potassium acetate K CO2CH3 anhydrous potassium K2CO3 carbonate 2.1 Preparation of Anhydrous Salt Most salts available contain crystal water or absorb ambient moisture easily. And the dehydration degree of salts has direct effect on the relative volatility. For nondecomposable species, we used high-temperature sand to expel moisture. While decomposable species were dissolved, they were dehydrated by distillation under vacuum until water-content is reduced to below 0.2%. 2.2 Analytic Apparatus The compositions of both liquid and gas phases were analyzed by local 2305 GC and the type of chromatographical column was Porpaka Q. 2.3 Selection of Solvent and Salt Typical recycling liquid-gas equilibrium systems were utilized in the experiment. First, the azeotropic ethanol-water solution was fed into the equilibrium system. Salt and solvent were at the ratio(volume ratio) of 1:1, and the concentration of salt was 3 0.2g(salt)/ml(solvent). After Shook well, the mixture was heated to boil. Twenty minutes later, the desired phase equilibrium was achieved. Samples were taken and analyzed. Then the relative volatility was calculated from: y /x 1 1 y2 / x2 where y1 , y 2 stand for the molecular fractions of ethanol and water in the gas phase respectively; x1 , x 2 stand for those in the liquid phase. For azeotropic ethanol-water system, the effects of solvent, salt and solvent-salt on the relative volatility are shown in Table 2. Table 2 Effects of solvent, salt and solvent-salt on relative volatility salt or solvent relative volatility solvent-salt relative volatility 1.01 ethylene glycol 1.85 calcium chloride 3.13 potassium acetate 4.05 ethylene glycol+NaCl ethylene glycol+CaCl2 ethylene glycol+SrCl2 ethylene glycol+AlCl3 ethylene glycol+KNO3 ethylene glycol+Cu(NO3)2 2.31 2.56 2.6 4.15 1.9 2.35 ethylene glycol+Al(NO3)3 ethylene glycol+ K CO2 CH3 ethylene glycol+K2CO3 2.87 2.4 2.6 The relative volatility of the system without salt or solvent was measured. The goal of this work is to verify the correctness of the experimental method and study the selection of salt and solvent. The result is the intended value equal to 1.01. When solvent is introduced with small amount of salt, the relative volatility is increased by 30%. So the conclusion that salt in solvent benefits separation can be drawn. The relative effect of specific kinds of salt obeys the Dybel static-electric theory about salt effect[4]: the higher the valence of metal ion is, the more obvious the effect is. The salt effect gradually decreases in the order of AlCl3 ,CaCl2 and NaCl. The trend is the same in the order of Al(NO3)3,Cu(NO3)2 and KNO3. Besides, the salt effect gradually decreases in the order of Ac-,Cl- and NO-3. The industrial requirements for salt selection are low cost, chemical stability, high dissolvability, minor apparatus corrosion, less poisoning, besides the possibly highest volatility. Therefore, the optimal system is ethylene glycol-potassium acetate. 4 2.4 Gas-Liquid Equilibrium Data We measured the equilibrium data of the ethanol-water system which accorded with the published data approximately. Then, we determined the data with solvent ethylene glycol (solvent ratio is 1:1) and salt-dissolved separating agent(solvent ratio was 1:1 and concentration of salt was 0.1 g/ml (solvent)) in the whole range of concentrations. The experimental results are shown in Table 3 and Fig.1. Table 3 Equilibrium data of ethanol-water system with ethylene glycol x 0.08 1:1 0.81 0.9019 0.9082 0.9607 y 0.519 0.716 0.813 0.8725 0.9085 0.949 with ethylene glycol- x 0.08 CaCl2(10%) 0.152 0.559 0.7 0.152 0.559 0.7 y 0.679 0.79 0.882 0.917 0.81 0.957 0.979 0.9019 0.9082 0.9607 0.9449 0.9672 0.969 0.986 We get the following result from those data: the effect of salt-dissolved solvent is better than that of the solvent without salt. 3. Practical Experiment on Salt-Added Extractive Distillation The practical experiment on salt-added extractive distillation was carried out in a small glass distillation column with a diameter of 30mm. The canon packing, which was contained in the column and amounted to 15 theoretical plates, had a height of 800mm. Vapor feed was 88% ethanol with azeotropic composition. The following solvents were used: ethylene glycol and ethylene glycol with salt. The process without salt obtained 99.5% ethanol when solvent ratio was up to 4 or 5. The process with salt (5%KCl) obtained >99.5% ethanol when solvent ratio was only 1:1. Solvents were 5 refreshed in the packed distillation column at 680mmHg vacuum degree. Water evaporates from the top of the column and refreshed solvent containing <0.2% water came out from the bottom when bottom temperature was 145℃. The refreshed solvent had satisfactory performance when used in subsequent extractive distillation. 4. Summary A novel extractive distillation process with salt in solvent has been forwarded on the basis of examining various kinds of methods. 1. This new technique has the advantages of both extractive distillation and distillation with dissolved salt and overcomes their drawbacks. There has been no report on this approach both at home and abroad. 2. It is more advanced than the widely used extractive distillation employing ethylene glycol. The new technique improve efficiency, reduces solvent ratio and number of necessary plates, and saves operation cost and equipment investment. 3. The new technique has replaced out-dated apparatus in many factories. Technical maturity has enabled it to create great economic profit. By now, more than thirty factories have utilized this method. 4. Necessary basic research and engineering scale-up exploration have been undertaken based on the industrial experience and technical data, and design calculating method is forwarded. 5. This approach can be transplanted to other chemical systems, so it has broad industrial prospect. REFERENCES [1]兰化石油化工厂等.丙烯腈萃取精馏塔第一阶段改造.石油化工技术,1976, 2-3:93∽98 Petrochemical Factory of Lanzhou Chemical Industry Corporation,et al. First stage renovation of extraction distillation tower for refining propenyl cyanide. Petrochemical Technology,1976,2-3: 93∽98 [2]Furter W F. Salt effect in distillation : a literature review. Inter. J. Heat Mass Transfer, 1967,10 : 23∽36 [3]Furter W F. Salt effect in distillation : a literature reviewⅡ. Canadian J.Chem.Eng., 1977,55:229∽239 [4]黄子卿.电解质溶液理论导论(修订版).北京:科学出版社,1983. 153∽162 Huang Ziqing. Introduction of Electrolyte Solution Theory . Beijing: Science Press, 1983.153∽162 6